Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

- Collections

Blue Water Boats

This collection of capable blue water boats features time-tested sailboats with rich histories.

Bluewaterboats.org built an encyclopedia of offshore sailboats for the sailing community. It contains a thorough summary of the history, details of the design and construction, and sailing characteristics on 99 sailboats.

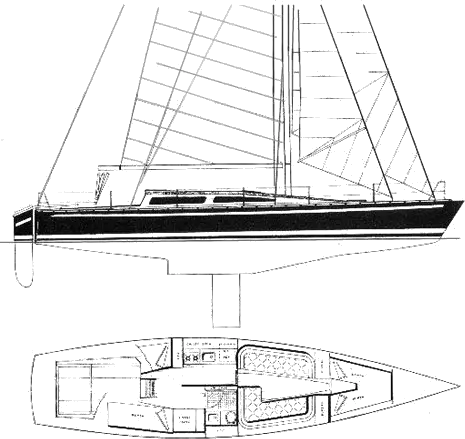

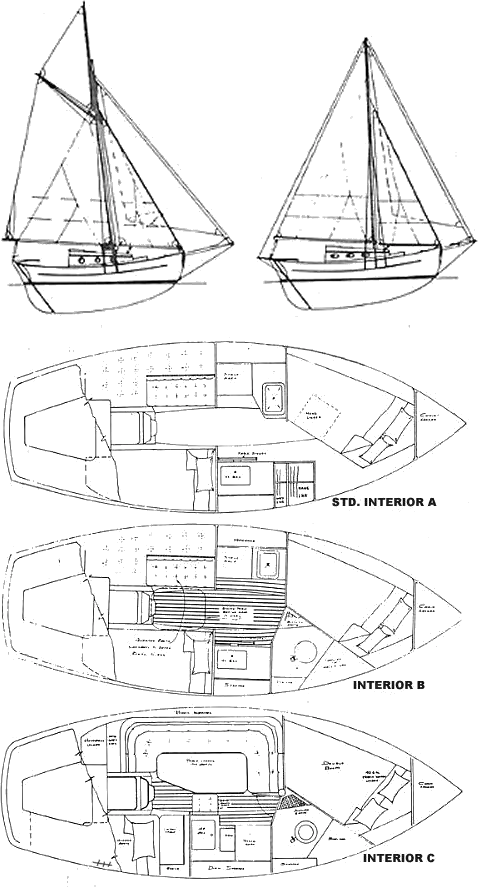

