Currency: GBP

- Worldwide Delivery

Mooring Warps and Mooring Lines

- LIROS 3 Strand Polyester Mooring Warps

- LIROS Braided Dockline Mooring Warps

- LIROS Classic Mooring Warps

- LIROS Green Wave 3 Strand Mooring Warps

- LIROS Handy Elastic Mooring Warps

- LIROS Moorex12 Mooring Warps

- LIROS Octoplait Polyester Mooring Warps

- LIROS Polypropylene Floating Mooring Warps

- LIROS Super Yacht Mooring Polyester Docklines

- Marlow Blue Ocean Dockline

Mooring Accessories

- Mooring Cleats and Fairleads

- Mooring Compensators

- Mooring Shackles

- Mooring Swivels

Mooring Strops

- LIROS 3 Strand Nylon Mooring Strops

- LIROS Anchorplait Nylon Mooring Strops

- Small Boat and RIB Mooring Strops

Mooring Bridles

- V shape Mooring Bridles

- Y shape Mooring Bridles

Mooring Strops with chain centre section

- 3 Strand / Chain / 3 Strand

- Anchorplait / Chain / Anchorplait

Bonomi Mooring Cleats

- Majoni Fenders

- Polyform Norway Fenders

- Dock Fenders

- Fender Ropes and Accessories

- Ocean Inflatable Fenders

Mooring Buoys

Max power bow thrusters.

- Coastline Bow Thruster Accessories

50 metre / 100 metre Rates - Mooring

Mooring information.

- Mooring Warps Size Guide

- Mooring Lines - LIROS Recommended Diameters

- Mooring Rope Selection Guide

- Mooring Warp Length and Configuration Guide

- How to estimate the length of a single line Mooring Strop

- Mooring Ropes - Break Load Chart

- Mooring Compensator Advisory

- Rope Cockling Information

- Fender Size Guide

- Majoni Fender Guide

- Polyform Norway Fender Inflation Guide

Custom Build Instructions

- More Article and Guides >

Anchor Warps Spliced to Chain

- LIROS 3 Strand Nylon Spliced to Chain

- LIROS 3 Strand Polyester Spliced to Chain

- LIROS Anchorplait Nylon Spliced to Chain

- LIROS Octoplait Polyester Spliced to Chain

Anchor Warps

- Leaded Anchor Warp

- LIROS 3 Strand Nylon Anchor Warps

- LIROS 3 Strand Polyester Anchor Warps

- LIROS Anchorplait Nylon Anchor Warps

- LIROS Octoplait Polyester Anchor Warps

- Aluminium Anchors

- Galvanised Anchors

- Stainless Steel Anchors

Calibrated Anchor Chain

- Cromox G6 Stainless Steel Chain

- G4 Calibrated Stainless Steel Anchor Chain

- Lofrans Grade 40

- MF DAMS Grade 70

- MF Grade 40

- Titan Grade 43

Clearance Chain

Anchoring accessories.

- Anchor Connectors

- Anchor Trip Hooks and Rings

- Anchoring Shackles

- Bow Rollers and Fittings

- Chain and Anchor Stoppers

- Chain Links and Markers

50 / 100 metre Rates - Anchoring

Chain snubbers.

- Chain Hooks, Grabs and Grippers

- Chain Snubbing Bridles

- Chain Snubbing Strops

Drogue Warps and Bridles

- Lewmar Windlasses

- Lofrans Windlasses

- Maxwell Windlasses

- Quick Windlasses

Windlass Accessories

- Coastline Windlass Accessories

- Lewmar Windlass Accessories

- Lofrans Windlass Accessories

- Lofrans Windlass Replacement Parts

- Maxwell Windlass Accessories

- Quick Windlass Accessories

Anchoring Information

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor Size Guides

- Anchor Rope Break Load and Chain Compatibility Chart

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

- More Articles and Guides

Stainless Steel Wire Rigging and Wire Rope

- 1x19 Wire Rigging

- 7x19 Flexible Wire Rigging

- Compacted Strand Wire Rigging

- Insulated 1x19 Wire Backstays

Wire Rigging Fittings

- Swaged Terminals

- Swageless Terminals

- Turnbuckles / Rigging screws

- Turnbuckle Components

- Backstay Insulators

- Wire Terminals

Rigging Accessories

- Babystay and Backstay Adjustment

- Backing Plates

- Backstay Blocks

- Pins, Rings and Nuts

- Rigging Chafe Protection

Fibre Rigging

- DynIce Dux Fibre Rigging

- LIROS D-Pro Static Rigging

- LIROS D-Pro-XTR Fibre Rigging

- Marlow Excel D12 MAX 78 Rigging

- Marlow M-Rig Max Rigging

Fibre Rigging Fittings

- Blue Wave Rope Terminals

- Colligo Marine Terminals

Dinghy Rigging

- Dinghy Rigging Fittings

- Fibre Dinghy Rigging

- Stainless Steel Dinghy Rigging

Wind Indicators

Guard wires, guardrails and guardrail webbing.

- Guard Rail Fittings

- Guard Rails in Fibre and Webbing

- Guard Wire Accessories

- Guard Wires

Furling Systems

- Anti-torsion Stays

- Headsail Reefing Furlers

- Straight Luff Furlers

- Top Down Furlers

Furling Accessories

- Continuous Furling Line Accessories

- Furling Line Accessories

50 / 100 metre Rates - Wire and Fibre

Standing rigging assistance.

- More Articles and Guides >

- Cruising Halyards

- Performance Halyards

- Dinghy Halyards

Rigging Shackles

- Bronze Snap Shackles

- Captive and Key Pin Shackles

- hamma™ Snap Shackles

- Selden Snap Shackles

- Soft Shackles

- Standard Snap Shackles

- Tylaska End Fittings

- Wichard Snap Shackles

Lashing, Lacing and Lanyards

- LIROS 3 Strand Lashing, Lacing and Lanyards

- LIROS Braided Lashing, Lacing and Lanyards

- Cruising Sheets

- Performance Sheets

- Dinghy Sheets

- Continuous Sheets

- Tapered Sheets

Running Rigging Accessories

- Anti-Chafe Rope Protection

- Barton Sail Handling

- Lazy Jack Sail Handling

- Rodkickers, Boomstruts

- Sail Handling Accessories

- Slab Reefing

Shock Cord and Fittings

Control lines.

