Login to my account

Enter your e-mail and password:

New customer? Create your account

Lost password? Recover password

Recover password

Enter your email:

Remembered your password? Back to login

Your cart is empty

Pond Yachts: How to Build & Sail Them

Description.

This is beautifully illustrated in watercolors, and shows you a bunch of neat detail items to make your model building all the easier and more pleasurable.

Table of Contents:

- Introduction

- Getting a Perspective

- The Rule and why have a Rule

- Designing to fit the Rule: ideas for shape, aesthetics, of hull design, displacement ,and other practical matters.

- Materials needed

- Carving the hull

- Making and fixing the keel

- Making a rudder

- Paint and Finishes for hull, keel, rudder, mast, etc.

- Boat stands

- Going for a sail

- Living with a pond model

- Other boats to build

- Appendices: Glossary, Materials, Miscellaneous Helps

by M. de Lesseps

86 pp., hidden wire-o-binding, softcover

Customer Reviews

This a helpful book very informative and clear language about the principals of design and construction.

very handy for my project

I was expecting the information to be a little more technical

Recently viewed

Our Store is in Brooklin, Maine

at 84 Great Cove Drive. We're open Mon-Fri 8am to 4:30 pm Call 1.800.273.7447. WE'RE RIGHT HERE .

Timely Shipping

We are 99-3/4% sure... that we will ship your order within 24 hours Granted, that does not include weekends and holidays.

Secure payments

Rest assured... not only is our site secure, we do not hold your credit card/payment info.

- Opens in a new window.

POPULAR SEARCHES:

- Raspberry Pi

- Woodworking

- 3D Printing

- Maker Faire

- All Stories

- Magazine Projects

- Board Guide

- Magazine Issues

Projects from Make: Magazine

Wooden mini yacht.

Build a Wooden Mini Yacht this weekend.

- Time Required: A weekend

- Print this Project

By Thomas Martin

Thomas martin.

When my son was 3 years old, I made a small bathtub boat with him, using scrap wood and a piece of dowel. It lasted much longer and got more of his attention than any dollar-store bath toy, and about six years later we decided to try building a larger boat for the pool and local ponds we fished.

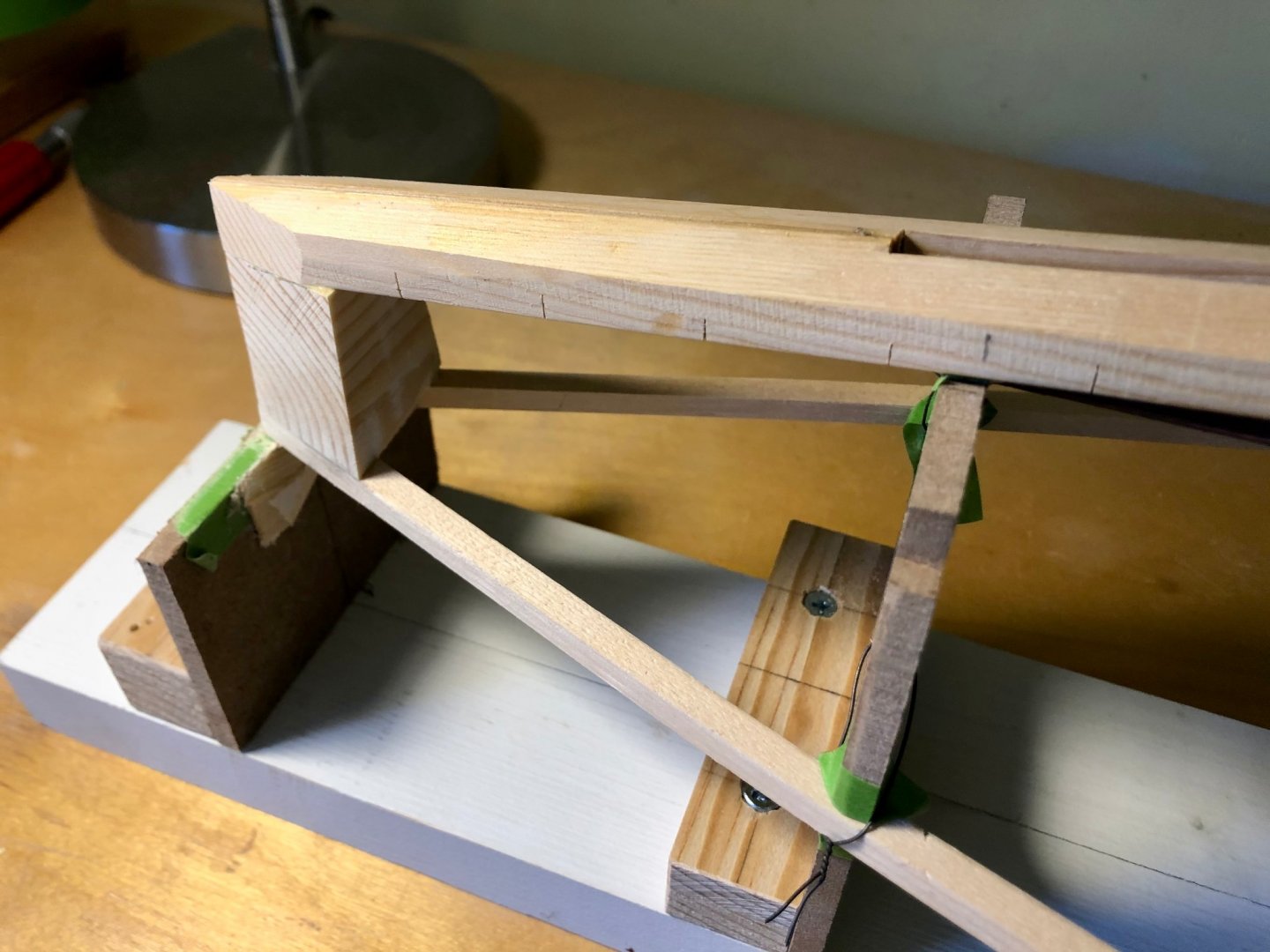

Here’s the result of our experimentation: a simple and worthy pond sailer that’s rigged and scaled like a real yacht. You can build it in a weekend using readily available materials and tools.

Project Steps

Prepare the sailcloth..

It’s hard to find waterproof fabric that’s easy to cut and won’t fray. You can make your own by stretching ripstop nylon loosely over a frame or 2 hangers, and spraying it lightly (in a well-ventilated area) with polyurethane.

First spray up and down, and then back and forth, until the fabric is well coated but not saturated.

Let dry overnight.

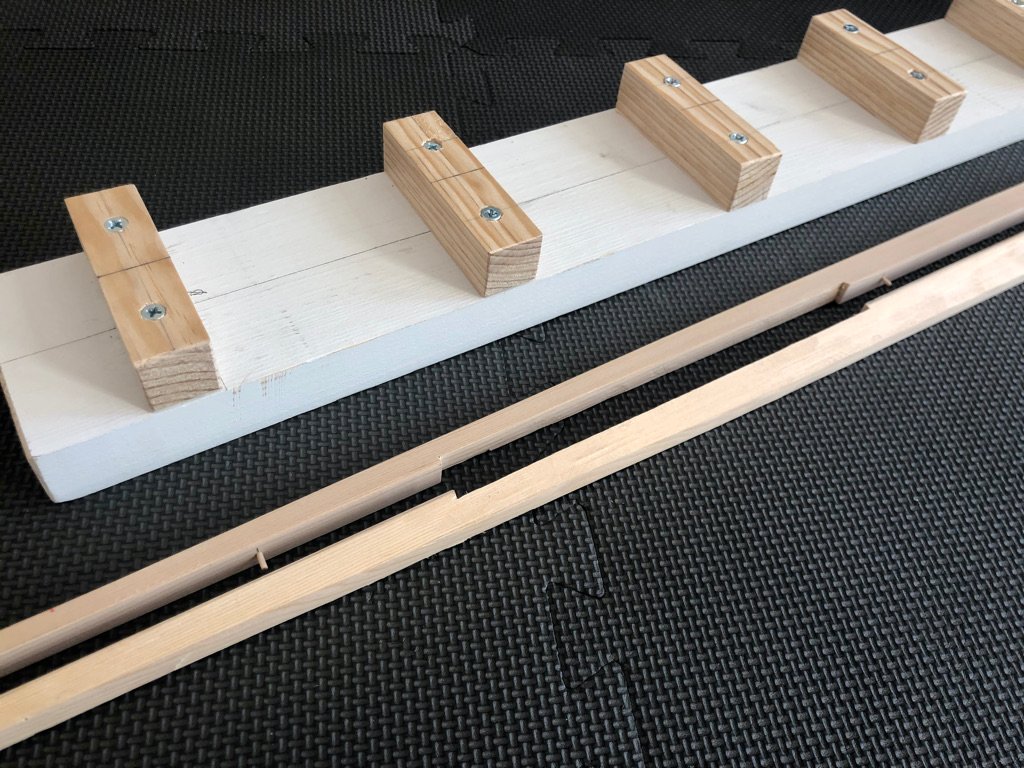

Mark and cut the parts.

