What Do Boat Measurements Mean? 11 Terms Explained!

Boat measurements are more than just numbers; they are the essence of maritime safety, efficiency, and compatibility.

Navigating the intricate world of boat measurements is crucial for anyone in the boating industry, from manufacturers to enthusiasts.

Understanding these measurements ensures proper vessel selection, compliance with marina requirements, and safe navigation in various water conditions.

Below we delve into the key aspects of how boats are measured and the main terms used, providing you with the essential knowledge to engage with the maritime world confidently.

11 Main Boat Measurement Terms

These are 11 main boat measurement terms with expanded descriptions and examples for better understanding:

- Length Overall (LOA) : This is the total length of the boat from the tip of the bow to the end of the stern. It’s the most common way to describe the size of a boat. LOA is important for determining mooring space, marina fees, and navigating in confined waters. For example, a boat with an LOA of 30 feet will need a berth slightly longer than 30 feet. For stability calculations, you should refer to LBP or length between perpendiculars .

- Length on Deck (LOD) : This measures the horizontal length of the boat’s hull excluding any extensions like bow sprits or swim platforms. LOD is used to provide a more accurate measurement of the usable space on the boat. A boat might have an LOA of 35 feet but an LOD of 30 feet if there’s a 5-foot bow sprit.

- Beam : The beam is the width of the boat at its widest point. It’s crucial for stability; wider beams generally provide greater stability. The beam also affects a boat’s capacity and maneuverability. For instance, a boat with a beam of 10 feet might be more stable but less maneuverable than a boat with an 8-foot beam. More about boat beam read here .

- Draft : Draft measures the minimum depth of water a boat requires to float. It’s key for determining where a boat can safely navigate. A sailboat with a draft of 6 feet can’t enter waters less than one fathom or 6 feet deep without risking running aground.

- Displacement : This is the weight of the water displaced by the boat’s hull. It roughly equates to the boat’s weight when fully loaded. Displacement impacts how a boat handles and its fuel efficiency. A boat displacing 5 tons will handle differently than one displacing 2 tons.

- Freeboard : The distance from the waterline to the upper deck level, indicates how much of the boat is above water. A higher freeboard can mean a drier and potentially safer ride in rough conditions. For example, a boat with 4 feet of freeboard will handle choppy water better than one with 2 feet of freeboard.

- Deadrise : This is the angle of the boat’s hull relative to a flat surface. A higher deadrise (sharp angle) helps cut through waves, providing a smoother ride in choppy conditions. A boat with a 20-degree deadrise will generally perform better in rough water than one with a 10-degree deadrise. Learn more about boat deadrise in a detailed article.

- Air Draft : This is the height of the boat from the waterline to its highest fixed point. It’s important to determine if a boat can fit under fixed bridges or other overhead obstructions. A sailboat with a mast height (air draft) of 50 feet needs to consider bridge clearances on its route.

- Gross Tonnage : This volume measurement is used for large vessels and is calculated based on the total internal space of the ship. Ship tonnage is important for regulatory, safety, and commercial purposes. A cargo ship with a gross tonnage of 50,000 indicates its large size and capacity.

- Ballast : This is the weight (often lead or water) added low in the boat to improve stability. Ballast is particularly important in sailboats to counterbalance the force of the wind. A sailboat with 2,000 pounds of ballast will heel (lean) less and be more stable than one with 1,000 pounds.

- Waterline Length (LWL) : The length of the boat at the waterline, can be shorter than the LOA due to overhangs. LWL affects speed and stability; longer waterline lengths generally allow for higher speeds. For instance, a boat with an LWL of 25 feet may be faster than one with an LWL of 20 feet.

Each of these measurements plays a critical role in the design, functionality, and performance of a boat. They are essential for builders, designers, and users to understand the capabilities and limitations of a vessel in various conditions.

How Do You Measure A Boat Hull?

Measuring a boat hull involves determining several key dimensions that are critical for understanding the boat’s design, performance, and suitability for certain conditions. Here are the main measurements taken for a boat hull:

- Length Overall (LOA) : Measure from the furthest point forward ( bow ) to the furthest point aft ( stern ), including any overhangs.

- Length on Deck (LOD) : Measure the length of the deck, excluding overhangs.

- Waterline Length (LWL) : Measure the length of the boat at the waterline, which may be different from the LOA due to the hull shape and overhangs.

- Beam : Measure the widest part of the boat hull, which is usually found at or near the midpoint of the boat’s length. The beam measurement is crucial as it affects stability and interior space.

- Draft : Measure the vertical distance from the waterline to the lowest part of the hull (usually the bottom of the keel ). This tells you how deep the water needs to be for the boat to float without hitting the bottom.

- Freeboard : Measure the distance from the waterline to the upper edge of the hull. This measurement gives an idea of how high the boat sits in the water and can affect how dry the boat stays in rough conditions.

- Deadrise : This is the angle between the hull bottom and a horizontal plane at the boat’s beam. It’s measured in degrees and indicates how the hull will handle different sea conditions. A higher deadrise usually means better performance in rough water.

- Hull Depth : Measure the distance from the deepest point of the hull to the top of the deck. This gives an idea of the overall volume of the hull.

These measurements are typically made using measuring tapes, laser measuring tools, or, in the design phase, through CAD (Computer-Aided Design) software. Accurate hull measurements are essential for boat builders, designers, and owners, as they influence the boat’s capacity, stability , speed, and seaworthiness.

How Does the Coast Guard Measure Boat Length?

The U.S. Coast Guard measures boat length primarily based on the Length Overall (LOA) method. This approach involves measuring the boat from the tip of the bow in its most forward position to the end of the stern in its most aft position.

This includes all structural and integral parts of the boat but does not include removable attachments and fittings such as outboard motors, bow pulpits, rudders , and similar extensions.

It’s important to note that the Coast Guard’s measurement for boat length can differ from how length is defined for registration or documentation purposes, or how it might be described by manufacturers or in boating literature.

For instance, Length on Deck (LOD) or Waterline Length (LWL) might be used in different contexts but are not the standard measurements the Coast Guard uses for defining a boat’s length.

The Coast Guard’s method of measuring boat length is significant for regulatory and safety reasons. For example, certain boating laws, safety requirements, and regulations apply differently to boats depending on their length class. Therefore, accurate measurement is crucial for compliance with federal and state boating laws .

About the author

I worked as an officer in the deck department on various types of vessels, including oil and chemical tankers, LPG carriers, and even reefer and TSHD in the early years. Currently employed as Marine Surveyor carrying cargo, draft, bunker, and warranty survey.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

Lifeboats: Regulations and Requirements

In an emergency, portable vessels called lifeboats will get a ship’s occupants to relative safety. So how do lifeboats work?

What Are the Most Common Shipbuilding Woods?

While shipbuilders have switched to other practices, wood still has a place in the maritime industry. The numerous types available mean manufacturers have myriad options, so here’s a guide on shipbuilding woods.

Fiberglass vs. Steel: Which Is More Reliable?

Shipping professionals should get the most from their investment, so which is more reliable: steel vs. fiberglass? Here’s how to determine the better option.

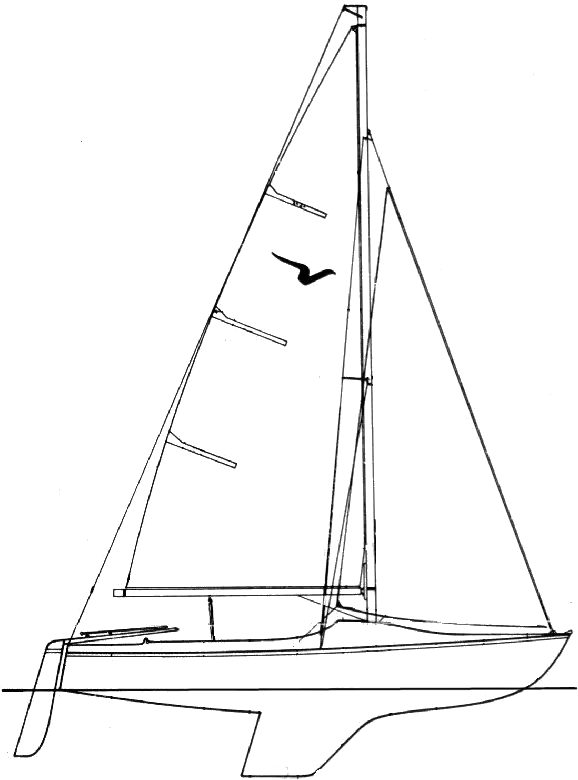

Sailboat Specifications 101: Explained For Beginners

As a newbie to sailing, the sailboat specifics can be overwhelming. Taking time to familiarize yourself with the measurements and vocabulary associated with boats will allow you to be more informed about boats and know which type is right for which activity. You’ll be a better sailor and boater with this knowledge.

Table of Contents

LOA – Length Overall

Length Overall (LOA) is the most common measurement used to describe the size of a sailboat. It refers to the total length of the vessel, from the tip of the bow (front) to the aft end of the stern (back).