- Cruising Control Lines

- Performance Control Lines

- Dinghy Control Lines

- Continuous Control Lines

Classic Ropes

- 50 / 100 metres - Classic

- Classic Control Lines

- Classic Docklines

- Classic Halyards

- Classic Sheets

- LIROS Classic 3 Strand Polyester

50 / 100 metre Rates - Running Rigging

- 50 / 100 metres - Cruising Ropes

- 50 / 100 metres - Dinghy Ropes

- 50 / 100 metres - Lashing and Lanyards

- 50 / 100 metres - Performance Ropes

- LIROS Ropes

- Marlow Ropes

Running Rigging Resources

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

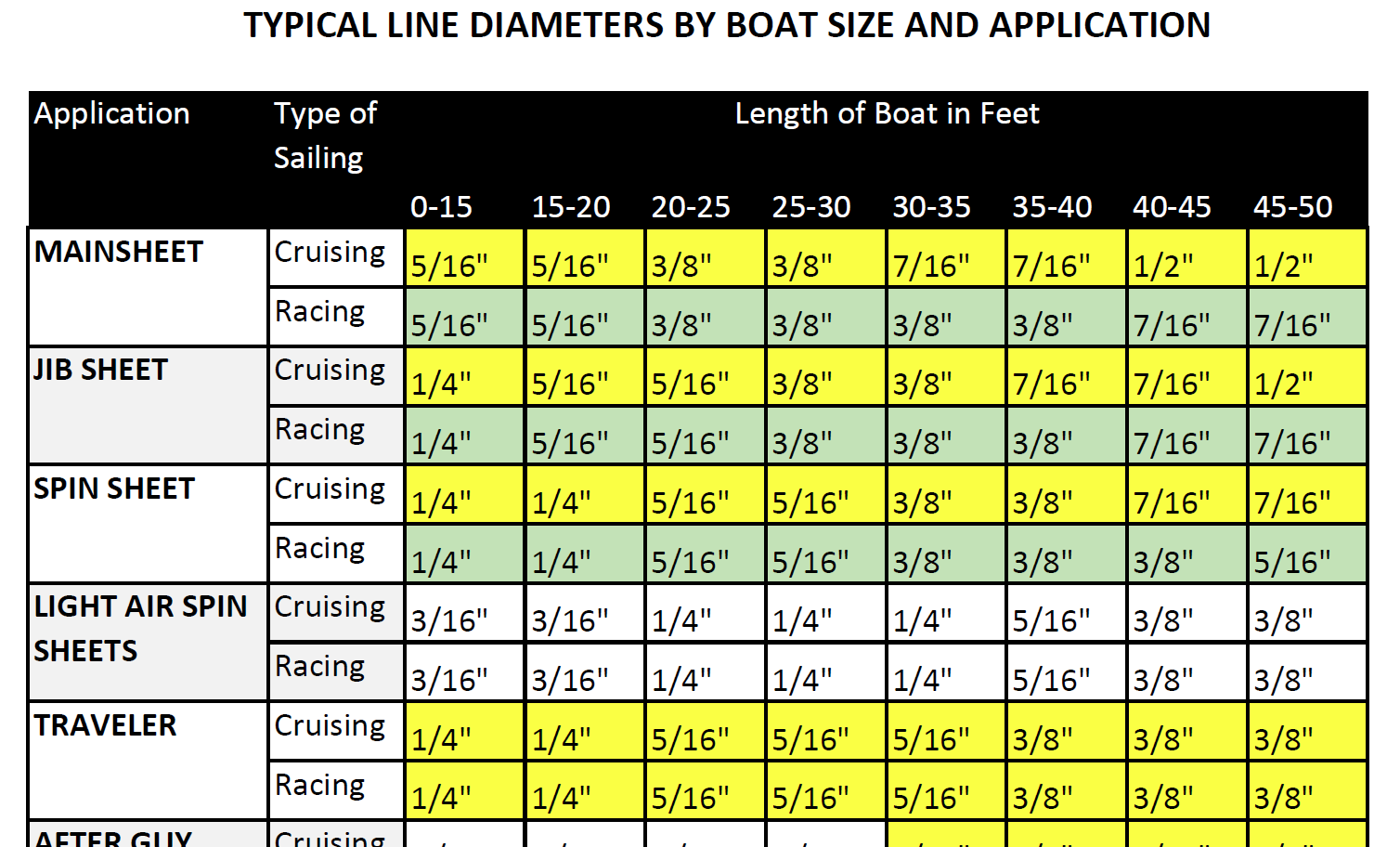

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Replacing your Furling Line

- Recycling Rope

- Running Rigging Glossary

Custom Build Instructions for Sheets, Halyards, Control Lines

Low friction rings, plain bearing blocks.

- Barton Blocks

- Harken Element Blocks

- Seasure 25mm Blocks

- Selden Yacht Blocks

Wooden Blocks

Ball bearing blocks.

- Barton Ball Bearing Blocks

- Harken Ball Bearing Blocks

- Holt Dynamic Blocks

- Selden Ball Bearing Blocks

Ratchet Blocks

- Harken Ratchet Blocks

- Selden Ratchet Blocks

Roller Bearing Blocks

- Harken Black Magic Blocks

- Selden Roller Bearing Blocks

Clutches and Organisers

- Barton Clutches and Organisers

- Lewmar Clutches

- Spinlock Clutches and Organisers

Genoa Car Systems

- Barton Genoa Sheeting

- Harken Genoa Systems

- Lewmar HTX Genoa Systems

Traveller Systems

- Barton Traveller Systems

- Harken Traveller Systems

Deck Fittings

- Bungs and Hatches

- Bushes and Fairleads

- Deck Eyes, Straps and Hooks

- Pad Eyes, U Bolts and Eye Bolts

Rudder and Transom Fittings

- Pintles and Gudgeons

- Tiller Extensions and Joints

Stanchion Blocks and Fairleads

Snatch blocks.

- Barton K Cam Cleats

- Harken Ball Bearing Cam Cleats

- Holt Cam Cleats

- Selden Cam Cleats

- Spinlock PXR Cleats

Block and Tackle Purchase Systems

- Barton Winches, Snubbers and Winchers

- Coastline Electric Winch Accessories

- Harken Winches, Handles and Accessories

- Karver Winches

- Lewmar Winches, Handles and Accessories

- Winch Servicing and Accessories

Deck Hardware Support

- Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

Sailing Flags

- Courtesy Flags

- Red Ensigns

- Blue Ensigns

- Flag Accessories

- Flag Staffs and Sockets

- Flag Making and Repair

- Signal Code Flags

- Galvanised Shackles

- Stainless Steel Shackles

- Titanium Shackles

- Webbing only

- Webbing Restraint Straps

- Webbing Sail Ties

- Webbing Soft Shackles

Hatches and Portlights

Sail care and repair.

- Sail Sewing

Maintenance

- Antifouling

- Fillers, Sealants, Adhesives

- Primers and Thinners

- PROtect Tape

Fixings and Fastenings

- Monel Rivets

- Screws, Bolts, Nuts and Washers

- U Bolts, Eye Bolts and Pad Eyes

Splicing Accessories

- Fids and Tools

- Knives and Scissors

General Chandlery

- Barrier Ropes

- Canvas Bags and Accessories

- Carabiners and Hooks

- Netting and Accessories

- Rope Ladders

Seago Boats and Tenders

Chandlery information, flag articles.

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

- Anchorplait Splicing Instructions

- Antifoul Coverage Information

- Hawk Wind Indicator Selection Guide

- Petersen Stainless - Upset Forging Information

- Speedy Stitcher Sewing Instructions

- Thimble Dimensions and Compatible Shackles

Jackstays and Jacklines

- Webbing Jackstays

- Stainless Steel Wire Jackstay Lifelines

- Fibre Jackstay Lifelines

- Jackstay and Lifeline Accessories

Safety Lines

Lifejackets.

- Children's Life Jackets

- Crewsaver Lifejackets

- Seago Lifejackets

- Spinlock Lifejackets

Buoyancy Aids

Life jackets accessories.

- Lifejacket Lights

- Lifejacket Rearming Kits

- Lifejacket Spray Hoods

Overboard Recovery

- Lifebuoy Accessories

- Purchase Systems

- Slings and Throwlines

Floating Rope

- LIROS Multifilament White Polypropylene

- LIROS Yellow Floating Safety Rope

- Danbuoy Accessories

- Jimmy Green Danbuoys

- Jonbuoy Danbuoys

- Seago Danbuoys

- Liferaft Accessories

- Seago Liferafts

Safety Accessories

- Fire Safety

- Grab Bag Contents

- Grab Bags and Polybottles

- Handheld VHF Radios

- Sea Anchors and Drogues

Safety Resources

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

Sailing Clothing

- Sailing Jackets

- Sailing Trousers

- Thermal Layers

Leisure Wear

- Accessories

- Rain Jackets

- Sweatshirts

Sailing Footwear

- Dinghy Boots and Shoes

- Sailing Wellies

Leisure Footwear

- Walking Shoes

Sailing Accessories

- Sailing Bags and Holdalls

- Sailing Gloves

- Sailing Kneepads

Clothing Clearance

Clothing guide.

- What to wear Sailing

- Helly Hansen Mens Jacket and Pant Size Guide

- Helly Hansen Womens Sailing Jacket and Pant Size Guide

- Lazy Jacks Mens and Womens Size Charts

- Musto Men's and Women's Size Charts

- Old Guys Rule Size Guide

- Sailing Gloves Size Guides

- Weird Fish Clothing Size Charts

The Jimmy Green Clothing Store

Lower Fore St, Beer, East Devon, EX12 3EG

- Adria Bandiere

- Anchor Marine

- Anchor Right

- August Race

- Barton Marine

- Blue Performance

- Brierley Lifting

- Brook International

- Brookes & Adams

- Captain Currey

- Chaineries Limousines

- Coastline Technology

- Colligo Marine

- Cyclops Marine

- Douglas Marine

- Ecoworks Marine

- Exposure OLAS

- Fire Safety Stick

- Fortress Marine Anchors

- Hawk Marine Products

- Helly Hansen

- International

- Jimmy Green Marine

- Maillon Rapide

- Mantus Marine

- Marling Leek

- Meridian Zero

- MF Catenificio

- Ocean Fenders

- Ocean Safety

- Old Guys Rule

- Petersen Stainless

- Polyform Norway

- PSP Marine Tape

- Sidermarine

- Stewart Manufacturing Inc

- Team McLube

- Technical Marine Supplies

- Titan Marine (CMP)

- Ultramarine

- Waterline Design

- William Hackett

Clearance August Race Boat Cleaning Kit £26.00

Clearance LIROS Racer Dyneema £55.08

Clearance Folding Stock Anchor £123.25

Clearance LIROS Herkules £0.00

Clearance Barton Size 0 Ball Bearing Blocks - 5mm £10.13

Clearance Marlow Blue Ocean® Doublebraid £18.48

Mooring Clearance

Anchoring clearance, standing rigging clearance, running rigging clearance, deck hardware clearance, chandlery clearance, safety clearance, standing rigging.

