My Sailing Fix

Catalina Rudder Bearing Replacement

While anchored two seasons ago, I noticed a clunk when Priorities rocked back and forth from the wakes of passing boats. The sound clearly came from the rudderpost area in the lazarette. After visually observing the rudderpost wobbling back and forth with each clunk, I figured last winter was finally time to act on a project I had been putting off for a while: replacing the top rudder bearing.

Priorities is a 1996 Catalina 400 Mark I, and like many Catalinas around her size and vintage she has rudder bearings made from a hard plastic. They are a wear item, but should last a decade or two. One symptom of excessive wear is a bunch of play in the rudder that’s noticeable when shaking the bottom of the rudder after haulout. Rudder bearing wear is a gradual process, and isn’t a crisis when first noticed. However, I can see where it might aggravate wear on steering cables and autopilot drive linkages… also items on my winter project list. It also wasn’t going to get better with time, either.

Several years ago, I hired a professional to help me replace the bottom rudder bearing. Though the job itself wasn’t that complicated, it needed to be done while the boat was out of the water and high enough above the ground to allow us to completely remove the rudder from the boat. With a rudderpost that extends 3 feet above the rudder, we needed 3 feet of clearance under the bottom of the rudder in order to remove it. I worked with the boatyard to do the project while still in the slings after haulout, but before being placed on her cradle. An alternative is to dig a hole in the ground below the rudder… but that’s not that easy in frozen Wisconsin, or for those of us that store on concrete!

I had purchased the complete set of rudder bearings from Catalina Direct when I replaced the lower bearing. It was a whopping $620! Though I initially planned on replacing the top bearing the same year I replaced the bottom, the looseness seemed much better after replacing just the bottom bearing. I put off what I saw as unnecessary work until I started hearing that clunk two seasons ago.

After haulout last winter, a quick check revealed nearly an inch of play when shaking the bottom of the rudder. The bottom bearing itself had become loose from the hull, too, which was part of the problem. It did seem, however, that most of the motion was in the top of the rudderpost, confirming my observations earlier in the season. After our steering cable failure on our trip to Pentwater that same season, a steering overhaul was big on my list of winter projects… so I replaced the top rudder bearing this same winter.

I started this project by climbing into the bottom of the lazarette and getting photos of everything. Having photos of how systems look when fully assembled helps when reassembling them later… especially if i don’t finish until spring.

Since I planned a complete steering overhaul including cable replacement, I disconnected the steering cables from the quadrant, and removed the quadrant from the rudderpost. I also removed the autopilot tiller. When I replaced the lower bearing a few years ago, I delivered the boat to the boatyard a day before haulout before disconnecting the quadrant. Some other 400 owners have used their emergency tiller for the final maneuvers to the crane… but mine didn’t fit until recently.

Since I didn’t need to replace the lower bearing this time, I didn’t need to completely remove the rudder. Therefore, I did this project out of the water in the cradle, making logistics simpler.

Before any more disassembly, I compared the new top bearing with the old top bearing. The new top bearing is a self aligning bearing, involving a partial sphere sandwiched between two plastic rings. The self aligning feature allows the bearing to “wiggle” to stay aligned while not allowing lateral movement. Apparently it helps reduce friction when underway, when the rudderpost bends with stress. Unfortunately, its overall size is larger than the original on my boat.

With some careful measurements and fussing, I figured that simply mounting the top bearing on top of the bearing box wouldn’t work due to a lack of space. Some other Catalina 400 owners, especially owners of later models, might not have this issue since I’m willing to bet each boat’s bearing box is semi custom made and has slightly different dimensions. Some boats might even use this new self aligning bearing as an OEM part.

I came up with a design that should be pretty strong: the upper bearing straddles the bottom of the bearing box, transferring any lateral loads directly into the box. The bottom flange of the bearing mounts under the box, held up by a piece of G10 fiberglass and through bolts that also hold the top flange in place. To keep the spacing right, the top flange had a ¼” piece of G10 under it as well. I used ¼” G10 under the bottom flange, but in retrospect the bottom G10 piece probably should have been ⅜” or ½” for additional stiffness.

