RM Yachts: French plywood sailboat manufacturer

Over 30 years of plywood yacht building expertise.

Welcome to RM Yachts!

French sailboat manufacturer since 1989, our shipyard based in La Rochelle is specialised in the construction of fast cruising yachts of 30ft to 45ft in plywood and epoxy – approximately 9 to 14 meters.

Whether you are looking for a coastal cruising sailboat, or planning longer open sea trips, such as Atlantic, Pacific crossing, or round-the-world sailing, there will always be an RM yacht fitting your project.

We are actually the sole shipyard and manufacturer having built over 500 monohull sailboats using this material and this sailing yacht building technique. Needless to say, we know plywood-epoxy in-and-out.

This material’s benefits are numerous: lightness and stiffness, for increased performance under sail, and a dry and sane interior atmosphere, thanks to its thermal and phonic specifications.

Not to mention its reduced impact on the environment, compared to other materials usually found in naval construction (GRP, polyester, etc.).

Designed by award-winning architect Marc Lombard, RM yachts are 100% made in France, and then sail around the world. Our clients frequently share their anecdotes and logbooks from their solo or family adventures on our modern sailing boats.

Available in different appendage versions (single-keel, twin-keel, lifting-keel, single or twin rudder), RM Yachts are customisable, starting with their hull colour and interior design.

Advising you to choose the best cruising sailboat

Thanks to our many years of experience as a sailing yacht manufacturer, we have designed our website to provide you with all the information you need to select your next cruising yacht :

- What is important when choosing a cruising sailboat?

- What is the best size for a coastal or bluewater cruising yacht?

- How to choose the best sailboat to live on?

- What options are to be considered when preparing an ocean crossing or a circumnavigation?

Our F.A.Q. section is also a great source of information to help you find the ideal sailing boat according to your needs and sailing plans.

You are more than welcome to visit our premises, and we can also set up a sea trial! Our team will be more than happy to help you configure your brand-new sailing yacht

Alternatively, you can also have a look at our previous models and see how high our used monohull sailboats are on the market. Our expert brokers remain available for additional information.

Finally, acquiring an RM also means you have access to a panel of services, provided by Grand Large Yachting group’s dedicated subsidiary: Grand Large Services. Whether it’s about training lessons, spare parts, maintenance, or refit before slipping lines, our specialists are here to help!

Bring your own dreams, we’ll take care of everything else.

Looking forward to meeting you soon,

The RM Yachts team.

ORC NEWSLETTER

Stay in touch - restons en contact.

ORC Catamarans News. No spam, No sharing of your information. Les news ORC. Pas de spam, pas de partage de vos données.

Beautiful design and masterful construction

- Advertorial

- Tech Briefs

Over the past 35 years RM Yachts has taken a unique, yet successful, path developing increasingly innovative and refined performance cruising yachts that harness the benefits of building in epoxy and plywood. The RM1080 is the La Rochelle-based yard’s latest little rocket and is in many ways a direct development of racing Class 40s, both inside and out.

It’s a Marc Lombard design that also retains key attributes of existing RM models, including exceptional attention to detail and standard of finish, plus bright interiors with excellent natural light thanks to the trademark big forward coachroof window. There’s also an option of very efficient twin bulb keels that combine moderate draught with the ability to dry out at low water, yet without compromising sailing qualities.

What are the big differences between this new model and the eight-year-old RM1070 it replaces? While that model was very well regarded, ‘the yacht design world has moved a lot in that time,’ says RM’s César Dohy. ‘The boats are getting more powerful and they are now much wider forward.’

The waterline beam of the new boat is much greater, especially in the forward sections, even if displacement and maximum beam at deck level remain the same. As with many new out-and-out performance designs, the mast is also positioned further aft, with a lot more rake – five to six degrees.

As a result of these changes, ‘this boat will have the same upwind ability as the previous model,’ according to Dohy, ‘but much better reaching and downwind stability, with easy control and higher average speeds.’

That’s where some of the changes to the cockpit layout become important. Given the overall length of only 36ft, when sailing fast in heavy seas there’s potential for a lot of water on deck. ‘That’s why we implemented the high Class40 style coaming,’ he adds.

This runs across the side deck at the front of the cockpit, then aft along the gunwale. O There’s also a big fabric sprayhood over the companionway. ‘She should be very dry when reaching in big seas and above 20kts,’ says Dohy.

A secondary benefit of the new coamings is that the entire width of the boat can be used for the cockpit when in port or at anchor. The backrests for the benches each side can be removed, creating enough space on each side of the boat for double sun beds.

It’s another first for a performance yacht of this size. All four winches are at the companionway, where almost all sail handling operations can be carried out easily by one person.

‘It’s a big point,’ Dohy emphasises. ‘You can do everything there, apart from the mainsail traveller, which is controlled from the helm.’

This is a great setup for cruising because manoeuvres, including reefing, can be carried out really easily and safely. Even if you’re on watch on your own everything happens in one place, under the shelter of the large fabric spray hood. This has three frames – one more than is typical – to make it almost as stiff as a solid structure. It’s also fitted with strong stainless steel handrails along the aft edge and on each side, for use when going forward.

A choice of carbon and aluminium spars is offered and owners can specify the sail wardrobe that suits them best. However, most are expected to opt for a standard five-sail configuration of mainsail, genoa, staysail, asymmetric kite and code zero. This gives a flexible all-round inventory that will cover all situations, without unnecessary cost, while minimising the number of sails that need to be stowed below decks.

The mainsail is exactly the same size as the genoa, while RM worked hard to make the staysail work as flexibly as possible, both with the gennaker and code zero. Sceptics might wonder whether such a sail is likely to get much use when cruising, especially as it’s unlikely to add more than 0.4kts of boat speed.

However, its presence, forward of the centre of effort, makes the boat more stable and easier to steer, especially when using the autopilot. That in turn makes for an easier motion and more comfortable ride, while simultaneously increasing average speeds.

‘For this reason,’ Dohy says,‘We find staysails are used a lot on all our boats.’

It’s also designed for use upwind when the true wind rises above about 16-17 knots. This makes for a much more efficient sail plan than a part furled genoa. And it can be set up in winds well under 20 knots, eliminating foredeck acrobatics in rougher conditions and a rising wind.

Why didn’t RM go for a full scow bow shape? ‘It just doesn’t make sense for this type of boat, says Dohy. ‘That’s partly because it’s would be too uncomfortable going upwind for a cruising boat.’ However, there’s a more fundamental reason as well. ‘We’ve tried hard to keep the displacement down, but if the hull shape is too wide it’s impossible to avoid extra weight.’

How much of an attempt was made to minimise wetted surface area to boost performance light airs and thus minimise use of the engine when cruising? ‘It’s a good question,’ says Dohy. ‘She’s very beamy on the waterline, but as soon as there is a few degrees of heel the immersed area reduces dramatically.’

At the same time, despite the broad bow sections, the RM 1080’s waterline length is relatively short by today’s standards at only 10.4 metres. This reduces frictional resistance in light airs. Yet, at the same time, the underwater profile has a flat run aft, akin to that of many motor boats. This is a crucial factor in promoting early planing.

Below decks the roomy two-cabin accommodation has the same general feel as existing models, with a lot of glazing and plenty of white paint. There’s lots of room, even though the entire design is quite simple to keep the weight down, and there’s less heavy joinery on show than typical heavier cruising yachts.

The biggest difference in the saloon compared with the 1070 is that the table is offset to one side and the new boat feels a little more spacious, simply as a result of the more powerful hull shape and additional waterline beam.

