- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Pearson Rhodes 41/Rhodes Bounty II Used Sailboat Review

Hallberg Rassy 42 Used Sailboat Review

How to Perform Your Own Pre-Buy Inspection

Beneteau 323 Used Boat Review

How Does the Gulf Stream Influence our Weather?

Can You Run a Marine Air-Conditioner on Battery Power?

Preparing Yourself for Solo Sailing

Your New Feature-Packed VHF Radio

Practical Sailor Classic: The Load on Your Rode

Anchor Rodes for Smaller Sailboats

Ground Tackle Inspection Tips

Shoe Goo II Excels for Quick Sail Repairs

What Oil Analysis Reveals About Your Engine

An Unusual Sailboat Shines a Light On A Sustainable Future

Is It Time to Get an Electric Dinghy Motor?

Bottom Paint 30-Month Update

Battle of the Teak Cleaners — Snappy Teak-Nu vs. Star Brite

New Seacocks for the Offshore Sailor

Bottom Paint Care

Are E-bikes Worth the Extra Weight and Cost?

How to Handle the Head

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Re-sealing the Seams on Waterproof Fabrics

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

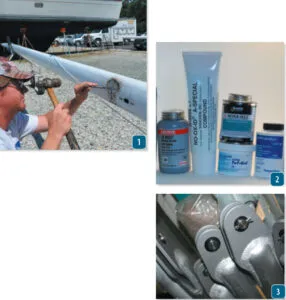

Revive Your Mast Like a Pro

Each spar section has unique signs of trouble to look for during inspection..

Unobtainium is the metal at the top of every Naval Architect’s wish list. It’s a perfect marine material; light, strong, stiff yet flexible—it’s as inert as gold, but costs only pennies per pound. Sadly, like the search for El Dorado, this metal quest remains more alchemy than chemistry.

For now, aluminum, especially the alloy 6061-T6, is the solid performer. It singlehandedly upstaged spruce as the mast material of choice, and for decades it’s done its job admirably. The alloy isn’t perfect, but by understanding its vulnerabilities, and mitigating those negative characteristics, the functional lifespan of an aluminum spar can be measured in decades not years.

Yes, carbon fiber spars are in many ways the next step forward. But for those intent on being cost effective and not in the hunt for a few tenths of a knot increase in boat speed, aluminum remains the cost effective alternative. In a future issue we’ll focus on carbon’s influence on spars, hulls, rigging, and sails.

Most metal masts are made from long, cylindrical billets of aluminum alloy. Each tube section is created using a powerful ram to force a heated billet (400-500 C) through a set of dies that squeeze and shape the billet into the cross section and wall thickness of a specific spar. Lots of lubricating release agent and 15,000 tons of ram pressure are used to reshape the malleable aluminum.

Billet residue is captured and recycled, while the tube shape undergoes quenching as it moves off on the runout table. The next stop in the line involves a process that draws (pulls) and straightens the tube section.

Once fully cooled, it goes through a T6 heat tempering process that elevates tensile strength from 35,000 to 45,000 psi. Lastly, spars can be anodized, painted, powder coated, or left uncoated. Some masts are extruded in half sections and machine-welded together lengthwise.

There are other aluminum alloys that are better suited to welded hull construction or used for metal casting purposes, but 6061-T6, containing small amounts of silicon, magnesium, and other trace elements, delivers the strength, stiffness and lightness that’s vital when it comes to making spars.

The “T6” alloy is weldable, but doing so anneals and weakens the area that’s welded. This is one of the reasons why, when splicing two sections together, a doubler is added internally that overlaps the junction. Excess heat buildup during the plug welding process that joins the sections is kept to a minimum. Some manufacturers mechanically fasten the junction using machine screws or heavy duty pop rivets.

Unfortunately, aluminum isn’t quite the sequel to tomorrow’s Unobtainium . Aluminum, like steel alloys, show a proclivity to oxidize. But in the case of most steel alloys, oxidation is an ongoing process that only reaches completion when the object in question has become an unrecognizable pile of rust.

Bare aluminum, on the other hand, reveals a very different oxidation curve. A shiny new piece of aluminum develops a speckled, gray, oxidized coating that actually becomes a protective layer, preventing further oxidation. Ironically, this means that the ugliest looking mast in the marina, that non-anodized, unpainted one with the aesthetic appeal of dirty socks, is about as well protected from further deterioration as the spar on the gold-plater with the automotive finish. This is the reason why most commercial mariners restrain from painting the deck and topsides of their aluminum workboats.

The root cause of this aesthetic injustice is the way moisture, especially salt water, finds every microscopic void or coating imperfection and causes aluminum to oxidize around voids and spread beneath the paint layer. By the time blisters appear and paint begins to flake, the sub surface is covered with aluminum oxide and starting to pit.

There are several ways to tame the effect of chloride-rich seawater. But when it comes to a failing painted surface, thorough prep work is essential. Modern epoxy primers help hold corrosion at bay, and single and two-part urethane coatings seal the surface. Hard-anodized or powder coated spars are even better protected, but cost more and are more complicated to refinish when they finally fail.

GALVANIC CORROSION

Galvanic corrosion is aluminum’s second major nemesis, and it stems from an electrical interaction rather than oxidation. Metals are rated on a galvanic corrosion scale that places less reactive (more noble) metals at one end and more reactive (less noble) ones at the other end.

Platinum, beryllium and magnesium lean against one of the bookends of this scale. Magnesium, a plentiful element, is strong and light, 35 percent lighter than aluminum, but way too reactive in the marine environment. Platinum and gold sit at the opposite bookend of reactivity and are so inert that all other metals become anodic in their presence. The metals that lie in between these are relatively ranked according to their behavior in an electrolyte such as seawater.

When it comes to marine applications, there aren’t many platinum thru hulls, but silicon bronze is a pretty good compromise between cost and corrosion resistance. It’s rank on the galvanic scale is toward the more noble end and it behaves as a cathode to less noble metals like zinc, brass, and aluminum, which become anodes in the proximity of more noble metals.

Unfortunately, when dissimilar metals are in direct contact, all it takes is a little rain or morning dew to set up a temporary galvanic cell. Salt spray finds all the nooks and crannies on a sailboat and as the water evaporates it leaves behind crystalized sodium chloride (NaCl). Each raindrop, wave splash or drop of dew rehydrates the electrolyte. And as every galvanic cell demonstrates, wherever two or more dissimilar metals are immersed, a current flows and the less noble material (anode) corrodes causing electrons to flow toward the more noble metal (cathode). The net result is pitting and eventual destruction of the anode.

This prolonged, double-barrel assault on an aluminum spar is most noticeable in areas where dissimilar metals make contact.

There’s an old superstition about putting a couple of silver or copper coins under the mast step, just before stepping the spar. It may have been a good luck charm in the days of iron men and wooden masts. But today, placing a copper penny or silver eagle in a wet mast step completes a highly reactive galvanic cell and creates a corrosion experiment of the first order. The right answer is to do everything possible to separate dissimilar metals. Putting a Delrin strip or dielectric PTFE tape between the hardware and the mast wall really helps.