LOA is typically measured in feet or meters. This measurement can be useful when comparing boats of similar types, as it gives you an idea of the overall size.

LOD-length on deck

LOD, or Length on Deck, is the measurement of the boat from the tip of the bow to the stern along the deck.

This length does not include any spars, bowsprits, antennas, etc. that are mounted above the main deck.

The difference between LOD and LOA (length overall) is that LOA takes into account any protrusions such as spars and bowsprits. LOD may be shorter than LOA sometimes.

LWL – Load Waterline Length

The LWL or Load Waterline Length is the measurement of the length of a boat at the point where it touches the water.

It is the length of the boat that makes contact with the water and is often shorter than the overall length (LOA) due to the curvature of the hull.

The LWL plays an important role in determining the performance of a sailboat; for example, a longer LWL can help increase stability and reduce drag, allowing the boat to move more efficiently through the water.

The LWL also affects the size of the sail area needed to power the boat. As such, boats with a longer LWL will require larger sails to generate adequate power, while boats with a shorter LWL may need smaller sails.

Beam – The width of the boat

The beam of a sailboat is the maximum width of the hull and is an important measurement for sailing performance.

A wider beam provides more stability on the water and increases the overall sail area. Having a larger sail area will help to increase speed and maneuverability in windy conditions.

It’s important to consider the beam of the boat when deciding what type of sails to use. A boat with a wider beam will require bigger sails, while a boat with a narrower beam will require smaller sails.

Draft – The depth of the boat in the water

Draft measures the distance from the waterline to the lowest point of the boat’s hull when it is fully loaded.

This is important because it affects the boat’s maneuverability, stability, and performance in different sea conditions.

It also affects the sail area of the boat, since a greater draft can provide more stability and lift, allowing for larger sails to be used. Shallow draft boats tend to be able to get into shallower waters than those with deeper drafts.

Full keel vs. modified keel vs. fin keel

The three main types of keels are full, modified, and fin keels.

Full keels are the oldest and most traditional type of keel. They are typically found on heavier displacement boats such as cruisers and larger sailboats.

Full keels provide more stability due to their size and weight, but also create more drag, which can slow down the boat.

Modified keels are a hybrid between full and fin keels. They are often used on boats with moderate displacement, meaning they have a moderate amount of weight.

Modified keels provide a good balance of stability and speed due to their shape and size.

Finally, fin keels are usually found on lighter displacement boats such as racing and performance sailboats.

Fin keels have the least amount of drag, allowing the boat to move faster, but they are not as stable as full or modified keels.

Displacement – The weight of the boat

The displacement of a boat refers to the total weight of the boat, including all of the materials used to construct it. It is usually measured in either metric tonnes or long tons.

The type of displacement your boat has will depend on its size and purpose, with light displacement boats usually being used for day sailing and racing, while moderate and heavy displacement boats are better suited for coastal and ocean cruising.

Light displacement boats are typically quite lightweight, with a hull weight of around 2 tonnes and a total weight of 4 tonnes or less.

These boats are often very fast and agile but can have limited load-carrying capacity due to their light construction.

Moderate displacement boats typically weigh between 4 and 10 tonnes, with a hull weight ranging from 3 to 8 tonnes.

These boats are best suited for coastal cruising and are usually made from heavier materials than light displacement boats. This makes them able to carry a greater load and handle rougher seas with more confidence.

Heavy displacement boats weigh more than 10 tonnes, with a hull weight of up to 15 tonnes.

These boats are built for long-distance ocean cruising and are designed to be sturdy and reliable even in heavy weather. As such, they are usually made from stronger materials than other types of boats and have a much larger load-carrying capacity.

D/L or DLR ratio- Displacement to length ratio

Displacement to length ratio (DLR) is a calculation used to measure the size of a sailboat.

It is determined by dividing the displacement (the weight of the boat) by the waterline length (the length of the boat that is in contact with the water when it is afloat).

The result of this calculation, also known as the DLR, can be used to compare different types of boats or to determine which type of sailboat is most suitable for specific conditions.

The formula for calculating the displacement-to-length ratio is: DLR = (Displacement/2240)/(0.01xLWL)^3 Displacement in pounds, LWL is Waterline Length in feet

Generally, sailboats with higher DLRs tend to have a more rounded hull shape and are better suited to deep-water sailing in heavy weather conditions.

Sailboats with lower DLRs tend to have a more slender hull shape and are better suited to shallow water sailing in light weather conditions.

Ballast is the weight of the boat that is not part of the boat’s structure. This weight can come from a lead, water, or other materials, and it is located in the bottom of the boat to help keep it stable in the water.

The amount of ballast affects the sail area, as more ballast will lower the sail area while decreasing ballast will increase the sail area.

This is because when there is more ballast in the boat, it will be pushed down into the water which reduces the area that a sail can reach. On the other hand, decreasing ballast will allow a sail to extend further.

Ballast is also important for maneuverability and stability; too much ballast and the boat will be sluggish and difficult to turn, while too little ballast could cause the boat to be unstable and even capsize.

Balancing the amount of ballast is key to achieving optimal performance for any type of sailboat.

CSF-Capsize screening formula

The capsize screening formula is a calculation that provides a good indication of the stability of a sailboat. It is the ratio of a boat’s displacement (weight) to its Beam (width).

Capsize ratio formula: Beam / ((Displacement/64.2)1/3) The beam is in feet. Displacement is in pounds

A good capsize ratio is generally considered to be between 1.33 and 2.0, although this can vary depending on the type of boat and its purpose.

A lower capsize ratio indicates that the boat is more stable, as it will be less likely to tip over in strong winds or waves. A higher capsize ratio indicates that the boat is more prone to capsizing.

Motion comfort ratio

Motion comfort ratio (also referred to as “Ted Brewer” ratio) is a measure of the overall stability of a sailboat.

Generally, a boat with a motion comfort ratio greater than 40 is considered stable and a boat with a motion comfort ratio less than 30 is considered unstable.

A boat with a motion comfort ratio between 30-40 is considered moderately stable. The higher the motion comfort ratio, the more comfortable the boat will be in rough waters.

Ted Brewer’s CR formula is: Displacement in pounds/ (.65 x (.7 LWL + .3 LOA) x Beam 1.333 ).

For instance, a boat with an LWL of 35 ft and a displacement of 10,000 lbs would have a motion comfort ratio of 37.5. This would indicate that the boat is moderately stable and should provide an adequate level of comfort in rough waters.

The motion comfort ratio was developed by Ted Brewer and has been used for many years as an indication of a boat’s stability.

It is important to keep in mind, however, that this ratio alone cannot give an accurate picture of how stable a boat is. Other factors such as hull type and keel type should also be taken into account when assessing a boat’s stability.

Ballast to displacement ratio

The ballast-to-displacement ratio is a measure of how much ballast is needed in relation to the weight of the boat.

The higher the ballast-to-displacement ratio, the more stable the boat will be and the less likely it will be to capsize.

the ballast-to-displacement ratio is important for ensuring the boat is adequately balanced and has good performance when sailing.

It is especially important for boats that have large sail areas, as larger sail areas require more ballast to keep the boat steady.

When considering a boat’s ballast-to-displacement ratio, keep in mind that a ratio of 40-50% is generally considered to be optimal. Any higher than that may be too much, while any lower may not be enough.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

What You Can Learn on a Quick Test Sail

Cabo Rico’s Classic Cutter

Bob Perrys Salty Tayana 37-Footer Boat Review

Tartan 30: An Affordable Classic

Preparing Yourself for Solo Sailing

Your New Feature-Packed VHF Radio

Preparing A Boat to Sail Solo

Solar Panels: Go Rigid If You have the Space…

Shoe Goo II Excels for Quick Sail Repairs

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

Taking Care of Your 12-Volt Lead-Acid Battery Bank

Hassle-free Pumpouts

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

New Seacocks for the Offshore Sailor

Bottom Paint Care

Quick and Safe Sail Cleaning

Simplifying Your Cleaning Chemicals Kit

Are E-bikes Worth the Extra Weight and Cost?

How to Handle the Head

The Day Sailor’s First-Aid Kit

How to Select Crew for a Passage or Delivery

Re-sealing the Seams on Waterproof Fabrics

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

A Quest for Keel Integrity

Recent tragedies at sea highlight structural shortfalls..

Over the past few years, weve noticed a worldwide uptick in keel failures. The problem has yet to reach epidemic proportions, but we are hearing more and more troubling accounts of what happens when the ballast parts company with the hull, and a crew faces capsize, flooding, and-all too often-death.

The number of incidents speaks for itself. When the International Sailing Federation (ISAF) formed a working group in 2013 to look into the keel loss issue, it tallied up 72 incidents (since 1984) that resulted in 24 deaths. Far from complete, this profile records only incidents where survivor reports or vetted secondhand accounts were available, or where vessel remains pinpointed keel failure as the cause of a loss. No numbers exist for cases in which sailboats simply disappeared at sea. Keel failure, resulting in major hull damage and loss of stability, certainly can’t be ruled out in those cases.