On my boat, the packing components around the rudderpost looked like they needed attention… large amounts of caulk had been put around a joint earlier in its life. Since a new packing assembly came with the bearing assembly, I decided I would replace it, too. This meant I needed to lower the rudder a foot to give me enough clearance above the rudderpost in the lazarette to swap old with new. Lowering the rudder this amount would also give me room to make minor modifications to the bearing box to accommodate my plan.

Filled with foam, I’ve heard the rudder isn’t that heavy when in water. On the hard, however, it’s pretty heavy, and felt like it weighed 100 pounds. It’s held up by one bolt above the top bearing. Since I was working alone, I built a stand of scrap 4×4 lumber to prop up the rudder a fraction of an inch and removed the top bolt.

After triple checking my measurements, I lowered the rudder down about a foot. I widened the hole in the existing bearing box to allow the upper bearing’s lower flange to fit better, and drilled holes for the through bolts. I installed the lower section of the packing assembly with screws, sealing the edges with 4200. Then I loosely fit all the remaining components that would end up under the bearing box around the rudderpost: the rest of the new packing assembly, the lower flange’s G10 brace, and the lower flange of the upper bearing. Then, I raised the rudder to full height again.

Getting the through bolts to line up took some work… I ended up drilling out the holes in the G10 pieces one size larger and used washers. The rudder is held up by a new stainless ring (supplied with the rudder bearings) atop the upper bearing. This ring needed to be drilled out as well to fit the new 5/16” bolt that matched the existing hole in the rudderpost.

Now that the new top bearing assembly fit correctly, I felt I could reinstall the loose bottom bearing again with adhesive. The bottom bearing is not self aligning, so I waited to glue this in place until after the top bearing was installed. Lowering the rudder one last time a few inches (or all the way out if replacing the whole thing), I removed the screws holding the bottom bearing in place, and pried the bearing out of the rudder tube with a crowbar and sharp knife.

The bottom bearing is mostly held in place with 3M 5200. Some call this the “devil’s glue,” since it forms a permanent bond that’s awful to remove from most substrates. However, the bearing is plastic, and not much bonds to plastic very well. On both occasions when I’ve removed the bottom bearing it wasn’t a disaster, especially since I could use a knife to cut through the bond. To facilitate future replacement, I used 5200 only on the bottom flange, NONE on the sides that go 2 ¼” into the rudder tube.

There are screws that hold the bottom bearing in place, too. With a hull thickness of 1 to 2 inches in this area, I used 1 ¼” long screws since the bearing flange is ½” thick. When I first replaced the bottom bearing I was told these screws are mostly there to hold the bearing in place while the 5200 sets. As a result, I didn’t tighten them much. At haulout last fall I noticed they had sheared off, possibly contributing to it coming loose again. This time around, I tightened the screws more firmly.

Raising the rudder one last time while the 5200 cured to ensure it cured in alignment, I installed the retainer ring and screw at the top bearing. A few days later I wiggled the rudder back and forth to check for any binding of the bearings. Without any steering connections, the rudder moved very easily, with only a slight resistance in one direction.

New ½” flax packing was installed in the new packing assembly, and the top compression ring tightened moderately to prevent leaks. This packing is above the waterline, so the boat won’t sink at the dock if this fails, but a seal is needed in waves and maybe when motoring.

To complete the project I reinstalled the quadrant and autopilot tiller. The bearing box cover was reinstalled and resealed with silicone caulk, and the emergency tiller access port got a new O-ring purchased from McMaster-Carr .

After a season of use, including several instances of being stressed when sailing overpowered, and sailing in 6-8 foot waves, everything seems to be holding up well. Hopefully, the new bearings will last many more years. If or when they need replacement again, though, it should be easier… assuming the bearing design doesn’t change again!

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

4 thoughts on “Catalina Rudder Bearing Replacement”

Do you spend time on the Catalina 400 Facebook page? Oh jeez, I practically live there! Sailing on hull 323, a 400 mkii and am planning a rudder bearings replacement upgrade soon/next haulout/Oct or sooner. Digging into this post as I spend time in the lazerattes and atop the aft bed with the ceiling molding pulled. If you don’t mind I’ll be sending a short video of my mid-bearing or mid-housing (remember, I’m just wrapping my head around the parts and nomenclature). More soon. Thanks. Instagram for us is beyond.the.bnb if you are curious. Cheers!