The Jimmy Green Rigging Team are very experienced in making up Yacht Rigging with quick turn-around times as a matter of course.

Team Jimmy Green can produce anything from a single replacement stay to a complete standing rigging re-rig and are well versed in meeting delivery deadlines in the UK, the EU and for export worldwide.

Strict Quality Control Procedures and Accountability Systems ensure that only the best quality stainless steel wire and terminals are considered. Traceability is an important feature of the Jimmy Green assurance policy: Stainless Steel Wire - Quality Control and Care

Wiretechnik Roller Swaging Technology is available from 2.5mm up to 12mm diameter (up to 10mm on-site).

Cabco Talurit soft or hard (thimble) eye wire termination from 2mm up to 8mm diameter are available on site.

Both these brands are the marine industry-leading manufacturers for wire termination machines.

Jimmy Green Marine offer the full range of Sta-Lok, Petersen and Hamma Regatta swage terminals e.g. eye, forks, tees, strap toggles plus all manner of turnbuckle and backstay insulator options.

Jimmy Green Marine also offer the full range of Sta-Lok, Petersen Hi Mod and Bluewave DIY fittings, plus Norseman replacement cones manufactured by Tylaska Marine.

All this is available to purchase online.

Standing Rigging Re-Rig Quotes

Customers frequently ask for standing rigging replacement quotes or even ballpark figures for valuation purposes citing only the yacht type/model or design. Even if your yacht is a well-known one-design production yacht e.g. Westerly, Moody, Beneteau, there is still a good chance that the specification has been altered since the original build. If the owners' manual has been preserved, it may state the standard specification, but this may have been altered/upgraded for the first owner.

The Jimmy Green Rigging Team have built up a database of information from completed re-rigs over the years, but this is by no means comprehensive. There is a certain amount of information that can be gleaned from the world wide web, but this will still not go as far as individual yacht rig specifications.

It is therefore difficult to give an accurate answer without some basic information about the rig. The diameter of the wire and therefore the associated size of the terminals is fundamental to the cost. In terms of price, the other major factor will be whether you intend to replace the rigging screws/turnbuckles. Clearly the number and configuration of the stays is important, but it is much simpler to estimate their lengths and probable terminals. More specification considerations include e.g. split, adjustable and/or insulated backstays, forestay foibles caused by headsail furler fitting, linked rigging.

Jimmy Green Marine have made it possible to get an instant standing rigging re-rig quote online.

You need to know or give us the following information:

- The type of wire: KOS 1 x 19, Petersen Compact Strand or KOS flexible 7 x 19

- The diameter of the wire

- The approximate length for each stay

- The terminal at the top

- The bottom terminal (with or without rigging screw)

These CUSTOM BUILD INSTRUCTIONS will help you through the process.

For a rough guide, approximate lengths and an educated guess for the terminals will suffice. The decision on whether to replace the turnbuckles makes a big difference to the price.

The Jimmy Green Rigging Team are always on hand to help you through this process, by email or on the telephone.

If the measuring seems a daunting responsibility, send us the old rigging as a pattern. We will measure, ask any pertinent questions about the new rig and quote you before starting any work.

Standing Rigging Complete Replacement

A complete Re-Rig i.e. replacement of all your standing rigging may seem like too big a job to tackle yourself but it needn't be too difficult with help from the Jimmy Green Rigging Team.

A common-sense approach combined with careful notetaking (photos) at each stage will be enough to ensure success.

Team Jimmy Green have written a step by step guide: STANDING RIGGING - GUIDE TO TACKLING A COMPLETE RE-RIG

Stay Diameter

- 2.5mm (15) 2mm (10) 3mm (12) 4mm (13) 6mm (12) 7mm (9) 8mm (12) 9mm (1) 10mm (12) 14mm (8) 16mm (2)

Rope Diameter *

- 2.5mm (2) 3mm (5) 4 - 5 mm (1) 5 - 6 mm (1) 4mm (4) 5mm (4) 5-9mm (1) 6mm (4) 8mm (5) 9-11mm (1) 10mm (4) 11-13mm (1) 12mm (4)

Wire Fitting Size

- 2.5mm - 1/4 (1) 3mm (17) 3mm - 1/4 (20) 3mm - M6 (2) 4mm (32) 4mm - 1/4 (16) 4mm - 3/8 (3) 4mm - 5/16 (25) 4mm - M6 (2) 4mm - M8 (2) 4mm - Z (1) 5mm (32) 5mm - 090 (1) 5mm - 5/16 (22) 5mm - 110 (1) 5mm - 3/8 (22) 5mm - 7/16 (3) 5mm - M8 (2) 5mm - M10 (2) 5mm - Z (3) 6mm (37) 6mm - 3/8 (21) 6mm - 1/2 (9) 6mm - 7/16 (20) 6mm - M10 (2) 6mm - M12 (1) 6mm Dyform (1) 6mm - S (1) 7mm (36) 7mm - 7/16 (12) 7mm - 1/2 (22) 7mm - 110 (1) 7mm - 140 (1) 7mm Dyform (1) 7mm - M12 (1) 7mm - Z (3) 8mm (30) 8mm - 1/2 (29) 8mm - 5/8 (28) 8mm DS (2) 8mm - M12 (1) 8mm - M16 (1) 10mm (37) 10mm - 3/4 (9) 10mm - 5/8 (23) 10mm - M16 (1) 12mm (35) 12mm - 3/4 (21) 12mm - 7/8 (6) 12mm - E (1) 12mm - M20 (1) 14mm (24) 14mm - 7/8 (11) 14mm - M22 (1) 16mm (11) 16mm - 1 (6) 19mm (6) 19mm - 1 1/8 (3) 19mm - 1 1/4 (1) 22mm (4) 22mm - 1 1/4 (2) 26mm (3) 26mm - 1 3/8 (2) 1/4" (1) 5/16" (2) 3/8" (2) 7/16" (2) 1/2" (2) 5/8" (2) 3/4" (2) 7/8" (2) 1" (2) 12mm Dyform (1)

- APL (1) BSI (6) Barton Marine (3) Blue Wave (27) Colligo Marine (8) Crewsaver (1) Cyclops Marine (2) Felco (1) Grunt (1) Hamma (17) Hampidjan (12) Harken (8) Hawk Marine Products (5) Holt (10) Jimmy Green Marine (3) KOS (27) Karver (3) LIROS Ropes (23) Loctite (1) Loos (1) Marlow Ropes (12) Mast (1) Meridian Zero (1) Ocean Fenders (1) PSP Marine Tape (2) Petersen Stainless (44) Plastimo (20) Proboat (2) Profurl (15) Rutgerson (1) STA-LOK (69) Schaefer (2) Seasure (3) Seldén (27) Spinlock (2) Team McLube (1) Technical Marine Supplies (2) Tylaska (1) Wichard (7)

Purchase Type

- 50 metre Coil (5) 50 metre cut length (2) 100 metre Reel (12) Clearance (11) Custom Build (61) Set Lengths (3) Spliced Set Length (1)

4mm 1x19 Stainless Steel Wire Standing Rigging

3mm 1x7 compact strand stainless steel wire rigging, 6mm 1x19 stainless steel wire standing rigging, 6mm flexible 7x19 stainless steel wire rope, liros 6mm d-pro-xtr, liros 8mm d-pro-xtr, marlow 8mm excel d12 max 78, 12mm dynice dux, sta-lok stud, sta-lok open turnbuckle - toggle and blank, sta-lok open turnbuckle - toggle and sta-lok, sta-lok st turnbuckle - welded fork & fork.

Yachting World

- Digital Edition

Pip Hare explains when to check and replace your standing rigging

- October 1, 2020

To prepare my IMOCA 60 Medallia for the Vendée Globe race, I have completed a full change of all the standing rigging

If the mast is stepped, the only way to thoroughly inspect rig fittings at the masthead is to go up there... Photo: James Mitchell

This was a ‘no brainer’ decision as my rigging has been around the world once already and I would never take it into the Southern Ocean for a second time.

In some ways it is easier to estimate the life of synthetic rigging, as it comes with a recommended mileage or stated lifespan if it can be UV damaged. For those with stainless steel rigging the decision on when to replace can be a harder one.

The main difficulties boat owners face when assessing the condition of the rig is the inability to see the first signs of wear, partly due to the majority of our rigging being out of sight in the sky, and partly due to the nature of metal fatigue itself.