This is particularly noticeable in the owner’s cabin forward, where there’s roughly an extra 30cm of room. It’s enough to make a big difference to the feeling of space and to improve stowage, making this a much more appealing area than that of the older boat. It’s a factor that should be a key selling point, after the boat’s top-notch performance and its innovative cockpit layout.

As with all RM designs, there’s a very large and well-appointed galley, plus a dedicated technical area aft on the starboard side. This is accessed from the heads compartment and has all the core systems and electrics laid out in an accessible manner. There’s plenty of space in this zone, which is a huge benefit for routine maintenance, for troubleshooting problems and for retrofitting extra equipment at a later date. The technical area is also fitted with a foul weather gear locker with a drain.

This construction method also benefits from a beautifully efficient production process. At RM all parts are cut by a CNC machine well in advance of each build so that they can settle to the temperature and the humidity of the carefully controlled factory environment. The plywood panels are connected fore and aft off the boat, using scarfs and big jigsaw style joints to create a single giant full-length plank, which makes for a very smooth, seamless finish.

These are then offered up to a permanently set up jig that automatically creates the hull shape, without the need for a wasteful full mould. After fitting of internal systems, and the galvanised frames that distribute keel loads, the hull is then married to a conventional foam sandwich deck. It’s a well-proven and more environmentally friendly system that creates powerful, distinctive state-of-theart yachts with excellent longevity.

Click here for more information on RM Yachts

Our sailing boats

Since its launch in 2013, the RM890+ never stopped to surprise and seduce. The goal was to conceive a true cruiser, with loads of living space, comfort yet performance, at ease for both coastal cruising and port-hopping. In her different versions – twin-keel or fin keel – this fast 30ft sailboat is easy to sail, and quick to set up.

The ideal 32ft yacht for family cruising. With the RM970, you’re entering the serial cruiser category! Conceived as the perfect family liveaboard, this 32-foot sailboat will be your best companion to create great memories.

With the RM1070+ we wanted to create a 35ft sailboat suitable for all navigation plans, including long-range cruising. She is available in three appendage versions: twin-keel, fin keel, or lifting keel.

Should you be looking for a fast, elegant cruising yacht, capable of crossing either oceans or the next bay nearby, solo or with your family, the RM1180 will satisfy all these expectations. Just add charm and seduction on top.

Designed by Marc Lombard and developed by our internal engineering team, this fast and modern 39ft sailboat is one of a kind monohull, representing the perfect synthesis of our definition of a transatlantic (or any other ocean!) sailing yacht: breathtaking lines, remarkable performances, non-to-second comfort, not to mention environment-friendly construction in plywood and epoxy.

The bluewater sailing yacht you’ve been dreaming of. For the past 30 years, Marc Lombard Design team and the RM Yachts engineering team have been conceiving legendary and head-turning sailing yachts, all contributing to the French shipyard’s reputation. The RM1380 is, somehow, the culmination of our efforts, and probably our most remarkable achievement.

A 45-foot sailboat made of plywood-epoxy, the RM1380 is exceptionally elegant and racy, and capable of long cruises, such as a circum-navigation or a transatlantic ocean crossing in the best conditions of speed, safety, and comfort.

Keep in Touch' Restons en contact

We will send you RM Yachts News (Only) to make sure you are up to date. Recevez (seulement) nos infos, pour être sûrs de ne rien rater !

- FR - Français

- EN - English

Boatindustry.com

Interview / RM Yachts: "We need to promote the construction methods of RM yachts"

Stéphan Constance, co-founder of the Grand Large group, which has just taken over Fora Marine, gives us a few key points on the situation and strategy for this new era of RM yachts.

The Grand Large Yachting group has taken over the Fora Marine shipyard , builder of RM sailboats, at the bar of the commercial court in February 2020. Its co-founder, Stéphan Constance, explains the situation and the plans for the boat brand.

What was RM's situation at the time of the takeover? Why were you a candidate for the acquisition of Fora Marine?

This is a dramatic situation. The shipyard costs 200,000 euros per month and in recent years, the boats were only bringing in 100,000 euros per month. 100,000 euros were lost each month, leading to an accumulated loss of 1.4 million euros. The equation to turn the company around is very complicated. We have given a lot of thought to this, and only a few of us have taken a position. But Grand Large has the levers to restore a healthy situation. We became interested because of the popularity of the RM brand and the quality of its teams. People are one of its main assets. We took over 80% of the staff. RM is based on a triptych:

- performance, in particular through Marc Lombard, with whom we hope to continue working

- the distinctive design. The flashy colors were a great idea from Martin Lepoutre

- comfort, which makes them ideal for families and travellers

It is an equation to be preserved and developed.

What are the levers you mention to develop RM sailboats?

We have 3 levers:

- industrial know-how, with an organization that already works in the Grand Large group

- the pooling of purchases. We don't buy at the same price from a site with a turnover of 6/7 million euros and from a group with a turnover of 60 million euros. This will help to clean up losses.

- distribution abroad, which currently accounts for only 20%, mainly in Spain and Italy. I have heard from Grand Large distributors who are interested in RM.

Major projects have already been launched on the ERP, for example.

What about the use of subcontracting by Fora Marine and a possible internalisation within the group, as well as the establishment of RM in La Rochelle?

We have never relocated a site, except for Gunboat . We don't want to lose the people and the infrastructure. We were told at the time of the Garcia takeover that we would not stay in Condé-sur-Noireau. We are still there. As for internalizing the work done by the suppliers, this is not our plan. As we told the court, the ability to internalize is more of a back-up in case of a problem in the market or with a failing supplier.

What is the business situation and future objectives?

Today, former customers have priority on orders before the summer of 2020 (Editor's note: The views of Stéphan Constance and former clients are detailed in a dedicated article). New customers are positioning themselves for 2021. The goal is to restore confidence with an objective of 8Meuros in 6 years, by returning to what was done in the past. To do this, we need to promote the high quality of the construction methods of RM yachts to boaters, so that they can charge a fair price without having to make large discounts.

Yachting World

- Digital Edition

First look: RM 1380 – largest new yacht from the French marque

- Toby Hodges

- December 28, 2022

The RM 1380 is set to be the biggest boat this popular French brand has produced and could well suit bluewater cruisers

Product Overview

I like RM 1380 and I’m clearly not alone in appreciating these (typically) brightly coloured plywood epoxy fast cruisers – with over 500 hulls launched during the La Rochelle yard’s 30 or more years in production. It describes this latest (now its largest) 45-footer as ‘the perfect balance of style, velocity and bluewater cruising.’

The RM 1380 includes many of the features that have made the RM name what it is, including the combination of plywood hulls and foam sandwich glassfibre decks, deep cockpit coamings and inboard winches sited forward in the protection of the coachroof. Then there are the light, open interiors, and the versatile draught options for lift or twin keels. The latter are bolted to a galvanised steel structure.

The Marc Lombard hull shape features his characteristic reverse sheerline, together with a sizable coachroof that blends well with these lines. The powerful shape, which is angular and chined to suit its plywood construction, creates a stiff result on the water. A light displacement of under 10 tonnes for this model, combined with beamy aft sections and twin rudder control, should prove fun off the breeze.

RM 1380 will feature a bright interior with plenty of natural light

Piaton Design has styled the bright interior, which looks like it has bountiful natural light. It is offered as a three cabin version with forward master, or alternatively this can be split in half to create a fourth cabin.

The 1380 is billed as a bluewater cruiser , but for those considering long voyages, the tankage may be a limiting factor at just 150lt for fuel and 270lt for water. However, there are options to upgrade these to 300lt and 400lt respectively – a watermaker will top the ‘to add’ list for many.