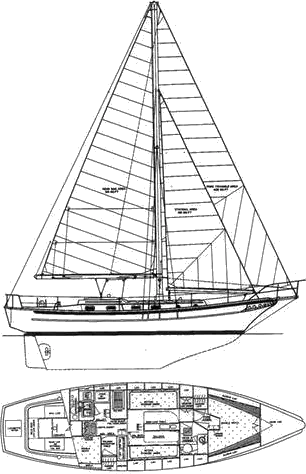

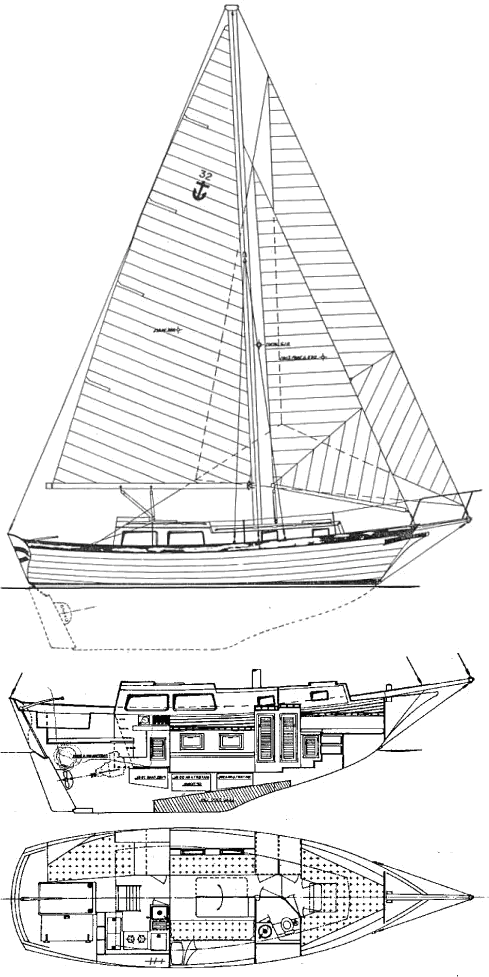

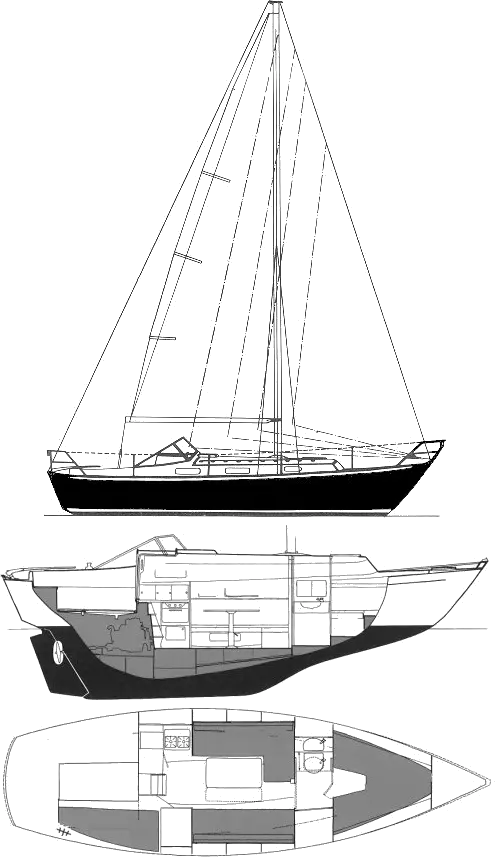

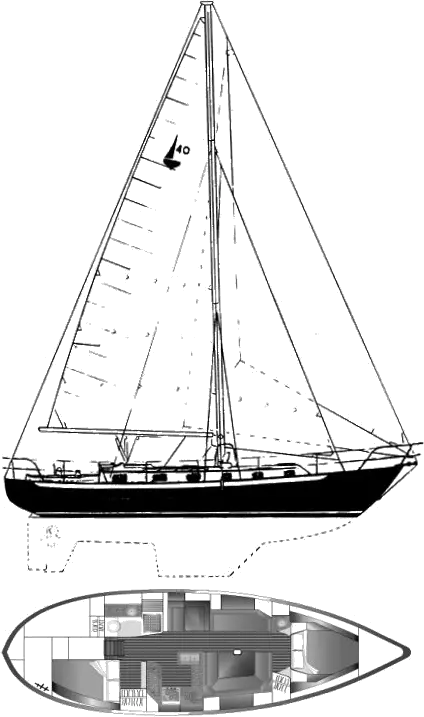

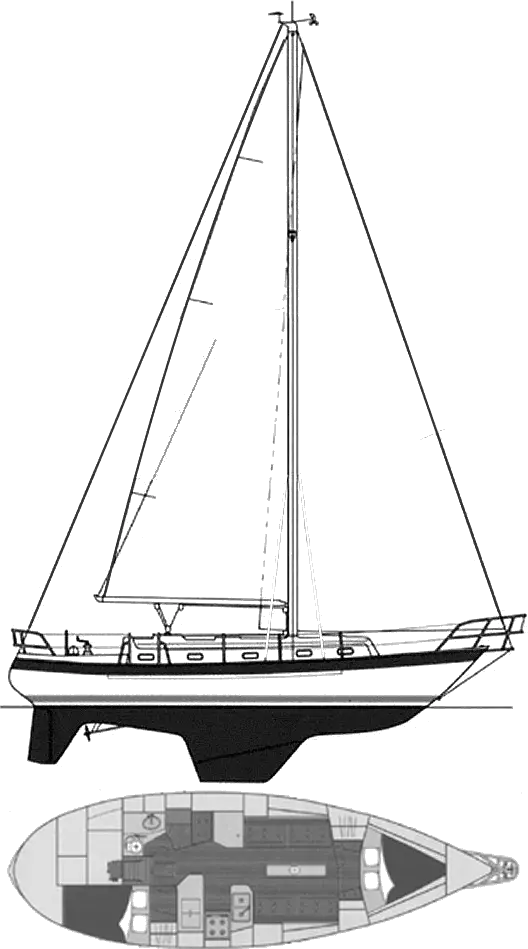

Alajuela 33

Alajuela 38

Albin Vega 27

Allied Seawind MK II Ketch

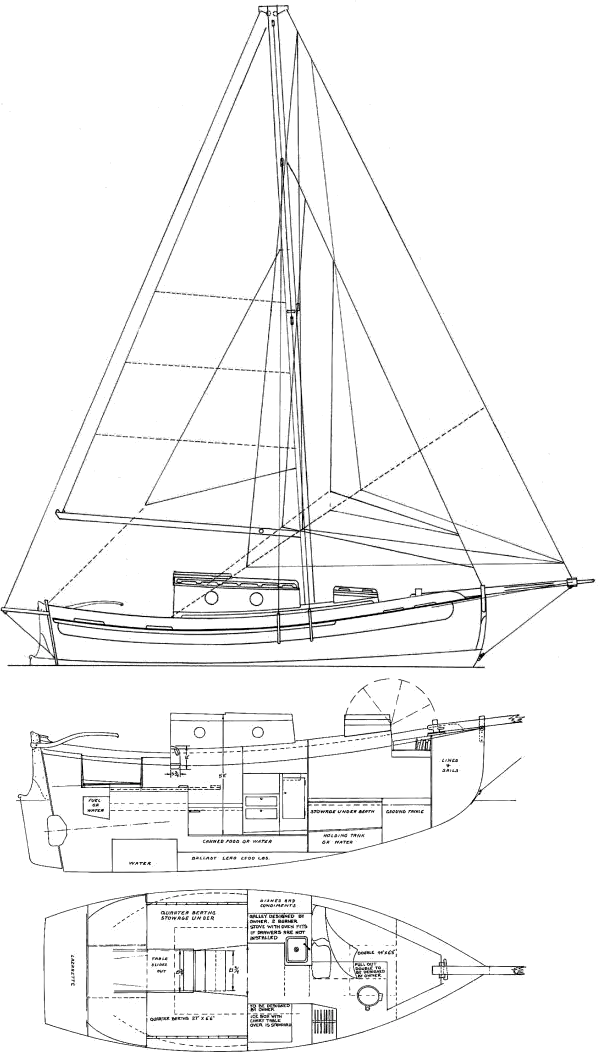

Aquarius 24 Pilot Cutter

Bayfield 36/40

Bristol 41.1

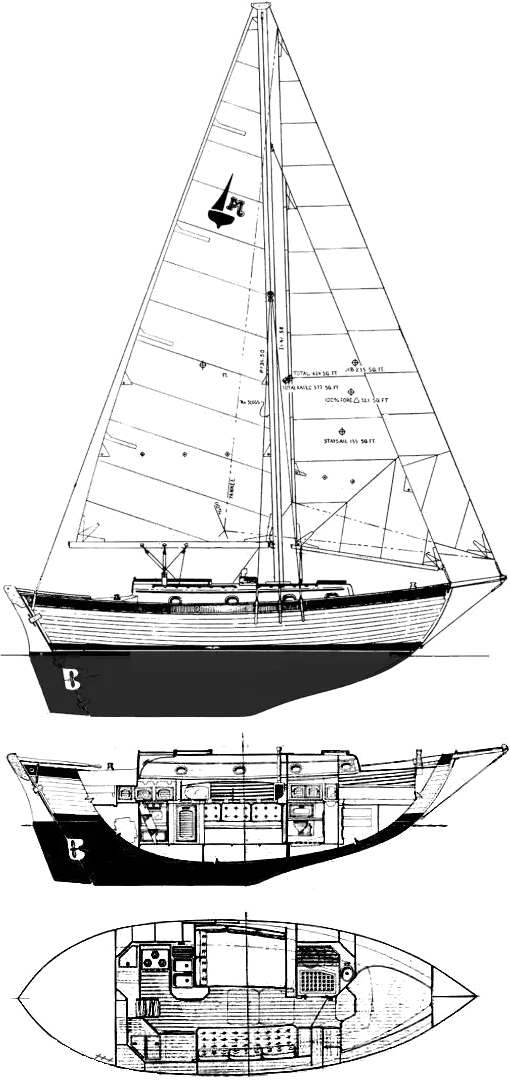

Bristol Channel Cutter

Cabo Rico 38