When installing larger stainless steel hardware on a mast, it’s easy to cut out a gasket from a sheet of 30 mil thick Teflon. Also be sure to use Tef-Gel or a similar dialecrtic grease or sealant on all screw threads.

MAST INSPECTION

Once the mast has been unstepped, positioned horizontally on horses and the headsail furling gear removed, it’s time to take a close look in all the nooks and crannies where things can go wrong. I prefer a bottom up approach and group the mast into four related subsets: base, column, spreaders, and masthead. If the mast is going to be painted, postpone this DIY inspection until all the rigging and hardware has been removed. In either case, scrutinize the spar, hardware and rigging attachment points, especially where high loads are focused.

It helps to have a good magnifying glass, a pick, knife and small scraper on hand to expose and inspect oxidized areas. Place a piece of contrasting color masking tape on each point of concern as you progress toward the masthead. Once the inspection is complete, use a digital camera or smartphone to document the more serious issues. These snapshots provide a record of the location and extent of all corrosion, deep pitting and any cracks emanating from fasteners or hardware. Also record all dents or other impact damage and any sign of ongoing abrasion. Serious damage can be caused by misled wire running rigging and the cycle loading wear linked to variations in tension. Naturally, all standing and running rigging should be thoroughly inspected at this time— a topic of a future article.

AT THE BASE

Keel-stepped masts aboard many cruisers and racers are hidden below the cabin sole and reside in a wet, corrosion prone, bilge ambiance. And it’s another reason why, when a mast is unstepped, the entire support structure, step and the heel fitting deserve a close look. Check for signs of corrosion and make sure the hardware that fastens the heel fitting to the grid or other transverse and fore-and-aft support is in good shape. This structure supports compression loads and also must respond to changes in backstay tension and side loading, not to mention the shock loads of a beat to windward in heavy seas. This is also the time to do what I call spar-oscopy. Take a compact LED flashlight and tape it to the end of a long, thin PVC tube or bamboo fishing pole that will be used to look at the mast interior.

This jury-rigged light on a pole, allows you see signs of internal corrosion and gives you a chance to locate abrasion points where halyards have been misled or are rubbing on hardware. A narrow spot beam will illuminate much of the inner wall of the mast, and if the running rigging has been replaced with thin messengers and the spreader “dog bones” (cross connecting supports) have been removed, you will have a clear sight line up the spar. This is a good time to sort out any halyard overlaps.

Riggers also look for an ailment called “elephant foot.” It’s a descriptive name for the partial crumpling of the spar near the base of the mast, It’s caused by over-compression and/or a wall section that is too thin. This wrinkling is usually just above the mast step, and it indicates a condition just shy of complete failure. It can be linked to prolonged ponding to windward with excessive backstay tension and overpressuring mast jacks. In some cases a new section can be spliced into the spar. By if it’s an older mast and other significant signs of deterioration are present, it may be time to opt for a new spar. Don’t bet the farm on an “it hasn’t failed yet” assumption; hire a skilled rigger to advise on the tough calls.

At first glance, the mechanical challenge linked to stripping hardware from a mast seems rather simple. All you need are a couple of screwdrivers and you’re ready to go. Unfortunately, the gods of galvanic corrosion have placed another obstacle in the sailor’s way.

The threads of those stainless steel screws attaching hardware to base plates or to the mast wall itself have become so corroded they are likely to be screwdriver-proof. Part of the blame goes to original hardware installers, who gave little attention to coating threads with an anti-seize compound and the effect it would have on future maintenance.

So after some years or decades, when it’s time to see what lies underneath the hardware, my first step is to clean all oxidation, paint and grime away from the screw slots and make sure that the chosen screwdriver fills the entire slot. A snug fit is the goal. Then, if a good counter clockwise twist fails to elicit any rotation, it’s time to add a wrench to the screw driver and deploy a good deal more torque.

If this also fails to loosen the bugger, I go to plan B before I ruin the screw slot. Step one is to use a pick to scrape away oxidation around the screw head perimeter. The next step is to douse the area with a penetrant such as PB Blaster, CRC’s Ultra Screwloose, Knocker Loose Plus, Gasoila Free-All or a similar product (see Inside Practical Sailor blog post, “More Boat Tips: Unsticking Stuck Nuts and Bolts”).

Before once again applying torque to the problem, I spend some time using a drift pin and a small ball-peen hammer to tap each chemically soaked fastener. Afterwards I add more penetrant around each screw head. Instead of immediately reverting to a brute force approach, which more often than not leads to a broken fastener or a damaged screw slot, I let the penetrant do its thing and return the next day with my portable impact driver and assortment of screw driver bits. The small Makita impact tool applies a pulsing torque. Combined with a little penetrant and a lot of patience, I’ve found this tool to be very effective on stubborn fasteners. Screw diameters of ¼ inch or less are not hard to snap so use pulsing torque is far better than more leverage and brute force.

If the screw slot is damaged it’s time to switch gears and be ready to drill out the head of the screw and pull the hardware off the remaining stud. A stud remover fitted to a socket wrench works better than vise grips when it comes to backing out a headless screw. But it requires a half-inch or more of the screw stem to be exposed.

The secret to drilling off the damaged head of a screw involves the use of a drill bit made for stainless steel. Place it in the chuck of a low-speed drill that delivers ample torque at slow speeds. Those using a dull bit and a high-speed drill are likely to work-harden the stainless steel screw head, making it even harder to drill. Applying cutting oil that both cools and lubricates a bit will make drilling more effective.

ALONG THE COLUMN

A sailboat mast is like a long electrical fuse: one bad spot and the show is over. Critical failures are usually linked to standing rigging failures and can occur at toggle or tang attachment points, on the spar itself or at spreader tips and roots. Upper shroud tang fittings, near the masthead, need a close look. Check clevis pin holes for elongation and Tball or stem ball cups for deformation.

Sight along the open spans of the spar, where no hardware is attached. It should be free of abrasion marks and signs of halyard shackle damage. It’s surprising how many painstakingly applied paint jobs are ruined by halyard slating cause by poorly set halyards. During this part of the inspection also check exit sheaves, winch bases/pads, mast steps, the bow light, radar bracket and other attached hardware.

The gooseneck fitting and boom vang points of attachment are highstress areas and prone to developing stress cracks. Just below this union, forces converge at the mast partners, the reinforced area where a keelstepped spar passes through the deck. Check here for stress-related damage as well as corrosion issues. If you find signs of extensive pitting or stress cracks, a cosmetic repair can be more harm than help. Have a local rigger with a good reputation take a close look at what you have uncovered.

The mainsail mast track should be straight and the slugs, slides or cars that run in or on them should slide freely. Take an extra slide or car and hand test the track, identifying any points where friction increases. Problems are often caused by burred or dented metal, oxidation in an internal track or misalignment at track joints. Most of these issues are easy to resolve while the spar is horizontal and access is optimized. In-mast or in-boom furling systems each have an inspection and maintenance routine outlined by the manufacturer. Maintaining optimum reliability revolves around following these guidelines. Care should be taken to avoid keeping paint and primer from hampering track function.