Photos by Ralph Naranjo

Its often hard to come by detailed information portraying what actually went wrong due to litigation and the regular use of gag orders that hold back the details and protect certain parties involved in the litigation. The much larger automotive and aviation industries attract more scrutiny and regulatory control, and product failures gather greater attention. But when it comes to keel failures, mums the word. So whos keeping track?

In the U.S., theres a long list of players who have a role in determining how well (or poorly) recreational boats are built. Theres the National Marine Manufacturers Association (NMMA), American Bureau of Shipping (ABS), American Boat and Yacht Council (ABYC), the American Boat Builders and Repairers Association (ABBRA), the Society of Naval Architects and Marine Engineers (SNAME), several marine surveyor organizations, and the U.S. Coast Guard, just to name a few. And to the credit of many of these august institutions, the topic of sailboat keels has not been ignored. However, in contrast to the Europeans effort to define keel attachment scan’tlings via ISO 12215-9, theres no apparent rush in the U.S. to better define structural standards for keel attachment. The ABS published the 1994 Guidelines for Offshore Racing Yachts, which incorporated some valuable specs defining scan’tlings (the dimensions for structural components) and engineering approaches for attaching the ballast to the hull. For example, where keel bolts penetrate the keel stub or canoe body of the hull, the laminate should be a minimum thickness equal to the diameter of the keel bolt. Even to the casual observer, this specification hardly seems adequate, especially in light of the radical, long bulb keels we see today. As it turns out, many of the recent keel failures reveal hull and keel stub laminates that fail to meet the 1994 ABS guidelines for thickness. How did these boats even make it onto the market?

From Paper to Production

Every naval architect quickly learns the peril of what can happen when a completed boat bears little structural resemblance to the boat he or she designed. Due to the nature of the boatbuilding business, design specifications often vary from the finished product specs. Seldom is a change for the better.

In the past, the naval architect or yacht designer was closely involved in the production of his design, often presiding in the boatyard during the building process. Those days, unfortunately, are long gone. It is only natural to wonder who oversees how the vessel is built today, and how the devils details are excised.

Currently, its not unusual for a boat builder to purchase the plans of a favored design and then take over the development with their own rendition of engineering specs. Vital issues such as the laminate schedule, which varies throughout the boat, must be applied according to engineering specs during the molding process. Loads vary in different parts of the boat, and structures that support the ballast keel must handle huge bending moments coaxed by wind, wave, and gravity. Top-quality builders carefully monitor the unit count of fiber reinforcement and resin volume used, pay heed to minimizing void content, check cure time and temperature, and confirm resin hardness. Some builders hire composite engineering firms that will gladly provide laminate plans that identify the specific fiber type, number of layers, core material, and resin used in specific regions of the boat. Most hull and reinforcing grids are built in female molds and later bonded together. The composite experts are often on hand to make sure that all goes as planned and that the secondary bond joining these components is as void free as possible.

But building shortfalls do happen. In one case, a new, 44-foot Tartan sloop was beating to windward as the cabin started to fill with seawater. The boat had started to split down the middle, the result of the builders laminating crew deciding to use a butt joint at the centerline rather than overlapping each layer of fiberglass.

A 36-foot boat serviced by PS Technical Editor Ralph Naranjo at the boatyard he used to manage clearly illustrated the problem with contemporary keels. The boat had a deep keel sump and bolt-on external ballast. Just out of curiosity, Naranjo had the travelift operator step down, and with the vessels keel suspended a few inches above the ground, the operator and Naranjo took turns putting pressure on the end of the keel with their feet. Immediately, the suspended, lead-ballast keel began to move back and forth. This minor can’ting caused the hull to dimple with each sway. The owner agreed with Naranjos suggestion that they add transverse framing in the sump and more laminate at the turn of the bilge.

Sailboat design has evolved over the years, and higher performance underbody configurations are definitely playing a role in many of the keel calamities we hear about. A few decades ago, a sailboats keel was designed to be contiguous with the hull, and the ballast could be external (bolted on) or internal (encapsulated in a keel/hull monocoque structure). The interface between the ballast and the hull extended fore and aft for a greater distance than its root-to-tip measurement.

Today, many race boats and performance cruisers incorporate a very different design paradigm. One of the contributing factors in keel vulnerability is that modern keel designs are like a lever that keeps attempting to split the hull in two. Naval architects responding to a demand for better upwind performance have turned to keel shapes that are optimized for lift and righting moment, making them look like tongue depressors with a bulb of lead at their base.

The big challenge lies in how to attach such a lever-like appendage to the hull and to transfer the loads away from the point where the fin root meets the hulls canoe underbody. The good news is that it can be done. The bad news is that the best material to use is the proverbial unobtainium-a strong, stiff, light, isotropic fiber-rich polymer that has yet to be invented. So the next best alternative is a tapered, grid-like reinforcement near where the keel meets the hull.

In the area where the keel meets the hull, skin thickness is increased, core is left out, and stiffness is achieved through the addition of internal structure. Any effort to save further weight in this region is like putting less carbon-dioxide in a fire extinguisher so it will be a little lighter. Somewhere along the way, boatbuilders and designers seem to have lost sight of the fact that this is the part of a boat where structural overkill is totally acceptable.

The quest to make racing sailboats lighter and stiffer has resulted in more and more of the laminate ending up as grid or other longitudinal and transverse support rather than hull skin. The net result is a thinner-skinned shell and a more rigid skeleton.

This paradigm was tried decades ago by the Kiwis and Australians who designed and built thin-skin, wood/epoxy hulls and stiffened them with aluminum-tube geometric shapes running fore and aft and linking to points where the keel, maststep, and chainplate loads were focused.

New Zealand designer Paul Whiting, a pioneer of ultralight, thin-skin racing sailboats, was lost at sea during a Sydney Hobart race when a Tasman Sea storm presumedly caused massive structural damage to his sloop Smackwater Jack. Similar hull failures occurred aboard around-the-world racing boats, and these data points led designers to reconsider scan’tlings and develop a better feel for how the dynamic impacts of a seaway influence structural decisionmaking.

Today, finite element analysis (FEA) and engineering software help guide designers. These new analytical tools allow boat designers to specifically locate the hotspots where the tug-of-war between righting moment and heeling moment act out their battle. Variables like wave impacts and sudden gusts can be modeled, but unlike the aviation industry, which does a superb job of keeping wings attached to aircraft, sailboats all too often develop keel woes. However, as a naval architect recently reminded us, most pilots arent running their wing tips into mountain peaks, and there are no sandbars in the sky. In other words, the sailboat-building industry is under-estimating the net effect of running aground.

The Engineers Perspective

Philosophers and engineers have an affinity for first principles reasoning. In lay terms, this means drilling down to the fundamental reasons why something holds together physically or how reasoned thought springs from observable fact. When it comes to keels, the engineers first principles focus on using numbers to define stress and geometry to show how forces impact structure. The engineers goal is to be able to quantify the energy transferred through the hull, rig, and appendages, and to respond to the empirical data with structures that can handle the load.

When it comes to external-ballast keels, there are several points where key connections are made. The ballast itself is usually lead or iron, and mechanical fasteners are used to secure it to the hull. Or ballast may be attached to a keel stub or blade-like foil before being attached to the hull.

Keels with higher aspect ratios (depth to length) and longer lever arms focus more force on the surface area of this critical junction. The person doing the engineering must juggle multiple factors at once. The ballast weight, the distance of the ballasts center of gravity from the critical keel-to-hull joint, the laminate schedule, the reinforcing structure, and the mode of fastening make it a multivariate challenge.

Lets start with the question of ballast material and its role in keeping the keel attached to the boat. Lead is still the ballast material of choice because of its density and the relative ease with which it can be cast into a hydro-

dynamic shape. But a few builders and boat owners have learned the hard way that pure lead is too malleable and may even allow keel bolts to pull free. Consequently, foundries that make keels have perfected an alloying process that involves adding a small amount of antimony (about 4 percent) to the lead to make it less malleable and more willing to hold both keel bolts and its shape.

Monel is the best metal to use for keel bolts due to its strength and corrosion resistance, but it is cost is prohibitive, so 316 stainless steel or even silicone bronze are good alternatives. It makes good engineering sense to offset keel bolts rather than run them down the centerline. The working rule of thumb is to keep the outer wall of a keel bolt at least an inch under the lead surface and far enough down in the ballast to prevent it from being pried from the ballast.

Care must be taken when casting a keel to make sure that the keel bolts, and any weldment used to hold them in place, are preheated prior to the pour so that theres no chance of bubbling around the colder metal. These bubbles become voids than can trap water and cause corrosion problems. Thanks to good quality control at keel-casting companies, failures caused by keel bolts pulling out of cast lead are less prevalent today.

Keel-bolt metallurgy is another factor, and its a two-part story. Part one is all about the tensile strength of the material and what kind of out-of-the-box safety margin the bolts will deliver. The second part is about lifespan and corrosion resistance.