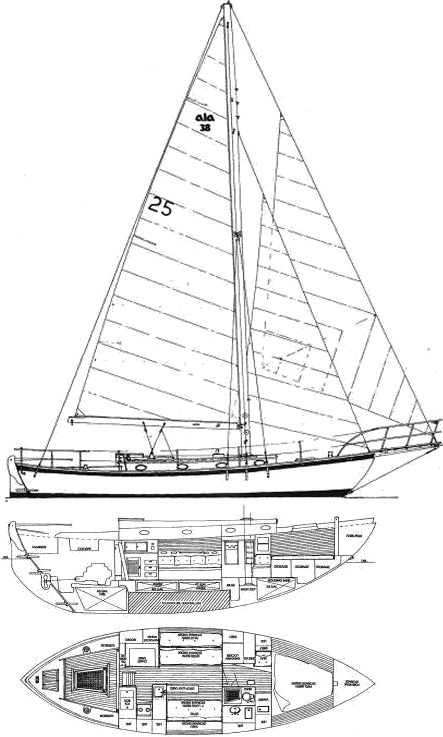

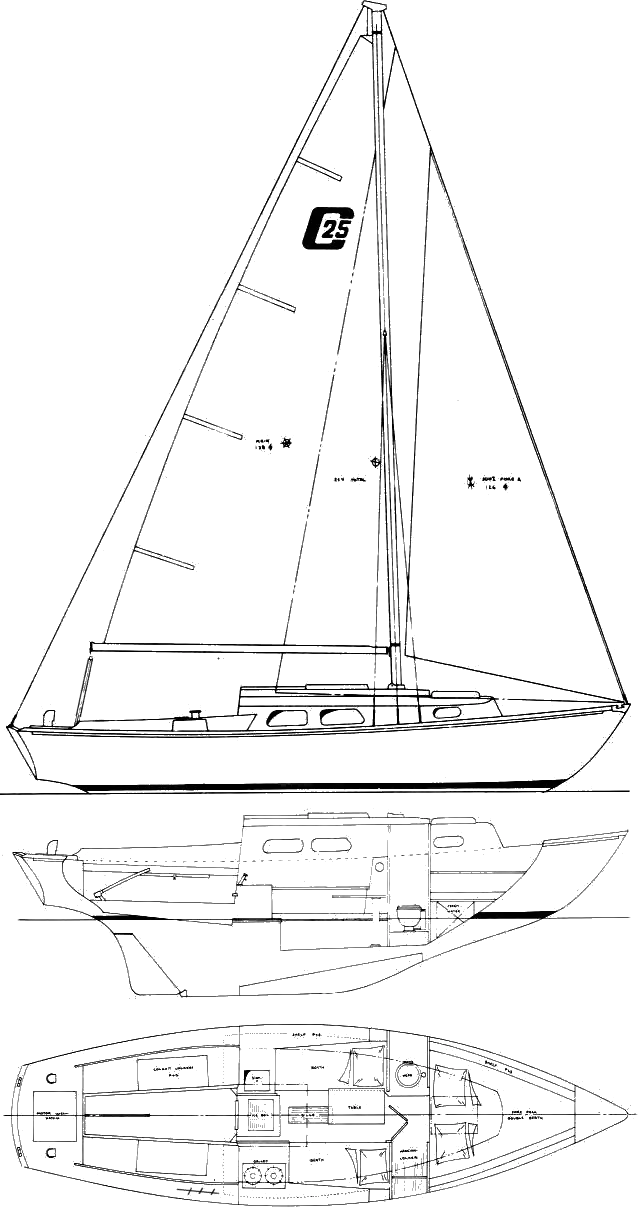

Cape Dory 25

Cape Dory 28

Cape Dory 36

Cape George 36

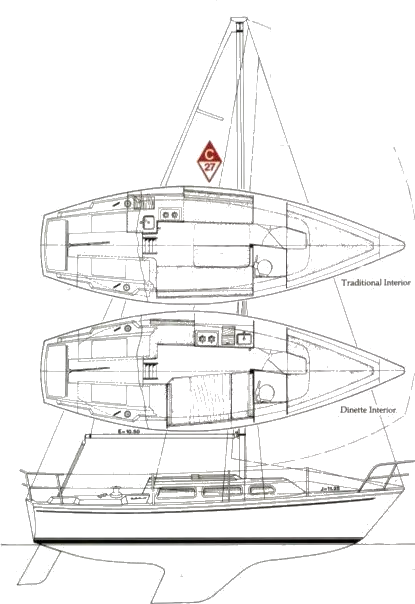

Catalina 27

Cavalier 32

Cavalier 36

Columbia 29

Contessa 26

Contessa 32

Pacific Seacraft Dana 24

Downeaster 32

Endeavour 42

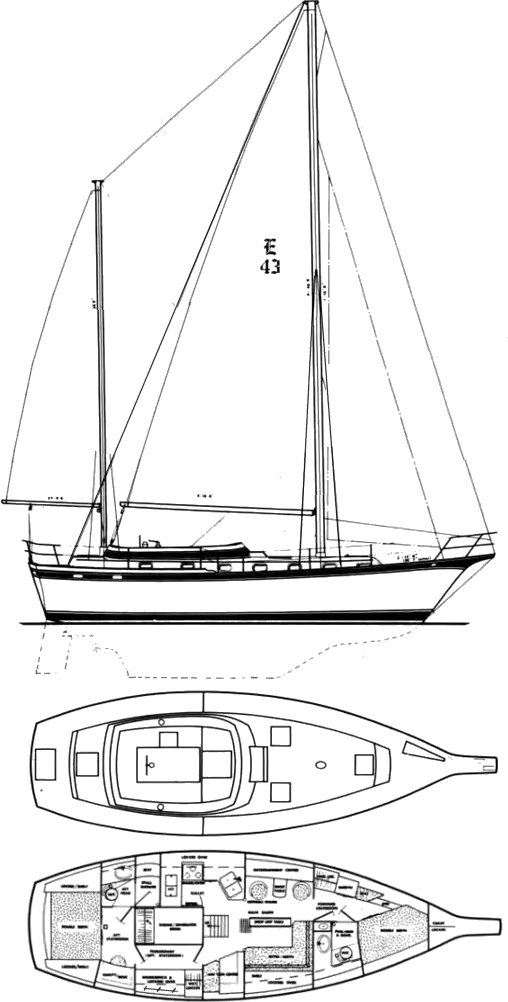

Endeavour 43

Falmouth Cutter 22

Fast Passage 39

Pipedream 37

Gemini 105M

Hallberg-Rassy 31

Hans Christian 33

Hans christian 38 mkii.