Search for causes of abrasion, eliminate the dings and dents from halyard shackles by solving lead problems. And be on the lookout for hairline cracks emanating from fasteners on the leading edge of the mast. Modern spar design accounts for backstay tensioning that induces bend in the mast to adust headsail shape. This bending results in an intentional tension increase on the spar’s leading edge, adding new stress to a column already in compression. Small cracks emanating from fasteners on the leading edge of the mast can be enlarged as the mast is intentionally bowed.

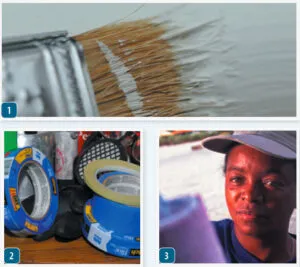

Every sailor who’s painted anything on their boat has plenty of tips to share. But when it comes to useful insider advice, pay more attention to the pros who have learned what works over many years. The good news is that although paint brand allegiance may vary, generic mast prep and painting techniques have a high degree of correlation.

When it comes to the first step in the prep process, every expert sings the same refrain. Remove the hardware if possible, especially if there’s any sign of blistering or paint failure around the edges. If there’s no sign of any corrosion at all, and the fasteners are likely to snap rather than release, carefully prep and tape around the hardware.

Sand, wire brush or sand/soda blast all areas where corrosion has pitted or left the surface covered with white aluminum oxide. Take a close look at the heel of the mast and the mast step itself. Both need to be free of corrosion and not damaged by metal loss or physical damage. The same goes for the area where spreaders, stays and shrouds attach. The masthead fitting also deserves close scrutiny. Inspect the aluminum around where the sheave axle(s) attach. A corroded aluminum masthead truck, with deterioration around the support for headstay or backstay toggles, can spell disaster. This corrosion inspection is a good time to catch pending problems.

In most cases, OEM painted spars hold up quite well, especially those that have been carefully prepped, epoxyprimed and LPU top coated. Eventually, weathering causes the gloss to disappear, but the paint retains excellent adhesive quality. If you’re facing such a challenge and there’s little or no sign of physical damage or corrosion around hardware, there’s nothing wrong with simply renewing the top coat.

In such cases, begin with a wash and/ dewax cleanup, sand with 220/320, remove dust, tape off hardware, solvent wipe and apply of two coats of the same (or similar type) topcoat, scuff-sand between coats.

However, if there are dings, scrapes or areas where corrosion has damaged the coating or areas where paint adhesion is failing, a decision must be made between spot repairs and complete mast redo. The latter involves removal of most or all of the hardware and stripping off every bit of the old paint. A spot repair approach is much less labor intensive, but if corrosion is rampant, spot repairing can be counterproductive.

During the prep process it’s essential to clean and degrease the surface before doing any sanding or other abrasive work. I prefer to use the solvent/cleaner of the paint manufacturer I’ve chosen. Clean cotton rags work best, and by meticulously wet wiping the surface you eliminate contaminants that can be forced into the substrate during sanding.

In the case of a repair and recoat effort, once the corrosion and flaking paint have been removed, feather in the adjacent painted mast surface with 60- 80 grit paper to achieve a toothy grip for the epoxy primer that follows. When doing a spot repair, this taper zone becomes an important test of one’s ability to feather an edge and hide the old to new paint junction. Seamless blending of the primer sets the stage for a successful, smooth transition spot repair. If, as you sand the boundary, the old paint continues to flake rather than allow you to feather the edge, It time to switch gears and consider removing all the paint.

An important step in painting aluminum is to get an epoxy primer on a freshly sanded and clean surface as soon as possible. When painting an entire spar, It helps if you can set up a way to hang the mast at waist level so it can be rotated in order to access all surfaces efficiently.

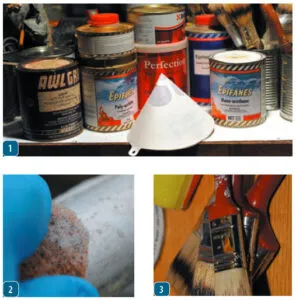

PRODUCT UPDATE

Interlux recommends doing the degrease wipe down with their 202 Solvent Wash prior to sanding. Then prime the spar using their InterProtect 2000E/2001E, thinned 15-20% with their brush or spray reducer. It’s a user friendly epoxy primer and easy to sand. Two coats makes the 60-80 grit sanding marks disappear. Both single-part Bright Sides and two part Perfection deliver a smooth glossy finish. The former is easier to apply and the latter is more durable and long lived.

Pettit offers a complete lineup of aluminum paint and prep products. Their approach kicks off with a solvent clean and a medium grit emery cloth sanding. When the residue has been removed, a thin coat of #6455 Primer should be applied. Two hours later, EZ Prime #6149 is applied and when it’s cured and sanded with 220 (repeat if necessary). Finish with two coats of Easypoxy.

Awl Grip recommends an initial cleaning with their surface cleaner T340 followed by a vigorous Scotchbrite scrubbing with Deoxidine and a thorough rinse to remove all residue. When dry prime with 30-Y-94 and within 3-6 hours, without sanding, apply 545 epoxy primer. Sand 220/320 and top coat with Awl Craft 2000.

If the spar was previously anodized precede the above with a 10-minute wash using a 33% solution of natrium hydroxide. Don’t let the solution dry on the spar. Immediately water-rinse and follow the prime and paint process above.

Spreader junctions are like a dangerous highway intersection, a point where competing forces interact and where there are no traffic lights to tame the flow. Rigging tension on the windward side of a sailboat cause compression loads to increase in the windward spreader(s) and decrease in the leeward spreader(s). Discontinuous standing rigging optimizes wire/rod diameter in each panel section, but it also complicates spreader tip hardware. All too often, spreader boots or a well-meaning taping effort, ends up looking like a response to an ankle injury. Even worse it creates a moisture-holding corrosion bath that enhances galvanic corrosion and oxidation. The goal is to avoid going overboard with padding and tape and making sure that water will not collect around spreader tip hardware.

Spreader bases are another realm of serious concern due to cycle loading, multidirectional forces and dissimilar metal contact. Swept back spreaders, especially those that eliminate the need for a backstay, cope with even greater loads. So when the rig is un-stepped, check how the spreader attachment was engineered. Was a doubler added to the mast wall and/ or were cutouts installed and hardware added to connect spreader pairs? In either case, corrosion in key load path areas can greatly decrease the spar’s ability to cope with the fluctuating loads. It’s no surprise that masts often break just above a set of spreaders.

AT THE MASTHEAD

Once launched, it’s hard to see what’s going on at the masthead. This means that when the spar is down it’s time to get a really close look at the mast truck and its associated fittings. Begin by disconnecting the standing rigging and checking the geometry of every hole that supports a clevis pin. The rule of thumb is: round is good, elliptical is bad. This goes for the tangs that connect upper shrouds to the spar as well as the holes in a welded aluminum masthead fitting. The loss of an upper shroud while beating to windward usually brings down the mast, so extra attention in this area is time well spent.