Every time a sailboat tacks or rolls in a seaway, keel-bolt loads swap from side to side. This on/off, tension-fatigue cycling causes changes in the metal at a molecular level, and some alloys are better than others at handling this type of cyclical loading. Of equal importance is the manner in which the ballast and hull surfaces mate. Imperfections in how the two surfaces make contact will result in uneven loading and even a perceptible wobble in the joint as gravity pulls the ballast from one side to the other. Simply filling minor voids between the keel and hull stub with a sealant is a big mistake. In cases where the surface-to-surface contact is imprecise, a high-density epoxy-filler repair should be carried out so that surfaces are both smooth and fit together precisely. (See PS Advisor, January 2008.)

Many production-boat builders opt for iron ballast and galvanized, high-carbon steel keel bolts. This is a cost-saving shortcut that, down the road, leaves an owner coping with rusting ballast and the ticking time-bomb of corroding keel bolts. Those buying a decade-plus-old, pre-owned sailboat with high-carbon steel keel bolts and iron ballast should consider having a good boatyard lower the ballast and carefully inspect the bolts. Simply torquing up the fasteners and heading off on a long ocean passage on a boat of this vintage is courting an unnecessary risk.

Some rust on keel bolts is to be expected, but how much is acceptable depends on how oversized the bolts are, how many hold the keel to the hull, and how long and wide the ballast-to-hull seam happens to be. Stainless-steel keel bolts arent totally immune to seawater chemistry, but high-nickel-content 316 stainless steel has a fine track record, as do silicone bronze keel bolts, keeping in mind that silicone bronze bolts must be slightly larger in diameter to deliver the same tensile strength.

Theres one keel usage where rust-prone carbon steel is gaining ground and its use makes sense. Its in radical race-boat fin/bulb keels where stiffness counts and deeper, thinner, shorter chord foils are the trend. In such situations, carbon fibers lighter weight isn’t a big advantage and high-tensile steels stiffness combined with its hardness and toughness are ideal for making mechanical junctions at each end of the foil. Slots in ballast bulbs and carefully engineered keel boxes built into the hull are costly, esoteric parts of many modern race boats. During the design process, much care is given to spreading the loads focused on these socket-like fixtures, and energy moves transversely across the hull and forward and aft via a network of frames and stringers.

Most production boats have a simpler solution for handling keel-bolt loads. In the era of wooden boats, floor frames and the keelson did a lot to dissipate ballast loads. Fiberglass changed some of the engineering. In the 1960s, solid fiberglass-reinforced plastic (FRP) laminate hulls with thickly laid-up keel sumps could easily cope with the loads from the long, shallow, ballast keel common for that era. As laminates grew thinner, core material spread throughout the hull and keels grew deeper but shorter fore-and-aft, attachment problems proliferated. Better engineering was on hand to offer solutions.

The modifications included keeping core material away from the critical interface where the ballast keel or keel stub met the hull. Another change was the introduction of grid structure to stiffen the hull so that it would reduce the bending moment induced by the keel. Cruisers were happy with the belt-and-suspenders approach of a thick hull skin and a strong grid. This increased the safety factor when it came to how well a keel was attached.

Racers, however, wanted a stiffer, lighter hull, but at the same time, they recognized that in order to win, one had to finish the race-which, of course, required keeping the keel and hull intact. Over the years, builders and designers have seen a proliferation of cautionary tales of what happens when this quest for a fast, light boat overshadows the sanctity of the keel-hull joint.

A key design consideration is the load imposed on the hull in a knockdown, when the mast is parallel to the water. In a knockdown, the loads at the point where the hull and keel meet skyrocket, especially when theres a bulb of lead at the other end and a very small area where the keel meets the hull. If the sailboat has been carefully engineered, the designer has calculated what this peak load will be and then chosen a healthy safety factor to hedge his or her bet. This safety factor will go a long way in accounting for some material deterioration due to minor corrosion, fatigue, or some other unforeseen situations.

The bible for many naval architects and sailboat designers is The Principles of Yacht Design (PYD) by Lars Larsson and Rolf Eliasson. And when it comes to the crucial links in keeping the ballast attached, the authors justifiably put much stock in hedging a bet. When it comes to keel-bolt diameter and floor-bending moment, they recommend a 5-to-1 safety margin. The less stringent ISO 12215-9 equations settle on a 2-to-1 safety factor for bending moment in category A and B vessels. But the wild card is not the sailing loads, which are quite definable; its the point loads linked to groundings and the ongoing weakening effect of cycle loading and corrosion.

The ABS guidelines mentioned earlier take a harder line when it comes to structure that mitigates grounding damage. It has the most stringent laminate thickness and core elimination requirements. Other classification scan’tlings diminish the projected loads of a grounding. They regard the inertial rotation of a hull as a means of significantly offsetting the stress of a grounding. The ISO guidelines, for example, take this into account. The result is a force of impact that is much lower than that envisioned by the ABS, which ignores the effect of inertial dampening during a grounding.

All this keel theory came into play two years ago, about 720 miles east-southeast of Nova Scotia, Canada, with the tragic loss of Cheeki Rafiki and all hands aboard. The incident occurred during a return passage to England from the Caribbean. The eight-year-old Beneteau 40.7 was in the charter trade as a race boat, and records revealed that it had been campaigned regularly in the United Kingdom during summers, in trans-Atlantic ARC races, and in Caribbean winter regattas between 2011 and 2014. On May 16, 2014, Cheeki Rafiki lost its keel and capsized in the cold North Atlantic; the life raft was apparently unable to be deployed. The Beneteaus upturned hull was later spotted by a merchant ship, and photographs revealed that some of the keel bolts, with nuts and washer plates in place, had pulled through the laminate and others had apparently snapped, leaving threaded rod, nuts, and washers behind.

According to the incident review done by the Marine Industry Accident Review Branch (MIARB), United Kingdom, the Farr-designed sloops had their structural details finalized by Beneteau. Beneteau indicated that the boat was designed to ISO A category standards and structural approval was made by Bureau Veritas. In the MIARB report, the University of South Hampton (Wolfson Unit) evaluated whether or not the Beneteau 40.7 would meet ISO 12215-9 criteria, which was not available when the boat was built. The reports conclusion was that the as designed parameters would meet the vast majority of structural requirements spelled out in the ISO 12215- 9 standard. However, according to the report, the keel washers did not meet the standard. Perhaps more tellingly, the standards did not allow for the elimination of a 24-millimeter keel bolt that should have been at the aft end of the keel.

The university report also commented on whether or not a change in grid stiffness caused by two previous repairs could have altered the grids load-spreading characteristics. In essence, investigators looked into whether or not a hard spot in the grid could have resulted in a stress riser that refocused loads and led to an area that was more prone to failure. Their finding was that the same FRP materials had been used in the repair, and it did not change the grids load-sharing characteristics.

Several things in the Cheeki Rafiki report stood out to us. First, its interesting to note the difference between the ABS minimum guidelines for skin thickness where keel bolts penetrate an FRP structure and the ISOs minimum. The ABS spec calls for a laminate thickness equal or greater than the diameter of the keel bolt. ISO guidelines call for a minimum of 9.1 millimeters. The Beneteau 40.7 had a hull skin thickness of 7.7 millimeters and made up for the shortfall by adding in the thickness of the stiffening structure, which was actually thicker than the hull itself (10.5 millimeters) but connected to the hull skin via a secondary bond. The total thickness, by this accounting, was 18.2 millimeters, but this is still less than the ABS minimum of 24 millimeters. Perhaps a thinner skin would be appropriate if the builder had been using a high-modulus, vacuum bagged, prepreg carbon-fiber laminate. (Prepreg laminate is pre-infused with resin to ensure a strong, lightweight laminate that has a high fiber content.) But the 40.7 was built using traditional wet layup, which results in a lower fiber content and a lower-strength laminate.

The report delves into Cheeki Rafiki s reported groundings and associated repairs. This section of the report leaves readers wondering whether ISO-compliant keels are too fragile. The ISO A categorization assumes correctly that all bets are off if you go and sail into the maw of a major hurricane, but should a relatively soft grounding render the hull a hazard?

The old Cal 40, Ericson 41, and plenty of 50-year-old Rhodes Bounty IIs still safely lug around their encapsulated-ballast keels. These designs have clearly stood the test of time. Well-designed and engineered, externally ballasted keels should be even more able to handle transverse and longitudinal loads, including the odd soft grounding.

One important consideration is the nature of the ISO ratings. PS has argued for years that the ISO rating is a standard meant to facilitate fair trade, not a benchmark for good design. Among the members of the ISO working group that came up with the standard were boatbuilders who had an interest in a broadly inclusive Category A standard.