Professional rig checks often lead to last-minute repairs for transatlantic ARC sailors. Photo: James Mitchell

The fact is that metal fatigue is inevitable and cannot be avoided. The only thing that will vary is the time a component takes to fail. So how can we make a good assessment of when rigging should be replaced?

There are a number of factors that will affect the lifespan of your standing rigging, most notably the initial quality of the rigging used and the type and frequency of sailing that you do.

Rigging quality

The quality of both wire and rod rigging is important because in both the crack initiation and growth phases of the fatigue process can be accelerated by metal impurities or unseen manufacturing defects in the component itself. Using high quality wire rigging from a well known supplier is a bigger initial outlay but the grade of metal used and manufacturing process should prolong the life of your rigging.

Article continues below…

How to prepare your yacht for anything: Preempting chafe, rig and crew problems

This is Part 2 of Vicky Ellis’ guide to preparing your yacht for any eventuality. You can read Part 1…

Ocean damage – tales of chafe, jury rigs and a shark on the rudder in the ARC

Crossing the Atlantic is hard on your gear, as the reports of ocean damage during the annual Atlantic Rally for…

When buying a secondhand boat, find out when the rigging was last replaced and try to get a copy of the invoice detailing who the supplier was – if you’re not sure, ask a rigger to take a look at it.

How you sail

In crude terms, every time your boat is used it is advancing the process of metal fatigue through the application of cyclical loads, so a boat that is raced regularly and hard will be approaching the point at which rigging failure could occur faster than a boat which is cruised intermittently.

This doesn’t mean that lightly used boats will never have to consider changing their rigging; even a dormant boat will be experiencing load cycles in some form when the mast is up. Just the action of the wind on a mast is enough to load up the rigging and any stays left loose will move with wind and wave action.

It’s not unusual for rigging wires to fracture around the swage collar

To minimise the stress caused by these load cycles while sailing it’s important to tune your rig regularly so the rigging is always at optimum tension. This will help ensure that changes in load are less extreme.

If you are not confident to set up your own rig tensions then ask your rigger to help, and later be sure to check your rig throughout the season.

Regular rigging checks

There are a couple of ways to test for early signs of fatigue not picked up by the naked eye; they include dye and NDT (non-destructive testing).

Water can enter swage terminals leading to crevis corrosion. Photo: Rupert Holmes

Both these surveys need to be carried out with the rig down and it may be worth balancing the overall cost of carrying out the test against the additional cost of re-rigging the boat, especially bearing in mind that if any faults or impurities are discovered your insurance may then require you to change the rigging anyway.

Regular visual checks should pick up the first signs of crack growth. Look for rust on T-terminals and at swage ends, check for powdery corrosion where T-terminals insert into the mast and any signs of cracking in the same area.

Run your fingers up and down the last metre of wire above or below the swage, feeling for deformities; if the wire is not uniform the chances are that one of the individual wires has broken, even if you can’t see it, and the stay and its partner should be replaced immediately.

Visual checks for rust and powdery corrosion are your first line of defence. Photo: Rupert Holmes

Checking the head of T-terminals is a harder job as they are inside the mast itself. This will need to be done with the mast removed so a full ‘mast down’ survey carried out by a professional rigger should be scheduled at least every three years.

Picking up early signs of corrosion or replacing select components after a thorough inspection is a worthwhile exercise because it may extend the lifespan of your standing rigging.

Inevitably your insurance policy will play a big part in your decision making about whether to replace your rigging. There has been a general assumption within the sailing community that insurance companies require rigging to be replaced after ten years, but I’ve found this is not actually the case; it’s far less prescriptive than that.

A small crack has developed in this stemhead fitting just above the forestay clevis pin

The IPID (Insurance Product Information Document) with your policy should give you a clear indication of what is covered in the event of a dismasting and may also provide some food for thought on when you should replace.

Insurance companies do not stipulate a timeframe at which your standing rigging should be replaced, but they do stipulate that all parts of the boat should be regularly and appropriately checked and maintained.

In the event of a dismasting claim, the insurance company would expect to see evidence of rigging maintenance and checks carried out at appropriate intervals by a qualified person; DIY inspections will not be accepted.

It is also worth taking note that in most insurance policies a depreciation element will be applied. This normally constitutes a deduction of one third of the new value of a rig and would start to come into play when a rig approaches 10-12 years old.

Emotional cost

There’s a consequential impact of a dismasting which cannot be covered by an insurance claim, and that is the human and emotional cost. In my own sailing career I’ve had two failures of standing rigging components which I spotted while sailing and was able to jury rig for a safe return to port. I’ve also experienced a dismasting, and I can vouch that it’s not a pleasant experience.

As a regular racer I take the health of my rig very seriously, perform checks before every major race and take my rig down annually for a thorough inspection. But this is the schedule that is right for me and the miles I sail, and would be considered overkill for the average sailor. Only you can give a proper evaluation of how often and how hard your boat is used, but that makes you ultimately responsible for setting the maintenance and replacement schedule.

Metal fatigue

Wires can break, unseen, within swaged terminals

Crack initiation starts when the metal first gets put to work and is caused by the cyclical loading of metal components. In the case of standing rigging on a sailing boat, this is the loading and unloading of shrouds and stays. Think about the windward shrouds loading up, while the leeward side relaxes: this cyclical loading causes cell structures to develop within the metal, these cells gradually harden and then develop microscopic cracks.

The crack growth stage follows next and these microscopic cracks will develop into larger ones, which may eventually be visible to the naked eye on the surface of the metal component. The speed of the crack growth phase will alter depending on how often and how hard your rigging is put under load.

Ultimate failure is caused when a crack exceeds a size that results in the component no longer supporting load. Failure will be sudden.

First published in the September 2020 issue of Yachting World.

Replacing Your Standing Rigging

Published by rigworks on november 27, 2018.

Question – When should I replace my standing rigging?

From the Rigger – According to industry standards, the anticipated lifespan for stainless steel rigging is 10-12 years for wire and 15-20 years for rod. Of course, a number of factors affect a rig’s lifespan including load, sailing conditions, mileage sailed, age, fatigue from cyclic loading, environmental influences such as salinity and contamination, and frequency of care and maintenance. Many people believe that only heavily used rigging needs to be replaced, but the continuous flexing of loose wire that is not under load can take a serious toll as well. The flogging of a loose shroud can actually be harder on wire than steady pressure.

Unfortunately, there are not always visual clues that your rigging has passed its life expectancy. Things to look for include corrosion, pitting, cracks, and broken strands or “meat hooks” on the wire. Rust and discoloration can indicate the location of a crack or crystallization of the metal. Check your spreaders, chainplates and turnbuckles for cracking, fatigue, missing cotter pins/rings, etc. Check the deck around the chainplates and mast for cracking and delamination. If in doubt, get a professional opinion.

The cost to replace standing rigging obviously varies from boat to boat. Give us a call, and we can give you a rough quote. With proper measurements (wire diameter, pin sizes, wire lengths), we can give you a very accurate price for the standing rigging itself, but there are often unforeseen complications during the job (bad spreaders, corroded mast bases, hardware that is stripped on the mast, frozen pins, chainplates that are failing, etc.). A rig inspection beforehand can minimize surprises. And word of warning… jobs often get expensive because the customer decides, once the mast is down, to add furlers, masthead units, new sheets and halyards, etc. These additions add up quickly and affect the cost of parts, labor, special order shipping, taxes, etc. We are happy to accommodate your requests, but the cost of your job will escalate quickly.

Although we work closely with the boatyard during the job, you will need to negotiate yard fees (crane, mast lay days, etc.) directly with the yard of your choice. They are not included in our estimate. Driscoll Boat Works and Shelter Island Boat Yard are both within walking distance of Rigworks. Assuming it fits in our racks and we have room, we may be able to avoid mast lay day charges by storing your mast here at Rigworks.

As a quick side note… people often ask if they should switch from rod to wire rigging or vice versa during the re-rig (usually from rod to wire as rod is much more expensive per foot). Be aware that this is not a simple conversion and can be quite expensive. The terminations for wire vs. rod can be quite different and require a lot of customization.

Want to prolong the lifespan of your rigging? Here are a few suggestions…

Maintain your standing rigging! Like your car, your sailboat needs TLC. Perform routine cleaning/polishing to remove corrosives, identify chafe points and other damage, and properly tune your standing rigging (shrouds, forestay, backstay). Stainless does not like to be deprived of oxygen, so keep tape off your rigging to avoid anaerobic corrosion. For more information on rig maintenance, visit our prior ‘Ask the Rigger’ article at https://rigworks.com/maintaining-your-standing-rigging/ and download our rig-care pamphlet at https://rigworks.com/wp-content/uploads/2016/03/Standing-Rigging-Care.pdf .