Download the project plan and print it at full size. Following the plan, measure and mark the mast, jib boom, and mainsail boom lengths on the ¼” dowel. Trace the hull from the printed pattern onto the top and 2 ends of the cedar block; cut templates or use carbon paper. Draw the keel and masthead crane patterns on the brass strips, and draw the bowser (rigging clip) pattern 8 times on the thin plastic.

Cut and drill all the parts. Any fine-tooth saw will cut the dowel, or you can roll it under an X-Acto blade and snap the score. Heavy-duty shears or a hacksaw will cut the brass; be sure to file away the sharp edges afterward. You can saw or file down the hull’s shape, then use a hobby knife or thin chisel to excavate the slot for the keel. Drill all holes, plus pilot holes for the screw eyes (in the hull, just poke pilot holes in by hand with a thumbtack).

Finally, file, sand, and smooth all parts. The more time you spend here, the better — especially if you plan to use a clear finish over the wood.

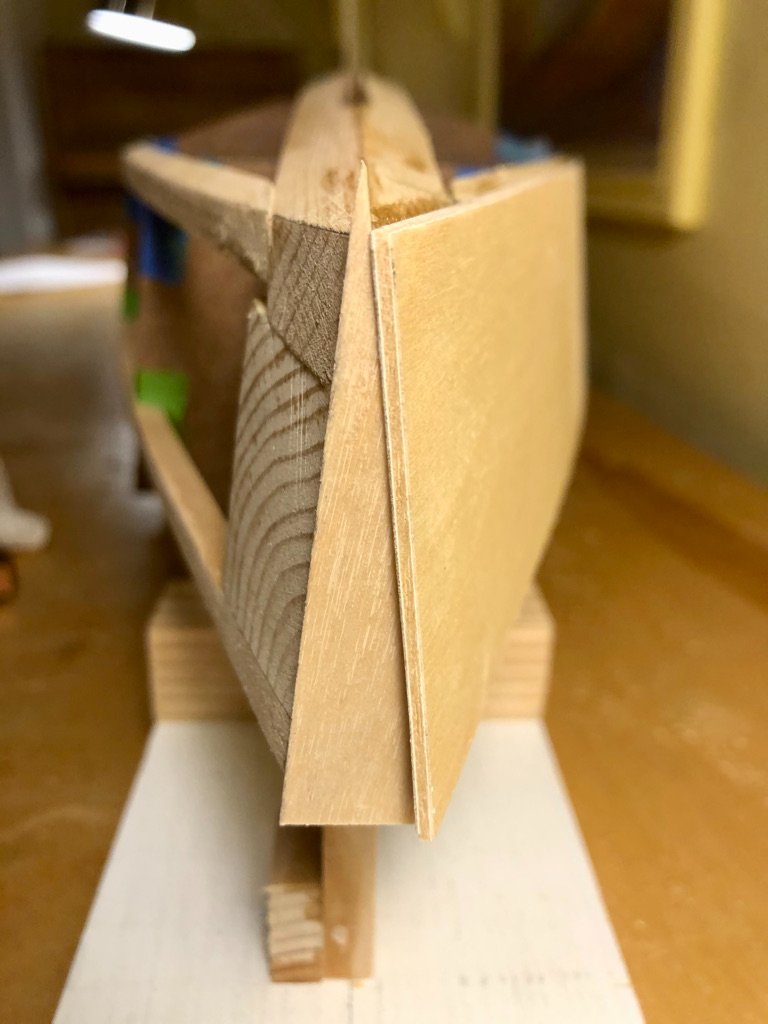

Mount the keel.

On the underside of the hull, mask both sides of the keel’s slot with tape. Wearing gloves, and in a well ventilated location, mix and spread some 5-minute epoxy into the slot using a scrap stick or wooden match.

Slide the keel into position and hold it there while the epoxy cures. You can square it up using a business card on each side.

Use a gloved finger to smooth the epoxy along the joint line, and fill any voids with more epoxy.

Finish the wood.

Finish the hull uniformly, or for a big-boat look, paint the outside of the hull and stain the deck.

Sand the hull with 100-grit paper over a sanding block, and again with 150-grit. Apply a first coat of paint or varnish, and re-sand with 180-grit before each subsequent coat.

For a stained deck, first paint the hull upside down, then re-sand the top perimeter to remove any overspray. Rub stain into the deck and edge, let dry, and coat with varnish or polyurethane.

For the mast and boom pieces, bevel the cut edges for a more finished look, then sand with fine grit to remove any fuzz. Stain if desired, and cover with at least 2 coats of varnish or polyurethane sealer, sanding lightly between coats.

Assemble the mast and booms.

Cut a slot in the top of the mast and glue in the masthead crane. Once that’s secure, follow the plan to install all screw eyes: 4 to the mast, 1 on the fore end of each boom, 1 more on the mainsail boom (for the boom vang), and 4 to the deck. Screw these in until the shank of the screw is completely into the wood.

Insert the brass brad down through the hole in the jib boom and bend it into a clew hook.

Use needle nose pliers to open the mainsail boom eye, hook it onto the eye on the mast, and close it. This forms the gooseneck, the joint that lets the boom swing from side to side (far left in the photo). Press the mast down into the hole in the deck with the masthead crane centered afterward, and tap it gently down into its hole with a hammer.

Add the sails.

After the sail material is dry, trace and cut it to the plan patterns. Lay the boat on its side on a hard surface with the masts and booms in place and fit the sails to the areas for rigging. For the grommets, cut a small X at each sail corner, insert a grommet up through the hole, press the cloth down around it, and tap the grommet flat with the eyelet tool until it firmly grips the cloth.

NOTE: It’s a good idea to practice setting grommets first with a couple of sailcloth scraps and extra grommets. It’s time for rigging. Knot and cut a short length of dacron line, thread it through a bowser, and string the boom vang. For these and all other knots, add a tiny drop of cyanoacrylate glue immediately after tying; the line is slippery and won’t hold knots otherwise.

Use 5″ lengths of line to tie each sail grommet to its corresponding screw eyelet or drilled hole with a square knot. You’ll need about 10″ for the top of the jib sail, which threads through 2 eyelets before tying off to the uphaul bowser.

Referring to the plans, tie the 4 lower connections on the booms first, and then add the upper lines for tension, so there are no wrinkles in the sails along the booms. Thread a bowser onto the jib uphaul as indicated: for their final tensions, you’ll adjust the jib using the uphaul at the top, and the mainsail using the boom vang.

For the backstay, tie in a long length of line at the masthead crane and install a bowser, routing the line through the eyelet at the stern.

Tighten the backstay and the sails so that they’re fairly tight but the mast is not bowed forward or aft. Finally, add the 2 lines called sheets. For these, cut two 15″ lines. Tie each one through the hole in the aft end of a boom, thread it through the sheet eyelet on the deck just underneath, then through 2 holes in a bowser, through the other sheet’s eyelet, and finally through the last hole in the bowser, doubleknotting the line.

NOTE: It’s important to tie the bowsers exactly as shown on the plan to make them work. The sheets let you adjust the angle (trim) of the sails — slack for downwind sailing or tight for crosswind — letting you cross a pond or pool in any direction that isn’t too close to directly upwind.

This project first appeared in MAKE Volume 20 , page 56.

From the Shed: New Arrivals

DIY Arcade Joystick Kit

Make: Arduino Electronics Starter Pack

Maker's Notebook - Hardcover 3rd Edition

Transistor Cat Kit

Our websites use cookies to improve your browsing experience. Some of these are essential for the basic functionalities of our websites. In addition, we use third-party cookies to help us analyze and understand usage. These will be stored in your browser only with your consent and you have the option to opt-out. Your choice here will be recorded for all Make.co Websites.

Escape to an island of imagination + innovation as Maker Faire Bay Area returns for its 15th iteration!

Buy tickets today save 15% and lock-in your preferred date(s)..