In several instances, the standard for keels would prompt an engineer to question the rationale behind the rules. Take for example the fact that when it comes to keel attachment, the ISO 12215-9 specification lumps Category B and Category A vessels together. But when it comes to stability requirements, ISO recognizes that a Category A vessel will be exposed to more hazardous oceanic conditions, and therefore, will need greater stability. Why didnt the same seafaring logic prompt ISO to make the keel attachment scan’tlings for Category A sailboats more stringent than they are for Category B? Its not unreasonable to assume that ocean-crossing sailboats need higher keel attachment standards than boats designed primarily for coastal sailing.

Boat shows slips are brimming with production boats rated Category A, but does the label really mean they meet the challenge? Cheeki Rafiki was sailing in conditions well within the wind and sea state couched in Category A. The keel snapped off, and the crew perished. The Action to be Taken section in the MAIRB report includes a warning about minor groundings, painting the rudder day-glow red, placing the life raft in a spot that enables launching even if the hull is overturned, training the crew about capsize and inversion, and finally, it recommends that the ISO insert the text, in case of grounding, a full assessment/survey needs to be completed. We were surprised, if not shocked, to see that there was no mention of designing and building a stronger keel attachment, and no suggestion that the current scan’tlings for Category A vessels needed to be re-examined.

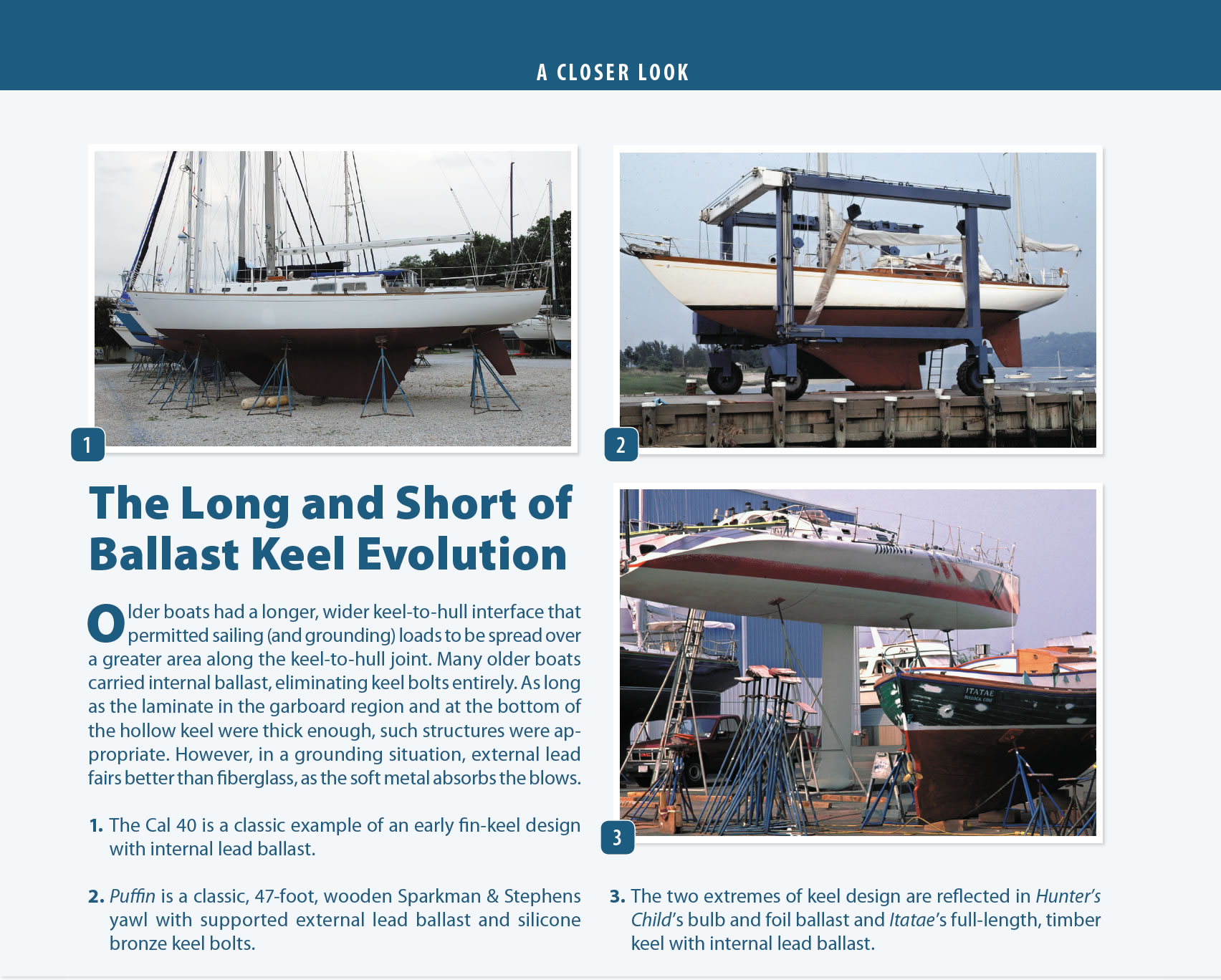

Older boats had a longer, wider keel-to-hull interface that permitted sailing (and grounding) loads to be spread over a greater area along the keel-to-hull joint. Many older boats carried internal ballast, eliminating keel bolts entirely. As long as the laminate in the garboard region and at the bottom of the hollow keel were thick enough, such structures were appropriate. However, in a grounding situation, external lead fairs better than fiberglass, as the soft metal absorbs the blows.

- The Cal 40 is a classic example of an early fin-keel design with internal lead ballast.

- Puffin is a classic, 47-foot, wooden Sparkman & Stephens yawl with supported external lead ballast and silicone bronze keel bolts.

- The two extremes of keel design are reflected in Hunter’s Child’s bulb and foil ballast and Itatae’s full-length, timber keel with internal lead ballast.

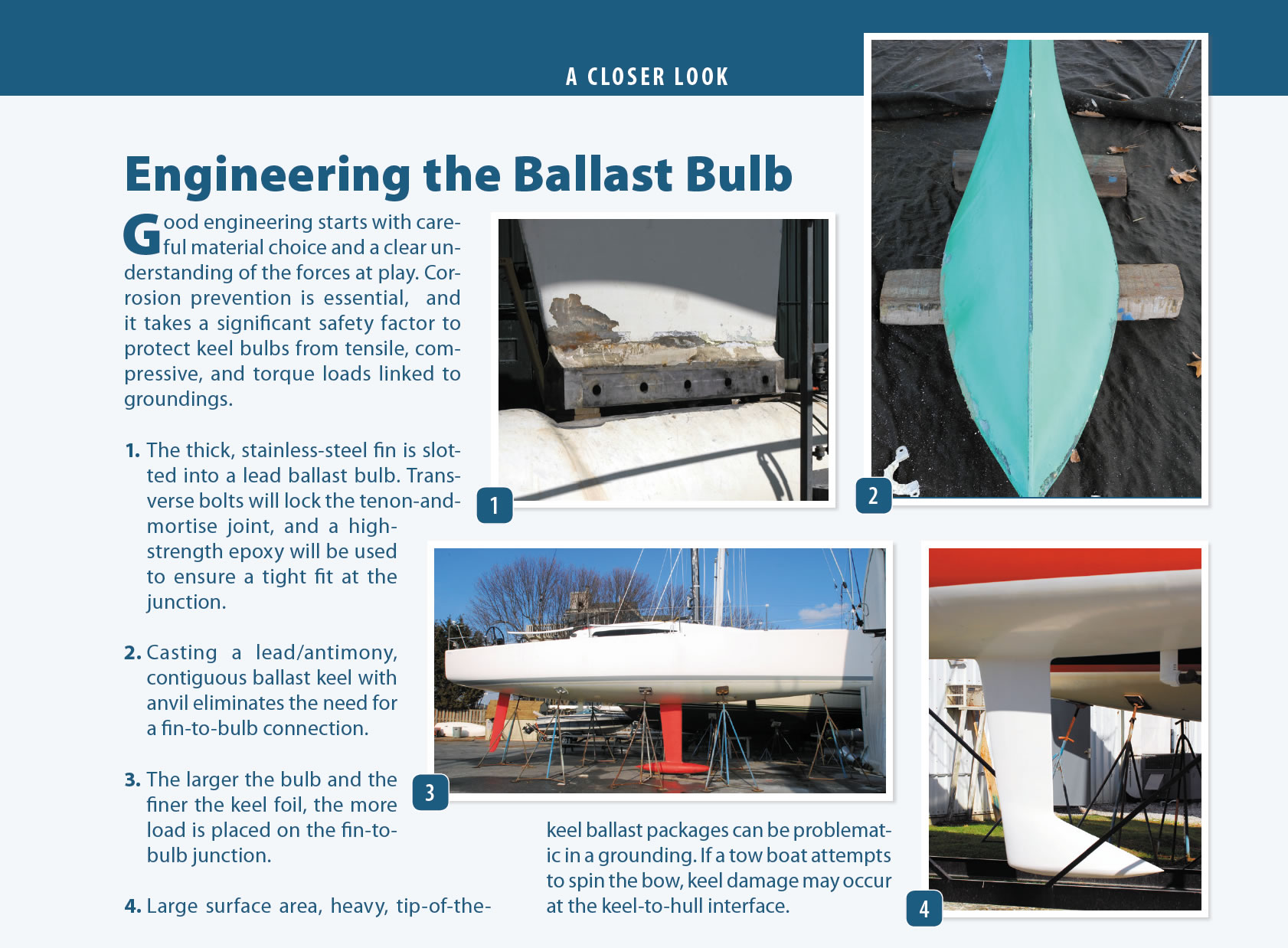

Good engineering starts with careful material choice and a clear understanding of the forces at play. Corrosion prevention is essential, and it takes a significant safety factor to protect keel bulbs from tensile, compressive, and torque loads linked to groundings.