Hans Christian 38 Traditional

Hans Christian 41 Traditional

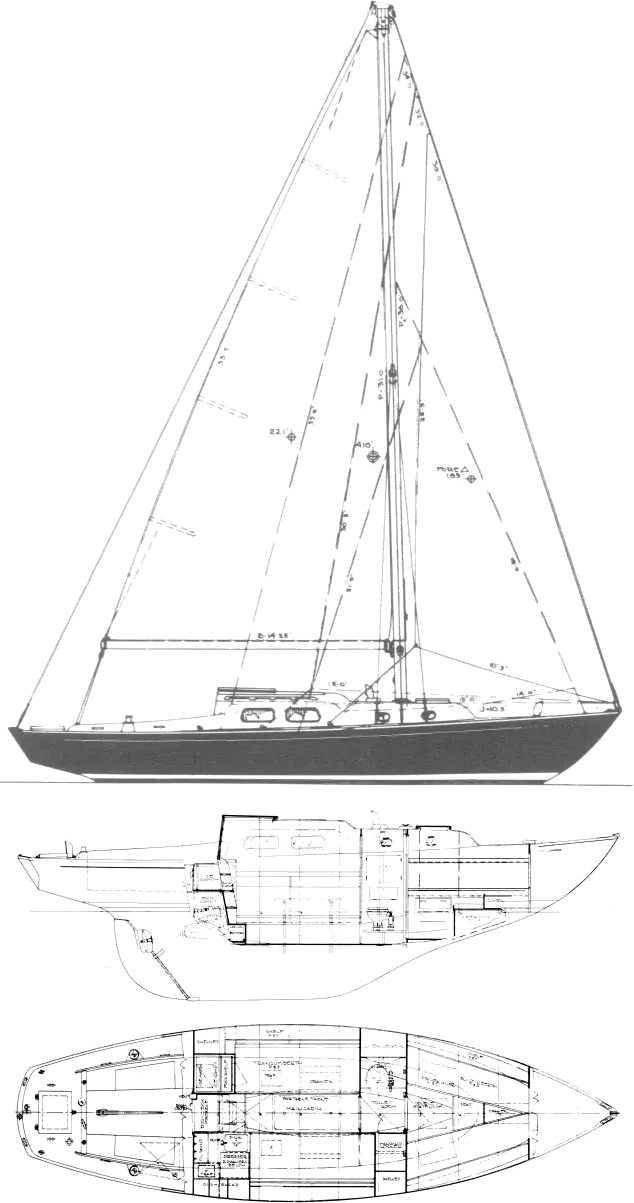

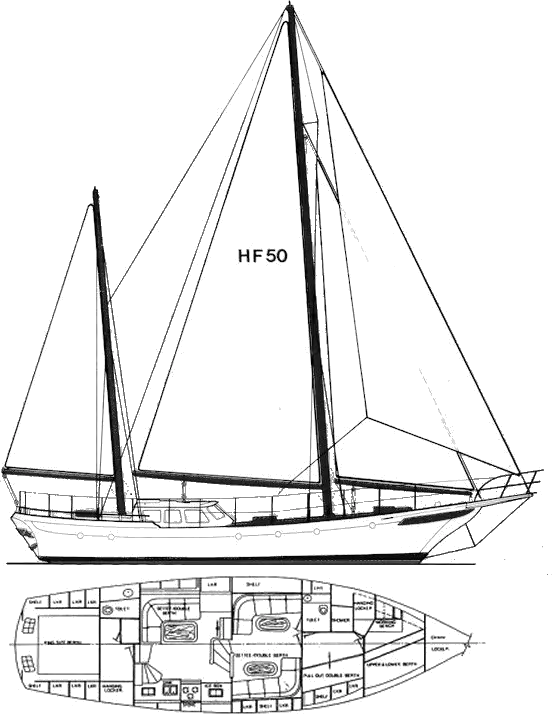

Hudson Force 50

Island Packet 31

Gin Fizz 37

Kelly-Peterson 44

Lord Nelson 35

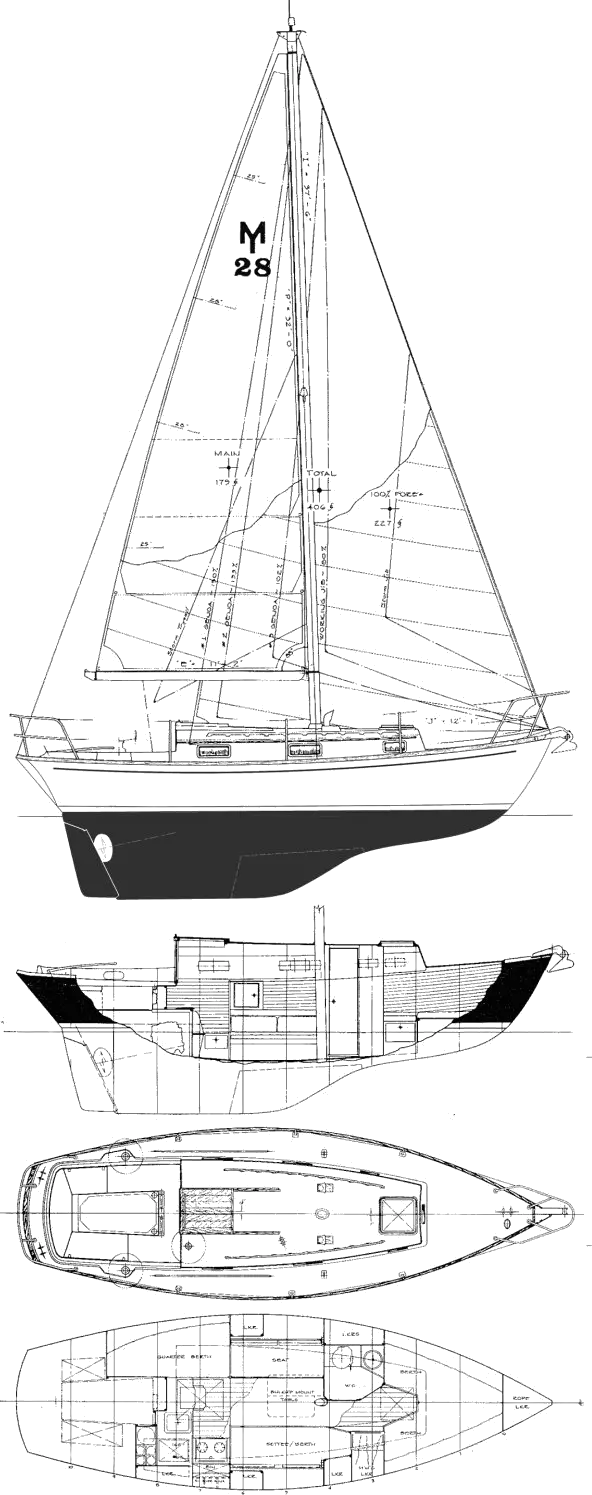

Morris 28 Linda

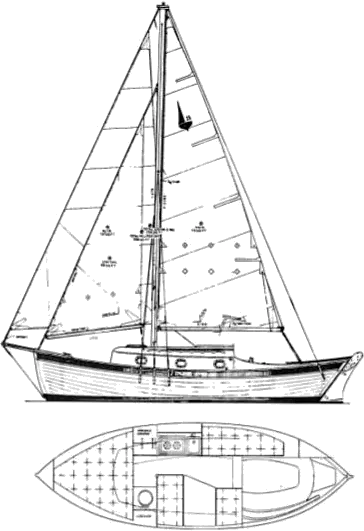

Nor'sea 27.