Each RM looks unique because each comes with the owner’s choice of paint finish. This new flagship model is due to make its debut at the Paris and Düsseldorf boat shows in December and January.

RM 1380 specifications

LOA: 14.40m 47ft 3in Hull length: 13.30m 43ft 8in Beam: 4.50m 14ft 9in Twin keel draught: 1.95m 6ft 5in Lift keel draught: 1.45m-3.35m 4ft 9in-11ft 0in Price: €393,600 ex VAT Builder: rm-yachts.com

If you enjoyed this….

Yachting World is the world’s leading magazine for bluewater cruisers and offshore sailors. Every month we have inspirational adventures and practical features to help you realise your sailing dreams. Build your knowledge with a subscription delivered to your door. See our latest offers and save at least 30% off the cover price.

RM 1380 : The exciting alternative made of plywood

Michael Good

· 25.01.2023

The creases in the hull, which result from the special construction method, are typical of RM Yachts. The yacht builders in La Rochelle traditionally produce boats with a plywood hull and GRP deck, which is a unique selling point in this market segment. Like all RM boats, the new 1380 is supplied with chine keels and a rudder blade as standard, which means that the boat can easily fall dry. Alternatively, an electro-hydraulic swing keel is available, which can reduce the draught from an impressive 3.35 metres to just 1.45 metres. In this case, the boat is built with two rudder blades. Thanks to the plywood construction, this variation is possible without any problems.

The RM 1380 was designed by Marc Lombard. In addition to the multi-buckling frame, the forward sloping bow stem, the pronounced negative deck step and the large panoramic window in the cabin superstructure are typical of the brand. A pinhead mainsail is set on the standard aluminium mast, plus a short overlapping genoa with hole points on deck. However, a self-tacking jib is not provided.

The RM 1380 in the 360° tour:

At this point, you will find external content that complements the article. You can display and hide it with a click.

Trim front, steer rear

With the tried-and-tested RM cockpit layout, all lines remain at the front and are operated from the side of the companionway. Large winches are available on each side for this purpose. The winch for the genoa sheet is located slightly lower on a separate platform in front of it. This allows the winches to be close together and still be easily operated with the cranks. This arrangement proved its worth in the test of the smaller RM 1180 (YACHT 20/2019). There are also additional winches for the mainsheet aft within reach of the helmsman. As a novelty for RM yachts, the new 1380 is now also available with a folding bathing platform in two sizes, but only as an option.

The standard layout below deck is a conventional layout with two cabins aft and a large owner's cabin forward. Alternatively, it is possible to divide the foredeck lengthways and thus realise two cabins forward. In both variants, there is still a separate wet room in the foredeck, with a toilet room on one side and a bathroom with shower on the other. Instead of the double cabin on the starboard side, sailors who want to go on long journeys can also set up a workshop or a walk-in locker there. However, this area is only accessible from the inside, not from the cockpit.

The price currently communicated in Düsseldorf is 468,370 euros, including 19% VAT and a set of Amwind sails.

Technical data RM 1380

- Designer: Marc Lombard Design Group

- Interior styling: Piaton Yacht Design

- Hull length: 13.30 m

- Overall length with bowsprit: 14.40 m

- Width: 4.53

- Draught of bilge keels: 1.95 m

- Draught swing keel: 1.45-3.35 m

- Mast height above waterline: 20.50 m

- Weight: 9.7 tonnes

- Mainsail: 55.0 m²

- Genoa: 55.0 m²

- Stagfock: 33.0 m²

- Gennaker: 150,0 m²

- Code Zero: 110.0 m²

- Motorisation: Volvo Penta, 60 hp, Saildrive

- Fuel capacity: 150 litres

- Fresh water capacity: 270 litres

- Black water tanks: 2x 50 litres

- CE design category: A (8)

- Standard price ex shipyard: 468,370 euros gross, including sails

All boot Düsseldorf 2023 trade fair premieres at a glance

- The most important innovations at the boot 2023 trade fair - Part 1

- The most important innovations at the boot 2023 trade fair - Part 2

Further links on the topic

- YACHT test RM 1180 for download

- Grand Large Yachting takes over RM Yachts

- YACHT test RM 970 for download

- YACHT test RM 1270 for download

Most read in category Yachts

At RM Yachts of La Rochelle

- April 16th, 2017

- On Location

It has been the naval architect Marc Lombard himself who awoke my interest in RM Yachts: When I got the chance to meet him during the Boot boatshow in Dusseldorf this year to talk about the very process of designing a sailing yacht and his personal approach (read the article here ). He directed me to the stand of Fora Marine – RM Yachts where we sat down to discuss the topic. It was here when I first heard about the fact that a yacht builder is making big and yet fast sailing cruisers from plywood.

Last week I happened to be in La Rochelle at the Atlantic Ocean Coast and it suddenly struck me as I was driving through a large commercial area when I saw the big RM-Yachts logo and I suddenly remembered. I took the chance and called the company and I was very excited to have Justine at the other end of the line – the very lady who was so kind to arrange the meeting with Marc during the boatshow in the first place: “Sure, of course you can come and have a visit at our yard. We would be delighted!”, she said and offered me her company to show me around. That was my lucky day.

Plywood as an ideal material for building boats

Why is it such a news that there is a company making sailing yachts from plywood? Boats and ships have been made from timber for many hundred years before: Mankind´s first boats have been hollow dug out canoes, Egyptians have set out on the Mediterranean in rafts made of reed, Polynesians have conquered much of the Pacific Ocean in cleverly rigged, very fast tiny outrigger boats and finally had the Europeans roamed the Oceans in huge sturdy yet fast and reliable timber made sailing vessels. But I admit: In a world made of plastic it sounds a bit awkward to have a yacht made from plywood considered to be “modern” or state-of-the-art.

When we entered the large production facility, not after the owner of the company greeted me and was wishing me a nice stay, I was surprised to hear from Justine than RM Yachts is selling some 40 units annually. That is much, much more than very renown Scandinavian boat yards such as admired Luffe for example. “We want to make some 48 boats this year”, she says, “The maximum limit for these facilities as you may see would be some 80 boats anually.” You know what struck me most as I stand in the hall? The smell. No biting GRP polystyrene-odors but the fine smell of wood. Very nice.

“This is how it all starts”, she says pointing to a storing area: Large piles of plywood of all sizes and thicknesses are stored here, some piles made of pre-cut parts for the boats. “The parts are laser cut”, Justine explains. I can see what will be future portholes, stringers, parts which will form a bulkhead of a yacht. Where do these raw plywood sheets come from? “They are made especially for us nearby. Also the laser cutting service is performed by a local company in the area around us. We try to have most of the boat done by ourselves of course. If this can´t be done, we are always seeking the help of local companies first.”, Justine explains.

Making a plywood sailing yacht is – not unlike the building of a GRP boat – a lot of hand labor. When I was visiting the yard it was bristling with people. What I liked a lot was the fact that I equally saw young people working here as well as elder craftsmen which is a sign of a good healthy workforce and the ensuring of knowledge transition between the generations. There appeared to be no pressure here – people did their work thoroughly, I often saw them putting away the tools to intensively check on the outcome. All of the male workers of course found their time to greet Justine with French bisous as well.

Making the structural skeleton of the sailing yacht

“We have no molds to make a yacht´s hull”, Justine explains as we stand in front of a huge construction made of thick plywood: “That´s the negative model of the hull and the equivalent to the GRP-mold if you want. The craftsmen will put the pre-cut parts in a certain manner to a certain place and thus form the skeleton of the hull.” I get closer to watch: First they will put in the bulkheads. Then stringers and ribs will be complemented. The longitudinal parts such as stringers will be put in place as well. “It´s a giant puzzle!”, I said and she nods, smiling.