Carbon spar manufacturing mimics the engineering pioneered in the aerospace industry. They have become an essential component In the most competitive ranks of sailboat racing and caught on with cruising sailors who own lighter, more performance oriented sailboats.

Most spars are built on metal mandrels by carefully aligning layers of prepreg unidirectional and multi-axial carbon fiber from masthead to heel. Intermittently, a debulking process is used to squeeze the layers together, and after the laminate schedule has been carefully aligned, it’s placed in an autoclave. Here the epoxy prepreg in the carbon material becomes viscous and cures under controlled heat and air pressure. These materials are expensive, the labor is time-consuming and the quality control must be rigorous.

One of the major advantages of carbon mast building is the ability to engineer the layup to coincide with the load paths and stresses in the structure. Finite element analysis has helped identify how and where forces are transferred through the tube section. Weight is saved by only adding material where it is needed.

A cruising boat designer may opt for extra reinforcement that increases the safety factor by raising the breaking point of the material. Racing sailors have validated the performance uptick associated with carbon spars. Carbon/epoxy laminates do not suffer from corrosion but they are anything but immune to UV light. It’s one of the reasons a white primer and LPU topcoat is the sensible finish.

Minor impact damage and abrasion from poorly led running rigging is fairly straight forward to repair. But damage linked to sailing loads that cause major cracks in the laminate or interlayer delamination is another story altogether. In these cases, the spar builder or a composites shop engineer has some tough decisions to make. The big challenge is when a high-tech laminate bundle fails it’s very difficult to scarf in a new section that will handle all the loads in a manner that’s equivalent to, let alone, better than new. Some insurance companies put restrictions or higher premiums on coverage of carbon masts.

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

What Is The Best Folding Bike For Your Sailboat?

The No Expense Spared Antigua 60 Cruising Sailboat Soolaimon

How To Buy Sails – With Joe Cooper

Bavaria C42: What You Should Know | Boat Tour

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- International Marine Coatings

- International Protective Coatings

How do I paint my anodized aluminum mast?

It is difficult to paint over anodizing. If it is in very poor shape remove it before painting. To paint anodized first degrease using Fiberglass Solvent Wash 202. Then give it a heavy sanding using 60 or 80-grit sandpaper. Apply one coat of InterProtect 2000E (Thinned 15-20% with 2316N Reducing Solvent). Allow to dry overnight and apply a second coat of either Epoxy Primekote (thinned 25%) or Pre-Kote primer. Sand and apply Perfection (if using Epoxy Primekote) or Brightside (if using Pre-Kote).

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

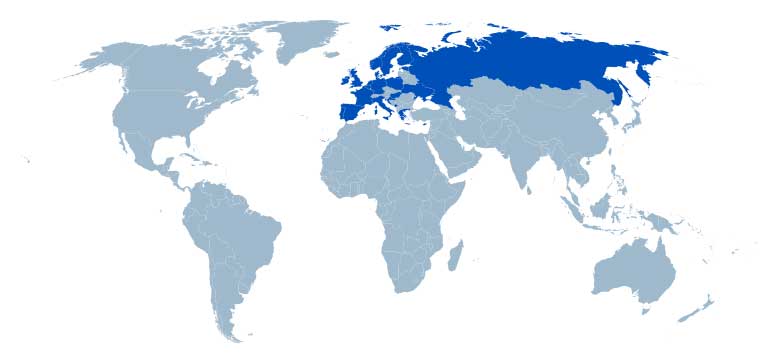

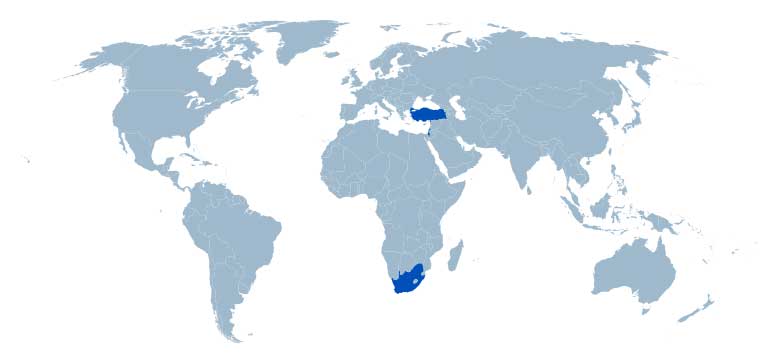

Select your country

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Repainting mast and boom

- Thread starter Dalliance

- Start date Mar 18, 2008

- Forums for All Owners

- Ask All Sailors

The spars on my 1982 Hunter 30 were originally painted white by the manufacturer. Over the years the P.O. added a couple additional coats and last summer all three, but mostly what remained of the 26 year old original coat, started peeling badly - exposing bare aluminum. At haul out last fall I unstepped the mast with the intention of stripping and repainting it myself this spring. Then I did the research I should have done first and realized it's a bigger job than I will have time to take on myself this year, so I got a cost estimate for the work today from Lakeshore Marine. They were recommended by the yacht yard. It's good I was sitting down at the time because it's a bit more than I expected. $4,616.17 to be exact. They propose to chemically strip, etch, prime and paint the 40 foot mast, boom & spreaders with Awlgrip. The breakdown is $3,570 for 42 hours labor @$85/hour, $959.79 for supplies & materials, and $86.38 tax. At that price, it won't happen this year. Or next. Oh well, it's a good time to give the standing rigging a good inspection anyway. So, that said, I have three questions for everyone: First, does this sound like a reasonable, fair price for this work? Second, is Awlgrip the right choice or is it overkill for this job? And third, can any of you recommend someone less expensive in the Chicago area?

You can probably get it anodized for less than that.

Rich (P303)

sounds about right... for a boatyard... your getting screwed @ 85 an hour. Somebody will go out there and tell the High School kids what to do... until it's time for the awlgrip. I would go the anodized route... if you can find someone that can handle that length. Sounds like a project.

Big Job James - Thats about right. It took me about 4 weekends to do the job myself not counting the evenings I put in disassembling and reassembling my boom in the basement over the winter. Sanding and paintings is actually the easy part.....disassembling and reassembly takes a lot of work and detail. I used imron which is similar to Awlgrip - but you will find many opinions on that (both 2-part types coatings). I also replaced all the wiring and hardware which added extra time to the project so perhaps you can do it in less time. I am not familiar with anodizing as mentioned here. My recco if your going to use paint and DIY - go for a quality 2-part paint and just roll-n-tip it on. You will give up some of the shine but it will be minimal. Its a mast / boom - not a hull where you would really want a wet-finish shine. Good luck - Rob

Mast/boom maintenance When the boom on my O28 started exhibiting signs of deterioration, I removed it, took it home, wirebrushed the daylights out of it after removing as many fixtures as I could, wiped it down with acetone and hit it with an aluminum outdrive spray primer paint, then gave it two coats of off-white rustoleum. I don't remember the total cost, but it held up for at least the three years until I sold it. FWIW, Bill Coxe, O40 Kukulcán, New Bern, NC

New Mast? I did mine last year when I had the rigging replaced. Decided to do it myself after an estimate similar to yours. Did it in 3 weekends but it was a LOT of work. Halfway through the job my rigger suggested that it would cost about the same to replace with a new mast and I would end up with a new spar. I didn't check on price but he said he has replaced several for about the same price (or even less ) than having the yard do the painting. Might be worth a check. Down time would probably be a factor.