Pacific Seacraft 25

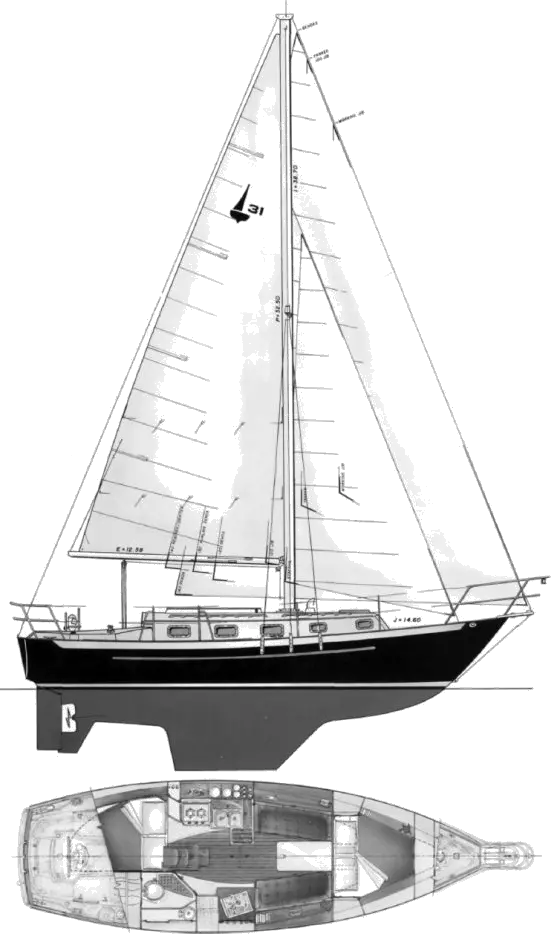

Pacific Seacraft 31

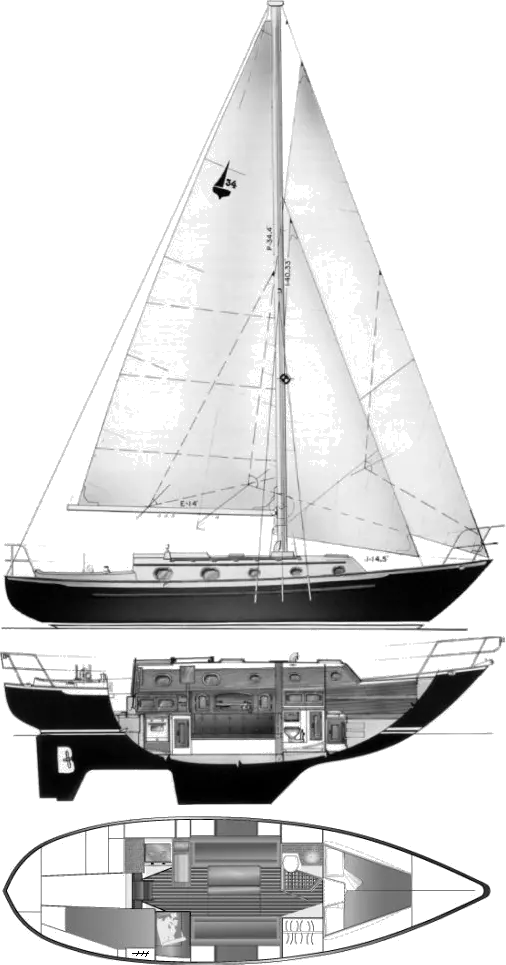

Pacific Seacraft 34

Pacific Seacraft 40

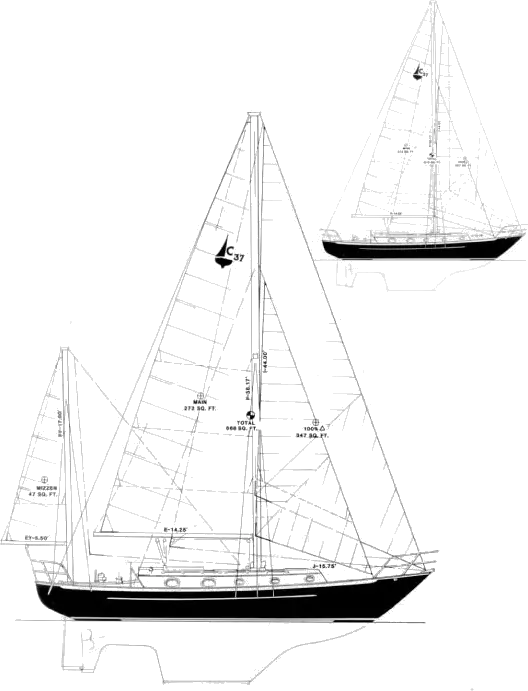

Pacific Seacraft Crealock 37

Pacific Seacraft Orion 27

Passport 40

Pearson 36 Cutter

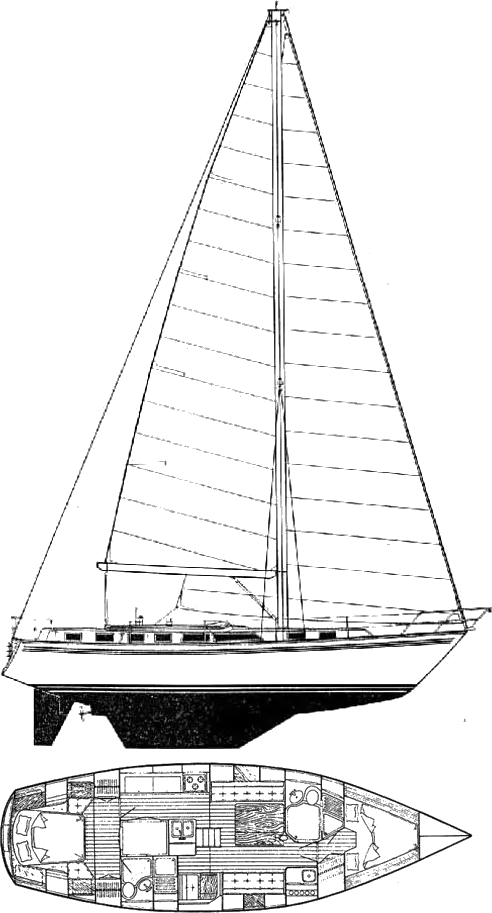

Pearson Rhodes 41

Pearson Triton

Tom thumb 24.

Southern Cross 31

Southern Cross 35

Southern cross 39.

Spencer 35 MK I

Tartan 37 (S&S)

Tayana Vancouver 42

Valiant Esprit 37

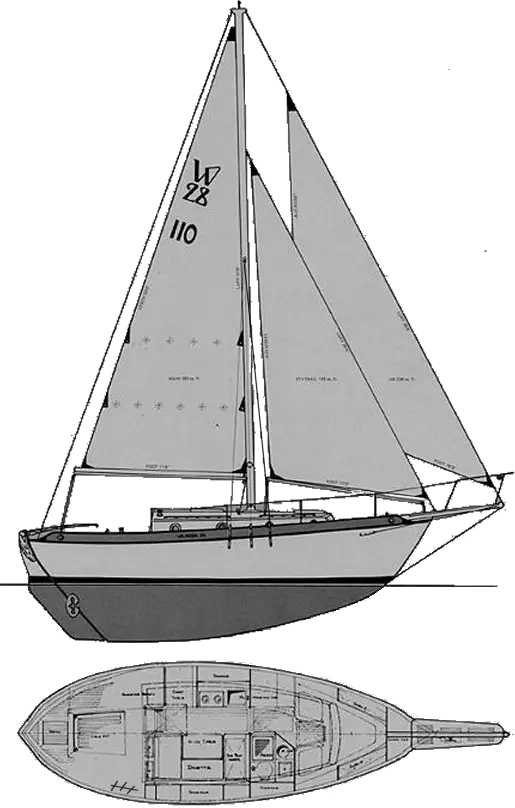

Vancouver 27

Pretorien 35

Westsail 28

Westsail 32

Westsail 42

Embed this page on your own website by copying and pasting this code.