Hey Curt! Remember your MKII will likely have a significantly different steering system… probably a radial drive wheel rather than a quadrant like on my MKI. I think the bearings will work similar, though.

Great article. Any tips on how you removed the rudder bearing box cover? I removed the sealant in the gap around the cover but cannot lift or pry it out.

From what I remember, all I had to do to remove the cover was remove the sealant and unscrew the cover. There may be an extra layer of 4200 hiding deeper in the joint, so you might need a long blade or scraper to cut it.

Leave a Reply Cancel reply

- PSS Shaft Seal

- Fendertex® Fenders

- Revolve Boat Hook

- Jefa Rudder & Rudder Bearings

- Jefa Autopilot Drives

- Jefa Steering

- Lecomble & Schmitt Autopilot Drives

- Lecomble & Schmitt Hydraulic Steering

- R&D Marine

- Crystal Prop

- Floor Anchor

- Clamp Jacket

- Shaft Retention Collar

- Machine Shop

- Max-Prop Reconditioning

- Testimonials

- Schedule Virtual Meeting

- Company Info

- Boat Show Calendar

- Roller Bearings

- Retrofit & Replacement Bearings

- Standard & Self Aligning

- Rudder Stocks & Rudders

- Bearing Maintenance

Rudder Stocks

Rudder Blades

Rudder Bearings

Sealing Systems

Tiller Heads

Deck Covers

(Scroll down for a overview about Jefa Rudder System products)

Beginning in 1980, Jefa Rudder & Steering Systems has supplied Rudder Bearings to over 40,000 boats along with more than 15,000 steering systems. Jefa was founded by Jan Faurschou and Stig Jensen. Jan and Stig continue with hands on management of Jefa’s two manufacturing facilities.

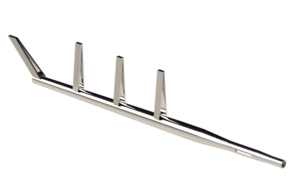

Jefa rudder bearings offer the utmost in feel and durability. Utilizing captive roller bearings in rugged aluminum housings, there is a full range of sizes and styles including self aligning bearings to suit all sizes of sailboats. Sizes are available from 30mm to 260mm for production and custom applications.

You'll find Jefa Rudder Bearings on these brands and many more.

Roller Bearings, No Roller Cage Needed

All Jefa rudder bearings are produces with precision machined rollers and close tolerances to provide smooth operation under load. The close tolerance allows Jefa to eliminate the roller cage needed with sloppy bearings and keep the design simple for long term reliability.

Retrofit Bearings

Jefa offers replacement and retrofit bearings for many boats built using bearings that are no longer produced. We have replacement bearings for many U.S. built, and European boats. These include J-Boats, Beneteau, Express, Bavaria, Santa Cruz, Dehler, Olson, Moody, and many more.

Standard & Self-aligning Bearings

Jefa produces self-aligning bearings for rudder stocks engineered to flex. Self-aligning bearings also eliminate the need for precise alignment during installation. Standard or Non Self-aligning bearings are available at a lower cost and normally have a smaller outside diameter.

Plastics vs. Aluminum

Whenever possible, Jefa uses Engineering plastic below the waterline. This offers a durable bearing while helping to eliminate electrolysis at the waterline and near antifouling paint.

Jefa Rudder Stocks & Rudders

Jefa has delivered rudder stocks and complete rudder for 1000’s boats. Rudder stocks are available machined from Stainless Steel, or aluminum alloy. Rudders are laminated in female molds and filled with high density foam. Complete rudders are built to OEM specification or as replacement rudders for existing boats by Jefa in purpose built production facility allowing us to deliver the highest quality rudders to a competitive.

Here are common questions we receive about our Jefa Rudder Bearings. If you can't find an answer to your question here please feel free to contact us by using the contact form below.

1. Why do you use plastics on your bearings?

Jefa uses engineering plastic on bearings below the waterline as it helps to eliminate electrolysis at the waterline and near antifouling paint.