Get regular rig inspections! This is a very inexpensive investment (by yachting standards ) to ensure that your rig is in sound condition. Why not schedule annual service as you would with a car? Let us go over your rig from top to bottom and end to end to identify trouble before it gets worse. For more information on rig inspections, visit our prior ‘Ask the Rigger’ article at https://rigworks.com/the-scoop-on-rig-inspections/ . Our riggers can also tune your rig, either at the dock or under sail. Not only will your rig last longer when properly tuned, your boat will sail better, and who doesn’t love that!

Consider pulling your rig every 5-6 years to inspect the mast base, chainplates, turnbuckles, wire, etc. This is considerably less expensive than a full re-rig and, again, may identify issues before they become catastrophic.

And PLEASE do not buy a used boat without a professional rig inspection! We have had many customers who have found a ‘great deal’ on a used boat only to discover that they need to spend a small fortune on new rigging. A boat with bad rigging is at best a pain in the #@$ and at worst a lethal weapon. There is nothing more expensive than a “cheap” boat!

A customer came into our shop the other day to discuss his 33-year old rigging. He said it looked fine. He asked “Isn’t the industry standard just a ploy by manufacturers to sell more wire”. Since we also stand to gain when you replace your rigging, let us say that many insurance companies will not insure sailboats with aged rigging. This should be a warning. If they are not willing to take the financial risk, are you willing to risk yourself and your crew?

Finally, should you decide to sail with that old rigging, consider checking out the ‘Ask the Rigger’ article titled “Rigs Fail… Are You Ready?” at https://rigworks.com/rigs-fail-ready/ .

Safe Sailing!

Related Posts

Ask the Rigger

Do your masthead sheaves need replacing.

Question: My halyard is binding. What’s up? From the Rigger: Most boat owners do not climb their masts regularly, but our riggers spend a lot of time up there. And they often find badly damaged Read more…

Standing Rigging (or ‘Name That Stay’)

Question: When your riggers talk about standing rigging, they often use terms I don’t recognize. Can you break it down for me? From the Rigger: Let’s play ‘Name that Stay’… Forestay (1 or HS) – Read more…

Selecting Rope – Length, Diameter, Type

Question: Do you have guidelines for selecting halyards, sheets, etc. for my sailboat? From the Rigger: First, if your old rope served its purpose but needs replacing, we recommend duplicating it as closely as possible Read more…

- Boat Rigging: Setting Sail for Success

In the world of sailing, boat rigging plays a crucial role in ensuring the safety, efficiency, and performance of your vessel. From standing rigging to sail rigging types, it's essential to understand the intricacies of rigging a yacht to embark on smooth sailing adventures. In this comprehensive guide, we'll dive into the nuances of boat rigging, helping you navigate the open waters with confidence.

Boat Rigging Basics

Before we delve into the details, let's start with the fundamentals of boat rigging. Understanding the key components and their functions is essential for any sailor, whether you're a novice or a seasoned pro.

Standing Rigging

Standing rigging refers to the fixed support structure of a boat's mast, including wires, cables, and rods. It plays a critical role in maintaining the mast's vertical position and overall stability.

Sail Rigging Types

Sail rigging is not a one-size-fits-all concept, but rather a diverse world with various types and configurations to suit different sailing needs. Understanding these rigging types is essential for any sailor looking to optimize their boat's performance and safety.

Ship Riggings

Ship riggings have played a pivotal role in shaping the history of seafaring and maritime exploration. These complex systems of ropes, wires, and sails have been integral to the functionality and success of various vessels throughout the ages.Explore the significance of ship riggings, their evolution, and their influence on modern-day boat rigging.

Materials Matter

The choice of materials for your boat rigging is a decision that can't be taken lightly. Two popular options, Dyneema and Kevlar, offer distinct advantages.

Dyneema Rigging

Dyneema rigging represents a breakthrough in the world of sailboat rigging. This cutting-edge material, known for its remarkable strength and low stretch properties, has revolutionized the way sailors experience the open water. Often referred to as the ultimate innovation in the world of sailing, Dyneema rigging offers a myriad of advantages:

- Exceptional Strength: Dyneema rigging boasts remarkable strength-to-weight ratio, making it incredibly robust and reliable even in demanding conditions.

- Low Stretch: Dyneema has minimal stretch, which translates to improved sail control and responsiveness, ensuring better performance.

- Lightweight: It's significantly lighter than traditional rigging materials like steel, reducing the overall weight of your vessel and enhancing speed and maneuverability.

- Low Maintenance: Dyneema rigging requires minimal maintenance, offering sailors peace of mind and more time on the water.

- Resistance to Corrosion: Unlike metal rigging, Dyneema is not susceptible to corrosion, ensuring a longer lifespan and durability.

- UV Resistance: Dyneema is highly resistant to UV rays, making it ideal for prolonged exposure to sunlight.

- Easy Handling: Its flexibility and ease of handling simplify rigging installation and adjustments.

- Enhanced Safety: Dyneema's strength and reliability contribute to safer sailing experiences, reducing the risk of rigging failure.

- Versatility: It's suitable for a wide range of applications, from standing rigging to halyards, making it a versatile choice for sailors.

- Eco-Friendly: Dyneema is an environmentally friendly option as it doesn't release harmful substances into the water, contributing to a cleaner marine ecosystem.

Dyneema vs. Kevlar

Weigh the pros and cons of Dyneema and Kevlar to determine which suits your sailing needs best:

Dyneema Rigging:

- Exceptional Strength: Dyneema boasts impressive strength, making it highly reliable for rigging purposes.

- Low Stretch: It has minimal stretch, enhancing sail control and overall performance.

- Lightweight: Dyneema is significantly lighter than traditional materials, reducing the vessel's weight.

- Low Maintenance: Requires minimal upkeep, saving time and effort.

- Corrosion Resistance: Dyneema is not susceptible to corrosion, ensuring durability.

- UV Resistance: It's highly resistant to UV rays, making it suitable for extended exposure to sunlight.

- Safety: Dyneema's strength and reliability contribute to safer sailing experiences.

- Versatility: Suitable for various rigging applications, from standing rigging to halyards.

- Cost: Dyneema can be more expensive than some traditional materials, initially.

- Abrasion Resistance: It may be less resistant to abrasion compared to Kevlar.

Kevlar Rigging:

- Excellent Abrasion Resistance: Kevlar is highly resistant to wear and tear, ensuring longevity.

- High Tensile Strength: It offers impressive tensile strength, making it suitable for demanding applications.

- Stiffness: Kevlar is stiffer than Dyneema, which can be advantageous for some rigging configurations.

- Heavy: Kevlar is heavier than Dyneema, potentially impacting vessel performance.

- Low UV Resistance: It is less resistant to UV radiation, which can affect its durability over time.

- Higher Stretch: Kevlar tends to stretch more than Dyneema, which can impact sail control.

- Prone to Corrosion: Unlike Dyneema, Kevlar can be susceptible to corrosion.

- Cost: It can be expensive, and the initial investment may be higher than other materials.

Choosing between Dyneema and Kevlar depends on your specific sailing needs and priorities. Dyneema is favored for its strength, low stretch, and light weight, while Kevlar excels in abrasion resistance and tensile strength. Consider these factors when making your rigging material selection.

Stainless Steel Yacht Rigging

When it comes to yacht rigging, durability is paramount, and stainless steel rigging wires stand out as a top choice. Their robust nature, coupled with an unmistakable touch of elegance, makes them an ideal option for discerning sailors. Stainless steel yacht rigging is highly resistant to corrosion, even in the harsh marine environment. This resistance not only ensures a longer lifespan but also reduces maintenance efforts, allowing you to spend more time on the water. Additionally, the sleek appearance of stainless steel adds a touch of sophistication to your vessel. Whether you're cruising the open seas or participating in regattas, stainless steel yacht rigging combines style and substance to offer a premium sailing experience.

Spectra Standing Rigging

Spectra standing rigging is a game-changer for sailors seeking top-tier performance and durability. This advanced material, known for its incredible strength and low stretch properties, has revolutionized the way we approach standing rigging. Spectra rigging offers advantages that are hard to beat – it enhances the stability and safety of your vessel while providing exceptional responsiveness. The minimal stretch ensures precise sail control, making it the go-to choice for those who demand the utmost from their rigging. If you're looking to take your sailing experience to the next level, Spectra standing rigging is a choice that can't be ignored.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine.

Rigging a Yacht: A Step-By-Step Guide

Now that you've grasped the basics and material options, let's dive into the practical aspect of rigging a yacht. Follow these steps to ensure a smooth and safe sailing experience.