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

7 Legendary Solo Bluewater Sailboats Worth Considering

When setting out to explore the open seas solo, you'll have to choose the right bluewater sailboat from so very many available options. The perfect boat for sailing single-handed is one that's not only safe and seaworthy, but also easy to handle on your own. In this article, we've handpicked the top 7 legendary solo bluewater sailboats worth considering for their excellent track records.

The most legendary solo bluewater sailboats are the Contessa 32, Westsail 32, Hallberg-Rassy 42F, Pacific Seacraft 37, Island Packet 38, Tayana 42, and Amel 54. These boats have it all: from robust designs to a world-renowned reputation for performance and reliability. They are known for their seaworthiness, durability, and comfort.

We understand the importance of balancing comfort and performance when spending prolonged periods at sea. Each of these sailboats has been proven to provide a harmonious blend of these attributes. Let's get to know them more below.

- Solo bluewater sailboats are designed to be sailed by a single person, making them ideal for solo circumnavigation or long-distance cruising.

- You can get the Contessa 32 and Westsail 32 for as little as $30,000.

- The maintenance and repair costs of the seven boats range from $5,000 to $50,000 per year.

- Marina fees and insurance can range from $5,000 to $20,000 per year.

- Factor in upgrades and equipment costs that can reach up to $100,000.

On this page:

The best solo bluewater sailboats, what makes a good solo bluewater sailboat, cost considerations when choosing a sailboat, maintaining your bluewater sailboat, contessa 32 is a classic, compact, and seaworthy sailboat.

Contessa 32's sturdy construction and excellent sailing performance have earned it a legendary reputation among sailors. With a well-designed interior layout, it has space for living aboard during your solo adventures. The Contessa 32 is a classic bluewater sailboat designed by David Sadler in the 1970s. It is known for its excellent balance, seaworthiness, and speed. It has a full keel, moderate displacement, and a classic design that has stood the test of time.

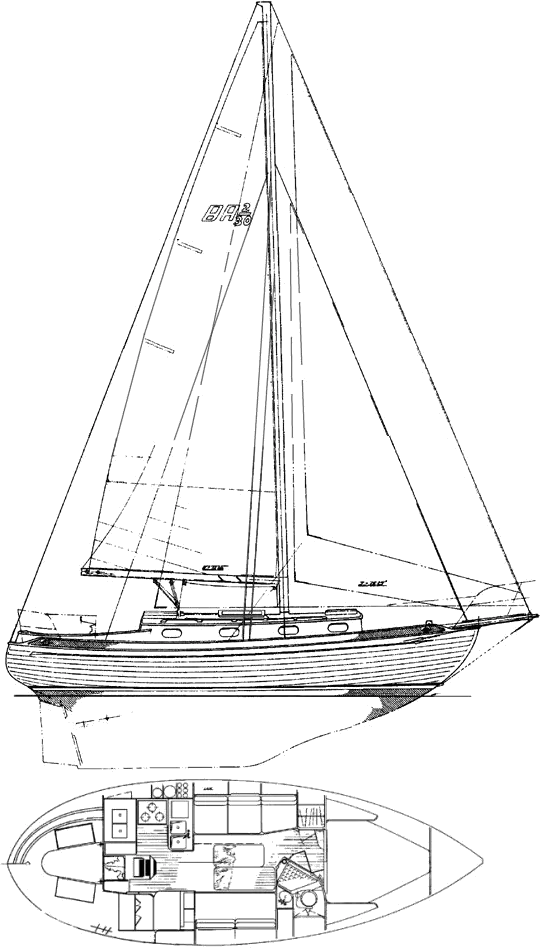

Westsail 32 is known for its rugged construction

The Westsail 32 gained fame as an affordable, rugged, and capable long-distance cruiser. Its full keel and sturdy hull ensure a comfortable ride in rough seas. The practical, function-driven interior makes it easy for solo sailors to maintain and navigate the vessel while providing essential amenities for an extended voyage.

Westsail 32 is another classic bluewater sailboat that was designed by William Crealock in the 1970s. It is known for its rugged construction, spacious interior, and excellent performance in heavy weather. The Westsail 32 has a full keel, heavy displacement, and a classic double-ender design.

Hallberg-Rassy 42F is known for its top-notch craftsmanship

The Hallberg-Rassy 42F is another superb choice for single-handed bluewater sailing. This Swedish-built yacht is well-renowned for its top-notch craftsmanship, stability, and comfort. It offers a spacious, well-lit interior, ensuring you'll enjoy your time below deck while cruising the open seas.

Hallberg-Rassy 42F is a modern bluewater sailboat designed by German Frers in the 1990s. It is known for its luxurious interior, excellent performance, and high-quality construction. The Hallberg-Rassy 42F has a fin keel, a spade rudder, and a modern design that combines comfort and performance.

Pacific Seacraft 37 is designed for serious cruising

Pacific Seacraft 37 is a sturdy and reliable boat for solo sailors. Its moderate displacement and full keel provide excellent stability, while the well-thought-out interior layout includes abundant storage and comfortable living quarters. Its reputation as a proven bluewater cruiser makes it a top choice for solo sailors. The Pacific Seacraft 37 is another classic bluewater sailboat designed by Bill Crealock in the 1970s. It is known for its excellent balance, seaworthiness, and comfort.

Island Packet 38 is known for its spacious interior

Island Packet 38 is a popular choice among solo cruisers, thanks to its stable full keel design and living space. Its build quality, comfort, and performance make it well-suited for long-distance sailing. The spacious interior and practical layout ensure you have everything needed for a successful solo journey. Island Packet 38 is a modern bluewater sailboat designed by Bob Johnson in the 1990s. It 38 has a full keel, moderate displacement, and a modern design that combines comfort and performance.

Aside from bluewater sailing , there are other types of sailing discussed in this article.

Tayana 42 is known for its excellent balance, seaworthiness, and comfort

Tayana 42 is a comfortable, sea-kindly sailboat, ideal for single-handed offshore cruising. Its balanced performance, easy handling, and well-equipped interior ensure a safe and comfortable journey. It is well-regarded among sailors for its proven bluewater capabilities and timeless styling. The Tayana 42 is another classic bluewater sailboat designed by Bob Perry in the 1970s. It has a full keel, heavy displacement, and a classic design that has stood the test of time.