- The thick, stainless-steel fin is slotted into a lead ballast bulb. Transverse bolts will lock the tenon-and-mortise joint, and a high-strength epoxy will be used to ensure a tight fit at the junction.

- Casting a lead/antimony, contiguous ballast keel with anvil eliminates the need for a fin-to-bulb connection.

- The larger the bulb and the finer the keel foil, the more load is placed on the fin-to-bulb junction.

- Large surface area, heavy, tip-of-the-keel ballast packages can be problematic in a grounding. If a tow boat attempts to spin the bow, keel damage may occur at the keel-to-hull interface.

Mechanically fastening a keel to the hull should be done with longevity in mind. Most bilges are wet, so corrosion-resistant metals are preferred. Monel and Aquamet 22 are superior to 316 stainless steel and are preferable where the interface between the ballast and the hull is small. Otherwise, a fair compromise is side-by-side, 316-grade keel bolts with backing plates installed over a thick, void-free, keel stub. Care must be taken to ensure internal grids are adequately bonded to the inside of the hull.

- American Bureau of Shipping guidelines call for the keel-stub base to be at least as thick as the diameter of a keel bolt.

- Here, carefully bonded transverse and longitudinal supports spread keel and mast step loads.

- Gaps between the keel and hull should be filled with high-density epoxy faired to create a complete face-to-face junction.

- Nuts should press down on thick backing plates. Galvanized, mild-steel plates are acceptable, but using non-ferrous metal for keel bolts and nuts is recommended.

- Some builders use steel weldments to spread loads at the keel bolts. These should be tapered, or extra laminate should be added to prevent stress risers where the metal ends.

- American Bureau of Shipping

- International Standards Organization

- Cheeki Rafiki Report

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Beneteau 423: What You Should Know | Boat Review

Buying A Sailboat Is Scary! Yacht Broker Interview

The Great Loop – The Basics

Bottom Paint Showdown – Six Paints, One Winner!

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Do you know your numbers when it comes to sizing up your boat? Accurate measurements for figures like length, draft, beam and clearance will keep your boat free from damage in marinas and private boat dock slips as well as while traveling beneath fixed bridges.

Boat length is measured from the bow to the stern. However, the number is not as set in stone as it may seem. It can vary depending on whether there’s a swim platform, a bow pulpit, a dinghy on a davit or other things that contribute to the length overall (LOA). Knowing the correct length of your boat is just as important as knowing how to properly operate it. We’re not talking about that number the manufacturer says it is … the one that’s part of the model name. For example, a Hatteras GT45X is 45 feet long, but with a swim platform and a bow pulpit, it could technically come closer to a total of 47.5 feet. This number can change from boat to boat (even among the same model and manufacturer) as well as type of boat. Correct length is especially useful when docking or choosing a private boat dock rental. Trying to fit a boat into a slip that’s too small can result in damage to the boat, the dock and other property around it.

Example Average Length

- Cruising Sailboat: 16’ – 50’

- Catamaran: 32’ – 47’

- Cabin Cruiser: 25’ – 45’

- Motor Yacht: 29’- 65’

- Center Console: 18’ – 32’

Another important factor is draft. A boat’s draft refers to the vertical distance from the waterline (where the hull touches the water) to the bottom of the hull, or keel on a sailboat. It determines the minimum depth of water a boat can safely navigate without running ashore (which, by the way, is very bad). Put simply, it helps you know how deep the water needs to be. Like length, it can vary from boat to boat. A sailboat can have a very large draft based on whether it has a keel (and whether the keel is removable). Each dock has its own specific draft allowance, which is based on things like water level, tides and how flat or angled the ground is under the water. One dock can be vastly different than others in the area. Dock draft measurements can be taken by dropping a long length of rope (weighted) or chain into the water, marking it at the water level and then measuring from the bottom up out of the water. Private docks on our site are listed at the low tide water level. This way, you know the absolute minimum depth of water. It’s always best to be conservative by one or two feet if you’re not completely sure you’ll be able to dock at that boat slip – due to things like changing tides, weather and boat wakes.

Boat Size vs Draft

- Low Draft: A boat 32 feet long and under needs 3 feet or less of water

- Medium Draft: A boat 45 to 65 feet long needs 4 to 5 feet of water

- High Draft: A boat 65 feet long or greater needs 5 to 7.5 feet of water

To throw a wrench into these statistics, there are instances where this might vary. Sailboats can be an exception as they may have a non-retractable keel, which gives them the need for a larger draft (since the keep gives them a bigger draft measurement). On the other hand, since catamarans are wide and displace water very efficiently, they may only need 4.5 feet of draft even if it falls into a bigger category.

Average Boat Draft

- Cruising Sailboat: 5’ (but could be more if it has a non-retractable keel)

- Catamaran: 2’ – 4’(large cats could need more)

- Cabin Cruiser: 3’

- Motor Yacht: 4’ (the bigger the yacht, the bigger the draft)

- Center Console: 2’

As a general rule, the bigger the boat is, the deeper the draft will need to be. Factors like weight and beam play into this concept. The hull shape can also play a part. A flat or multi-hull boat (like pontoon boats, jet skis and dinghies) has a low draft. A deep V-shaped displacement hull (like most power boats and cruisers) allows the boat to sit deeper in the water, resulting in a high draft.

Beam refers to the distance from the widest point of the boat to the other side (think: middle of the boat from side to side). Catamarans are very wide compared to that of center consoles and cabin cruisers. Most boats fall into the 18 to 20-foot beam category, but cats can be as wide as 22 to 30 feet.

The beam of a boat will determine how wide of a boat slip rental you need. You’ll want to measure the dock to make sure it’s wide enough that your boat won’t bang against the sides.

Average Beam

- Cruising Sailboat: 12’

- Catamaran: 22’ to 30’

- Cabin Cruiser: 8.5’

- Motor Yacht: 13’

- Center Console: 9’

Clearance, or vertical clearance, is important for sailboats and catamarans with a fixed mast, as well as sportfish boats with tall towers. It refers to the height of the boat from the waterline to the top of the mast or flybridge (or any non-removable part). Some masts can be lowered, so that would not be included in your clearance number.

Out in the wide-open ocean, clearance isn’t too much of an issue. The time it becomes an issue is when you’re sailing under a fixed bridge. A drawbridge is no problem. You just need the patience to wait till it opens. Sailboats can require anywhere from 35 to 75 feet of vertical clearance, so you’ll want to check out those fixed bridge heights when charting your course or choosing a boat dock for rent. Be sure to take into account low tide when determining clearance.

Average Boat Clearance

- Cruising Sailboat: 50’

- Catamaran: 39’

- Express Cabin Cruiser: 9’ 10 “ with tower up / 7’ 7” with tower down

- Motor Yacht: 14’ to 15’

- Center Console: 9’ 6”

Whether you’re docking your boat at a marina, a mooring or a private boat dock rental, the correct measurements play a big factor. Hopefully this has given you some good advice to make the whole docking process a bit easier. Now if you could just control the wind while docking.

- Previous Article

- Next Article

Resistive forces

Predicting speed, the physics of sailing.

- Open the PDF for in another window

- Reprints and Permissions

- Cite Icon Cite

- Search Site

Bryon D. Anderson; The physics of sailing. Physics Today 1 February 2008; 61 (2): 38–43. https://doi.org/10.1063/1.2883908

Download citation file:

- Ris (Zotero)

- Reference Manager

In addition to the recreational pleasure sailing affords, it involves some interesting physics. Sailing starts with the force of the wind on the sails. Analyzing that interaction yields some results not commonly known to non-sailors. It turns out, for example, that downwind is not the fastest direction for sailing. And there are aerodynamic issues. Sails and keels work by providing “lift” from the fluid passing around them. So optimizing keel and wing shapes involves wing theory.

The resistance experienced by a moving sailboat includes the effects of waves, eddies, and turbulence in the water, and of the vortices produced in air by the sails. To reduce resistance effectively by optimizing hulls, keels, and sails, one has to understand its various components.

Moving air has kinetic energy that can, through its interaction with the sails, be used to propel a sailboat. Like airplane wings, sails exploit Bernoulli’s principle. An airplane wing is designed to cause the air moving over its top to move faster than the air moving along its undersurface. That results in lower pressure above the wing than below it. The pressure difference generates the lift provided by the wing.