Joseph Shirley

I did my mast last year I had to unstep my mast to truck my boat back from Mexico and thought it was a good time to redo the paint job on the mast since it hadn't been done in 10 years. The boat yard at that time had a rate of $65/hr and I winced at their estimate. Fortunately for me they were extremely busy and their mast paint shed was stuffed with stuff so they suggested that I do all the prep work which I did. They ended up just spraying the mast with Sterling (similar to Awlgrip) and it only cost a few hundred dollars. My problem was that they didn't finish there part of the deal for almost 3 months which cost me most of the sailing season. I was unhappy at the time but feel a little better about it now that some time has passed and it still looks good. See if they will let you do the prep. A few days, A couple of gallons of paint remover, some sandpaper, some tarps, and a few beers and sandwiches for some help, could save you a bundle.

You can save a lot if ... you do it yourself. Having the time and the place to do it is a big factor, though, and you will have to pay for those commodities if you don't have them. I'm assuming that transporting a 40' mast to your basement is a problem. When I did the job, I was able to get our 33' mast home to do the job and it took at least the 42 hours that they quote; but, I expect that they could be much more efficient with their time. What if you took the boom and the spreaders home and did them yourself ... that could save something. I guess I would start out by asking a lot of questions. Will they let you remove all the hardware and sand (I sanded rather stripped the old paint off)the spars? Maybe you can cut down on the hourly rate if you can do the prep work. Like somebody said, much of the work will take no skill so maybe there could be some negotiation on that end of the work. Having said that ... are they removing all the hardware rather than painting around it? I would clarify that. There were some parts that were rivited on to the mast and boom with some pretty substantial stainless steel rivits and I really didn't want to mess with that so I took the short cut and worked around those few parts (the spreader ears and the vang attachment). I would expect that they would be prepared to remove them but I would ask the question just the same. Will they fix the hours or is it just an estimate? They could easily spend more hours doing this job, especially if they use cheap, inefficient labor for the prep work. You don't want to be paying $85 per hour when they go over the hours budgeted because the were using some kids that weren't all that efficient. You want to do this with a 2-part primer and 2-part surface paint. I don't know if Awlgrip is the premier product or not. I used Interlux Perfection and love the result. The price for supplies seems way too high. The products are expensive but you don't need that much. You won't need even a quart of the etching primer so that should cost less than $50. You need to spend about $200 for the 2-part primer and surface. I think I got a quart of primer and 2 quarts of Perfection. I had plenty of primer left after 2 coats and I put on at least 4 coats of the surface just to use it up. My memory is a little fuzzy because I bought a quart of each to do the boom one year and it was good for the next year when doing the mast, except that I had to buy another quart of Perfection to finish the mast at about $65 per quart. Unless you are buying other parts or supplies, $900 for paint is about 3 times too much. What else do they need to provide? With your 40' stick, and the boom, I would think that you could get multiple coats of the final product with 2 to 3 quarts tops. I bet you would need only 1 quart of the 2-part primer and 1 quart of the etching primer. I would ask those questions and be armed with the price per quart from any retailer. I WOULD encourage you to find a way to get this job done. The improvement is really noticeable and you will be happy. Failing to get the price down, maybe new spars are a better alternative!

Thanks everyone. This is real good input from a lot of experienced people. I think my next step will be to ask a lot of questions about what I would really be getting for this price and then see were negotiation gets me. It's really helpfull to see your responses before I do that. You've also pointed out several options I had not thought of.

Warren Milberg

A few years ago, I watched the pro's in our yard here on the Chesapeake take a huge mast down off of a Hans Christian. Not sure how long it was, but it looked like a telephone pole when they laid it out on horses near my slip. Since I had to walk by it every time I sailed, I watched the work and progess. They removed all the hardware (lots of it...)and the old paint, then prepped the surface (not sure of the method), then Algripped it in ivory. It looked spectacular. Whenever I see a job like this, I always ask myself if I could (1) do it myself and (2) if so, could I replicate the results. Both answers were clearly "no." I don't know what that job cost, but am sure it was a bundle. But it sure was worth it to whoever the owner was.

not sure why I am replying Scotty, engage the safety shield. Aye, Captain. I used to anodize aluminum tanks. We used an acid that ate into the metal. Two coatings did the trick. You will have to find a place in Chicago that does it to find out what type of acid it was. Believe me, anodizing is a simple job. Why bother? A. You are on a fresh water lake. B. The mast was painted once before and probably still has paint on it. C. Why not lightly sand it and repaint it? D. Lightly sanding will most likely take any anodizing off. Maybe. So if it does, you should only have to do those areas. I'd just wash it and repaint it. You might want to call a few places that powder coat stuff and ask them if they could do a 40' pole or whatever the length is. Or, if you are handy, you could buy the stuff and do it yourself. However, I'd go with two part paint and roll and tip it.

Thanks again - Letterman (and others), anodizing does intrigue me. I like the idea of letting aluminum look like what it is. I was actually hoping to find that the mast was originally anodized and the PO had just painted over it. That was not the case. Hunter confirmed that the mast was orignially painted by the spar manufacturer and was not anodized. Since Dalliance is one of the "Cherubini Hunters" designed by John Cherubini and thought of so fondly by many Hunter owners, I felt that I should stay true to the designer's intent and repaint the mast. That I felt that way is no doubt due to my also being a designer. Though of buildings, not boats. Given the first cost estimate and my limited time available this spring, the light sanding and Rustoleum route is tempting, but I think it would be a short term fix at best since it appears that most of the paint that is failing is the orignal manfacutrer's paint under the others. If the job is really done right, my gut instinct is that the stripping and prep work represents about 2/3 of the project cost and the net difference between anodizing and painting could be nominal. However, if I find that anodizing can really save me money, then forget the designer, I'll have to seriously consider it... And that makes me sound like one of my clients.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Gear & Maintenance

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Why Are Aluminum Mast Painted?

- Add to quote

Why are aluminum mast painted? If you answer to protect from corrosion, then why is the inside of the mast not painted? The interior would get salt spray from all the holes in the mast and would not get the benefit of a rain shower or wash down. Now if the mast is anodized, I could see how that could provide good corrosion protection- and look good for a long time. Paint seems to be just a maintenance problem. My mast is painted, and needs to be repainted. Should I just strip the paint and leave as bare aluminum?

casey1999 said: Why are aluminum mast painted? Click to expand...

Ok, since I do not care about looks, I should just strip all the paint from the mast and leave as bare aluminun? Actually, I think bare aluminum looks better that paint, if paint is there just to look "pretty". I like function over looks, and if a bare aluminum mast functions as well as a "pretty" painted aluminum mast, I would go bare.

Painting aluminum doesn't make a whole lot of sense IMHO. When paint starts to delaminate, water gets underneath and the aluminum corrodes with little chance of the native oxide reforming. I prefer anodization. I suppose paint looks good and if the prep is well done, it can last quite a while, but still... I just had to redo the boom and part of the mast, not a fun job.