March / April Issue No. 297 Preview Now

50/800 Marblehead Pond Yacht

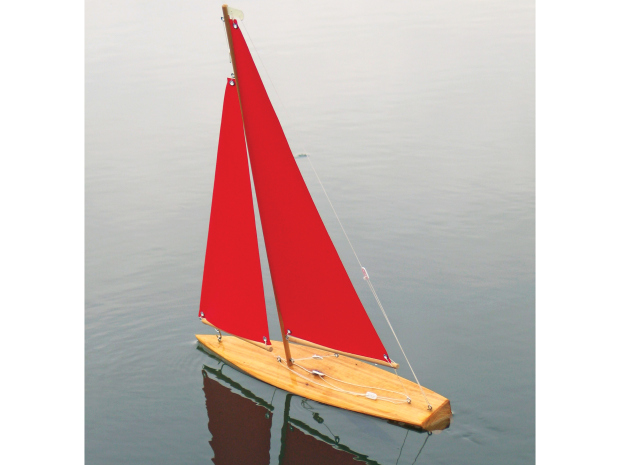

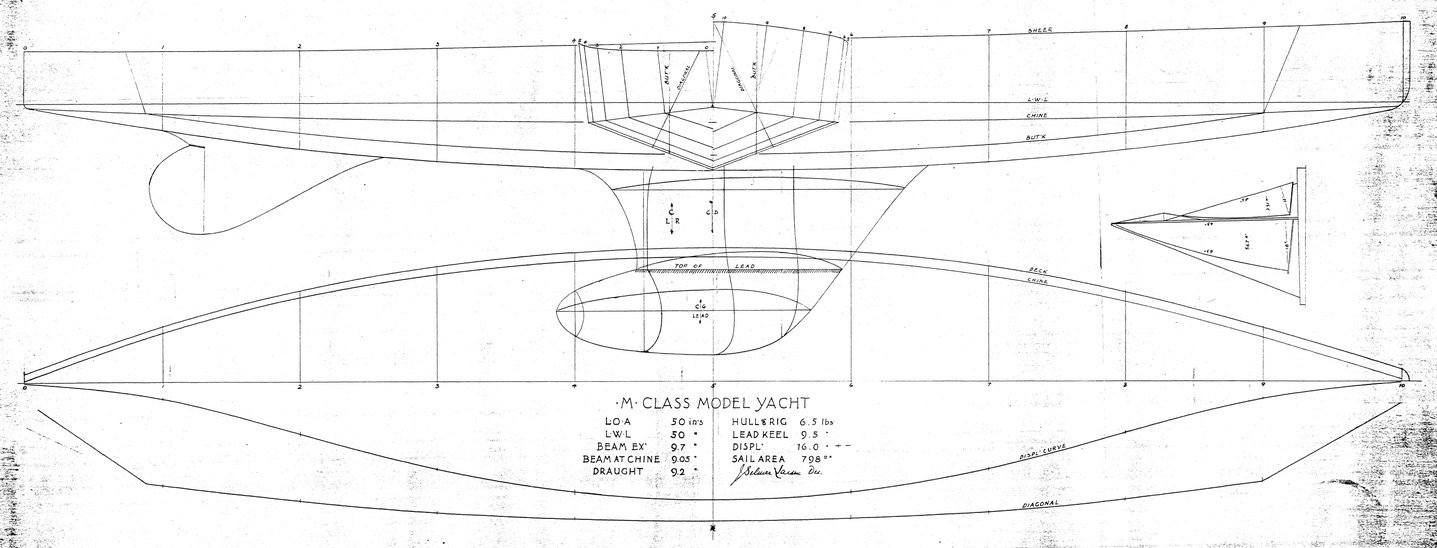

After taking Thom McLaughlin’s class on building pond yachts at the WoodenBoat School in 2009, John Stoudt spent the rest of that year into the early winter of 2010 working on this model. It is a 50/800 Marblehead Vintage class design that John built with very thin planks, tacked to wood frames. John also planked the deck. All of the fittings are solid brass.

Design Specifications

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from launching.

SAUNDRA MAE

From the Community

1962 40' Sparkman & Stephens Yawl

Alita is a Sparkman & Stephens yawl (design #1245-S), built in 1962 by Astillero Bottini in M

1947 Quincy Adams 17 -Price reduction to $9,000. Make offer.

Mahogany planked on oiled oak frames. Spruce spars and stainless rigging.

New Lion 550 Trailer Sloop

2023 Lion 550 18ft Sloop.

26' Luders 16 sailboat

Beautiful 1945 26' Luders 16 sailboat #18, excellent condition. $15,000.

DO IT NOW! David Beede GAFF KETCH CHAMELEON For ages 5 to 95... Dream Catcher Pond Skiffs ... I'm no longer building these pond boats,but I'm leaving the page up to inspire home builders. A Celebration of Traditional Sail... 3 Models and many rigs - I have a book in the works with full sized plans! BLUE HERON SHARPIE Projects... Summer Breeze Wins Design Contest! Click the duck! This is an 11'8" skiff from two sheets of plywood inspired by Phil Bolger's Teal. I was gratified to win best overall, and best use of materials Duckworks 2001 contest. All drawing and most current build notes here . Prototype build diary Maiden voyage All the entries were very impressive so I won by a slim margin. Please check them out. Summer Breeze sea trials at the Cedar Key mess about 2002! Steve Bates , of Australia, did a bang-up job on his mini-sharpie - then turned her into a double ender and had a ship wreck! Check it out! Mini Sharpie Here's a one sheet high bowed sharpie skiff of my own design. A Family builds her. She gets a sail rig! Daydream... var options = {}; options.mediaPath = "http://www.simplicityboats.com/Day%20Dream.mp3"; var params = {}; params.allowScriptAccess = "always"; swfobject.embedSWF("http://www.simplicityboats.com/OriginalMusicPlayer.swf", "player-holder", "250", "90", "9.0.0",false, options, {}, {}); A.K.A. Least Cuts Boat This is a 15' Sharpie Skiff made with all straight saw cuts! Rob Smith and 2 nephews build her in 22 hrs in South Africa! Brian Schmittling's Daydream ! A couple of One Sheet boats with capacity for 2 Adults! (click the pic) Wackless Lassie - A double paddle canoe. Cygnet - A One Sheet Skiff designed by Herb McLeod. Featherwind - actually Dave Carnel's $200 sailboat Alternative Methods and Materials for boat building! Yuloh info... - a collection of resources on the oriental sculling oar. $10 Yuloh!! Shantydock! - This is an 8' x 16' swim platform with an arched canopy roof. Dream Catcher Pond Skiffs ... are here! " Coolwater " a shoe string shanty boat! Also.... Shantyboat Dreams - sketches and resources... Model making - this one is a one sheet skiff of my own design superceded by my Mini Sharpie. Local Builders See what the local (North Florida) boys are up to. Old Boat Plans from the 40s, 50s & 60s This is a cheap and quick boat shelter that can be easily broken down and moved. PVC and poly tarp to the rescue again! Alternative Methods and Materials for boat building! Miscellaneous ... Resources - informational and inspirational stuff like Gavin Atkin's Free Design Page - Gav, in addition to starting the Boat Design group on Yahoo, won the Duckworks design contest in 2000 and originated the "Mouse" line of boats, which are being built all over the globe! (Good starting point... less overwhelming than the links page.) Links from my bookmarks for the last year, loosely categorized. A Rant Ravings about boat building, music, and life as spectator sport. [the above email link is NOT clickable - thanks to the spam web bots - please type it in]

The truth about Acorn

ail freesailor line sailing pond skiff model sailboat model boat model sailboat toy sailboat toy boat model sailboat pond sailer model boat sailboat pond sailer pond boat pond boat model yacht miniature yacht toy boat toy boat toy boat pondsailer pond sailer pond boat model pondsailor pond sailor sailboat model sailboat models sail sail sail sail sail toy toy toy boats sailing sailing model sailing model miniature sailboat model sailboat boat kit sailboat kit ship model sailing model scale model scale model scale boat scale boat scale sailing model ship model fun yacht sloop model sloop model yacht sailboat model sailboat radio control model sailboat modelsailboat pond yacht

tion. Boat design addiction may lead to a new 12 step program.

- Basic Kayaking Knowledge , Learn

15 Free Boat Plans You Can Build This Week (with PDFs)

Boatbuilding is one of the most ancient forms of craftsmanship still alive today. As long as our ancestors have had a curiosity about exploring open waters, they have been practicing and honing their boatbuilding skills.

To be honest, however, building a boat is no small task. It will require a lot of work and patience to ultimately create a finished product that you are happy with and that is actually seaworthy.

Of course, we have also included a few free boat plans. You can keep in your back pocket for the next time you are asked to build a cardboard boat as part of a contest or lakefront teambuilding adventure.

We hope that these resources help you in your journey to build your own boat!

Photo by SeventyFour via Shutterstock

Free Boat Plans

Why build your own boat, 1. the wanigan, 2. the mouse, 3. the slipper, 4. the handy andy, 5. the junior, 6. the jolly roger, 7. the cork, 8. the hobby kat, 9. the tern, 10. the falcon, 11. the white duck, 12. the sea midge, 13. the zephyr, 14. the gypsy, 15. the crazy cardboard boat, 15 free boat plans you can build this week (with pdfs) – final thoughts, share on pinterest.

- The Wanigan

- The Slipper

The Handy Andy

- The Jolly Roger

- The Hobby Kat

The White Duck

- The Sea Midge

The Crazy Cardboard Boat

Photo by Halsey via Shutterstock

There are a lot of reasons why you should explore building your own boat versus buying a pre-made model. Here is a quick breakdown of the most obvious benefits:

- You will know the ins and outs of your finished boat better than anyone

- It can be a great project to work on with your teenage or even adult children

- You will gain valuable skills molding and shaping wood and other materials

- You can design your boat for your specific needs

- You don’t have to trust the sometimes-questionable manufacturing of mass-produced boats

- You can create a boat that functions as your second home on the water

- You can save money if you source materials mindfully

Of course, most first-time boatbuilders still experience some level of trial-and-error. With patience and perseverance, however, you can craft a one-of-a-kind vessel that has no equal anywhere in the world.

Free Boat Plans You Can Build This Week (with PDFs)

PC Duckworks Boat Builders Supply

The Wanigan boat began as a garvey design, which is one of the older boat plans known to the Americas. Traditionally, these boats were built as work scows and were very popular among American summer camps.