The Amel 54 is known for its luxury and exceptional build quality

This French-built vessel offers a spacious and comfortable interior with top-of-the-line amenities, making it an excellent option for solo sailors seeking a bluewater cruiser to explore the world in style and comfort. Its easy-to-handle design with advanced sailing systems allows you to sail solo with confidence and ease. The system includes electric winches, furling sails, and a self-tacking jib, which make it easy to handle the boat in all conditions.

To learn more about bluewater sailing , here's our comprehensive article on it.

These factors will ensure not only your safety but also your comfort and ease during your sailing adventure.

Size and stability of a solo sailboat

A boat with a wide beam and short waterline provides more stability, making it easier for you to handle the vessel on your own. Some popular sailboat models known for their size and stability include the Westsail 32 and the Hunter Channel 31.

A good solo bluewater sailboat should be large enough to provide adequate storage space for supplies and equipment, while also being stable enough to handle rough seas and high winds. It should also have a well-designed hull shape that provides good stability and balance, and a keel that provides good tracking and prevents the boat from capsizing.

Ease of use and maneuverability of any solo sailboat

Features like roller furling and an electric windlass can make handling the sails and anchor much more straightforward. Also, hydraulic bow/stern thrusters with remotes can help you maneuver your boat easily and safely. Make sure to look for these features when choosing your bluewater sailboat.

A good solo bluewater sailboat should be easy to handle and operate by a single person. It should have a sail plan that is easy to adjust and control, and a steering system that is responsive and easy to use. It should also have a well-designed cockpit that provides good visibility and protection from the elements.

Durability and seaworthiness for long-term safety

A well-built sailboat with a history of proven offshore performance should be at the top of your list. Some of the best and most famous bluewater sailboats include the Alberg 30 and Hanse 371.

A good solo bluewater sailboat should be built to withstand the rigors of extended ocean voyages. It should have a strong, well-built hull that is capable of withstanding heavy seas and high winds. It should also have a well-designed rigging system that is strong and durable, and a keel that is designed to provide good stability and balance.

To learn more about the best keel design for bluewater sailing , here's our article on it.

Comfort and livability of a solo sailboat

Consider the layout and features of the boat, ensuring that it has a comfortable sleeping area, a well-equipped galley, and ample storage space. A good example is the Valiant 40, known for its excellent layout and seaworthiness.

A good solo bluewater sailboat should be comfortable and livable for extended periods of time. It should have a well-designed interior that provides adequate storage space, comfortable sleeping quarters, and a functional galley and head. It should also have good ventilation and lighting, and be well-insulated to provide protection from the elements.

Affordability and availability determine the sailboat's practicality

Set a budget and research suitable sailboats within that price range. Some budget-friendly options include the J/109 and Westsail 32. A good solo bluewater sailboat should be reasonably priced and readily available. It should be affordable for most sailors who are interested in long-distance cruising, and should be available for purchase or charter in most parts of the world.

If you're looking for bluewater sailboats under 40 feet , here's our article where we picked the top 13 most famous ones.

You'll be faced with a range of solo bluewater sailboat options, from budget-friendly to luxury models. Let's explore some factors you should keep in mind to make the best decision for your needs and budget.

Initial purchase price : This is often the first thing people think of when it comes to the cost of a sailboat. There's a wide range in prices, depending on factors like age, size, and brand. For example, a used Alberg 30 might cost between $10,000 and $15,000, while a new Amel 54 could be in the range of hundreds of thousands of dollars. It's important to find a balance between quality and affordability that suits your needs and financial capabilities.

Maintenance and repairs : Owning a sailboat comes with ongoing expenses to keep it in good sailing condition. Regular maintenance tasks like painting, replacing worn rigging, and inspecting safety equipment can add up over time. Be prepared to allocate a portion of your budget for these essential tasks, as neglecting them could lead to more expensive repairs down the line.

Marina fees and insurance : Depending on where you plan to keep your boat, you may incur costs for marina or dockage fees. Additionally, securing insurance coverage for your sailboat is a must to protect your investment. Both of these costs can vary widely, so make sure you factor them into your overall budget.

Upgrades and equipment : To ensure your sailboat is well-suited for solo bluewater sailing, you might need to invest in upgrades to improve its safety and performance. For instance, you may want to add a roller furling system, wind vane, or more advanced navigation equipment. These enhancements can amount to a significant investment, so it's wise to plan financially for any desired upgrades.

Here are some essential tips to keep your boat in top shape, and ensure its long life and performance during solo journeys:

Regular inspections : Make it a habit to perform a thorough inspection of your sailboat periodically. Examine the rigging, sails, hull, and all mechanical components. Routine inspections allow you to detect any signs of wear, damage or potential problems before they escalate.

Cleaning : Keep your sailboat clean by washing it regularly with freshwater and appropriate cleaning solutions. This simple practice prevents the buildup of dirt, salt, and other debris, which can cause corrosion and damage to your vessel over time.

Checking the bilge : Ensure that your bilge pump is working efficiently and that there's no water accumulating in the bilge area. If there are any signs of water accumulation, investigate the source and address any leaks or issues promptly.

Servicing the winches : Winches play a crucial role in your sailboat’s performance, so it’s essential to inspect, clean, and grease them regularly. This practice will guarantee their smooth operation and prolong their lifespan.

Sail care : Inspect your sails frequently for any tears, wear, or damage. Repair or replace them as necessary. To protect your sails from the sun’s harmful UV rays, always use a sail cover when not in use.

Keeping records : Maintain a logbook to document all maintenance tasks, inspections, and repairs. Not only will this help you keep track of what has been done, but it will also provide valuable information if you decide to sell your sailboat in the future.

Leave a comment

You may also like, what is bluewater sailing.

It's easy to confuse offshore sailing with bluewater sailing - and it's no wonder. Many people do, including myself. So I've decided to list the difference once and …

13 World-Famous Bluewater Sailboats Under 40 Feet

What's the Best Keel Design for Bluewater Sailing?

Different Types of Sailing and Racing Explained

41 Sailboat Cruising Essentials for Long Trips

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

- Embarking on a Seafaring Odyssey: Exploring the World of Bluewater Yachts and Cruising Sailboats

Are you ready to embark on a seafaring odyssey that will take you across the endless expanse of the open ocean? If the thought of navigating the deep blue waters on a luxurious boat has always been a dream, then you're about to set sail on an exciting journey. In this comprehensive guide, we'll dive deep into the captivating world of bluewater yachts, sailing on top-tier vessels, and the exhilarating thrill of ocean-going expeditions. Whether you're an experienced sailor seeking new horizons or a novice with a thirst for adventure, this article is your compass to the enchanting realm of maritime exploration.

Introduction

Imagine yourself standing at the helm of a majestic vessel, the wind whispering tales of distant shores, and the gentle rhythm of waves inviting you to set forth on a voyage of a lifetime. The allure of bluewater yachts encapsulates the essence of exploration, luxury, and freedom on the open sea.