Planning and Preparation

Rigging a yacht is a meticulous process that requires careful planning and thorough preparation. Before embarking on your sailing adventure, it's crucial to ensure that every aspect of your yacht's rigging is in top-notch condition. The advantages of this step-by-step guide are manifold. It guarantees the safety of both the vessel and its passengers, reduces the risk of mid-sail complications, and ultimately enhances your overall sailing experience. By meticulously inspecting your rigging and addressing any issues during the planning and preparation phase, you can set sail with confidence, knowing that your yacht is ready to navigate the open waters seamlessly.

Inspecting Your Rigging

Rigging a yacht is a meticulous process that demands careful attention to detail. One crucial aspect is inspecting your rigging. This step ensures the safety and efficiency of your sailing adventure. Regular inspections , even before you set sail, can identify potential issues and help prevent mishaps on the water . Inspecting your rigging is not only a safety measure but also a way to guarantee that your yacht performs at its best, allowing you to enjoy smooth and stress-free sailing experiences.

Rigging Replacement

When it comes to maintaining your yacht's rigging, the necessity of rigging replacement cannot be overstated. Whether due to wear and tear or a desire to upgrade to modern materials, knowing when and how to replace your rigging is crucial.

Specialized Rigs for Small Sailboats

For small sailboat enthusiasts , specialized rigs can enhance your sailing experience. Explore the options available for these nimble vessels.

Ship Rigging Terms

Sailboat rigging comes with its unique terminology. Get acquainted with the essential terms:

- Mast: The vertical spar or structure that supports sails and rigging.

- Boom: A horizontal spar that extends from the mast to support the bottom of a sail.

- Shroud: Rigging wires that support the mast from the sides.

- Stay: Rigging wires that support the mast from the front or back.

- Halyard: Lines used to raise and lower sails.

- Sheet: Lines used to control the angle of the sails with respect to the wind.

- Jib: A triangular foresail set in front of the mast.

- Tack: The lower forward corner of a sail.

- Clew: The lower after corner of a sail.

- Topping Lift: A line that supports the boom when the sail is not in use.

Understanding these ship rigging terms is essential for efficient and safe sailing, allowing you to communicate effectively with your crew and navigate the open waters with confidence.

Sailboat Stays and Shrouds

Sailboat rigging comprises various components, and among the most critical are sailboat stays and shrouds. Stays are the fixed support cables or wires that keep the mast upright, while shrouds add lateral support, preventing the mast from swaying. These components work together to maintain the mast's stability and ensure safe and efficient sailing. The proper tension and alignment of stays and shrouds are crucial for the overall performance and safety of a sailboat. Regular inspections and maintenance of these rigging elements are essential to prevent wear and tear, making sure they remain reliable on your sailing adventures. Understanding the role of sailboat stays and shrouds is fundamental for any sailor, whether you're navigating coastal waters or crossing the open sea.

In conclusion, boat rigging is a multifaceted subject that greatly influences your sailing experience. Understanding the fundamentals, material choices, and the process of rigging a yacht is essential for a successful voyage.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite

sailing destinations .

Average Cost to Replace Running Rigging (with Examples)

Replacing the running rigging is a crucial part of the upkeep of your sailboat. Its cost can vary, mainly depending on the size of your boat, the type of lines used, and whether you opt for professional installation or take on the project yourself. In this article, we will discuss some examples to give you a better understanding of what you may be looking to spend on running rigging replacement.

For a 30-foot sailboat, the cost to replace a main halyard can be around $500. The estimated cost of replacing your boat's running rigging with sheets is around $1,700–$2,000+. For an average 40-foot boat, you can expect to pay around $4,000 for wire rigging replacement, which may include control lines.

The average maintenance cost for boats under 30 feet is around $255 per month, or just under $3,000 per year, so you may want to plan for periodic rigging replacement. This way, you can avoid unexpected expenses and maintain your sailboat's performance and safety.

- Replacing the running rigging on your sailboat can be a necessary expense, but also an investment in safety and performance.

- Timely replacement of your sailboat's running rigging not only ensures a smooth sailing experience but also prevents costly scenarios such as having to hire a rigger to go up your mast to replace a broken halyard.

- Sta-set-x might be a suitable option for halyards as it has less stretch compared to other materials and only costs a few pennies more than regular sta-set.

- Make sure to include other additional expenses (like shiv replacement) if needed when estimating the cost.

On this page:

Average cost to replace running rigging, cost breakdown by rigging type, factors affecting replacement cost, ways to save on replacement costs, understanding running rigging replacement, when to replace running rigging.

In this section, we'll cover the average costs associated with replacing running rigging, focusing on different materials and professional services.

Dyneema lines offer a long-lasting solution

Dyneema lines are known for their strength, durability, and lightweight nature. They can be more expensive than other options, but they offer a long-lasting solution. The cost of replacing running rigging with Dyneema lines can be:

Keep in mind that pricing can vary based on the quality and brand of the lines.

Polyester lines offer a good balance between strength and handling

If you're looking for a more budget-friendly option, consider using double braid polyester lines. They are more affordable than Dyneema but still offer a good balance between strength and handling. The cost of polyester lines can be:

Wire rope for replacing running rigging

For specific applications like certain types of forestay and backstay, you might require wire rope. The cost of stainless steel wire rope varies depending on the diameter and type.

Basic materials cost for your running rigging

As an example, let's assume you're replacing all the running rigging for a 30-foot sailboat with polyester lines. Your total basic material cost could be around $180–300 with approximately 200 feet of line (main halyard, jib halyard , sheets, etc.).

Professional services cost to replace your running rigging

If you decide to hire a professional rigger, the service fees might increase the overall cost. For example, to replace the main halyard on a 30-foot sloop, a professional rigger may charge close to $500. Labor rates can vary, so it's recommended to get quotes from multiple riggers in your area to find the best deal.

Here's an overview table with the cost to replace rigging for different boat and rig types.

Below, we will break down the average cost of replacing running rigging for your sailboat, with examples for each type of rigging: Halyards, Sheets, and Control Lines.

Halyard replacement costs vary depending on the length, material, and quality of the line you choose

Replacing halyards can vary in cost depending on the length and material. For instance, a basic double braid polyester halyard for a 30-foot sailboat may cost around $500.

For a standard 30-foot sailboat, you can expect the cost to be around $500 for the main halyard. Keep in mind, this estimate includes installation by a professional rigger. If you opt to replace it yourself, the price might be lower. It is essential to research the specific halyards your boat requires and compare prices from different retailers to find the best deal.

Sheet replacement costs will depend on the size, material, and quality of the line

Sheets are essential for controlling sails, and their replacement cost also depends on length, material, and whether you're doing the work yourself or hiring a professional. Here are some average costs for different types of sheets:

A common material for sheets on smaller sailboats is a double braid polyester line. The estimated cost of replacing your boat's running rigging with this material is around $1,700–$2,000+ for a 30-foot sailboat. This cost includes hiring a professional to complete the task. Keep in mind that if you are comfortable replacing the sheets yourself, the overall cost might be lower. As with halyards, research your specific needs and compare prices from different retailers.

Control line replacement costs will vary depending on your sailboat's configuration

Control lines cover a wide range of rigging elements, each with different cost considerations. Some common control lines and their respective average costs include:

Control lines are often replaced with materials similar to those used for sheets, like double braid polyester. Unlike halyards and sheets, control lines are specific to the control systems used on your boat, such as traveler, vang, or furling systems, so the costs will vary depending on your sailboat's configuration. For an average 40-foot boat, you can expect to pay around $4,000 for wire rigging replacement, which may include control lines. It's crucial to understand the control lines you need to replace and their specifications before sourcing the best prices and materials for the job.

Material and quality of the rigging components

Higher-quality materials, such as Sta-Set-X , are more durable and offer less stretch, which translates to a slightly higher price. On the other hand, more affordable materials might not provide the same level of performance or longevity, requiring more frequent replacements.

Boat size impacts the amount of running rigging you'll need

A larger vessel requires more line, sheet, and other components, increasing the overall cost of replacement. For example, replacing the standing rigging on a sailboat can cost around $4,000 every ten years .

Labor charges when replacing running rigging

If you choose to hire professional help to undertake the project, you can expect to pay for their time and expertise. Labor costs vary by region and can also depend on the complexity of your boat's rigging system.

When it comes to replacing your sailboat's running rigging , there are a few ways to save money without sacrificing quality. By following these tips, you can ensure that you get the best value for your investment.

DIY approach on running rigging replacement

Although it might take some time and effort, learning how to replace your own running rigging will save you labor costs. Many sailors find this process rewarding and educational. Familiarize yourself with the different components and materials used in your sailboat's running rigging system, then research how to install and maintain them. There are numerous online tutorials and guides available to help you along the way.