2. Do I need a roller cage with a Jefa rudder bearing?

No, Jefa rudder bearings are produced at a very high precision. The machined rollers are at such a close tolerance that they provide a smooth operation while under load. The close tolerance allows Jefa to eliminate the roller cage needed with sloppy bearings and keep the design simple for long term reliability.

3. Does Jefa offer retrofit bearings?

Yes, Jefa offers replacement and retrofit bearings for many boats built using bearings that are no longer produced. We have replacement bearings for many U.S. built, and European boats. These include J-Boats, Beneteau, Express, Bavaria, Santa Cruz, Dehler, Olson, Moody, and many more. Please contact us for more details.

Talk To An Expert!

Want to know which Jefa rudder bearing is for you? Have more questions about Jefa rudder bearings? Please contact us.

Need to know more information? Feel free to download our Jefa Rudder Bearing brochures, installation instructions and price lists. Can't find what you're looking for? Please contact us!

Brochures, Instructions & Price Lists

- Jefa J105 Rudder Bearing Flyer

- Jefa J120 Rudder Bearing Flyer

- Jefa Rudder & Rudder Bearing Antifouling Instructions

- Jefa Rudder Bearing Price List

- Manufacturing Process

- (714) 973-2878

- (949)646-0244

- Search for:

We build rudders with passion and precision since 1963.

Ships anywhere, cost effective, satisfaction guaranteed.

In the early sixties, an innovative man named Chuck Foss developed several polyurethane foam systems useful for a variety of purposes, including the production of surfboards. His new firm, The Foss Company, soon became one of the top U.S. suppliers of foam surfboard blanks, which he sold under the name of “Foss Foam.”

Later in the sixties, one of his Foss Foam systems used to make surfboard skags was found to be an excellent material for making sailboat rudders. It was not long before The Foss Company supplied rudders to most of the boat builders in Southern California through the seventies and eighties.

The Foss Company’s former headquarters. During the eighties and nineties, the company specialized in fiberglass and foam composites. High performance sailboards and paddleboards were some of the products produced. With an extensive inventory of rudder molds, the company now specializes in supplying sailboat owners and boat repair yards with replacement rudders.

In recent years, The Foss Company has formed a strategic partnership with FinCo Fabrication, a major fiberglass manufacturing firm based in Santa Ana, California. This partnership will assure that The Foss Company’s long tradition of quality products and service will continue for years to come.

CAL 20 CAL 25 CAL 28 CAL 34 CAL 40

CATALINA YACHTS

CAPRI 18 CATALINA 22 CATALINA 25 CATALINA 250 CATALINA 30 CATALINA 45

ERICSON YACHTS

Ericson 35 Ericson 38 Ericson 41 Ericson 46

Oceanis 37 Oceanis 46.1 Beneteau 56

Manufatures A-C

Balboa Yachts B-Boats Beneteau Catalina Yachts Cal Boats Coronado Yachts Columbia Yachts Coastal Recreation Chrysler Yachts Corsair Marine C & C Yachts

Manufatures D-L

Down East Yachts Ericson Yachts Hunter Hobie Cat Irwin Yachts Islander Yachts J Boats J24 Kirby Boats Kettenburg Marine Lancer Yachts Laguna Yachts

Manufatures M-R

Merit Marine Morgan Marine MacGregor Yachts Newport Boats Olsen Boats O’Day Boats Pearson Yachts Pacific Sea Craft Ranger Yacht Reynolds Sailing

Manufatures S-Z

Sam Morse Boat Company San Juan Boats Sidelmann Tarten Marine W. D. Schock Boats Westsail Marine Westerly Marine Willard Boats

Start your rudder with us now (714) 973-2878 or (949)646-0244

Great old boats - cal 40's new rudder, click to open video, our manufacturing process..

Working together with you the owner we select an exciting mold or sketch out a new design for a custom rudder. All based off years of experience and time tested best practices.

Prepping mold

Experienced Finco craftsmen begin the manufacturing process by sanding, polishing and waxing the rudder mold.

Gelcoat & first layer

After applying Gelcoat to the mold, they apply a layer of unidirectional fiberglass saturated with Vinylester™ resin.