The design itself is very simple, but these boats can carry heavy loads. It can also handle a trolling motor being mounted to the stern so you can cover more ground if you want to use it as a fishing boat.

The creator of this boat plan became aware of some of the downsides of the garvey design, such as the heavier weight that made it less efficient than some other designs. So he combined elements of dory and wanigan designs to create a hybrid.

The main changes include an enlarged beam, tilted lathes to provide a stiffer hull, and knocking off the top strakes to reduce the boat’s overall weight.

The Wanigan text

These additional The Wanigan drawings  may also prove useful for your build process!

The Mouse is one of the most compact and nimble boat plans we have found for this list. It is an easy build and also a great boat for two kids or a single teenage paddler.

The original builder began with a one-sheet boat design in an effort to create the lightest and most affordable boat possible. This means it is only suited for calm waters and should not be used in high winds or wavy conditions.

That said, it was built in roughly 12 to 24 hours of work time and doesn’t require a full workshop to construct. The main material that is required for building this boat is quarter-inch plywood. But the builder recommends using one-inch by half-inch pine or something a little sturdier.

The plywood and pine components are held together using a method called ”˜stitch and glue’. This method requires choosing one of the best glues for kayak outfitting , which are typically made of epoxy and glass tape rather than something cheaper like polyurethane.

The Mouse Instructions

Also, here are a few extra useful The Mouse Notes for builders

The Slipper is the first of many sailboat plans on our list and it is faster, easier, and cheaper to build than most. It also features a deeper cockpit than many other sailboat designs, which makes it safer for intermediate sailors.

This sailboat plan features dual steering stations so that you can sail from inside or outside of the helm. It also includes a centerboard trunk that hardly intrudes into the cabin at all. So that, it is easier to work around while you are in the cockpit.

The exterior hull and cabin of this sailboat feature a modified dory design using two sheets of plywood ripped to three feet wide before being joined together. The resulting hull is a modified V-shape that reduces drag.

The centerboard of this boat can also be winched up to the level of the top of the cabin or lowered down to alter the draft. This allows you to customize the boat design for a stiffer and more weather-worthy vessel if you need it.

The Slipper was also intentionally designed with an aft cabin that naturally helps to keep the bow pointed into the wind whether you are underway or the boat is anchored in the port.

The Building Slipper

PC DIY Wood Boat

The Handy Andy is a great little 10-foot portable rowboat for hunting, camping, fishing, and other recreational uses. It is actually the only folding boat design on our list, which makes it best for folks that need the most portable boat plan possible.

This boat features a 42-inch beam and a depth of about 15 inches at the mid-section. It also weighs roughly 80 pounds when assembled and can handle up to three average-sized human passengers.

The design boasts a flat bottom with canvas-bound edges and the primary material used for construction is ⅜-inch marine-grade plywood. Despite its lightweight nature, this rowboat can handle trolling motors or even outboard motors with a maximum of five horsepower.

Once finished, the hull can be folded or unfolded in less than a minute’s time.

This design makes it one of the only boats on this list that can be stored in a truck bed or easily carried by two people to be launched at more remote locations.

If you are looking for an all-purpose dinghy that can handle almost any use you might imagine, look no further than The Junior free boat plan. It can carry three or four average-sized adults and is much easier to row than a traditional dinghy.

It is also durable enough to be equipped with a small outboard motor. You could even set it up with sailing equipment if you want to use it as a sailing vessel. As we said, this is truly an all-around boat design!

This boat plan requires constructing three frames that will provide the majority of the load-bearing support. The builder recommends using ¾-inch framing with ⅜-inch plywood as the exterior material for this boat build.

Resin glue and flathead screws are also required to hold this boat together. But there is a full list of materials included in the plans we have linked to below. Sticking to that plan should also give you enough leftover materials to construct two six-foot oars for rowing this boat until you install a trolling motor or outboard motor down the line!

Channel your inner Captain Morgan when you are following these plans to build your very own Jolly Roger boat. This flat bottom boat design is designed for pond fishing . It can also be a useful yacht dinghy for getting from your dock to a larger vessel anchored offshore.

The plan follows conventional dinghy construction methods but also includes a few modifications that will save you time and energy. The wide design is super stable for boaters of all ages.

The keel, frame, chines, and risers are all cut from ¾-inch oak, ash, or any other trusted hardwood you can get your hands on. For the smaller components, the builder recommends using cedar, cypress, fir, or white or yellow pine.

Because this boat plan is also sturdy enough to handle a small motor, it includes important points for protecting the wooden hull from spark plug damage.

Be careful to follow these guidelines to build the safest boat possible if you imagine installing a motor down the line.

The Jollyroger

The Cork is another simple rowboat design. This one trends away from the flat bottom plans that we have included thus far. Instead, it features a deeper, V-shaped hull that makes it better suited to more efficient rowing and easier maneuverability.

It can be rowed easily from either seating position and is durable enough to handle up to three average-sized adult passengers. The ends of the boat are identical, which allows for multi-directional rowing.

The list of materials required for this boat plan should cost you between $30 and $50, depending on your location and hardware costs there. The resulting build is lightweight enough for two people to be carried and also to be transported on top of a vehicle .

Inside the boat, the builders use aluminum tubing to secure the struts that hold the seats. This material choice keeps the overall weight of the boat down while still adding the necessary rigidity across the beam of the boat.

The Hobie Cat is one of the most iconic and recognizable small sailing vessels ever made. This Hobby Kat plan is your answer to building your own iconic sailboat without spending thousands of dollars.

Your finished boat will be able to handle speeds of up to 20 miles per hour. It will be a super fun vessel for windy days on the lake or bay. The builder was able to construct the hulls, decking, and rudder for this boat while spending little more than $200.

From there, they purchased and installed the mast, boom, sail, and rigging, which brought the total amount spent to roughly $650 (still much less than a name-brand Hobie!). Without the mast and sail, this boat weighs roughly 165 pounds and is constructed using primarily 3/16-inch marine plywood.

You can also elect to build your own mast, boom, and sail if you have the time and skills to do so.

Those elements are not included in this boat plan, but they do offer some recommendations for where to buy these components!

The HobbyKat

Named after the common seabird found around the world, the Tern is a lightweight and nimble sailboat with a 72 square foot base design. She is made for inland sailing and planes very well in moderate breezes.

The hull design also provides minimal water resistance and the small floor plan makes this boat easier for intermediate sailors to handle. Even though it offers a small footprint, this boat is sturdy enough to handle up to four adult passengers.

One of the best things about this boat plan is that it can be built almost entirely by using only common hand tools.

Of course, you can speed things up if you have power tools and you are skilled enough to use them correctly.

The Tern boat plan includes a 20-foot mast, but you can shorten that length if you desire. The plan includes a complete list of materials and step-by-step instructions on how to plane and assemble each element.

As you might expect from its name alone, the Falcon is an incredibly speedy sailboat for its size. It boasts a 14-foot centerboard and can handle two to four passengers, depending on its size and weight.

In tests of the original build, the creators claim that this boat out-distanced many Snipe and Comet sailing vessels as well as pacing evenly alongside longer 18-foot sailboats. When finished, your boat will have a six-foot beam and a total weight of roughly 475 pounds.

For the main framing components, they recommend using white oak and plywood will be the main material used in the hull construction. The hull features a V-shaped that was inspired by larger schooners.

The Falcon is best suited to sailing on bays, lakes, and wide rivers. It is also a boat plan with just under 120 square feet of deck space and it is a great build for amateur craftsmen and sailors.

The White Duck is a flat-bottomed rowboat with a total length of 13’6” and a four-foot beam. The cockpit is approximately 15 inches deep all the way around and this boat can handle up to five passengers while maintaining buoyancy and stability.

When fully constructed, it will weigh roughly 200 pounds, but the final weight will depend on the type of lumber you choose for your build. This boat plan features plywood planking over solid wooden frames.

The White Duck is built with a pointed bow that cuts nicely through the water. The flat stern of this boat design will make it easy to attach a small outboard motor with a maximum of six horsepower.

As you might expect from its name, this rowboat is a great option for duck hunting trips. That being said, it is a highly versatile craft that can also be used for pond fishing or casual rowing on your nearby lake.

The Sea Midge is one of the smallest rowboats on our list and it is ideally suited for one average-sized rower or two small paddlers. It is only about 8 feet in length and offers a 52-inch beam at its widest point.

The Midge’s small dimensions make her ideal for navigating narrower creeks and streams. With an approximate weight of 62 pounds, she is easy to maneuver on the water and can also be much more easily transported than some of the larger boat plans on our list

The Seamidge

The Zephyr is a compact and speedy dinghy sailboat that measures roughly 14 feet long and approximately five feet across. This boat style was originally developed for safely crossing the English Channel. This means it can stand up well in rough waters.

When finished, it is also light enough to be transported on a small trailer or on top of a larger vehicle.

The boat plan calls for using hemlock or fir for the framing and oak or Douglas fir for the keel and chines.