There is much discussion of whether the pressure difference arises entirely from the Bernoulli effect or partly from the wing’s impact and redirection of the air. Classic wing theory attributes all the lift to the Bernoulli effect and ascribes the difference in wind speeds above and below the wing to the wing’s asymmetric cross-sectional shape, which caused the path on top to be longer. But it’s well known that an up–down symmetrical wing can provide lift simply by moving through the air with an upward tilt, called the angle of attack. Then, despite the wing’s symmetry, the wind still experiences a longer path and thus greater speed over the top of the wing than under its bottom. A NASA website has an excellent discussion of the various contributions to lift by an airplane wing. 1 It disputes the conventional simple version of wing theory and emphasizes that lift is produced by the turning of the fluid flow.

The case is similar for sailboats. A sail is almost always curved and presented to the wind at an angle of attack. The situation is shown schematically in figure 1(a) . The wind moving around the “upper,” or downwind, side of the sail is forced to take the longer path. So the presence of the surrounding moving air makes it move faster than the air passing along the “lower,” or upwind, side of the sail. Measurements confirm that relative to the air pressure far from the sail, the pressure is higher on the upwind side and lower on the downwind side.

Figure 1. Forces on a moving sailboat. (a) Sail and keel produce horizontal “lift” forces due to pressure differences from different wind and water speeds, respectively, on opposite surfaces. (b) The vector sum of lift forces from sail and keel forces determines the boat’s direction of motion (assuming there’s no rudder). When boat speed and course are constant, the net lift force is precisely balanced by the velocity-dependent drag force on the boat as it plows through water and air.

For downwind sailing, with the sail oriented perpendicular to the wind direction, the pressure increase on the upwind side is greater than the pressure decrease on the downwind side. As one turns the boat more and more into the direction from which the wind is coming, those differences reverse, so that with the wind perpendicular to the motion of the boat, the pressure decrease on the downwind side is greater than the pressure increase on the upwind side. For a boat sailing almost directly into the wind, the pressure decrease on the downwind side is much greater than the increase on the upwind side.

Experimenting with what can be done, a beginner finds some surprising results. Sailors know well that the fastest point of sail (the boat’s direction of motion with respect to the wind direction) is not directly downwind. Sailboats move fastest when the boat is moving with the wind coming “abeam” (from the side). That’s easily understood: When a sailboat is moving directly downwind, it can never move faster than the wind because, at the wind speed, the sails would feel no wind. In fact, a boat going downwind can never attain the wind speed because there’s always some resistance to its motion through the water.

But when the boat is moving perpendicular to the wind, the boat’s speed doesn’t decrease the force of the wind on the sails. One sets the sails at about 45° to the direction of motion—and to the wind. The boat’s equilibrium speed is determined by the roughly constant force of the wind in the sails and the resistance against the boat’s motion through the water. If the resistance can be made small, the velocity can be large. That’s seen most dramatically for sail iceboats, which skate on the ice with very little resistance. They can glide along at speeds in excess of 150 km/h with the wind abeam at speeds of only 50 km/h! Of course sailboats plowing through the water experience much more resistance. Nonetheless, some specially constructed sailboats have attained speeds of more than twice the wind speed.

It was recognized centuries ago that a sailboat needs something to help it move in the direction in which it’s pointed rather than just drifting downwind. The answer was the keel. Until the development of modern wing theory, it was thought that one needed a long, deep keel to prevent side-slipping. But now it’s understood that a keel, like a sail, works by providing sideways lift as the water flows around it, as shown in figure 1(a) . A keel must be symmetrical for the sailboat to move to either side of the wind.

A keel works only if the motion of the boat is not exactly in the direction in which it’s pointed. The boat must be moving somewhat sideways. In that “crabbing” motion, the keel moves through the water with an angle of attack. Just as for the sails in the wind, that causes the water on the “high” (more downstream) side of the keel to move faster and create a lower pressure. Again, the net lift force on the keel is due to the combination of that decreased pressure on the high side and increased pressure on the other (low) side.

In figure 1(b) , the keel lift thus generated points almost in the opposite direction from the lift provided by the sails. The two vectors can be resolved into components along and perpendicular to the boat’s direction of motion. For a sailboat moving in equilibrium—that is, at constant speed in a fixed direction—the transverse lift components from sail and keel cancel each other. The component of the driving force from the sails in the direction of motion is the force that is actually moving the boat forward. For equilibrium motion, that force is balanced by the opposing component of the keel lift plus the total resistive force.

Wing theory, developed over the past 100 years for flight, indicates that the most efficient wing is long and narrow. Vortices produced at the wing tip cost energy. A long, narrow wing maximizes the ratio of lift to vortex dissipation, thus providing the best performance for a given wing surface area. That also applies to sailboat sails and keels.

It is now recognized that the most efficient keels are narrow from front to back and deep. Such a keel can have much less surface area than the old long keels. Less area means less resistance. Most modern racing sailboats, such as those used in the America’s Cup races, have deep, narrow keels that are very efficient at providing the lift necessary to prevent side-slipping. Of course, such keels are a problem for recreational sailors in shallow waters.

A sailboat experiences several kinds of resistance. The first is simply the resistance of the hull moving through water. As the boat moves, it shears the water. Water molecules adhere to the hull’s surface. So there must be a shear—that is, a velocity gradient—between the adhering molecular layer at rest with respect to the hull and the bulk of water farther away. The shear means that van der Waals couplings between water molecules are being broken. That costs energy and creates the resistive force, which becomes stronger as the boat’s speed increases. The energy dissipation also increases with the total area of wetted surface.

Although the effect is called frictional resistance, it’s important to realize that the resistive force in water is basically different from the frictional force between solid surfaces rubbed together. To reduce ordinary friction, one can polish or lubricate the sliding surfaces. That makes surface bumps smaller, and it substitutes the shearing of fluid lubricant molecules for shearing of the more tightly bound molecules on the solid surfaces.

For a boat moving through water, however, polishing the hull doesn’t eliminate the shearing of the molecules of water, which is already a fluid. The resistive force cannot be reduced significantly except by reducing the wetted surface. It does help to have a smooth surface, but that’s primarily to reduce turbulence.

The generation of turbulence is a general phenomenon in the flow of fluids. At sufficiently low speeds, fluid flow is laminar. At higher speeds, turbulence begins. Its onset has to do with the shearing of the molecules in the fluid. When the shearing reaches a critical rate, the fluid can no longer respond with a continuous dynamic equilibrium in the flow, and the result is turbulence. Its onset is quantified in terms of the Reynolds number

where ν is the velocity of the flowing fluid, μ is its viscosity, ρ is its density, and L is the relevant length scale of the system. Rearranging factors in equation (1) , one can think of R as the ratio of inertial forces ( ρν ) to viscous forces ( μ /L). In the late 19th century, English engineer Osborne Reynolds found that, with surprising universality, turbulence begins when that dimensionless parameter exceeds about a million.

For a boat of length L moving through water at velocity ν to see when turbulence begins in the flow along the hull, R is about 10 6 Lν (in SI units). A typical speed for a sailboat is 5 knots (2.4 m/s). At that speed, then, one should expect turbulence for any boat longer than half a meter. (Used worldwide as a measure of boat speed, a knot is one nautical mile per hour. A nautical mile is one arcminute of latitude, or 1.85 km.)

Because turbulence dissipates energy, it increases the resistance to motion through the water. With turbulence, a sailboat’s resistance is typically four or five times greater than it is when the flow along the hull is laminar. A rough surface will cause turbulence to be greater and begin sooner. That’s the main reason to have a smooth hull surface.

Turbulence also occurs in the air flowing along the surface of the sail. Water is a thousand times denser than air and 50 times more viscous. So for the air–sail system one gets

For a typical wind speed of 5 m/s, then, one gets turbulence if the sail is wider than about 3 meters. When turbulence forms in the air flow along the sail, the desired pressure difference between the two sides of the sail—its lift—is diminished.

Another important resistive force comes from vortex generation at the bottom of the keel and at the top of the sails. When the air or water moves around the longer-path side of the sail or keel, its speed increases and therefore its pressure falls. As the air or water moves along the sail or keel, it will respond to the resulting pressure difference by trying to migrate from the high-pressure side to the low-pressure side. Figure 2 sketches that effect for a keel. What actually happens, as shown in the figure’s side view, is that the flow angles a bit up on one side and down on the other. When those flows meet at the back of the sail or keel, the difference in their arrival angles has a twisting effect on the fluid flow that can cause a vortex to come off the top of the sail or the bottom of the keel.

Figure 2. Vortex formation by the keel. Unless the boat is sailing straight ahead, there’s a pressure difference between the two sides of the keel. As a result, the water flow angles down on the high-pressure (lower water-speed) side and up on the low-pressure side, creating a twist in the flow that generates vortices behind the bottom rear of the keel.