The parts are then glued together by means of Epoxy. “We are using a lot of Epoxy in our yachts of course.”, Justine says pointing to the thick joints of the plywood plates: “Epoxy is the best glue in this matter as it will be virtually sucked into the plywood material. It will form a very, very strong bond with the wooden parts no other glue will achieve.” They use different forms of Epoxy here, I will learn later. Looking at the joints I notice the sheer thickness of them: Not as thick a thumb, but as thick as two thumbs!

It´s funny to see that there are no nails, no screws no bolts and nuts whatsoever needed to form the structural skeleton of this yacht. Looking at the huge strains which will go into a yacht´s hull when sailing, when the shrouds are under immense loads, when waves pound the hull, it´s just amazing to see that there is not a single bolt needed to support the wooden mainframe of an RM Yacht.

I crawl deeper into the huge 3D-puzzle to look thoroughly. All joints are glued from either sides to the adjoining parts, the quality of the joints is as high as expected – no seams visible. Even the Epoxy glued areas – though made by hand – seem to have been done by a robot as perfect and even as they appear. Thanks to a precise laser-cutting technology this boat will be as symmetrically perfect as one could think of.

I wonder how long it would take to fabricate a plywood yacht hull. Justine is asking a worker how looks at the construction and estimates: The large boats, 10 to 12 meters, will take a good week to be made, the smaller, 8 to 9 meter yachts are faster: “The hull of an RM 890 will take three to four days in this production step.”, Justine translates. Wow, that´s fast for sure, faster than molding (and drying) a GRP-hull.

Achieving structural strength of a plywood yacht hull

Plywood – this word may for some people sound odd in connection with making a proper oceangoing yacht. You could use plywood for furniture or panels, but could you use it to make a ship that is sailing on the Oceans and withstand the sheer forces of nature? These boats all have Cat A CE-rating and are thus made for sailing in all conditions in all areas of our planet. The boats needs to be strong. How do they achieve it?

Before I enter the large workshop-hall I take a look at a steel frame unit ready for assembly outside. That´s a thick piece of stainless steel, not dissimilar to those massive main frames for example X-Yachts is utilizing in their respective yachts. “This cage is also done by a partner company in this area.”, Justine explains: “Every RM yacht has one of these built in.” The steel has a thickness of some 10 millimeters.

The frame will be partially jacket with plywood which is glued to the steel and be put into the caliber right from the beginning. This it will be obstructed into the hull to form solid bonds. “The steel main frame serves many purposes”, Justine tells me: “It will first of all take on the keel. We offer three kinds of keels with our yachts: The solid T-keel, a twin-keel with which the yacht can fall dry and the lifting keel. Especially for the very long lifting keels you need to have a very strong frame to take on the loads.”

I take a look under one of the hulls and can clearly see how the steel cage is built in. Most of the steel-parts have been covered with plywood, others had been bolted to thick plywood stringers of the hull. The cage is securely attached to the wooden structure: “The second purpose of the steel cage is to take on the loads from the shrouds which will be diverted directly to the steel.”, Justine tells me.

All in all the hull makes a deep impression on me. On the one hand I am fascinated by the plywood construction, the thick joints and the perfect seamless assembly, the effort that goes into each and every part of the structure. When I touch the structure or knock on it, it feels solid and the “Clang” of my knocking reassures me of the solidity of the hull. On the other hand … it´s still plywood, isn´t it?

What about collision damage on a plywood yacht?

As we roam the workshop, I do ask Justine some further questions on stability of the boat. What about collisions? Hitting floating object is a nightmare for every skipper and whilst the sea gets more and more polluted, yards need to find answers. Of course, she says, that´s a problem for every yacht maker and RM Yachts has an answer to this one too.

“Look at the bow section here”, she shows me a half-ready hull. The very bow has been laminated with multiple layers of glass reinforced fibre-matts and Epoxy. “This is just the outside. From the inside you will notice that in the collision compartment of the yacht we have built in no less than 4 layers of thick plywood – each one glued to the hull, laminated to the hull and soaked with Epoxy. This is really a very, very strong construction and makes a firm bond in case some collision takes place.”

I go down to my knees and look right into the collision compartment (which will house the anchor-chain and gas-bootle) later. There I can see what she meant. I can further see some solgitudinal stringers which will add further strength in this area. Seems appropriate and to be honest, it looks a lot more assuring that some GRP-made hulls I had to inspect where there isn´t any of these elements but just 0.8 centimetres of GRP.

“There is an option we offer,” Justine tells me as we stand next to a half-ready hull: “See this yellow layer? This is Kevlar.” I touch the garment which feels like any other laminated denim: Solid. “The whole hull is covered with one layer of Kevlar and some spots of the boat, especially the bow section, with two layers. That´s an option we offer for clients who want to be 110 per cent safe against collisions.” They don´t like this option at RM Yachts, Justine tells me, just because it´s not necessary as they judge: The boat is safe and strong even without Kevlar. It will only add weight to the hull. “But many clients want this reassurance so we do it.”

Epoxy resin & plywood: An ideal team

Marc Lombard told me during our interview that plywood is the ideal material to make a ship because of a certain feature of it: It is soaking itself automatically with Epoxy if done right. Justine gets me deeper into this: “When the hull is completed on the stand, it will be completely painted with Epoxy resin. As plywood is naturally made of a more softer timber, the material will literally soak itself full of resin instantly. When drying out, the once soft plywood will then be a rock solid new material. And this is what we want to achieve.” Again under one new hull I watch a worker doing exactly this job. Very tedious, on your knees for hours and re-doing the joints, painting the inner hull with Epoxy. The nice smell of wooden material in this area of the workshop is of course instantly replaced by the familiar odour of resin and chemical agents helping to stick to the material and dry fast.

Of course, plywood-made hulls cannot bear round shapes like it is achieved with a GRP mold. RM Yachts are therefore hard chined hulls. Naval architect Marc Lombard sees no problems in that especially in view to most of the contemporary GRP-hull concepts which themselves feature more or less extreme developed chines to gain more volume. For performance-oriented hull designs like this of a Pogo for example a chine will add sufficiently to the stability of the yacht when sailing heeled.

When the inside of the hull is completely painted with Epoxy, all adjoining areas of all bulkheads, stringers and other parts will be laminated at least twice. In the end, no wooden surface of the original plywood hull will be touchable anymore: An owner will have the impression of being on an ordinary GRP-made boat. From the outside, the same treatment is applied: The plywood is soaked with Epoxy, then the adjoining seams will be laminated twice. As I stand there to admire a raw 890 hull, they are pulling a white painted hull out of another workshop: “That´s the latest of our boats, the 1370.”, Justine explains: “Please don´t take pictures: She is brand new …”

Filling and smoothing the yacht´s hull

We enter another section of the complex. Huge fans are constantly taking out and filtering the air from dust particles. Air condition keeps the hall inside a certain small range of temperatures so that an optimum surrounding for the very working steps is created which are performed here.

“When the raw hull is dried thoroughly”, Justine explains, “it will be brought here. One layer of Epoxy is brought to the outside of the hull as you may see at this boat. This layer is for example white.” It will then sanded down to create a smooth surface. “After the first there comes a second layer with the same, more thicker Epoxy, and this will have a different color just to check. This will also be sanded down. After these steps the hull has perfect shape without any scratched. No seam will be visible anymore.”