Purchasing rigging materials in bulk

Instead of buying only the specific amount that you need for your boat, consider buying larger quantities at lower prices per foot. For example, Sampson Ropes and other manufacturers offer double braid Dacron rope products at prices ranging from $1.00 to $2.50 per foot. By purchasing larger quantities, you may be able to secure a more favorable price per foot, which will ultimately lower your overall replacement cost.

Take advantage of shopping deals and discounts

Keep your eyes open for sales and promotions at your local chandleries or online retailers. Signing up for newsletters from sailing or marine supply stores can provide you with access to exclusive discounts and information about upcoming sales. Additionally, consider purchasing gently used or clearance items, which can offer significant savings without sacrificing quality.

Running rigging consists of all the lines, sheets, and halyards used to haul and operate the sails. As a boat owner, you should be aware of the signs that your running rigging needs replacement and the average costs associated with it.

First, let's look at the reasons for replacing your running rigging. The primary reason is wear and tear caused by continuous use, exposure to the sun, saltwater, and friction . Over time, these factors can weaken your lines, making them prone to breaking or developing other issues that can impact your boat's functionality and safety. It's important to inspect your running rigging regularly and spot any signs of wear like fraying, chafing, or discolored fibers . These indicate a need for replacement before any accidents happen.

Now, let's discuss the average cost of replacing your running rigging. The overall cost varies depending on factors such as your boat's size, the quality of materials used, and labor expenses. For a 30-foot sailboat, the cost to replace a main halyard without going aloft can be around $500, including labor and materials. However, this is just an example, and costs may differ based on your specific boat and your location.

When planning to replace your running rigging, you can opt for various material options, each with its own price range and characteristics. Materials like polyester, Dyneema, and Vectran can offer different benefits, such as increased strength, reduced stretch, and improved durability. It's important to research and choose the right material for your sailboat based on your needs and budget.

Another aspect of expenses to consider is the labor cost , which depends on the rigging service you hire and the complexity of the replacement job. For instance, some tasks may require a rigger to climb the mast , adding to labor hours and overall costs. To save money, you can learn to do some running rigging replacements yourself; however, make sure you know your limits and call a professional for complex tasks.

Signs of wear and fraying on your running rigging

Regularly inspect key areas such as halyards, sheets, and control lines . If you notice any frayed or chafed sections, consider replacing the affected line immediately. A broken halyard can lead to expensive repairs and even pose safety risks for you and your crew while sailing. Keeping these components in good condition is crucial for smooth sailing and the optimal performance of your boat.

Maintenance schedule that includes regular inspection and cleaning of your lines

A proactive approach to maintaining your running rigging will prolong its life and ensure the safety of your vessel. It's a good idea to establish a maintenance schedule that includes regular inspection and cleaning of your lines. While it may be tempting to wait until a problem arises, preventative upkeep can help you avoid costly repairs or emergency situations in the long run . Check your rigging for signs of wear and replace parts when necessary to maintain optimal sailing conditions.

Leave a comment

You may also like, sailboat parts explained: illustrated guide (with diagrams).

When you first get into sailing, there are a lot of sailboat parts to learn. Scouting for a good guide to all the parts, I couldn't find any, so I wrote one myself.

Guide to Understanding Sail Rig Types (with Pictures)

Average Cost to Replace Standing Rigging (with Examples)

What's the Best Rig for Single-Handed Sailing?

The Ultimate Guide to Sail Types and Rigs (with Pictures)

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

No products in the cart.

Sailing Ellidah is supported by our readers. Buying through our links may earn us an affiliate commission at no extra cost to you.

The Standing Rigging On A Sailboat Explained

The standing rigging on a sailboat is a system of stainless steel wires that holds the mast upright and supports the spars.

In this guide, I’ll explain the basics of a sailboat’s hardware and rigging, how it works, and why it is a fundamental and vital part of the vessel. We’ll look at the different parts of the rig, where they are located, and their function.

We will also peek at a couple of different types of rigs and their variations to determine their differences. In the end, I will explain some additional terms and answer some practical questions I often get asked.

But first off, it is essential to understand what standing rigging is and its purpose on a sailboat.

The purpose of the standing rigging

Like I said in the beginning, the standing rigging on a sailboat is a system of stainless steel wires that holds the mast upright and supports the spars. When sailing, the rig helps transfer wind forces from the sails to the boat’s structure. This is critical for maintaining the stability and performance of the vessel.

The rig can also consist of other materials, such as synthetic lines or steel rods, yet its purpose is the same. But more on that later.

Since the rig supports the mast, you’ll need to ensure that it is always in appropriate condition before taking your boat out to sea. Let me give you an example from a recent experience.

Dismasting horrors

I had a company inspect the entire rig on my sailboat while preparing for an Atlantic crossing. The rigger didn’t find any issues, but I decided to replace the rig anyway because of its unknown age. I wanted to do the job myself so I could learn how it is done correctly.

Not long after, we left Gibraltar and sailed through rough weather for eight days before arriving in Las Palmas. We were safe and sound and didn’t experience any issues. Unfortunately, several other boats arriving before us had suffered rig failures. They lost their masts and sails—a sorrowful sight but also a reminder of how vital the rigging is on a sailboat.

The most common types of rigging on a sailboat

The most commonly used rig type on modern sailing boats is the fore-and-aft Bermuda Sloop rig with one mast and just one headsail. Closely follows the Cutter rig and the Ketch rig. They all have a relatively simple rigging layout. Still, there are several variations and differences in how they are set up.

A sloop has a single mast, and the Ketch has one main mast and an additional shorter mizzen mast further aft. A Cutter rig is similar to the Bermuda Sloop with an additional cutter forestay, allowing it to fly two overlapping headsails.

You can learn more about the differences and the different types of sails they use in this guide. For now, we’ll focus on the Bermuda rig.

The difference between standing rigging and running rigging

Sometimes things can get confusing as some of our nautical terms are used for multiple items depending on the context. Let me clarify just briefly:

The rig or rigging on a sailboat is a common term for two parts:

- The standing rigging consists of wires supporting the mast on a sailboat and reinforcing the spars from the force of the sails when sailing.

- The running rigging consists of the halyards, sheets, and lines we use to hoist, lower, operate, and control the sails on a sailboat.

Check out my guide on running rigging here !

The difference between a fractional and a masthead rig

A Bermuda rig is split into two groups. The Masthead rig and the Fractional rig.

The Masthead rig has a forestay running from the bow to the top of the mast, and the spreaders point 90 degrees to the sides. A boat with a masthead rig typically carries a bigger overlapping headsail ( Genoa) and a smaller mainsail. Very typical on the Sloop, Ketch, and Cutter rigs.

A Fractional rig has forestays running from the bow to 1/4 – 1/8 from the top of the mast, and the spreaders are swept backward. A boat with a fractional rig also has the mast farther forward than a masthead rig, a bigger mainsail, and a smaller headsail, usually a Jib. Very typical on more performance-oriented sailboats.

There are exceptions in regards to the type of headsail, though. Many performance cruisers use a Genoa instead of a Jib , making the difference smaller.

Some people also fit an inner forestay, or a babystay, to allow flying a smaller staysail.

Explaining the parts and hardware of the standing rigging

The rigging on a sailing vessel relies on stays and shrouds in addition to many hardware parts to secure the mast properly. And we also have nautical terms for each of them. Since a system relies on every aspect of it to be in equally good condition, we want to familiarize ourselves with each part and understand its function.

Forestay and Backstay

The forestay is a wire that runs from the bow to the top of the mast. Some boats, like the Cutter rig, can have several additional inner forestays in different configurations.

The backstay is the wire that runs from the back of the boat to the top of the mast. Backstays have a tensioner, often hydraulic, to increase the tension when sailing upwind. Some rigs, like the Cutter, have running backstays and sometimes checkstays or runners, to support the rig.

The primary purpose of the forestay and backstay is to prevent the mast from moving fore and aft. The tensioner on the backstay also allows us to trim and tune the rig to get a better shape of the sails.

The shrouds are the wires or lines used on modern sailboats and yachts to support the mast from sideways motion.

There are usually four shrouds on each side of the vessel. They are connected to the side of the mast and run down to turnbuckles attached through toggles to the chainplates bolted on the deck.

- Cap shrouds run from the top of the mast to the deck, passing through the tips of the upper spreaders.

- Intermediate shrouds run from the lower part of the mast to the deck, passing through the lower set of spreaders.

- Lower shrouds are connected to the mast under the first spreader and run down to the deck – one fore and one aft on each side of the boat.