The Gypsy is a small cruising sailboat that is meant to be equipped with an outboard motor for powered locomotion. The original design resulted in an incredibly seaworthy vessel that logged more than 6,000 nautical miles in her lifetime.

It includes a comfortable cabin that makes it well-suited for multi-day sailing adventures. This boat plan includes improvements on the original design that will help you build an extremely durable and long-lasting sailboat.

The Gypsy boat design will help you construct a vessel that can handle a motor up to 25 horsepower so that you can enjoy cruising speeds of up to nine miles per hour.

While it may require a bit more of an investment in time and money, it will also help you produce one of the best boats you can build with a free boat plan!

PC Saint Dominic Catholic School

Finally, let’s talk about a crazy cardboard boat plan that you can build in less than a day. This is a great boat plan to bookmark for your next teambuilding project so that you can earn bragging rights with your coworkers.

The plan calls for using 1.5 sheets of cardboard. But you can use the remaining half sheet to build your own boat paddle if you want to get creative.

Triple-thick cardboard is best for this boat plan. But you can always double up thinner sheets if that is all you can find.

These plans include an easy-to-follow diagram for marking, cutting, and folding the cardboard sheets to create the hull of your boat. From there, it calls for using contact cement and construction adhesive to seal the edges and corners.

If you are looking to save a little money on this build you could also use duct tape and then wrap the entire design in plastic sheeting to provide waterproof qualities.

Overall, this build is one of the cheapest and easiest on our list. It is also a great project for hot summer camp days on the lake or river!

Photo by Alexandra Soloviova via Shutterstock

We hope that you now have a couple of free boat plans to inspire you to begin your own construction project.

Don’t hesitate to check out YouTube for some useful boat-building videos when you are getting into the nitty-gritty of these build processes!

Enjoyed 15 Free Boat Plans You Can Build This Week (with PDFs)? Share it with your friends so they too can follow the Kayakhelp journey.

Peter Salisbury

Pete is the Owner of KayakHelp.com. Born and raised in Cleveland, Ohio, he grew up kayaking, fishing, sailing, and partaking in outdoor adventures around the Great Lakes. When he’s not out on the water, you can find him skiing in the mountains, reading his favorite books, and spending time with his family.

Important Registration Information - 2024 Registration

Pond Yacht Restoration

Restore/complete your own pond yacht and get it ready for sailing or display..

John Stoudt was an industrial arts teacher focusing on woodworking, metalworking, and architectural and engineering drawing. He honed his skills and further developed his expertise here at WoodenBoat School. John took his first class with Alan Suydam, returning many years to build and sail model yachts. He has built and restored over 100 model boats, including many vintage model yachts. His skill set enables him to build a complete boat including hull construction, custom fittings, casting ballasts, making the sails, and tuning the rig for sailing. John is president of the United States Vintage Model Yacht Group (USVMYG) and an associate regional director of the American Model Yacht Association. He collects model yachts and currently has over 60 boats in his collection. John races various pond yachts in Maryland, New Jersey, and Pennsylvania and has participated in National events, placing in the top three on multiple occasions in the vintage Marblehead class USVMYG National Championship regatta with his 1934 vintage Marblehead.

This course is appropriate for students with some knowledge and experience. Basic knowledge and use of hand tools is required for most shop courses. Basic knowledge and ability to sail is required for most waterfront courses.

This course involves a low level of activity throughout the week including: occasional standing and working, seating is usually available, working on your own project at your own pace is common.

This is a six-day course ending Saturday

There are various models and pond yachts out in the world in need of repair or restoration. The boat may have been a family heirloom, a model you found in an antique shop or at a flea market, or a project that you began but couldn’t find time to complete. If you happen to have such a boat, this week with John Stoudt will present you with the opportunity to evaluate your model and determine a plan for its restoration and completion. The work might include repairing a damaged hull, building a new rig, making fittings, repairing a vane gear, getting the electronics working, installing new electronics, or re-rigging the boat. An unfinished boat could have a planked deck built and installed, hatch openings framed, hatches built and fitted, spars constructed, electronics installed and set up, or the rig built and installed. A display and travel stand could also be built. And there may even be the chance to establish a waterline and paint the model to your specifications.

Students may bring any type of pond yacht, especially those rigged for remote control. Some older self-steering boats could be reconfigured for remote control sailing or the self-steering mechanism could be repaired. If you have any questions about the boat or model you have, you can contact the instructor through the WoodenBoat School office.

John Stoudt will consult with each student prior to the course to develop an understanding of your boat and plan of work. Together you will determine what materials and supplies you will need to bring along and what John will make available. He will have other materials and parts on hand for the unexpected. A final plan for the restoration and/or completion of your boat will be established on the first day of class. Each morning, the students and John will evaluate where they are, how they have progressed, and how to proceed. Come spend a week at WoodenBoat School and develop a passion for models that is both fun and rewarding!

This course is appropriate for students with some knowledge and experience. Basic knowledge and use of hand tools is required for most shop courses.

What Our Students Are Saying

John Stoudt is absolutely one of the best instructors I’ve had here at your school. Very knowledgeable and willing to share his expertise with all his students. POND YACHT RESTORATION was exactly what I wanted and needed. I would definitely take this course again!

T.B., Kenosha, Wisconsin

Register For This Course

Courses fill quickly, so don't delay if this is a course you want to take.

Related Courses

Woodcarving, carving name boards, build your own plank constructed pond yacht, introduction to woodworking.

You are using an outdated browser. Upgrade your browser today or install Google Chrome Frame to better experience this site.

If you would like to add an event to this list, or if you are the organizer of one of the events listed and need to update or correct anything here, please contact [email protected].

« All Events

- This event has passed.

Build Your Own Plank-Constructed Pond Yacht

September 9, 2018 - september 14, 2018.

The WoodenBoat School, Brooklin, ME, is offering a class this summer for those interested in building their own pond yacht. The course will be offered September 9–14, 2018.

The course boat Norumbega was designed by Thom McLaughlin; its name is derived from the Downeast area of Maine where WoodenBoat School is located. Construction of this pond yacht will pleasantly challenge and inform students in planking practices similar to those used in building full-sized boats. Students will make decisions based on blueprints and develop an eye for form. During the week, the boat will be planked and faired, and the fin and rudder will be fabricated. Thom will also discuss the steps that follow to complete the boat—decking, rigging, electronic installation, and painting.

Students who have started construction of their model in previous years at WoodenBoat School are also welcome to participate in this course to finish their boat. This week will be an excellent opportunity for further guidance. This will also allow those just beginning their boat to view firsthand the final steps in construction.

Tuition: $850.00. Materials: Pond Yacht I – $310.00, includes CNC cut molds, strongback, keelson, planking, fin, and rudder. Pond Yacht II – $160.00, includes material to finish the boat other than sails, fittings, and electronics.

Located on the beautiful coast of Maine, in the small community of Brooklin, WoodenBoat School is a meeting place where people of all ages, backgrounds, and experience levels can gather to meet, live, and work among others who share similar interests. The school has been offering 1- and 2-week courses designed around the arts of boatbuilding, woodworking, seamanship, and related crafts for the past 37 years. Courses on pond yacht construction and elements of sailing these radio-controlled boats have been offered at WoodenBoat School since 1999.

Landlocked in the Midwest, Thom McLaughlin grew up working on farms and having the cycles of nature deeply rooted under his skin. After finishing a graduate degree in visual arts (sculpture), he found himself surrounded by water as an art professor at the University of South Florida. In 1993, while searching for an art form that could more directly inspire an awe of nature, he stumbled onto pond yachts. Since then he has written articles on, investigated the history of, and made many vintage pond yachts. He is currently the Southeast regional vice-president of the US Vintage Model Yacht Group. In the last seven Vintage Marblehead National Regattas, boats of Thom’s design had third or better placing in final standings. In the 2011 National Regatta, he placed first overall in class and also received the Craftsmanship Award.

For more information contact: Rich Hilsinger, Director [email protected] 207-359-4651 https://www.thewoodenboatschool.com/

- Google Calendar

- Outlook 365

- Outlook Live

DIY Boat Building Plans

Yacht Plans & Blueprints

Download over 500 Boat Plans. Click on the link below.

-->click here<--.

Table of Contents

Key Takeaways – Yacht Plans & Blueprints

🚤 Yacht plans and blueprints are detailed drawings and specifications for building a yacht from scratch.

📐 They include information on dimensions, materials , tools , assembly, rigging, and performance data.

💰 Building a yacht from scratch allows customization, cost savings, and personal satisfaction.

🤔 Considerations before building include budget, skill level, time frame, purpose, and location.

⚠️ Safety precautions are crucial when undertaking the complex and risky task of building a yacht.

⛵ Yacht design involves hull , deck , cabin , and rig considerations, with various types like motor yachts, sailing yachts, catamarans, and trimarans.

🔄 Key components of a yacht include hull, deck, cabin, rig, engine, and rudder.

🤑 Factors in choosing yacht plans include budget, skill level, purpose, location, and design preferences.

✔️ Evaluating yacht plans for accuracy and completeness is essential before starting the construction.