Rudder Shaft Turned

A new rudder shaft is turned from the same material as the original (or stronger.) After it is cut to length and tapered, the tangs are welded into place.

Shaft set & foam+

Once the fiberglass has cured, the tapered stainless steel shaft is set into the mold. After the shaft is aligned, the halves are mated, clamped and sealed, and liquid foam is poured into the mold.

Sand to Smooth

When the foam has cured, the rudder is removed and the seams sanded smooth. Most OEM rudder fabrication stops here; we go farther .

Taped and cured

Fiberglass tape is laminated to the seams. After the tape has cured and has been sanded smooth, the rudder gets a final coat of gelcoat.

Faired & prepped

In the last step, the entire rudder is faired and sanded in preparation for you to apply a coat of bottom paint.

Packed in custom box

The finished rudder is packed in a purpose-built crate suitable for shipping to you anywhere in the world.

Why Select Us?

We have many of the original molds and tooling for production boats made over the mast 60+ years in our inventory and can replace damaged rudders with the exact factory replacement. If you would like a custom rudder, we can modify or design from scratch a rudder that meets your exact needs.

The original rudders originally were manufactured by “clam-shell” method and our exact replacements use the same tooling. Plus over the years there have been advances in glass cloth and in laminating resins making them stronger and more reliable. The closed cell foam core of the rudder remains the same, but the selective addition of unidirectional fibers has increased the strength of our rudders, and the use of Vinylester™ resins has eliminated blisters and the need for expensive barrier coats.

Newer designs to improve handling and directional control. This is most important when sailing very fast and can help prevent broaching and spin-outs. Most boats can use upgraded rudders without incurring a rating penalty. Some local PHRF boards will hit some designs with a 3 seconds-per-mile penalty so you should check with your local board before making your change.

Get in Touch

Here for you.

Phone: (714) 973-2878 (949) 646-0244 Email: [email protected]

Foss Rudders fondued in 1963 has partnered with FinCo Fabrication, a major fiberglass manufacturing firm in Santa Ana, California. We make precision rudders for you.

Where to find us

2520 South Broadway, Santa Ana CA 92707

Welcome to Jefa Rudder

We have rudder and bearings for your boat.

Who is Jefa Rudder?

Beginning in 1980, Jefa Rudder has supplied Rudder Bearings to over 40,000 boats. Jefa was founded by Jan Faurschou. Today Jefa Rudder is steered with the second generation at its helm, by Jan’s daughter Louise.

Did you know

Quality roller bearings.

All Jefa rudder bearings are produces with precision machined rollers and close tolerances to provide smooth operation under load. The close tolerance allows Jefa to eliminate the roller cage needed with sloppy bearings and keep the design simple for long term reliability.

Retrofit Bearings

Jefa Rudder produces replacement rudder balls for all old JP3 and Seaway (Bavaria, Elan, Salona, etc..) rudder bearing.

Jefa Rudder produces replacements for old Harken rudder bearings which is precisely match the original outer dimensions

Standard & self-aligning bearings

Jefa produces self-aligning bearings for rudder stocks engineered to flex. Self-aligning bearings also eliminate the need for precise alignment during installation. Standard or Non Self-aligning bearings are available at a lower cost and normally have a smaller outside diameter.

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Gear & Maintenance

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

J/Boat Rudder Bearing Replacement

- Add to quote

OK, I have entirely too much lateral movement in my rudder (3/4") and I am 99.9% positive this means I'll be tackling / paying for at least a lower rudder bearing replacement, possibly even an upper. This is a common and known issue on these boats. Who has done this before (or had it done)? I've read most of the related material online. I'm am specifically looking for comments on J/Boats. 1. Which bearing manuf did you choose (Jeffa or Edson) and why? 2. How much did the bearing part cost? 3. How much was the total job? 4. What were the gotchas, or other 'I didn't anticipate THAT' learnings? I understand that most of these require the fiberglassing of the new bearing...which is not something I am going to tackle. So I am trying to educate myself enough to the point where I can specifiy parts and general process to the yard. Thanks.