This configuration is called continuous rigging. We won’t go into the discontinuous rigging used on bigger boats in this guide, but if you are interested, you can read more about it here .

Shroud materials

Shrouds are usually made of 1 x 19 stainless steel wire. These wires are strong and relatively easy to install but are prone to stretch and corrosion to a certain degree. Another option is using stainless steel rods.

Rod rigging

Rod rigging has a stretch coefficient lower than wire but is more expensive and can be intricate to install. Alternatively, synthetic rigging is becoming more popular as it weighs less than wire and rods.

Synthetic rigging

Fibers like Dyneema and other aramids are lightweight and provide ultra-high tensile strength. However, they are expensive and much more vulnerable to chafing and UV damage than other options. In my opinion, they are best suited for racing and regatta-oriented sailboats.

Wire rigging

I recommend sticking to the classic 316-graded stainless steel wire rigging for cruising sailboats. It is also the most reasonable of the options. If you find yourself in trouble far from home, you are more likely to find replacement wire than another complex rigging type.

Relevant terms on sailboat rigging and hardware

The spreaders are the fins or wings that space the shrouds away from the mast. Most sailboats have at least one set, but some also have two or three. Once a vessel has more than three pairs of spreaders, we are probably talking about a big sailing yacht.

A turnbuckle is the fitting that connects the shrouds to the toggle and chainplate on the deck. These are adjustable, allowing you to tension the rig.

A chainplate is a metal plate bolted to a strong point on the deck or side of the hull. It is usually reinforced with a backing plate underneath to withstand the tension from the shrouds.

The term mast head should be distinct from the term masthead rigging. Out of context, the mast head is the top of the mast.

A toggle is a hardware fitting to connect the turnbuckles on the shrouds and the chainplate.

How tight should the standing rigging be?

It is essential to periodically check the tension of the standing rigging and make adjustments to ensure it is appropriately set. If the rig is too loose, it allows the mast to sway excessively, making the boat perform poorly.

You also risk applying a snatch load during a tack or a gybe which can damage the rig. On the other hand, if the standing rigging is too tight, it can strain the rig and the hull and lead to structural failure.

The standing rigging should be tightened enough to prevent the mast from bending sideways under any point of sail. If you can move the mast by pulling the cap shrouds by hand, the rigging is too loose and should be tensioned. Once the cap shrouds are tightened, follow up with the intermediates and finish with the lower shrouds. It is critical to tension the rig evenly on both sides.

The next you want to do is to take the boat out for a trip. Ensure that the mast isn’t bending over to the leeward side when you are sailing. A little movement in the leeward shrouds is normal, but they shouldn’t swing around. If the mast bends to the leeward side under load, the windward shrouds need to be tightened. Check the shrouds while sailing on both starboard and port tack.

Once the mast is in a column at any point of sail, your rigging should be tight and ready for action.

If you feel uncomfortable adjusting your rig, get a professional rigger to inspect and reset it.

How often should the standing rigging be replaced on a sailboat?

I asked the rigger who produced my new rig for Ellidah about how long I could expect my new rig to last, and he replied with the following:

The standing rigging should be replaced after 10 – 15 years, depending on how hard and often the boat has sailed. If it is well maintained and the vessel has sailed conservatively, it will probably last more than 20 years. However, corrosion or cracked strands indicate that the rig or parts are due for replacement regardless of age.

If you plan on doing extended offshore sailing and don’t know the age of your rig, I recommend replacing it even if it looks fine. This can be done without removing the mast from the boat while it is still in the water.

How much does it cost to replace the standing rigging?

The cost of replacing the standing rigging will vary greatly depending on the size of your boat and the location you get the job done. For my 41 feet sloop, I did most of the installation myself and paid approximately $4700 for the entire rig replacement.

Can Dyneema be used for standing rigging?

Dyneema is a durable synthetic fiber that can be used for standing rigging. Its low weight, and high tensile strength makes it especially popular amongst racers. Many cruisers also carry Dyneema onboard as spare parts for failing rigging.

How long does dyneema standing rigging last?

Dyneema rigging can outlast wire rigging if it doesn’t chafe on anything sharp. There are reports of Dyneema rigging lasting as long as 15 years, but manufacturers like Colligo claim their PVC shrink-wrapped lines should last 8 to 10 years. You can read more here .

Final words

Congratulations! By now, you should have a much better understanding of standing rigging on a sailboat. We’ve covered its purpose and its importance for performance and safety. While many types of rigs and variations exist, the hardware and concepts are often similar. Now it’s time to put your newfound knowledge into practice and set sail!

Or, if you’re not ready just yet, I recommend heading over to my following guide to learn more about running rigging on a sailboat.

Sharing is caring!

Skipper, Electrician and ROV Pilot

Robin is the founder and owner of Sailing Ellidah and has been living on his sailboat since 2019. He is currently on a journey to sail around the world and is passionate about writing his story and helpful content to inspire others who share his interest in sailing.

Very well written. Common sense layout with just enough photos and sketches. I enjoyed reading this article.

Thank you for the kind words.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

When should standing rigging be replaced?

- Thread starter Project_Mayhem

- Start date Nov 9, 2020

- Forums for All Owners

- Ask All Sailors

Project_Mayhem

I've read that standing rigging should be replaced anywhere from 10 all the way up to 20 years and also simply based on condition. My boat has been in fresh water all its life. To the best of my knowledge it hasn't had a trailer until last year so the mast was up through the winter. Most recent receipt was for lower stays 10 years ago. Overall condition is good with some kinks here and there. No signs of corrosion or stray strands anywhere. Would you replace this?

If you have (reasonable) evidence that the PO replaced only the worst sections, it's safe to assume that the rest of the rig is getting ancient and failure prone. 20 years is what we go by for fresh water usage, for a max time.... and matter of fact we are now replacing our 2004 complete rig. Be sure to replace the turn buckles also -- not much more $, and it's great to be sure of the integrity of the entire rig.

Standing rigging replacement. Just got home from my first sail with my 7 year grandson on my 47 year old boat. One of his first observations “Granddad that’s a pretty big pole. Is it going to fall down, cause that would hurt.” When and why do you change standing rigging. Easy answer “before it can fall down.” There is sailors knowledge based on observations and experiences that have formed the rules of thumb. 6-10 years for salt water exposed rigging and 15-25 years for fresh water rigging. Rough guides that depend on location of the boats sailing experience, how the boat has been used, and how the boat will be used. On a new to me boat I want to know the condition by inspection of the rigging and all the connections to the mast and hull. If I’m a day sailor with close proximity to repairs and my mast is easily fixed/taken down that is different than if I am planning an extended cruise isolated from repair resources and skilled help. Racing and heavy weather sailing tests the strength of the rigging. Replacement of the rigging components is more frequent and based on inspection. Kinks in wire is like chafe on a line. It requires more careful consideration of condition, usage, and inspection for signs of failure. Proper size and material components for the rig are further consideration. When I refitted my mast and rigging I had the help of a seasoned rigger. He advised that with the size of my mast, the manufacturer was known to have undersized the rigging. Based on my sailing plans he suggested we increase the wire and components one size. I base my decisions on my planned usage and condition of rig more than on a number of years. The reactive answer to your question is a probable Yes it is time. The resulting knowledge of “The Rigging” was new in 2021, is peace of mind and will serve a little should you decide to sell at a future date. Also there is a sense of confidence when that thunderstorm approachs that the rigging is new and solid. It should be one less worry about will we weather the storm. Now those 20 year old sails might be the next issue. Good luck.

Project_Mayhem said: Overall condition is good with some kinks here and there. Click to expand

Project_Mayhem said: ...I've read that the inner stays rarely snap. Does that mean that replacement time for those is longer? Click to expand

ontherocks83

On our old boat we had the Port Aft lower shroud fail while sailing. The mast stayed up, but it sounded like a gun shot and was scary as hell. On our new boat the PO could not remember when or provide receipts to how old the standing rigging was. When applying for insurance they either wanted proof that the rigging was under 10 years old or to have a rigger inspect it and report its condition. I ended up just replacing all of the standing rigging through rigginonly.com in Fairhaven Ma. They were awesome to deal with and the price was very reasonable. To be honest I feel much more comfortable knowing the age and condition of the rigging especially when the wind picks up. And realistically all of the rigging on a 25' boat should not be expensive at all.

ontherocks83 said: I ended up just replacing all of the standing rigging through rigginonly.com in Fairhaven Ma Click to expand

dlochner said: For Rigging Only . If you don't live nearby, call them and then send them the old rigging, they will duplicate it. Good service, good quality, nice people. Click to expand