🌐 Yacht plans can be found online on websites like Yacht Design Net, Boat Plans Online, Boat Builder Central, and CAD Boat Design.

💡 Tips for choosing the right yacht plans include defining needs, comparing plans, seeking expert advice, and reading reviews.

📏 Learning basic blueprint conventions is essential for interpreting yacht plans, and identifying components and dimensions.

🛠️ Troubleshooting common yacht plan issues involves addressing missing or incomplete information, incompatible or outdated details, and conflicting instructions.

🏗️ Building a yacht involves transferring plans to materials, cutting and shaping components, and following detailed construction notes.

🛠️ Cutting and shaping yacht components require the use of appropriate tools like saws, drills, cutters, and sandpaper.

🛠️ Assembling a yacht involves aligning, joining, and fastening components according to plans.

🌊 Rigging the yacht includes installing sails, mast, boom, and rigging, followed by testing its control and power systems.

If you have ever dreamed of building your own yacht , you might have wondered what yacht plans and blueprints are, and how to use them. In this article, we will explain everything you need to know about yacht design, construction, and maintenance, and how to find and acquire the best yacht plans and blueprints for your needs.

What are Yacht Plans & Blueprints and Why Use Them?

Yacht plans and blueprints are detailed drawings and specifications that show how to build a yacht from scratch. They include information such as:

- The dimensions and shape of the yacht hull, deck, cabin, and other components

- The materials and tools required for the yacht construction

- The assembly and installation instructions for the yacht components

- The rigging and wiring diagrams for the yacht sails, mast, rudder, engine, and other systems

- The performance and safety data for the yacht, such as speed, stability, buoyancy, and load capacity

Yacht plans and blueprints are essential for anyone who wants to build a yacht from scratch, because they provide a clear and accurate guide for the entire yacht building process. By using yacht plans and blueprints, you can:

- Save time and money by avoiding trial and error and unnecessary waste of materials

- Customize your yacht according to your preferences and requirements

- Learn new skills and gain confidence in your yacht building abilities

- Enjoy the satisfaction and pride of creating something unique and valuable

Benefits of Building a Yacht from Scratch

Building a yacht from scratch is not only a fun and rewarding hobby, but also a smart investment. Here are some of the benefits of building a yacht from scratch:

- You can choose the size, style, and features of your yacht, and make it as simple or as luxurious as you want

- You can control the quality and durability of your yacht, and ensure that it meets your standards and expectations

- You can save a lot of money by avoiding the high costs of buying a new or used yacht, or hiring a professional yacht builder

- You can increase the value of your yacht by adding your personal touch and creativity

- You can enjoy the freedom and adventure of sailing your own yacht, and explore new places and experiences

Essential Considerations Before Building a Yacht

Before you start building a yacht from scratch, there are some important things you need to consider, such as:

- Your budget: How much money can you afford to spend on your yacht project? You need to factor in the costs of the yacht plans, materials, tools, equipment, and maintenance.

- Your skill level: How experienced are you in yacht building? Do you have the necessary skills and knowledge to handle the yacht construction? Do you need any assistance or guidance from experts or other yacht builders?

- Your time frame: How long do you plan to spend on your yacht project? Do you have enough time and patience to complete the yacht building process? Do you have any deadlines or commitments that might affect your yacht project?

- Your purpose: What is the main reason why you want to build a yacht? Is it for personal use, for business, for recreation, or for competition? What are your goals and expectations for your yacht project?

- Your location: Where do you plan to build and store your yacht? Do you have enough space and facilities for your yacht project? Do you have access to water and electricity? Do you need any permits or licenses for your yacht project?

Safety Precautions and Guidelines

Building a yacht from scratch is a complex and challenging task that involves many risks and hazards. Therefore, you need to follow some safety precautions and guidelines, such as:

- Wear protective gear, such as gloves, goggles, masks, and boots, when working with tools and materials

- Use the right tools and equipment for the job, and follow the manufacturer’s instructions and recommendations

- Keep your work area clean and organized, and store your tools and materials properly

- Avoid working alone, and have someone nearby who can help you in case of an emergency

- Check your yacht regularly for any defects or damages, and repair them as soon as possible

- Test your yacht thoroughly before launching it, and make sure it is seaworthy and compliant with the regulations and standards

Understanding Yacht Design and Types

Yacht design is the art and science of creating a yacht that is functional, efficient, and aesthetically pleasing. Yacht design involves many aspects, such as:

- Yacht hull: The hull is the main body of the yacht that provides buoyancy, stability, and hydrodynamic performance. The hull can be classified into different types, such as displacement, planing, or multihull, depending on the shape and mode of propulsion.

- Yacht deck: The deck is the upper surface of the yacht that supports the crew, passengers, and equipment. The deck can be divided into different sections, such as foredeck, cockpit, aft deck, or flybridge, depending on the function and layout.

- Yacht cabin: The cabin is the enclosed space inside the yacht that provides shelter, comfort, and amenities. The cabin can have different rooms, such as saloon, galley, head, or berth, depending on the size and configuration.

- Yacht rig: The rig is the system of sails, mast, boom, and rigging that provides propulsion and control for the yacht. The rig can have different configurations, such as sloop, ketch, yawl, or schooner, depending on the number and arrangement of masts and sails.

Different types of yachts have different designs and characteristics, depending on the purpose and preference of the yacht owner. Some of the common types of yachts are:

- Motor yacht: A motor yacht is a yacht that is powered by one or more engines, and does not rely on sails for propulsion. Motor yachts are usually faster, larger, and more luxurious than sailing yachts, and can accommodate more people and equipment. Motor yachts are ideal for cruising, fishing, or entertaining.

- Sailing yacht: A sailing yacht is a yacht that is powered by sails, and uses the wind for propulsion. Sailing yachts are usually slower, smaller, and more economical than motor yachts, and require more skill and experience to operate. Sailing yachts are ideal for sailing, racing , or exploring.

- Catamaran: A catamaran is a yacht that has two parallel hulls connected by a platform or a bridge. Catamarans are more stable, spacious, and maneuverable than monohulls, and can sail in shallow waters. Catamarans are ideal for family, charter, or adventure.

- Trimaran: A trimaran is a yacht that has three hulls, with a main hull in the center and two smaller hulls on the sides. Trimarans are faster, lighter, and more agile than catamarans, and can handle rough seas. Trimarans are ideal for speed, sport, or thrill.

Key Components of a Yacht

A yacht is composed of many components that work together to provide functionality, performance, and comfort. Some of the key components of a yacht are:

- Hull: The hull is the main body of the yacht that provides buoyancy, stability, and hydrodynamic performance. The hull is made of materials such as wood, fiberglass , steel, or aluminum , and can have different shapes and sizes, depending on the type and design of the yacht.

- Deck: The deck is the upper surface of the yacht that supports the crew, passengers, and equipment. The deck is made of materials such as wood, fiberglass, steel, or teak, and can have different features and fittings, such as hatches, windows, doors, rails, cleats, or winches, depending on the function and layout of the yacht.

- Cabin: The cabin is the enclosed space inside the yacht that provides shelter, comfort, and amenities. The cabin is made of materials such as wood, fiberglass, steel, or plastic, and can have different rooms and facilities, such as saloon, galley, head, or berth, depending on the size and configuration of the yacht.

- Rig: The rig is the system of sails, mast, boom, and rigging that provides propulsion and control for the yacht. The rig is made of materials such as fabric, metal, or carbon, and can have different configurations and components, such as sloop, ketch, yawl, or schooner, depending on the number and arrangement of masts and sails.

- Engine: The engine is the device that converts fuel into mechanical power for the yacht. The engine can be either inboard or outboard, and can use different types of fuel, such as diesel, gasoline, or electric, depending on the power and efficiency of the yacht.

- Rudder: The rudder is the movable blade that controls the direction and steering of the yacht. The rudder is attached to the stern of the yacht, and can be operated by a tiller, a wheel, or a joystick, depending on the type and design of the yacht.

Factors to Consider When Choosing Yacht Plans

Choosing the right yacht plans for your needs is a crucial step in your yacht building project. Here are some factors to consider when choosing yacht plans:

- Budget: How much money can you afford to spend on your yacht plans? You need to compare the prices and quality of different yacht plans, and choose the ones that suit your budget and expectations. You also need to consider the costs of the materials, tools, equipment, and maintenance that are required for your yacht plans.

- Skill level: How experienced are you in yacht building? You need to assess your skills and knowledge in yacht construction, and choose the yacht plans that match your skill level and learning curve.

- Purpose: What is the main reason why you want to build a yacht? You need to define your purpose and goals for your yacht project, and choose the yacht plans that align with your purpose and goals. You also need to consider the intended use and function of your yacht, such as cruising, fishing, racing, or entertaining.

- Location: Where do you plan to build and sail your yacht? You need to consider the location and environment of your yacht project, and choose the yacht plans that suit your location and environment. You also need to consider the availability and accessibility of the materials, tools, equipment, and water for your yacht project.

- Design: What kind of yacht do you want to build? You need to consider the design and style of your yacht, and choose the yacht plans that match your design and style. You also need to consider the size, shape, and features of your yacht, such as hull, deck, cabin, rig, engine, and rudder.