There's info at these sites: J40 Rudder Bearings Eos Rudder Bearing Replacement Paul L

Thanks for the links. Good info. I've read both of these. Is there any other information out there? Experiences from other owners who have gone through this process?

When I looked at my J/34c before I bought it, the bearings were junk. The owner replaced the bearings before I purchased, and he had Jefa bearings installed. I am pleased with the operation of the bearings, but am not very pleased with the installation. The guy that did the installation did not know what he was doing and the lower bearing hangs out by about 1/4". He also glassed them to the stock. I talked to PYI, Phil I think is who I talked to, and he was very helpful in makeing sure how my bearings were installed would work ok. It is a pretty big job as you have to drop the rudder (duh!) and then fit the bearings to the stock. Also, you should repack the stuffing box around the rudder stock. It is not a cheap fix, but done correctly, should be a one time job. Keep us posted. Doug

- ?

- 174K members

Top Contributors this Month

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Rudder Bearing Replacement

- Thread starter A. Todd Henker

- Start date Oct 18, 2001

- Hunter Owner Forums

- Mid-Size Boats

A. Todd Henker

I have a 1991 30T, and started noticing excessive motion in the steering Quadrant /rudder post (1/2" ). I need to replace the rudder bearings. Does anyone know how to remove the old bearings? Are they a light press fit, or are they glued in place? Can they be pressed/tapped out, or do they have to be cut/ground out? The bottom bearing appears to have a molded fiber glass flange around the bearing, preventing removal from the bottom? Do they both have to come out of the top? Also, I would prefer to replace them with a higher quality bearing, such as a roller. Can anyone recommend a good source for roller type bearings. I have looked at Jefa, but they start at around $200.00 each (upper and lower), and it appears that, for the post diameter (2.330") and stern tube I.D. 3.25", this would either require a custom size, or would result in an Bearing O.D. larger than the existing tube I.D. I would appreciate any information, suggestions, experience anyone has with this issue.

Almost had to replace I almost had to replace the rudder bearing, as it was cited in my pre-purchase survey as being needed. However, the boatyard mechanic said it wasn't sloppy enough (only slight movement) to require replacing, especially since it wasn't leaking. He said a replacement would have about the same amount of play in it. My point in writing this, is to advise only that when I thought replacement was necessary the boatyard said it wasn't a major project for them. I got the impression it was either pressed or pounded in, and may have been nothing more than a cutlass bearing cut to fit.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

IMAGES

VIDEO

COMMENTS

Hey Guys!This week our friends were about to purchase new rudder bearings for HUNDREDS of dollars and lift out for a week to do a rudder bearing replacement ...

A small amount of wear, maybe around 1mm at the bearing, is acceptable, but if there's significantly more than this further investigation will be needed. A 30ft (9m) boat with new Delrin bushes fitted - the black collar of the lower bush can be seen - and the rudder replaced, ready for antifouling. Photo: Rupert Holmes.

To facilitate future replacement, I used 5200 only on the bottom flange, NONE on the sides that go 2 ¼" into the rudder tube. There are screws that hold the bottom bearing in place, too. With a hull thickness of 1 to 2 inches in this area, I used 1 ¼" long screws since the bearing flange is ½" thick. When I first replaced the bottom ...

Jefa rudder bearings offer the utmost in feel and durability. Utilizing captive roller bearings in rugged aluminum housings, there is a full range of sizes and styles including self aligning bearings to suit all sizes of sailboats. Sizes are available from 30mm to 260mm for production and custom applications.

Check out our latest Sailboat Restoration video where we complete the rudder rebuild and finally install new rudder bearings and the rebuilt rudder! Don't Li...

We are back in our boat! This chapter is all about HOW TO REPLACE THE RUDDER BEARING on your own.If you have any questions feel free to ask us in the comment...

Bolt the rudder post bearing in upside-down, Six-10 the gap, and then pop it out before the Six-10 was fully cured to create a perfect, flush fit for the rudder post. Now, "all the components work as a system," as Brandon explained, to hold the rudder post firmly in place. Again, while it was a pretty extensive project, the knowledge ...