Casy, have you looked down the inside of your mast? Have you seen corrosion? How many "holes" do you have? Don't know who built your mast (Charleston? Selden?) but chances are there is some sort of protective coating on it which would be sufficient for the inside (at least when the mast was built.) The exterior of the mast really gets weathered and should be annodized or painted. Scatches in either should be touched up. Stripping the paint would also strip any annodization. Repainting the mast is your cheapest and most effective option. If you have a lot of "holes", I'd tap them and screw in a short shank screw in them (after bedding). Not only do holes weaken the structure, but like you said, can introduce salt spray/fog corrosion into the interior of the mast.

I have looked inside my mast as best I can and see no corrosion. The mast is deck stepped and I can inspect the inside of the base- no corrosion issues. I also have interior haylards (total of 7)- which means quite a few holes (actually slots) both at the top, middle and base of mast. the mast also appears to have many holes (about 1/8 inch diameter) along the first 1/3 of the mast track- I am thinking this might be fore a storm tri sail mast track that was never fitted. As far as the make of the mast, I am not sure, the mast was first stepped in Australia in 1978. There is no name plate or number I can find on the mast. The exterior was originally painted and then painted one time. There are a few areas under the paint where corrosion has formed- nothing significant.

Attachments

I have seen some boats that have bare poles. I believe many are painted to give them a clean finished look for those new boats. I actually plan on repainting mine someday.

There is an anodizing process that imparts color to the metal. So you can have your mast anodized and the looks of painted too. Daniel, check out AAA Custom Anodizing & Metal Finishing. They are in Piney Flats TN and have a tank 39 feet long. I'm not connected with them at all but they did anodize the spreaders and will do some electro polishing on some stainless steel parts for me.

Captainmeme said: There is an anodizing process that imparts color to the metal. So you can have your mast anodized and the looks of painted too. Daniel, check out AAA Custom Anodizing & Metal Finishing. They are in Piney Flats TN and have a tank 39 feet long. I'm not connected with them at all but they did anodize the spreaders and will do some electro polishing on some stainless steel parts for me. Click to expand...

casey1999 said: Why are aluminum mast painted? If you answer to protect from corrosion, then why is the inside of the mast not painted? The interior would get salt spray from all the holes in the mast and would not get the benefit of a rain shower or wash down. Now if the mast is anodized, I could see how that could provide good corrosion protection- and look good for a long time. Paint seems to be just a maintenance problem. My mast is painted, and needs to be repainted. Should I just strip the paint and leave as bare aluminum? Click to expand...

I like the look of red hulls, not sure about red masts. Call me a traditionalist, but if it was me, and the stick was pulled for maintenance anyways, I’d be (light) sanding, priming and painting white. Not sure that I like big, open exposed slots on my spars. Have you considered putting in halyard exit plates to “fill – in” those open slots? Harking and others make these plates. Is the corrosion you see near screws or rivets? Without seeing your boat, I’d guess you have a little galvanic corrosion going on under the paint. I would clean up/sand. Then prime with aluminum primer and then paint the top coat. Tap and screw in “plugs” for your trysail hole pattern. You might want to drill a tiny weep hole at the base of your mast (rear side). My guess is you have accumulated a lot of water in it since the last time the stick was pulled.

GeorgeB said: I like the look of red hulls, not sure about red masts. Call me a traditionalist, but if it was me, and the stick was pulled for maintenance anyways, I'd be (light) sanding, priming and painting white. Not sure that I like big, open exposed slots on my spars. Have you considered putting in halyard exit plates to "fill - in" those open slots? Harking and others make these plates. Is the corrosion you see near screws or rivets? Without seeing your boat, I'd guess you have a little galvanic corrosion going on under the paint. I would clean up/sand. Then prime with aluminum primer and then paint the top coat. Tap and screw in "plugs" for your trysail hole pattern. You might want to drill a tiny weep hole at the base of your mast (rear side). My guess is you have accumulated a lot of water in it since the last time the stick was pulled. Click to expand...

Most 'bare' aluminum masts are in fact clear anodized.. Aluminum will oxidize to a stable outer layer, but it's usually fairly rough/dusty when you rub or touch it. An example of that could be the rough, pimply surface on a below decks aluminum backing plate that didn't quite stay dry.

My mast base tabernacle is a fabricated from aluminum. Never was painted. Can be seen in the pic. It is like you say rough, but has developed a tough protective skin.

The corrosion resistance of aluminum varies tremendously, depending on the specific alloy. Think about a cheap generic bracket (Home Depot style) that develops the white pox in a few months, and compare that with the hull on an Ovni, which just forms a nice protective layer of dull gray oxidization. I don’t know but I would bet that the extrusions that are used for most spars aren’t anything special. BTW, all that fancy colored anodizing, starts out as clear and then gets a dip in the dye tank. At least that’s what I was told by the company that used to do all our anodizing. That’s why it fades, and red is the worst.

Geoff54 said: The corrosion resistance of aluminum varies tremendously, depending on the specific alloy. Think about a cheap generic bracket (Home Depot style) that develops the white pox in a few months, and compare that with the hull on an Ovni, which just forms a nice protective layer of dull gray oxidization. I don't know but I would bet that the extrusions that are used for most spars aren't anything special. BTW, all that fancy colored anodizing, starts out as clear and then gets a dip in the dye tank. At least that's what I was told by the company that used to do all our anodizing. That's why it fades, and red is the worst. Click to expand...

Selden currently uses 6082 alloy. 6061 is the somewhat traditional alloy because it is a primary alloy in aircraft building but has 3-4 times the copper as 6082. The extra copper makes 6061 a lot more suseptable to corrosion. A lot of class societies have disallowed 6061 because of the corrosion problem, but this is a relatively recent change (10 years or so). So what alloy any particular boat has is a bit of an open question.

I think a white painted mast is one of the classiest things one can do to improve the look of their boat. However, you have to be one of those boaters that likes top coating brightwork, waxing your hull more than once per year, etc. Once painted, always painted. I do like my boat to be maintained properly and that means I can't have everything. I sanded off some of the brightwork and will never paint the mast. Poorly maintained paint or brightwork look much worse than none at all. I have enough to do to keep her in the shape I want her in.

^^ Exactly. I've had both (2 each). The shine isn't worth it. But then again, I don't sail for dock apeal. Some do.