Evaluating Yacht Plans for Accuracy and Completeness

After you have chosen your yacht plans, you need to evaluate them for accuracy and completeness. You need to check if the yacht plans:

- Are clear and detailed, and provide all the necessary information and instructions for the yacht construction

- Are accurate and reliable, and reflect the current standards and best practices of yacht design and building

- Are complete and consistent, and cover all the aspects and components of the yacht project

- Are compatible and adaptable, and can be modified or customized according to your needs and preferences

You can evaluate your yacht plans by:

- Reading and reviewing the yacht plans carefully, and looking for any errors, omissions, or inconsistencies

- Comparing and cross-referencing the yacht plans with other sources, such as books, magazines, websites, or experts

- Testing and verifying the yacht plans with simulations, models, or prototypes, and checking for any issues or problems

If you find any problems or discrepancies with your yacht plans, you need to contact the yacht plan provider and ask for clarification, correction, or replacement. You can also seek advice or assistance from other yacht builders or experts, or use your own judgment and creativity to solve the problem.

Finding and Acquiring Yacht Plans & Blueprints

Once you have decided to build a yacht from scratch, you need to find and acquire the best yacht plans and blueprints for your project. In this article, we will show you where to find yacht plans and blueprints, how to choose the right ones for your needs, and how to read and understand them.

Where to Find Yacht Plans & Blueprints

There are many sources where you can find yacht plans and blueprints, both online and offline. Some of the common sources are:

- Websites: There are many websites that offer free or paid yacht plans and blueprints, either as downloadable files or as online services. Some examples of websites that offer yacht plans and blueprints are:

- Books: There are many books that contain yacht plans and blueprints, as well as information and instructions on yacht design and building. Some examples of books that contain yacht plans and blueprints are:

- Magazines: There are many magazines that feature yacht plans and blueprints, as well as articles and reviews on yacht design and building. Some examples of magazines that feature yacht plans and blueprints are:

- Online Forums: There are many online forums where you can interact with other yacht builders and enthusiasts, and get advice and feedback on yacht design and building. You can also find and share yacht plans and blueprints with other members of the forum. Some examples of online forums that are related to yacht design and building are:

How to Choose the Right Yacht Plans for Your Needs

Finding yacht plans and blueprints is not enough. You also need to choose the right ones for your needs. Here are some tips for choosing the right yacht plans for your needs:

- Define your needs and preferences: Before you start looking for yacht plans and blueprints, you need to define your needs and preferences for your yacht project. You need to consider factors such as your budget, skill level, time frame, purpose, location, and design, and choose the yacht plans that suit your needs and preferences.

- Compare and contrast different yacht plans: After you have found some yacht plans and blueprints that match your needs and preferences, you need to compare and contrast them to find the best ones for your project. You need to consider factors such as the price, quality, reliability, completeness, compatibility, and adaptability of the yacht plans, and choose the ones that offer the best value and performance for your project.

- Seek advice and feedback from experts and other yacht builders: If you are not sure about which yacht plans and blueprints to choose, you can seek advice and feedback from experts and other yacht builders. You can consult with yacht designers, boat builders, or yacht owners, or join online forums or communities, and ask for their opinions and recommendations on yacht plans and blueprints. You can also read reviews and testimonials from other yacht builders who have used the yacht plans and blueprints that you are interested in, and learn from their experiences and insights.

Reading and Understanding Yacht Plans & Blueprints

Once you have chosen your yacht plans and blueprints, you need to read and understand them. You need to learn how to interpret the information and instructions that are provided in the yacht plans and blueprints, and how to apply them to your yacht project. Here are some steps for reading and understanding yacht plans and blueprints:

- Learn the basic blueprint conventions: Before you start reading and understanding yacht plans and blueprints, you need to learn the basic blueprint conventions that are used to represent the yacht design and construction. You need to learn the symbols, abbreviations, units, scales, and dimensions that are used in yacht plans and blueprints, and what they mean and how to use them. You can find the basic blueprint conventions in books, websites, or online tutorials, or ask for help from experts or other yacht builders.

- Identify the different components and dimensions: After you have learned the basic blueprint conventions, you need to identify the different components and dimensions that are shown in the yacht plans and blueprints. You need to recognize the parts and features of the yacht, such as the hull, deck, cabin, rig, engine, and rudder, and their shapes and sizes, as well as their positions and orientations. You also need to measure and calculate the distances, angles, areas, and volumes of the yacht components, and check for any errors or discrepancies.

- Read and understand the yacht construction notes: In addition to the drawings and specifications, the yacht plans and blueprints also provide the yacht construction notes that explain how to build the yacht from scratch. You need to read and understand the yacht construction notes, and follow the instructions and guidelines that are given. You also need to pay attention to any warnings, cautions, or tips that are provided in the yacht construction notes, and avoid any mistakes or problems that might occur during the yacht construction.

Troubleshooting Common Yacht Plan and Blueprint Issues

Even if you have chosen the best yacht plans and blueprints for your project, you might still encounter some issues or problems with them. Here are some of the common yacht plan and blueprint issues, and how to troubleshoot them:

- Missing or incomplete information: Sometimes, the yacht plans and blueprints might be missing or incomplete, and lack some of the information or instructions that are needed for the yacht construction. This might be due to the poor quality or reliability of the yacht plan provider, or the modification or customization of the yacht plans and blueprints. To troubleshoot this issue, you can contact the yacht plan provider and ask for clarification, correction, or replacement, or seek advice or assistance from experts or other yacht builders, or use your own judgment and creativity to solve the problem.

- Incompatible or outdated information: Sometimes, the yacht plans and blueprints might be incompatible or outdated, and not match the current standards and best practices of yacht design and building. This might be due to the changes or developments in the yacht industry, or the differences or variations in the yacht materials, tools, equipment, and regulations. To troubleshoot this issue, you can compare and cross-reference the yacht plans and blueprints with other sources, such as books, magazines, websites, or experts, and update or adapt the yacht plans and blueprints according to the current standards and best practices of yacht design and building.

- Conflicting or contradictory information: Sometimes, the yacht plans and blueprints might be conflicting or contradictory, and provide different or opposite information or instructions for the yacht construction. This might be due to the errors or mistakes of the yacht plan provider, or the customization or modification of the yacht plans and blueprints. To troubleshoot this issue, you can contact the yacht plan provider and ask for clarification, correction, or replacement, or seek advice or assistance from experts or other yacht builders, or use your own judgment and creativity to resolve the conflict or contradiction.

Building a Yacht from Plans

After you have found and acquired the best yacht plans and blueprints for your project, you are ready to start building your yacht from scratch. In this article, we will guide you through the steps of building a yacht from plans, and provide you with some tips and tricks for a successful yacht construction.

Transferring Yacht Plans & Blueprints to Building Materials

The first step of building a yacht from plans is to transfer the yacht plans and blueprints to the building materials. This means that you need to mark and cut the materials according to the dimensions and shapes that are shown in the yacht plans and blueprints. Here are some steps for transferring yacht plans and blueprints to building materials:

- Choose the right materials: Depending on the type and design of your yacht, you need to choose the right materials for your yacht construction. Some of the common materials that are used for yacht building are wood, fiberglass, steel, or aluminum. You need to consider the advantages and disadvantages of each material, such as the cost, weight, strength, durability, and appearance, and choose the ones that suit your budget, skill level, and preference.

- Use the right tools: To transfer the yacht plans and blueprints to the building materials, you need to use the right tools for the job. Some of the tools that you need are a scale ruler, a compass, a protractor, a tape measure, a pencil, a marker, a saw, a drill, a clamp, and a cutter. You need to follow the manufacturer’s instructions and recommendations for using the tools, and wear protective gear, such as gloves, goggles, masks, and boots, when working with the tools.