So be prepared to have the boat on the hard until the new bearings come in. And be sure of your measurements.u000bu000bHint: Remove the rudder while the boat is in the slings. Otherwise wou will have to dig a hole to remove it. You'll have to dig a hole, anyway, to replace it, but it'll be easier to dig if the rudder's not in the way.

Jul 28, 2016. #1. I have a 1990 Hunter 28, and am considering replacing the rudder bearings. The boat is on the hard, and the rudder has been removed. The rudder post rides in a rudder tube that extends from the hull to the deck. There are two bearings made from UHMW, that are fitted in the rudder tube. One bearing is at the point the rudder ...

Catalina 310, 2000, #31 31 Santa Cruz. Dec 7, 2015. #5. When we surveyed the C310 we bought (#31) the surveyor recommended replacing the rudder bearings. There was maybe 1/4" play at the top of the rudder post (removing inspection port for emergency tiller). CD sells a kit with all the parts, probably Catalina does also.

We have many of the original molds and tooling for production boats in our inventory and can replace damaged rudders with the exact factory replacement as originally provided by Cal, Santana/Schock, Ranger, Ericson, Islander, Columbia and many more. The original rudders originally were and are now manufactured using what has become known as the ...

In a thousand miles the shaft might go through 80,000 cycles, but bearing failure isn't normally unpredictable, so the play will slowly increase to the point there is a mechanical failure - replace early or check regularly. 12mm is the maximum play allowable on a NEW beneteau at the bottom rudder tip.

Rudder bearing replacement C&C 36 + other issues. Dear ... Forum. Before i point my questions, a short introduction to Sailnet and her users! April 2014 i bought a C&C 36, 1980 in Miami. Sailed her through the Bahamas, Haiti (where the canoo boys made some nice deep scratches), Dominican Republic to Curaçao. Now docked in Curaçao, this year i ...

The internet was a fantastic resource which was always there to help with the rebuild process, from sourcing supplies to researching new skills there was alm...

With an extensive inventory of rudder molds, the company now specializes in supplying sailboat owners and boat repair yards with replacement rudders. In recent years, The Foss Company has formed a strategic partnership with FinCo Fabrication, a major fiberglass manufacturing firm based in Santa Ana, California.

May 4, 2022. #1. The upper bearing/bushing located just under the seat that supports the end of the rudder post is pretty loose. It's made of teak or mahogany and is attached to the underside of the seating surface. I plan on replacing it with the rudder in place by cutting it out and replacing with a two piece design glueed and screwed together.

Rudders. Jefa rudder bearings offer the utmost in feel and durability. Utilizing captive roller bearings in rugged aluminum housings, there is a full range of sizes and styles including self aligning bearings to suit all sizes of sailboats. Sizes are available from 30mm to 260mm for production and custom applications.

Aug 15, 2013. 193. Hunter 35.5 Legend 003 San Carlos, Sonora, Mexico. Jan 19, 2014. #1. So it looks like rudder bearing replacement is in the future for me.

The Upper Rudder Bearing Standard (URB-STD) and the Upper Rudder Bearing-Low Profile (URB-LP) are both ABS and Lloyds approved, self-aligning design which accomodates up to 10 degrees of off-axis alignment between the mounting surface (rudder shelf) and the rudder stock. Tides Marine rudder bearings can be produced in custom sizes and lengths ...

J. jason3317 Discussion starter. 201 posts · Joined 2007. #1 · Jan 14, 2009. OK, I have entirely too much lateral movement in my rudder (3/4") and I am 99.9% positive this means I'll be tackling / paying for at least a lower rudder bearing replacement, possibly even an upper. This is a common and known issue on these boats.

Feb 14, 2005. 4,773. Tayana 37 cutter; I20/M20 SCOWS Worton Creek, MD. Jan 26, 2012. #2. The wear on such rudder bearings is usually due to abrasion between the SS shaft and the (usually delrin/acetal) bearing material. The surface roughness of the shaft abrades away the bearing material. To reduce the bearing wear, the shaft area at the ...

Almost had to replace I almost had to replace the rudder bearing, as it was cited in my pre-purchase survey as being needed. However, the boatyard mechanic said it wasn't sloppy enough (only slight movement) to require replacing, especially since it wasn't leaking. He said a replacement would have about the same amount of play in it.