Why are aluminum mast painted? 1.Against corrosion 2.For looks --- If you answer to protect from corrosion, then why is the inside of the mast not painted? The interior would get salt spray from all the holes in the mast and would not get the benefit of a rain shower or wash down. Now if the mast is anodized, I could see how that could provide good corrosion protection- and look good for a long time. Paint seems to be just a maintenance problem. 1. Some masts are painted in and out, but the inside of a mast doesn't get the wear that the outside does and thus can oxidize in peace 2. It's friggin' expensive to anodize most anything, and a 50 foot stick would be REALLY expensive. Much cheaper to paint, and that's likely the main reasons why mfg paint masts. 3. Good paint, well painted isn't that much of a maintenance problem ___ My mast is painted, and needs to be repainted. Should I just strip the paint and leave as bare aluminum? No, unless you have a lot of time and patience and are willing to take the chance of a good oxidation layer may or not form. ___ One way to do it is to sand the mast and then literally IMMEDIATELY get a primer coat of paint on. If you can't do that, then after sanding you want to get a coat of zinc chromate primer on (the yellow stuff.) After your prime, if you use a good two-part polyurethane like AwlGrip or Imron, and do the job well, you'll have a quite durable paint. --Use anti-seize on all threads and other thru-fasteners, such as rivets. I use the Permatex silver stuff. TefGel is another good choice --Install fasteners with a coating of caulking as an insulator (BoatLife LifeCaulk is a good choice, or 4200) --As a backing for bigger fittings, you can also install anti-corrosion insulation pads. These are commercially available from Sparcraft with nice sticky back, but I bought thin sheets of ABS plastic from McMaster-Carr (ABS WHT .020x60x6 size is what I use) and cut to size

Multihullgirl, Good advice. I will be pulling the stick in a few months. Some of the paint is in good shape, other areas have been worn down to bare aluminum. I will not strip the entire mast, only the areas that are bad, then prime and paint. Is it ok to prime with zinc chromate in areas were the existing two part paint is in good shape? I do like the thought of anodizing. Sailed on this boat Evohe over 20 years ago and had a chance to see her a few years back. After many miles at see including circumnavigatioins and a run through the northwest passage the masts (from Protor Mast Southhampton England) still looked brand new- and this was a working boat. Evohe was built in 1979: Evohe yacht charter: charter sailing vessel for scientific, documentary filming and diving expeditions to remote locations - recent expeditions include Subantarctic, south Pacific, and northwest passage - specifications

casey1999 said: Multihullgirl, Is it ok to prime with zinc chromate in areas were the existing two part paint is in good shape? [/url] Click to expand...

The J24 mast was easy to keep that nice There is NOT ENOUGH money in the world to do anything bit leave the Cal 29 mast its nasty carefree bare self

We patched our mast in order to deliver the boat down here. It was pretty bad, big flaked off areas, etc. What we did was sand the worst spots to metal, applied zinc chromate to the bare spots, and then painted with Rustoleum (matte finish, that's all they had in Callao, VA, ha ha) We just had it professionally stripped and painted a couple weeks ago, and the Rustoleum had held up pretty well over the last couple years, although it looked dingy from the matte finish. Pleasantly surprised

1. Aesthetics. Paint is pretty. 2. Navigation. Honest. "Go to the boat with the white mast" as opposed to the black one or all the silver ones. 3. And most important of all...the econazis have made anodizing into an unacceptable industry. All your mast needs is anodizing, but good luck finding anyplace that still does anodizing because of all the ecological compliance issues. But they ARE allowed to paint. If you left aluminum bare, most alloys would form a protective layer of white aluminum oxide powder. Which would rub off at every chance, leaving you with a really ratty looking mast very quickly.

ive seen a lot of bare masts and like them, my only complaint is the slight rough surface and maybe its me but the dust is dark colored and rubs off dark not white, maybe its white initially... at least on the bare masts I have touched... I have contemplated sanding off all the paint and leaving mine bare on my boat but without a yard to take the mast off thats going to be too much work aloft... maybe some touchup paint and roll on will be better...

Christian- I think the "bare" masts are still clear anodized from the factory. Dark dust is dust and dirt from the air, same that you'd find on a parked car. Aluminum oxide is white. Leave a block or bar of "pure" aluminum (or any of the wrong alloys) sitting in your cockpit for even a week, and you'll find the salt air leaves it covered with a white oxide powder. Of course, if you leave it outside that will also have the dark dust from the air hiding it.(G) But I've seen aluminum electrical boxes, engine pulleys, etc. down below in the salon go white within a week. A lot depends on the alloy.

hmmmmmmmmmmmmmmmm I know what yo are saying but maybe Im seeing it differently Ive had anodized gold masts and clear coated masts as well as bare masts and wood, painted etc... what I have noticed is the best overall clear winner hands down was the anodized mast(go figure) and the worst was the painted mast... in any case the masts Im familiar with clearly had dark stuff rubbing off it even after cleaning it and washing it down...not the typical white stuff that appears especially around fittings and or dissimilar metals Im specifically talking about the rough surface bare masts that have been sanded down... maybe just maybe its that these masts have been taken PAST the clear coat initially applied... maybe thats why I see it differently its similar to hwat happens to magnesium engine cases or alloy wheels...its not white powder that you see when bare but a very dark ashy like oxidation my motorcycle cases showed the same symtoms(after compromising the clear coat) anywhoo

dunno, but I think we basically agree: Stuff that sits outside or gets exposed to the elements? Gets crud on it. Black crud, white crud... Reminds me of what Chairman Mao once said: "Black cat, white cat, all same. Catch mice."

- ?

- 174.5K members

Top Contributors this Month

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

How to Touch Up Painted Aluminum

- By Steve D'Antonio

- Updated: March 20, 2013

Painted Aluminum

When it comes to aluminum and paint, the best coating is—nothing. As a result of a process known as passivation, aluminum, when exposed to air, develops an extremely hard and resilient oxide coating. The reason aluminum spars, ports, and pedestals are painted or coated is simply to enhance their appearance. Anodizing is a popular alternative, but many feel it’s not as attractive as the high-gloss finish of polyurethane.

The weak link in painted aluminum hardware is its propensity to corrode when the coating is breached. A nick or scratch allows water to migrate under the coating, where air is in short supply. The aluminum remains active rather than passive, and the result is poultice corrosion, of which there are two types: dry, identifiable by a white powder, and wet, which produces a white goo.

Therefore, if you have painted aluminum hardware on board—and nearly every boat does—the best approach is to prevent damage to the paint; if damage does occur, make your repairs quickly. In terms of prevention, bed each and every piece of hardware, from individual fasteners to mast steps, tracks, and compass bases, where they interface with painted surfaces. Bedding reduces paint damage and seals that which occurs, preventing water from entering the breach.

For small nicks and scratches, first remove any loose paint or chips. Next, use a clean rag that’s been rinsed in fresh water and allowed to dry to dewax the surface by wiping it down with a solvent such as 3M General Purpose Adhesive Remover. Then, with an artist’s brush and a high-quality enamel or single-part epoxy paint that closely matches the existing pigment, simply fill the nick or scratch. A couple of coats will build up thickness. Priming is impractical for small areas, so don’t sweat it. If it’s a high-visibility area, let the repair fully cure, then lightly sand it using 600-grit sandpaper followed by paste polishing compound and wax.

If you’re handy, repair larger areas, such as peeling ports or pedestals, using sandpaper, masking tape, and a brush. Remove all loose paint, then sand the hard edges where the sound paint remains using 220-grit sandpaper; sand so there’s a gradual transition between paint and bare metal.