- Lay the building material on a flat and stable surface, and secure it with clamps or weights

- Use a scale ruler to measure the scale of the yacht plans and blueprints, and adjust it to the size of the building material

- Use a compass and a protractor to draw the curves and angles of the yacht components, such as the hull, deck, cabin, and rig, on the building material

- Use a tape measure and a pencil to mark the lengths and widths of the yacht components, such as the hull, deck, cabin, and rig, on the building material

- Use a marker to highlight the outlines and details of the yacht components, such as the hull, deck, cabin, and rig, on the building material

- Use a saw and a drill to cut and shape the yacht components, such as the hull, deck, cabin, and rig, from the building material

- Use a cutter to trim and smooth the edges and surfaces of the yacht components, such as the hull, deck, cabin, and rig, from the building material

Cutting and Shaping Yacht Components

The second step of building a yacht from plans is to cut and shape the yacht components according to the yacht plans and blueprints. This means that you need to use the tools and materials that you have prepared in the previous step, and follow the instructions and guidelines that are provided in the yacht plans and blueprints. Here are some steps for cutting and shaping yacht components:

- Place the building material that has the yacht component marked on it on a flat and stable surface, and secure it with clamps or weights

- Use the saw to cut along the outlines and details of the yacht component, such as the hull, deck, cabin, and rig, from the building material

- Use the drill to make holes and openings for the yacht component, such as the hull, deck, cabin, and rig, from the building material

- Remove the excess material and the clamps or weights from the yacht component, and set it aside

- Place the yacht component that has been cut from the building material on a flat and stable surface, and secure it with clamps or weights

- Use the cutter to trim and smooth the edges and surfaces of the yacht component, such as the hull, deck, cabin, and rig, from the building material

- Use the sandpaper to polish and refine the edges and surfaces of the yacht component, such as the hull, deck, cabin, and rig, from the building material

- Remove the dust and the clamps or weights from the yacht component, and set it aside

Assembling the Yacht According to the Plans

The third step of building a yacht from plans is to assemble the yacht according to the plans. This means that you need to use the tools and materials that you have prepared in the previous steps, and follow the instructions and guidelines that are provided in the yacht plans and blueprints. Here are some steps for assembling the yacht according to the plans:

- Place the yacht components that have been cut and shaped from the building materials on a flat and stable surface, and arrange them according to the layout and orientation that are shown in the yacht plans and blueprints

- Use the tape measure and the pencil to mark the positions and distances of the yacht components, such as the hull, deck, cabin, and rig, from each other and from the surface

- Use the marker to highlight the marks and the level to check the alignment of the yacht components, such as the hull, deck, cabin, and rig, from each other and from the surface

- Place the yacht components that have been aligned from the previous step on a flat and stable surface, and secure them with clamps or weights

- Use the screws, nails, glue, and brackets to join the yacht components, such as the hull, deck, cabin, and rig, from each other and from the surface, according to the instructions and guidelines that are provided in the yacht plans and blueprints

- Remove the clamps or weights from the yacht components, and set them aside

- Place the yacht components that have been joined from the previous step on a flat and stable surface, and secure them with clamps or weights

- Use the bolts, nuts, washers, and pins to fasten the yacht components, such as the hull, deck, cabin, and rig, from each other and from the surface, according to the instructions and guidelines that are provided in the yacht plans and blueprints

Rigging and Testing the Yacht

The final step of building a yacht from plans is to rig and test the yacht. This means that you need to use the tools and materials that you have prepared in the previous steps, and follow the instructions and guidelines that are provided in the yacht plans and blueprints. Here are some steps for rigging and testing the yacht:

- Place the yacht that has been assembled from the previous step on a flat and stable surface, and secure it with clamps or weights

- Use the sails, mast, boom, and rigging to install the rig system for the yacht, according to the instructions and guidelines that are provided in the yacht plans and blueprints

- Remove the clamps or weights from the yacht, and set it aside

- Place the yacht that has been rigged from the previous step on a flat and stable surface, and secure it with clamps or weights

- Use the rudder, engine, and instruments to install the control and power systems for the yacht, according to the instructions and guidelines that are provided in the yacht plans and blueprints

- Remove the clamps or weights from the yacht, and transport it to the water

- Launch the yacht into the water, and check the buoyancy, stability, and performance of the yacht, according to the data and specifications that are provided in the yacht plans and blueprints

- Make any adjustments or repairs that are needed for the yacht, and enjoy your yacht

FAQs – Yacht Plans & Blueprints

In this article, we have covered everything you need to know about yacht plans and blueprints, and how to build a yacht from scratch. However, you might still have some questions or doubts about yacht design and building. Here are some of the frequently asked questions (FAQs) that we have received from our readers, and our answers to them.

What are the most common challenges faced when building a yacht from plans?

Building a yacht from plans is a rewarding and satisfying project, but it also comes with some challenges and difficulties. Some of the most common challenges faced when building a yacht from plans are:

- Finding and acquiring high-quality and reliable yacht plans and blueprints that suit your needs and preferences

- Reading and understanding yacht plans and blueprints, and transferring them to building materials

- Cutting and shaping yacht components, and assembling them according to the plans

- Rigging and testing the yacht, and ensuring its safety and performance

- Dealing with any errors, mistakes, or problems that might occur during the yacht construction

To overcome these challenges, you need to follow the tips and tricks that we have provided in this article, and seek advice and feedback from experts and other yacht builders.

How can I ensure the safety and stability of my yacht?

Safety and stability are two of the most important aspects of yacht design and building. You need to ensure that your yacht is safe and stable, and can withstand the forces and conditions of the water. To ensure the safety and stability of your yacht, you need to:

- Choose the right yacht plans and blueprints that match the current standards and best practices of yacht design and building

- Choose the right materials and tools that are durable and suitable for yacht construction

- Follow the instructions and guidelines that are provided in the yacht plans and blueprints, and avoid any deviations or modifications that might compromise the safety and stability of your yacht

- Check and test your yacht regularly for any defects or damages, and repair them as soon as possible

- Follow the regulations and certifications that are required for yachts, and obtain the necessary permits and licenses for your yacht project

What are the regulations and certifications required for yachts?

Depending on the type, size, and purpose of your yacht, you might need to comply with some regulations and certifications that are required for yachts. These regulations and certifications are designed to ensure the safety, quality, and performance of yachts, and to protect the environment and the public interest. Some of the common regulations and certifications that are required for yachts are:

- Registration: You need to register your yacht with the appropriate authority, such as the coast guard, the maritime administration, or the local government, and obtain a registration number and a certificate of registration for your yacht. Registration is required for identification, taxation, and ownership purposes, and to prove that your yacht meets the legal requirements and standards.

- Inspection: You need to inspect your yacht periodically by a qualified inspector, such as a surveyor, an engineer, or a naval architect, and obtain a certificate of inspection for your yacht. Inspection is required to verify that your yacht is seaworthy and compliant with the regulations and standards, and to identify and correct any issues or problems that might affect the safety and performance of your yacht.

- Insurance: You need to insure your yacht with a reputable insurance company, and obtain a policy and a certificate of insurance for your yacht. Insurance is required to protect your yacht from any risks or damages that might occur during the yacht construction or operation, and to cover any liabilities or claims that might arise from your yacht project.

What are the ongoing maintenance and upkeep requirements for a yacht?

Owning a yacht is not only a one-time investment, but also a long-term commitment. You need to maintain and upkeep your yacht regularly, and ensure that it is in good condition and working order. Some of the ongoing maintenance and upkeep requirements for a yacht are:

- Cleaning: You need to clean your yacht frequently, and remove any dirt, dust, or debris that might accumulate on your yacht. Cleaning is required to prevent any corrosion, deterioration, or infection that might affect the quality and appearance of your yacht, and to keep your yacht hygienic and comfortable.

- Painting: You need to paint your yacht occasionally, and apply a fresh coat of paint or varnish on your yacht. Painting is required to protect your yacht from the effects of the sun, water, and weather, and to enhance the beauty and durability of your yacht.

- Repairing: You need to repair your yacht promptly, and fix any faults or damages that might occur on your yacht. Repairing is required to restore the functionality and performance of your yacht, and to avoid any further complications or consequences that might result from the faults or damages.

- Servicing: You need to service your yacht regularly, and check and tune the systems and components of your yacht, such as the rig, engine, rudder, and instruments. Servicing is required to optimize the efficiency and reliability of your yacht, and to prevent any breakdowns or malfunctions that might occur on your yacht.

Where can I find resources and support for building and maintaining a yacht?

Building and maintaining a yacht is not an easy task, and you might need some resources and support for your yacht project. Here are some of the resources and support that you can find for building and maintaining a yacht:

- Books: There are many books that contain yacht plans and blueprints, as well as information and instructions on yacht design and building. You can find these books in libraries, bookstores, or online, and use them as references and guides for your yacht project.

- Websites: There are many websites that offer yacht plans and blueprints, as well as articles and resources on yacht design and building. You can find these websites on the internet, and use them as sources and tools for your yacht project.

- Magazines: There are many magazines that feature yacht plans and blueprints, as well as articles and reviews on yacht design and building. You can find these magazines in newsstands, subscriptions, or online, and use them as inspiration and feedback for your yacht project.

- Online Forums: There are many online forums where you can interact with other yacht builders and enthusiasts, and get advice and feedback on yacht design and building. You can find these online forums on the internet, and use them as communities and support for your yacht project.

- Experts: There are many experts who are knowledgeable and experienced in yacht design and building, such as yacht designers, boat builders, or yacht owners. You can find these experts in person, by phone, or online, and use them as consultants and mentors for your yacht project.

Conclusion – Yacht Plans & Blueprints

Building a yacht from scratch using plans and blueprints is a rewarding endeavor that allows you to create a unique vessel tailored to your preferences and needs. From choosing the right plans to assembling and testing the yacht, the process involves careful consideration of various factors. By following safety precautions, adhering to design principles, and seeking guidance when needed, you can turn your dream of building a yacht into a reality.

Remember, the journey of constructing a yacht is not only about the final product but also about the skills gained, the challenges overcome, and the satisfaction of creating something truly special. Whether for personal use, business, recreation, or competition, building a yacht from scratch offers a fulfilling experience that combines craftsmanship, creativity, and the joy of sailing on your own creation.

Written by DIY Boat Building Plans

Yacht Painting Tips

Yacht Polishing Tips

Model Yacht Building

Introduction: Model Yacht Building