Looking at the hull very closely, I notice the thickness of the Epoxy layers which is in some areas well more than 3 millimetres. The sanding process – which is a very, very nasty work, hazardous for the workers (that’s why they have to wear dust masks and the air is immediately filtered through the large machines, a loud work and a nasty work as I know from my own experiences with sanding GRP surfaces on my own yacht (read it here ).

Looking at the stern of this hull I notice the different strengths of the thickness of the plywood sheets forming the hull itself: The bottom sheet clearly is thicker than 2 centimetres, going to the outside and up the hull to the ship´s sides the sheets get thinner, but no thinner than one centimetre. Sanding work has been done just fine on this hull: The once “hard” chines are now rounded to a nice and soft shape.

Here it is where I can finally take a look at the finished raw-inside of the hull with all of the plywood soaked with Epoxy, the adjoining areas laminated twice for additional strength and everything covered with another single layer of GRP-garment. Looks rock-solid and walking on the hull is no problem: No squeeking nor any other sound coming from the surface when walking on it.

It doesn´t work completely without GRP

Of course, RM Yachts are no complete plywood boat. This is what I understand now. The basic material may be plywood, but the construction bears nevertheless a significant portion of modern-day materials just like Epoxy resin and different types of GRP-garments. As Marc Lombard told me during Boot boatshow Dusseldorf, the one and only part of the boat that is made the “traditional-modern” way in a mold is the deck.

“You cannot achieve nice round surfaces and forms with plywood”, he said: “We just want to offer not solely a fast sailing hull but also sailing pleasure which derives from a large portion of the comfort a cabin offers.” Marc explained that the deck will be done traditionally by hand-laminating a GRP mold. And this is what I see at the next station. “These decks are done at a nearby shop by another local partner”, Justine tells me as we walk by.

“Salut!”, we greet loud and clear as we enter another part of the hall, the joiner´s workshop. Now that´s the smell I love indeed! Wooden parts are sawn, sanded and worked with so that it scents like being in a forest here. “Now the GRP molded deck will be outfitted with wooden parts as you may see here.” This could be interesting, I am thinking for myself, since I am right now working on my own yacht on the roofing .

Just as I did it on my own King´s Cruiser 33, the workers are glueing wooden parts to the ceiling which will later be the substruction to take on the roofing panels. Wiring for lighting and other electric installations are already attached to the roof. And there it is: My inspiration! Velcro-tape is used to hold the roofing panels, at least as a secondary joining point. I am taking this idea for my own project since my roofing panels are somewhat heavy and very long – utilizing Velcro will make working with it a lot more easier.

At the same time, the hull – readily painted in the inside – is brought to the assembly line. “Now you can see we have painted the internal hull completely white.”, Justine shows me a 970-hull. “It´s no different in her appearance from a GRP-molded hull anymore and you won´t see any plywood.” Which is perfectly true. The white paint has been applied flawlessly and workers are busy installing machinery, wires and tubes.

“Finally, after the marriage – when the deck joins the hull – the yachts will be brought here and all connecting areas between hull and deck will be closed with multiple layers of this thick Epoxy.” The deck will be attached in two ways at the same time: The deck will be glued with Epoxy to the hull. That’s why they had built a wide strip at the edge of the ship´s side so that a large area is formed to glue the deck onto. Second, thick nuts and bolts will be drilled through deck and hull every 20 centimetres to form a solid mechanical bond.

Interior design and final fitting of the yacht

With this step the boat has been finished to a raw state. All major pats like engine, additional machinery, all electric wires and parts had been already installed. Most of the joinery is of course assembled and put into the boat before the marriage of hull and deck – just as it is the case with all yachts. “Now the boats will be brought into our paint shop”, Justine adds, pointing to a now empty area at the end of the workshop. Where the secret RM 1370 just left.

We leave the large workshop. Two RM Yachts are on the outside to be fitted and rigged. An RM 1270 is the first we inspect. “All colours from the RAL-palette are possible”, Justine says: “We can even create tones if a client won´t find his favourite colour among the thousands of variants.” She smiles. “There´s always the one favourite colour not supplied by RAL, I can assure you …” We enter the 1270 and go down the entryway.

“With every RM Yacht you will only have to make three steps to enter the saloon”, Justine insists. What impressed me (again) was the sheer light suffused saloon. Wow, that´s almost as spacious as on a deck saloon yacht, I tell her. She agrees: “Yet it isn´t a DS. We achieved to offer almost a 360 degree view of the surrounding which is fantastic when sailing.” I can only imagine.

Partially this fantastic situation is due to the huge skylights in the fore part of the saloon: These large windows allow huge amounts of light entering the saloon for sure. “It´s wonderful to see the sails in full bloom. Even when sailing with autohelm, you´ll have a perfect view to what´s happening around and in front of you from down below here”, Justine adds.

Just like windshields of modern sportive cars the RM Yachts bear this feature: As I stand outside on the fore deck of the 1270 I can compare this 34 feet boat to the nearby RM 890, the smallest in the RM range, that also have these large skylights. Light is even more important the smaller a yacht will be, so that is well done, Marc!

But what I loved most about the RM: The navigation station. “We take pride in the fact that every RM Yacht features a proper chart table”, Justine tells me. I dislike current trends in “modern” cruisers to further miniaturizing the chat table, to make it disposable of because most sailors don´t do proper chart work but rely solely on their chart plotters. The RM1270 has a huge nav station – compared with her boat´s size – which I so much adore. (Read about the chart table of my own yacht here )

The price of an RM Yacht

I conclude the tour oft he RM Yachts facilities with a chat about the efforts which go into these boats. RM Yachts is making around 40 yachts per year, which is more than I thought. “We like to produce more and this year there will be a slight increase in the amount of units sold, but growth is not our primary goal”, Justine assures me. “We want to keep our high standards of quality both in the building of the boats as well as in their sailing abilities.” She is proud to tell me that when they´ve tested the RM 890 against the all new Pogo 36 (read it here ), at this very day, the RM was faster.

All this comes with a price tag of course. Making a yacht is always almost solely paying for handmade craftmanship. That´s no different between a GRP-made boat to these plywood yachts. Nevertheless, as Marc Lombard told me, the price for a plywood-epoxy-hull is around 20 per cent higher than compared with a similar hull made of GRP alone. RM Yachts is definitely an exclusive brand and therefore these boats do cost. In sheer numbers: One meter of the RM 970 does come in at some 14.900 Euros. A Pogo 36 will be slightly cheaper, 14.700 Euros. The Dehler 34 will come in at 12.000 Euros per meter, the Oceanis 35.1 at 10.800 Euros. So there´s the difference, some 25 to 30 per cent to the production boats.

In the end I did have some very, very interesting two hours at RM Yachts workshop in La Rochelle with my wonderful host Justine who allowed me to take a free look at everything that was of interest. I was offered to look behind every corner, to turn things upside down (but to avid making pictures of the brand new RM 1370 – which I however did and will publish another article on this yacht when RM has officially launched the boat in the coming weeks. Thank you so much, Justine, thanks RM for having me as your guest. All that remains is the longing for an … at least small … RM Yacht (I´d take the green one) and maybe I will get the chance to sail one of these at the German RM-dealer not far from where I live.