Next, clean the surface with solvent (avoid touching it after) and mask the area (the tape should bisect the area on the existing, sanded paint). Then, using a good brush that won’t shed, apply an aluminum-compatible primer, preferably from the same manufacturer as the paint you intend to use. Follow the directions, which may call for sanding between primer and topcoat. Then apply the topcoat; use either a high-quality brush that’s designed for the type of paint you’re using or a one-time spray bottle, such as those from Preval . If you use the latter, masking will be much more important and will need to cover a larger area; never attempt this job on a breezy day. Depending on coverage, several coats may be required.

Once the paint is cured, carefully remove the masking tape by pulling it parallel with the surface, not perpendicular. Use the same sanding and polishing techniques described above. Some might ponder the use of a two-part paint for such repairs. While more durable, it’s not for the inexperienced; be prepared to use a respirator and other protective gear. If you’re experienced with such paints and use the necessary gear, the finish is more durable.

Steve D’Antonio offers services for boat owners and buyers through Steve D’Antonio Marine Consulting (http://www.stevedmarineconsulting.com).

Also planning to paint your decks? Click here to learn how .

- More: DIY Sailboat Projects , How To , maintenance , monthly maintenance

- More How To

Cruising with a Pet

Fatty Goodlander: Have Little, Want Less

How to Ride a Wave

How To Prioritize Your Sailboat’s Spring Checklist

A Big, New World

Cruising World On Board: Windelo 50

Into the Mystic: A Pacific Northwest Adventure

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

IMAGES

VIDEO

COMMENTS

Sand with 80 grit paper to achieve a smooth but "toothy" taper from the good paint to the damaged area. Wipe with an alcohol or acetone and a clean cotton cloth. The next step is to etch prime the surface and follow up with a two part epoxy primer or single part primer depending on what type of top coat is being used.

Mar 17, 2004. #5. Painting an old alum. mast We repainted our alum. mast but used a different approach as suggested by a rigger. He suggested we wet sand the mast, wash it off, treat it with alum. prepainting solution and paint it with Krylon clear enamel.

After a rough surface prep you will want to use Alumiprep (acid etch/cleaner) follow directions for dilution, let dwell for 5 minutes or so and rinse with plenty of fresh water. Then you will want to make sure the surface is dry and the temperature is over 70 degrees at min., hotter is much better, and then coat with Alodine.

A sailboat mast is like a long electrical fuse: one bad spot and the show is over. ... The good news is that although paint brand allegiance may vary, generic mast prep and painting techniques have a high degree of correlation. When it comes to the first step in the prep process, every expert sings the same refrain. Remove the hardware if ...

I did the mast on my 26 footer thirty years ago. Used two-part epoxy paint (Awlgrip). Removed all the mast hardware, sanded it down to bare metal, used the proper etcher and primers, and applied a few coats of paint. Sold the boat a few years later, then saw it about 20 years later and the mast looked great. Anything less than properly applied ...

If it was my 16' boat, I'd either do the mast right or not do it. I say that because it's aluminum, and painting aluminum is more difficult to paint properly as compared to wood, steel, or fiberglass. Paint doesn't like to stick to it unless the surface has been properly prepared. That means, as others have suggested, properly abrading it.

To paint anodized first degrease using Fiberglass Solvent Wash 202. Then give it a heavy sanding using 60 or 80-grit sandpaper. Apply one coat of InterProtect 2000E (Thinned 15-20% with 2316N Reducing Solvent). Allow to dry overnight and apply a second coat of either Epoxy Primekote (thinned 25%) or Pre-Kote primer.

Did my 44 year old boat mast 17 years ago. The stainless halyards over the years wore through the anodized finish. I did a full strip down of hardware, wiring harness inside of the mast and paint outside. New paint has held up very well. I had to go to the top this year to replace the wind vane.

19468 posts · Joined 2005. #2 · Mar 9, 2008. "Unpainted" masts are actually clear anodized. Aluminum, if left bare, will oxidize to a degree and stabilize, but the oxidation leaves a dusty/flaky surface that is unattractive and rubs off on contact. If the paint is in good shape you should be able to do a scuff sand and repaint.

I have an aluminum mast that I stripped paint from. I am thinking of spray painting with a clear paint. Will this work or should I just leave plain? Menu Menu. Search ... Boat Info. Downloads Weekly Quiz Topic FAQ 10000boatnames.com. Classifieds. Sell Your Boat Used Gear for Sale. Parts.

We were advised to coat the mast as thinly as would provide coverage since it was a fairly flexible rig and a thick coat of paint might tend to crack. We sprayed with a borrowed HVLP setup with a pressurepot gun (similar to what bathtub refinishers use) I saw the boat last year, more than 10 years after the job and the mast still looked pretty ...

Oct 1, 2011. #5. guys - i painted my mast several years ago and it was a much bigger job than anticipated; but very well worth the effort and the painted mast / boom dramatically increased the overall look of my boat. Its all in the prep and I would recommend removing all hardware and do it right and do it once.

322 posts · Joined 2010. #1 · Jan 28, 2012. Doing my annual mast maintenance. I have an aluminum mast, i have noticed it looks like it used to be painted black. I guess after years of use, it has started to fade off and now just looks bad. Question is, why would anyone paint an aluminum mast in the first place?

The paint looks nice, but is a pain. Our last boat (I made the rig) and didn't paint it. Had that boat ~15 yrs. and never regretted not painting it. It was easy to clean w/white vinegar (if needed). Current boat is painted and is needing attention. Repainted the mizzen boom years ago and still looks good, but if it didn't have paint already ...

Mar 19, 2008. #8. I did my mast last year. I had to unstep my mast to truck my boat back from Mexico and thought it was a good time to redo the paint job on the mast since it hadn't been done in 10 years. The boat yard at that time had a rate of $65/hr and I winced at their estimate.

There's a lot going on in this video as we try to get the boat ready for launch. We repaint the topsides after our our last coat of paint went terribly wrong...

Mast Painting. I just got an estimate from the yard for painting the mast and boom it looks chipped and not very seamanlike at all. does 2500.00 seem like a bunch of money it''s only a thirty foot boat to break it down it goes like this lift time 150.00 labor 165.00 r&r standing rigging 220.00 prep and paint mast and boom 1485.00 plus 400.00 ...

1. Some masts are painted in and out, but the inside of a mast doesn't get the wear that the outside does and thus can oxidize in peace. 2. It's friggin' expensive to anodize most anything, and a 50 foot stick would be REALLY expensive. Much cheaper to paint, and that's likely the main reasons why mfg paint masts. 3.

I moved a boat from San Diego to Port Townsend, in the spring of 2017. The mast was showing some corrosion and loosing paint in several spots. So on the advice of a well know PT Boat Rigger, I scraped and sanded those areas, wiped it down with Denatured Alcohol, painted the bare spots with zinc chromate, sanded that lightly and recoated any bare spots again with zinc chromate and applied a ...

Therefore, if you have painted aluminum hardware on board—and nearly every boat does—the best approach is to prevent damage to the paint; if damage does occur, make your repairs quickly. In terms of prevention, bed each and every piece of hardware, from individual fasteners to mast steps, tracks, and compass bases, where they interface with ...