The effect is well known for airplane wings. Called induced drag, vortex formation costs energy. Figure 3 shows vortices generated at the tops of sails by racing sailboats moving through a fog. A long keel will generate very large vortices. By making the keel short and deep, one can increase the ratio of lift to energy dissipated by vortices. The same is accomplished—especially for sailboats racing upwind—by having tall, narrow sails. It’s also why gliders have long, narrow wings.

Figure 3. Sailtops form vortices visible in fog. The boats were participating in the 2001–02 Volvo Ocean Race off Cape Town, South Africa.

Because it’s often impractical to have a short, deep keel or a narrow, long wing, one can install a vane at the tip to reduce the flow from the high-pressure to the low-pressure side. On planes they’re called winglets, and on keels they’re simply called wings. A modern recreational or cruising sailboat will have a keel that’s a compromise between the old-fashioned long keels and the modern deep, narrow keels—with a wing at the bottom rear end to reduce induced drag. Such keel wings were first used by the victorious sailboat Australia II in the 1983 America’s Cup race. Modern wing theory also suggests that to minimize induced drag, keels and sails should have elliptic or tapered trailing edges. 2 Such shaped edges are now common.

A sailboat also has a resistance component due simply to its deflection of water sideways as it advances. That’s called form resistance, and it obviously depends on hull geometry. It’s easy to see that narrow hulls provide less resistance than do wider hulls. Any boat will always be a compromise between providing low form resistance and providing passenger and cargo space. Seeking to minimize form resistance for a given hull volume, shipbuilders have tried many basic hull shapes over the centuries. Even Isaac Newton weighed in on the question. He concluded that the best hull shape is an ellipsoid of revolution with a truncated cone at the bow.

Extensive computer modeling and tank testing have resulted in a modern hull design that widens slowly back from the bow and then remains fairly wide near the stern. Even with a wide stern, designers try to provide enough taper toward the back to allow smooth flow there. That taper is often accomplished by having the stern rise smoothly from the water rather than by narrowing the beam. If the flow from the stern is not smooth, large eddies will form and contribute to resistance.

As a boat moves through water, it creates a bow wave that moves with the speed of the boat. Water waves are dispersive; long waves propagate faster than short ones. Therefore the length of the full wave generated by the bow is determined by the boat’s speed. As a boat starts to move slowly through the water, one sees at first a number of wave crests and troughs moving down the side of the hull. As the boat speeds up, the wavelength gets longer and one sees fewer waves down the side. Eventually at some speed, the wave will be long enough so that there’s just one wave down the side of the boat, with its crest at the bow, a trough in the middle, and another crest at the stern (see figure 4 ). That’s called the hull speed.

Figure 4. Moving at hull speed, a sailboat generates a bow wave whose wavelength just equals the length of the boat’s water line. The wave crests at bow and stern, with a single well-formed trough in between.

If the boat speed increases further, the wavelength increases so that the second crest moves back behind the boat and the stern begins to descend into the trough. At that point, the boat is literally sailing uphill and the resistance increases dramatically. That’s called wave resistance. Of course, if one has a powerboat with a large engine and a flat-bottomed hull, one can “gun” the engine and cause the boat to jump up on the bow wave and start to plane on the water’s surface. Most sailboats don’t have either the power or the hull geometry to plane. So they’re ultimately limited by wave resistance.

The wave-resistance limit also applies to all other so-called displacement boats: freighters, tankers, tugs, and most naval vessels bigger than PT boats—that is, any boat that can’t rise to plane on the surface. The functional dependence of water-wave speed ν on wavelength λ is well known. From the limiting case for deep-water waves for the solution of the two-dimensional Laplace wave equation, 3 or from a simple derivation due originally to Lord Rayleigh, 4 one gets ν = g λ / 2 π , where g is the acceleration of gravity. In the form commonly used by sailors in the US,

where the λ is in feet and ν is in knots.

If one equates the wavelength to the waterline length of a boat, equation (3) gives the boat’s hull speed. For a sailboat with a waterline length of 20 feet (6 m), the hull speed is 6 knots. For a large cruising sailboat with a waterline of 40 feet (12 m), it’s about 8 knots. And for a 300-foot-long naval vessel, it’s 23 knots. In practice, it’s very difficult to make a displacement boat go faster than about 1.5 times its hull speed.

Combining all the components of resistance for a sailboat moving at close to its hull speed, one finds that the frictional resistance contributes about a third of the total, and the wave resistance another third. Form resistance accounts for about 10%, as does the induced drag from vortex generation at the bottom of the keel. The assorted remaining contributions, including eddy formation behind the boat and aerial vortex generation by the sails, provide the remaining 10 to 15%. Of course the fractional contributions vary with boat speed, wave conditions, and the direction of motion relative to the wind.

One can exploit the physics of sailing to calculate boat speeds for a given sailboat for different wind speeds and points of sail. Such calculations are usually performed iteratively by computer programs that start from two basic vector equations to be solved simultaneously:

Here F drive is the total driving force in the direction of motion provided by the wind in the sails, and F resistance is the sum of all the resistive forces. The torques M heel and M righting are the heeling and righting moments caused by the wind in the sails and the weight of the hull and keel.

The force of the wind on the sail is calculated as a lifting force perpendicular to the apparent wind direction and a drag force in the direction of the apparent wind. (The apparent wind is the wind as perceived by an observer aboard the moving vessel.) These lift and drag forces are then resolved into components along and perpendicular to the direction of motion. The net force in the direction of motion is then F drive , and the net force perpendicular to the boat’s motion is what produces the heeling moment. The two equations in ( (4) ) must be solved simultaneously because the angle of heel affects the total driving force.

Following Bernoulli’s principle, one takes the force of the wind in the sails to be proportional to the total sail area times the square of the apparent wind speed. The actual forces are then obtained with empirical lift and drag coefficients, given as functions of sail geometry and angle of attack. Frictional resistance is proportional to the hull’s wetted surface area and increases as the square of the boat’s speed. All the various contributions to total resistance involve empirical coefficients. Wave and form resistance are expressed as functions of the hull’s “prismatic coefficient,” which is an inverse measure of the tapered slimness of its ends.

There are simple and complex speed-prediction computer programs. Some that have been refined over decades for racing applications are kept private and closely guarded. Figure 5 shows the results of calculations I performed for a 30-foot (10-m) cruising sailboat using a publicly available program. 5 The figure shows the calculated boat speed as a function of wind speed and point of sail. The predicted boat speeds are greatest when one is sailing about 90° away from the wind direction. Sailors call that beam reaching. It yields a boat speed of about half the wind speed.

Figure 5. Speeds predicted by a computer model 5 for a 10-meter-long cruising sailboat, plotted for three different wind speeds from 6 to 20 knots as a function of the angle of the boat’s motion relative to the wind direction. (10 knots = 18.5 km/h.) An angle of 180° means the boat is “running” with the wind directly at its back. The fastest speeds are predicted when the boat is “beam reaching,” that is, moving at about 90° to the wind. The boat even makes some progress when it’s “close hauling” almost directly into the wind.

Such calculations are confirmed experimentally, with a degree of accuracy that depends on the sophistication of the model and on how much the program has been tuned for a specific kind of sailboat. Broadly speaking, a sailboat is faster if it is longer and narrower, with bigger sails and a smaller wetted surface. Such general rules can, of course, yield a boat that’s longer than one wants, or tips over too easily, or has too little room inside.

So every design feature is a compromise between competing needs. For sailing downwind, one wants fairly square sails, which are best at catching the wind. But for sailing upwind, taller, narrower sails are best, because they maximize the ratio of lift to energy lost by generating vortices. The most efficient keel is deep and narrow, to maximize lift with minimal surface area. But a deep keel is problematic in shallow waters. Shorter keels with wings or bulbs at the bottom usually represent the best compromise for overall sailing.

What’s the highest speed a sailboat can reach? The trick is to reduce resistance. An iceboat can outrun the wind because it has so little resistance. For a sailboat, the resistance comes primarily from having to plow through the water. The best way to reduce that resistance is to move less and less of the boat through the water. One answer is hydrofoils. They are vanes placed below the hull that raise it out of the water as the boat speeds up.

Sailboats with hydrofoils have reached speeds of more than 40 knots when the wind speed was barely half that. One such craft is shown in figure 6 . These vessels are not usually practical for cruising and other normal recreational activities. They’re sometimes dismissed as low-flying aircraft. A more practical alternative is the catamaran—a double-hulled sailboat. Catamarans are being developed to provide relatively stable, fast sailing. Although they are more expensive than traditional single-hull sailboats for a given amount of living space, catamarans are becoming increasingly popular.

Figure 6. A hydrofoil sailboat with solid, winglike sails, moving at about twice the wind speed with the wind abeam—that is, blowing from the side.

Bryon Anderson is an experimental nuclear physicist and chairman of the physics department at Kent State University in Kent, Ohio. He is also an avocational sailor who lectures and writes about the intersection between physics and sailing.

Citing articles via

- Online ISSN 1945-0699

- Print ISSN 0031-9228

- For Researchers

- For Librarians