More information on RM Yachts on their website

Other interesting articles on that topic:

Talking RM Yachts and plywood boats with Marc Lombard

Alex on his plywood-build: A Mini 650

Roofing panels made from plywood

Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

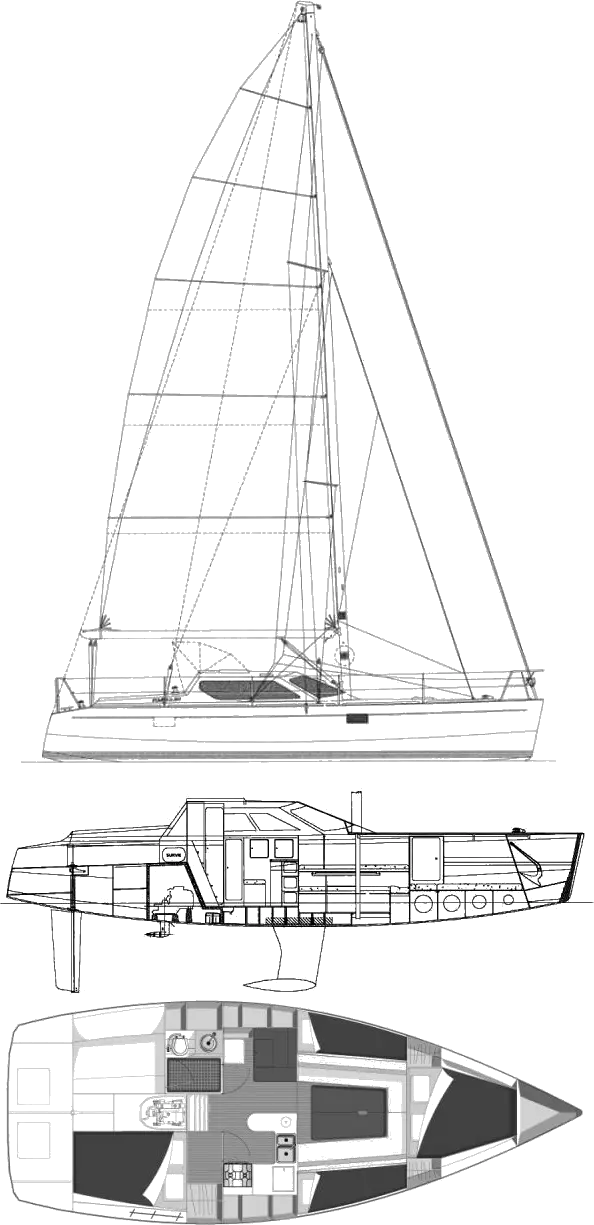

RM 1050 is a 34 ′ 4 ″ / 10.5 m monohull sailboat designed by Marc Lombard and built by RM Yachts between 1998 and 2011.

Rig and Sails

Auxilary power, accomodations, calculations.

The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more.

Classic hull speed formula:

Hull Speed = 1.34 x √LWL

Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL

Sail Area / Displacement Ratio

A measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more.

SA/D = SA ÷ (D ÷ 64) 2/3

- SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement Ratio

A measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize.

Ballast / Displacement * 100

Displacement / Length Ratio

A measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more.

D/L = (D ÷ 2240) ÷ (0.01 x LWL)³

- D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort Ratio

This ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more.

Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 )

- D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening Formula

This formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more.

CSV = Beam ÷ ³√(D / 64)

Embed this page on your own website by copying and pasting this code.

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

- Link to search page

- US: +1 (561) 833 4462

- US: +1 (206) 209-1920

- MC: +377 99 90 74 63

Yachts for Sale Location: Moscow

Unfortunately, we currently do not have any yachts in Moscow listed in our inventory. However, our knowledgeable brokers can assist you in locating and acquiring the perfect vessel, even if it's not currently advertised on the market.

Don't hesitate to reach out to our team of experts. They have extensive connections and resources to help you find your dream yacht, tailored to your specific preferences and requirements.

Our know-how: high-quality sailing yacht building

RM Yachts are “composite” as much as the best materials are carefully selected for each part of the boat:

- Plywood for the general structure

- Epoxy stratification for the assembly

- Iron for the keel

- Polyester sandwich for the roof

- And from now on epoxy sandwich for the planking above waterline (1180).

To better visualise our plywood sailboat construction technique, think about a wooden house, with concrete foundations, a roof with tiles and window frames made of aluminium.

RM monohull yachts, available from 30 to 45 feet – approximately 9 to 14 meters –, are in constant development to improve our performance level as well as the quality of our products.

Most of our highly skilled engineers have been with us for almost 20 years, so they clearly benefit from very valuable owners’ feedback when it comes to our sailing yacht building expertise.

- OUR BUSINESS UNITS

- MERTON ENGINEERING

- MERTON CONSTRUCTION

- MERTON REAL ESTATE

- MERTON INVESTMENTS

- MERTON RESEARCH AND DEVELOPMENT

- MERTON RETAIL

Merton Construction

Merton provides full scope of services for commercial, industrial, and public buildings with a firm commitment to safety and timely project completion – i.e. warehouses, shopping malls, hyper/supermarkets, hotels, residential buildings, hospitals, schools, industrial plants, retail complexes, showrooms.

Screening issue fixed after snarling security lines at Honolulu’s airport

HONOLULU (HawaiiNewsNow) - Some relief for travelers out of Honolulu’s airport Tuesday after checkpoint problems snarled security lines Monday.

Officials said issues impacting a screening system have been fixed.

Problems at Checkpoint 3 forced the Department of Transportation to advise flyers to arrive a full three hours before their departure time.

Airport officials told Hawaii News Now all systems are now up and running.

But as always, you should check your flight status just to be safe.

CORRECTION: Two checkpoints in Terminal 2 (highlighted below) are open. There are still delays in screening due to the closure of checkpoints for construction. Some travelers are being bused to Terminal 1 for screening. pic.twitter.com/1LPjYa690i — Hawaii DOT (@DOTHawaii) April 15, 2024

Copyright 2024 Hawaii News Now. All rights reserved.

6 motorcyclists injured, including one critically, after car plows head-on into convoy

Power restored in east Honolulu, but HECO warns longer-term fix will be needed

Kamehameha Schools Kapalama cancels classes after threat circulates on social media

Leaked grand jury transcripts, potential witness tampering could impact Kaneshiro trial

Latest news.

MFD outlines key areas of improvement identified in ‘after-action’ report on devastating wildfires

HNN News Brief (April 16, 2024)

HPD officers respond to Damien Memorial School following ‘possible threat’

First Alert Forecast: Best weather on the planet to linger into the weekend

latest in US News

Trump to visit bodega where clerk Jose Alba was hit with murder...

Soft-on-crime Heastie finally caves on increased penalties for...

NYC bouncer accused of fatally stabbing rowdy patron when bar...

Controversial CUNY Law grad now at helm of radical group gets...

China fueling US fentanyl crisis by subsidizing key chemicals,...

Here's what we know so far about the 7 jurors selected for...

10-year-old girl fatally mowed down by SUV in Brooklyn: cops

NYC parents give failing grade to public school class size law...

Live updates, body of fourth missing construction worker recovered from baltimore’s francis scott key bridge collapse.

- View Author Archive

- Get author RSS feed

Thanks for contacting us. We've received your submission.

The body of a fourth construction worker has been recovered from the site of Baltimore’s horrific Francis Scott Key Bridge collapse.

Salvage teams on Sunday located what they “believed to be one of the missing construction vehicles” that plunged into the water in the collapse last month, WBAL reported. A body was discovered inside the car.

At the request of the family, the name of the victim was not disclosed.

“As we mourn the lives lost and continue the recovery operation, we recognize each missing individual is someone’s beloved friend or family member,” Colonel Roland Butler, Jr., Superintendent of the Maryland Department of State Police, said in a press briefing.

“Along with all of our allied law enforcement partners, we pledge to exhaust the physical and technical aspects of their training while deploying every available resource possible.”

The FBI has opened a criminal investigation into the incident in which a cargo ship slammed into the bridge, causing it to collapse on March 26, senior law enforcement officials told NBC News .

Six construction workers who had been repairing potholes on the bridge were killed. Two of them remain missing.

The investigation will look into the events that led up to the ship leaving the port and a portion of the inquiry will also examine whether the crew knew of any potential mechanical problems making the vessel unsafe in the harbor.

FBI agents have been collecting physical evidence and data from inside the ship relating to moments before, during and after impact.

Everything you need to know about the Francis Scott Key Bridge's collapse in Baltimore

- The Dali, the Singapore-flagged container ship that smashed into the Francis Scott Key Bridge in Baltimore and destroyed it early Tuesday, reportedly lost propulsion and tried to warn officials that it was going to crash, according to a report.

- Six people were unaccounted for, according to authorities. Two people were pulled from the river by rescuers.

- Seven vehicles were missing after falling from the 1.6-mile-long span. Officials are using sonar technology to find the vehicles.

- Videos show power on the ship flickering off, and then on again, shortly before the crash. Watch footage of the bridge’s collapse here.

- A Baltimore resident described how the horrifying collapse of the Francis Scott Key Bridge early Tuesday caused his entire house to feel like it was falling down .

- The Dali was also involved in a collision while leaving the Port of Antwerp, Belgium, in 2016.

Follow along with The Post’s coverage of the Francis Scott Key Bridge collapse in Baltimore.

The probe comes as Baltimore Mayor Brandon Scott announced Monday that the city would be taking “legal steps” to address the bridge collapse.

The city has hired law firms to “launch legal action to hold wrongdoers responsible and to mitigate the immediate and long-term harm caused to Baltimore City residents.”

“The City of Baltimore will take decisive action to hold responsible all entities accountable for the Key Bridge tragedy, including the owner, charterer, manager/operator, and the manufacturer of the M/V Dali, as well as any other potentially liable third parties,” the mayor said in a statement .

The Singapore-flagged cargo ship collided into a support pillar of the Francis Scott Key Bridge.

The bridge snapped and crumbled into the Patapsco River with a livestream of the tragic event showing cars and trucks on the bridge just before impact.

Investigators revealed that the vessel’s lights had suddenly shut off for four minutes before coming back on.

And moments before the collision, dark smoke was seen coming from the ship’s chimney.

President Joe Biden promised he would make rebuilding the bridge a priority, citing the Port of Baltimore’s major economic impact on the region.

The National Transportation Safety Board is also investigating the collapse.

Attorneys representing two of the dead workers and one who survived are also conducting an independent investigation into the crash.

Share this article:

Advertisement

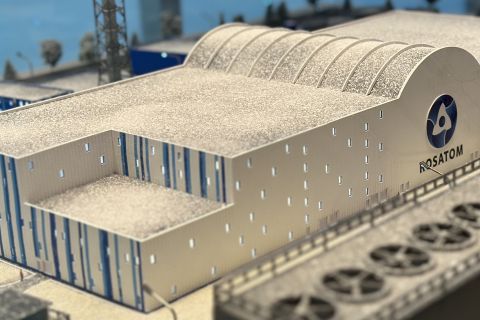

For the first time Rosatom Fuel Division supplied fresh nuclear fuel to the world’s only floating nuclear cogeneration plant in the Arctic

The fuel was supplied to the northernmost town of Russia along the Northern Sea Route.

The first in the history of the power plant refueling, that is, the replacement of spent nuclear fuel with fresh one, is planned to begin before 2024. The manufacturer of nuclear fuel for all Russian nuclear icebreakers, as well as the Akademik Lomonosov FNPP, is Machinery Manufacturing Plant, Joint-Stock Company (MSZ JSC), a company of Rosatom Fuel Company TVEL that is based in Elektrostal, Moscow Region.

The FNPP includes two KLT-40S reactors of the icebreaking type. Unlike convenient ground-based large reactors (that require partial replacement of fuel rods once every 12-18 months), in the case of these reactors, the refueling takes place once every few years and includes unloading of the entire reactor core and loading of fresh fuel into the reactor.

The cores of KLT-40 reactors of the Akademik Lomonosov floating power unit have a number of advantages compared to the reference ones: a cassette core was used for the first time in the history of the unit, which made it possible to increase the fuel energy resource to 3-3.5 years between refuelings, and also reduce the fuel component of the electricity cost by one and a half times. The FNPP operating experience formed the basis for the designs of reactors for nuclear icebreakers of the newest series 22220. Three such icebreakers have been launched by now.

For the first time the power units of the Akademik Lomonosov floating nuclear power plant were connected to the grid in December 2019, and put into commercial operation in May 2020. The supply of nuclear fuel from Elektrostal to Pevek and its loading into the second reactor is planned for 2024. The total power of the Akademik Lomonosov FNPP, supplied to the coastal grid of Pevek without thermal energy consumption on shore, is about 76 MW, being about 44 MW in the maximum thermal power supply mode. The FNPP generated 194 million kWh according to the results of 2023. The population of Pevek is just a little more than 4 thousand, while the FNPP has a potential for supplying electricity to a city with a population of up to 100 thousand people. After the FNPP commissioning two goals were achieved. These include first of all the replacement of the retiring capacities of the Bilibino NPP, which has been operating since 1974, as well as the Chaunskaya TPP, which has already been operating for more than 70 years. Secondly, energy is supplied to the main mining companies in western Chukotka in the Chaun-Bilibino energy hub a large ore and metal cluster, including gold mining companies and projects related to the development of the Baimsk ore zone. In September 2023, a 110 kilovolt power transmission line with a length of 490 kilometers was put into operation, connecting the towns of Pevek and Bilibino. The line increased the reliability of energy supply from the FNPP to both Bilibino consumers and mining companies, the largest of which is the Baimsky GOK. The comprehensive development of the Russian Arctic is a national strategic priority. To increase the NSR traffic is of paramount importance for accomplishment of the tasks set in the field of cargo shipping. This logistics corridor is being developed due regular freight voyages, construction of new nuclear-powered icebreakers and modernization of the relevant infrastructure. Rosatom companies are actively involved in this work. Rosatom Fuel Company TVEL (Rosatom Fuel Division) includes companies fabricating nuclear fuel, converting and enriching uranium, manufacturing gas centrifuges, conducting researches and producing designs. As the only nuclear fuel supplier to Russian NPPs, TVEL supplies fuel for a total of 75 power reactors in 15 countries, for research reactors in nine countries, as well as for propulsion reactors of the Russian nuclear fleet. Every sixth power reactor in the world runs on TVEL fuel. Rosatom Fuel Division is the world’s largest producer of enriched uranium and the leader on the global stable isotope market. The Fuel Division is actively developing new businesses in chemistry, metallurgy, energy storage technologies, 3D printing, digital products, and decommissioning of nuclear facilities. TVEL also includes Rosatom integrators for additive technologies and electricity storage systems. Rosenergoatom, Joint-Stock Company is part of Rosatom Electric Power Division and one of the largest companies in the industry acting as an operator of nuclear power plants. It includes, as its branches, 11 operating NPPs, including the FNPP, the Scientific and Technical Center for Emergency Operations at NPPs, Design and Engineering as well as Technological companies. In total, 37 power units with a total installed capacity of over 29.5 GW are in operation at 11 nuclear power plants in Russia. Machinery Manufacturing Plant, Joint-Stock Company (MSZ JSC, Elektrostal) is one of the world’s largest manufacturers of fuel for nuclear power plants. The company produces fuel assemblies for VVER-440, VVER-1000, RBMK-1000, BN-600,800, VK-50, EGP-6; powders and fuel pellets intended for supply to foreign customers. It also produces nuclear fuel for research reactors. The plant belongs to the TVEL Fuel Company of Rosatom.

Rosatom obtained a license for the first land-based SMR in Russia

On April 21, Rosenergoatom obtained a license issued by Rostekhnadzor to construct the Yakutsk land-based SMR in the Ust-Yansky District of the Republic of Sakha (Yakutia).

ROSATOM and FEDC agree to cooperate in the construction of Russia's first onshore SNPP

ROSATOM and FEDC have signed a cooperation agreement to build Russia's first onshore SNPP in Yakutia.

Rosatom develops nuclear fuel for modernized floating power units

Rosatom has completed the development of nuclear fuel for the RITM-200S small modular reactor designed for the upgraded floating power units.

IMAGES

VIDEO

COMMENTS

Welcome to RM Yachts! French sailboat manufacturer since 1989, our shipyard based in La Rochelle is specialised in the construction of fast cruising yachts of 30ft to 45ft in plywood and epoxy - approximately 9 to 14 meters. Whether you are looking for a coastal cruising sailboat, or planning longer open sea trips, such as Atlantic, Pacific ...

RM Yachts' plywood-epoxy sailboat construction technique. RM Yachts has over 30 years of experience as a French sailboat manufacturer. One of the originalities of our modern cruising yachts is that they are made using plywood, which is assembled on a jig. Our plywood is made in France and comes to us from a factory which supplies laser-cut ...

RM Yachts: learn more about our sailing yacht building technique. Over 500 monohull sailing boats built in plywood-epoxy in our French shipyard (30 to 45 feet). ... To better visualise our plywood sailboat construction technique, think about a wooden house, with concrete foundations, a roof with tiles and window frames made of aluminium. ...

How are RM Yachts built? It's a question that has often been asked, and we did our best to answer it in this video. Martin Lepoutre, General Manager, and Edo...

about rm yachts Our know-how: high-quality sailing yacht building RM monohull yachts, available from 30 to 45 feet - approximately 9 to 14 meters -, are in constant development to improve our performance level as well as the quality of our products. our know-how LA CONSTRUCTION BOIS/CONTREPLAQUÉ La méthode de construction des voiliers RM en … Continue reading "RM Yachts"

RM Yachts: French plywood sailboat manufacturer. Modern monohull sailing yachts from 30 to 45 ft (fin keel, twin keel, lifting keel) for all sailing projects. ... our shipyard based in La Rochelle is specialised in the construction of fast cruising yachts of 30ft to 45ft in plywood and epoxy - approximately 9 to 14 meters. Whether you are ...

When RM was founded in the late 1980s it ploughed a somewhat lonely furrow in producing plywood yachts with an outer layer of epoxy and glass to provide excellent impact resistance. However today, an increasing number of boatbuilders and owners understand the advantages of this type of construction.

Bienvenue chez RM Yachts ! Constructeur de voiliers français depuis 1989, notre chantier est spécialisé dans la conception de voiliers de croisière rapide en contreplaqué-époxy , de 9 mètres à 14 mètres (de 30 à 45 pieds). Que vous recherchiez un voilier de croisière côtière, un bateau pour traverser l'atlantique en solitaire, ou ...

Overview. RM Yachts of La Rochelle build a range of fast, light displacement, passage making cruising yachts. Constructed in marine plywood/epoxy with grp decks for weight reduction and enhanced performance, hard chined directional stability, they all feature large aft cockpits, wide side decks and cutter rigs.

RM 1180: our 39 ft sailboat for offshore sailing (ocean crossing, world travel, etc.). Monohull sailing boat, plywood construction, modern interior.

For the past 30 years, Marc Lombard Design team and the RM Yachts engineering team have been conceiving legendary and head-turning sailing yachts, all contributing to the French shipyard's reputation. The RM1380 is, somehow, the culmination of our efforts, and probably our most remarkable achievement. A 45-foot sailboat made of plywood-epoxy ...

Originally called Sysba Marine, RM Yachts of La Rochelle build a range of fast, light displacement, passage making cruising yachts. Constructed in marine plywood/epoxy with grp decks for weight reduction and enhanced performance, hard chined directional stability, they all feature large aft cockpits, wide side decks and cutter rigs. Boats have either twin keels with single rudder or single ...

New customers are positioning themselves for 2021. The goal is to restore confidence with an objective of 8Meuros in 6 years, by returning to what was done in the past. To do this, we need to promote the high quality of the construction methods of RM yachts to boaters, so that they can charge a fair price without having to make large discounts.

RM 1380 will feature a bright interior with plenty of natural light. Piaton Design has styled the bright interior, which looks like it has bountiful natural light. It is offered as a three cabin ...

The creases in the hull, which result from the special construction method, are typical of RM Yachts. The yacht builders in La Rochelle traditionally produce boats with a plywood hull and GRP deck, which is a unique selling point in this market segment. Like all RM boats, the new 1380 is supplied with chine keels and a rudder blade as standard ...

In sheer numbers: One meter of the RM 970 does come in at some 14.900 Euros. A Pogo 36 will be slightly cheaper, 14.700 Euros. The Dehler 34 will come in at 12.000 Euros per meter, the Oceanis 35.1 at 10.800 Euros. So there´s the difference, some 25 to 30 per cent to the production boats. Perfect yacht.

RM 1050 is a 34′ 4″ / 10.5 m monohull sailboat designed by Marc Lombard and built by RM Yachts between 1998 and 2011. Great choice! Your favorites are temporarily saved for this session. ... Construction Multi-chine ply w/FG ...

RM Yachts for sale on YachtWorld are listed for a swath of prices from $173,687 on the moderate end of the spectrum, with costs up to $226,879 for the most luxurious yachts. What RM Yachts model is the best? Some of the best-known RM Yachts models now listed include: 1260, RM 1200 and RM 1350. Various RM Yachts models are currently offered for ...

Tailored Solutions for Yacht Marketing; Superyacht Sales - Featured Yachts Sold; Sale Inquiry; Build. New Yacht Construction; Design & Build a Yacht. Design Studio; Yacht Designers & Naval Architects. Yacht Designer Adam Voorhees; Yacht Designer Ivan Erdevicki; Naval Architect Sergio Cutolo; Vripack Yacht Design; Luxury Yacht Builders Shipyards

RM Yachts: learn more about our sailing yacht building technique. Over 500 monohull sailing boats built in plywood-epoxy in our French shipyard (30 to 45 feet). ORC 50; ORC 57; ... To better visualise our plywood sailboat construction technique, think about a wooden house, with concrete foundations, a roof with tiles and window frames made of ...

Merton Construction. Merton provides full scope of services for commercial, industrial, and public buildings with a firm commitment to safety and timely project completion - i.e. warehouses, shopping malls, hyper/supermarkets, hotels, residential buildings, hospitals, schools, industrial plants, retail complexes, showrooms. Merton International.

RM-BETON, OOO Company Profile | Elektrostal, Moscow region, Russian Federation | Competitors, Financials & Contacts - Dun & Bradstreet

Lines are extra long for TSA screening at the Honolulu airport. The Department of Transportation says departing passengers should arrive three hours before their flight. We're told two ...

02:19. The body of a fourth construction worker has been recovered from the site of Baltimore's horrific Francis Scott Key Bridge collapse. Salvage teams on Sunday located what they "believed ...

To increase the NSR traffic is of paramount importance for accomplishment of the tasks set in the field of cargo shipping. This logistics corridor is being developed due regular freight voyages, construction of new nuclear-powered icebreakers and modernization of the relevant infrastructure. Rosatom companies are actively involved in this work.