Unveiling Bluewater Yachts: Masters of the Sea

Bluewater yachts are the maritime marvels designed to conquer the unpredictable waters of the open ocean. These vessels are engineered with a focus on resilience, safety, and comfort, making them the ultimate choice for those with a passion for venturing beyond the horizon.

Sailing Zenith: Reaching the Pinnacle of Seamanship

At the zenith of sailing prowess, a phenomenon known as the "sailing top" awaits the intrepid mariners. This pinnacle of seamanship represents the epitome of skill, where sailors harness the wind's energy to achieve unprecedented speed, precision, and navigational mastery.

Bluewater Yachts: Where Power Meets Elegance

The allure of bluewater yachts lies not only in their capacity to brave the open ocean but also in their opulent interiors and cutting-edge features. These vessels seamlessly blend power and elegance, offering a harmonious blend of performance and comfort.

Conquering the Vastness: Ocean-Going Yachts in Focus

Ocean-going yachts are the true conquerors of the sea, designed to tackle extensive journeys across the world's oceans. These vessels boast advanced technologies, robust construction, and top-notch safety measures, ensuring a smooth and secure passage, even in challenging conditions.

Oyster 56: A Symphony of Luxury and Performance

Amid the realm of bluewater yachts, the Oyster 56 stands as an emblem of sophistication and performance. With its impeccable balance of luxurious interiors and exceptional sailing capabilities, this yacht represents the zenith of modern maritime engineering.

Read our top notch articles on topics such as sailing , sailing tips and destinations in our Magazine .

Navigating Blue Water Sailing: A Journey Beyond Horizons

Blue water sailing transcends the ordinary. It's a calling to embrace the unknown, revel in the ebb and flow of the tides, and cultivate a profound connection with nature. It's an experience that fosters self-discovery while immersing sailors in the grandeur of the world's oceans.

Market Insights: Bluewater Boats Await New Captains

For aspiring sailors, the market offers a treasure trove of bluewater boats, each with its unique blend of features and capabilities. From sleek sloops to robust ketches, these vessels cater to varying preferences and aspirations, ensuring a perfect match for every seafarer.

Sailing the UK Waters: Blue Water Yachts on Sale

In the United Kingdom, the dream of owning a bluewater yacht is well within reach. The market showcases an array of blue water yachts available for sale, providing enthusiasts with the opportunity to explore the British coastline and beyond in style.

The Bluewater Dilemma: Making the Perfect Choice

The decision to select the ideal bluewater yacht requires careful consideration. Factors such as size, layout, amenities, and budget play a pivotal role in ensuring that your chosen vessel aligns with your seafaring ambitions.

Sailing Redefined: Thriving Aboard a Blue Water Catamaran

The blue water catamaran introduces a paradigm shift in sailing dynamics. With enhanced stability, spacious living areas, and shallow-water accessibility, these vessels redefine comfort and freedom on the high seas.

Cruising Sailboats: Where Comfort and Exploration Intertwine

Cruising sailboats offer the best of both worlds: the thrill of exploration and the embrace of comfort. These vessels are thoughtfully designed with cozy interiors, expansive cabins, and efficient navigation systems, making extended voyages an absolute pleasure.

Ocean Sailboats: Harnessing Power with Grace

Ocean sailboats epitomize the harmony between human ingenuity and the raw power of nature. Crafted to navigate the vastness of the ocean, these vessels showcase the art of harnessing wind energy to propel them across boundless horizons.

Centre Cockpit Yachts: A Unique Perspective on Navigation

Centre cockpit yachts offer a fresh perspective on sailing. With their distinctive design placing the cockpit amidships, these vessels provide enhanced visibility, protection from the elements, and a strong connection between the sailor and the sea.

Ocean Sailing Essentials: Navigating the High Seas

Embarking on an ocean sailing adventure demands a comprehensive understanding of essential skills and knowledge. From celestial navigation to weather forecasting, mastering these elements is key to a successful and safe voyage.

Bluewater Yacht Lifestyle: Where Luxury Meets Freedom

The bluewater yacht lifestyle is synonymous with opulence, exploration, and liberation. It's a lifestyle that invites you to roam the world's most captivating destinations while indulging in the opulence of a meticulously designed yacht.

Navigating Choices: Finding Your Ideal Blue Water Cruiser

Selecting the perfect blue water cruiser involves aligning your aspirations with the characteristics of different vessels. Whether you prioritize speed, comfort, or versatility, there's a cruiser tailored to fulfill your maritime dreams.

Exploring Boundless Horizons: The Allure of Bluewater Yachts

In closing, the realm of bluewater yachts invites intrepid souls to embrace the call of the sea. The allure of navigating boundless horizons, the thrill of encountering nature's grandeur, and the serenity of sailing await those who are ready to embark on this extraordinary maritime journey.

So what are you waiting for ? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

Faqs: bluewater yacht adventure: your questions answered.

Bluewater yachts are meticulously designed to handle long ocean voyages and challenging conditions, emphasizing durability, safety, and comfort.

Ocean-going yachts are best suited for experienced sailors due to their robust construction and advanced navigational systems.

The bluewater yacht lifestyle offers a unique blend of luxury, exploration, and the freedom to navigate the world's oceans at your leisure.

Home » Blog » Bluewater sailboats » The best bluewater sailboats under 40 feet (we analyzed 2,000 boats to find out)

The best bluewater sailboats under 40 feet (we analyzed 2,000 boats to find out)

By Author Fiona McGlynn

Posted on Last updated: August 17, 2023

What are the best bluewater sailboats under 40 feet?

Last year we analyzed 2,000 offshore designs to bring you a list of the most popular bluewater sailboats .

However, most people are searching for a boat in a particular size class. So, we decided to do a double-click and look at the best sailboats under 40 feet for offshore sailing.

If you’re interested in an even smaller boat, there are plenty of great options under 30 feet in our list of the best small sailboats for sailing around the world .

The characteristics that make a sailboat a bluewater sailboat are a hotly debated topic, so we wanted to use real-world data and find out what cruisers are using to cross oceans and sail around the world.

We looked at 2,000 boats that entered the Pacific Puddle Jump (PPJ) over the last 12 years. For those of you who aren’t familiar with the PPJ, it’s a rally that crosses the Pacific ocean. We took part in 2017 and had a ball!

Also, if you’re looking to buy one of the bluewater boats on this list, you might want to check out our post on the best places to buy used boats and how to find free or cheap boats for sale .

Just be aware that a bluewater boat isn’t necessarily offshore-ready. Our top five picks are all older boats and will undoubtedly require work.

Every cruiser we know made substantial repairs and additions before going offshore: adding watermakers , life rafts, solar panels, and more.

Also, always have a boat inspected by a professional and accredited marine surveyor before buying it or taking it offshore.

So, without further preamble, here are the best bluewater sailboats under 40 feet.

The best bluewater sailboats under 40 feet

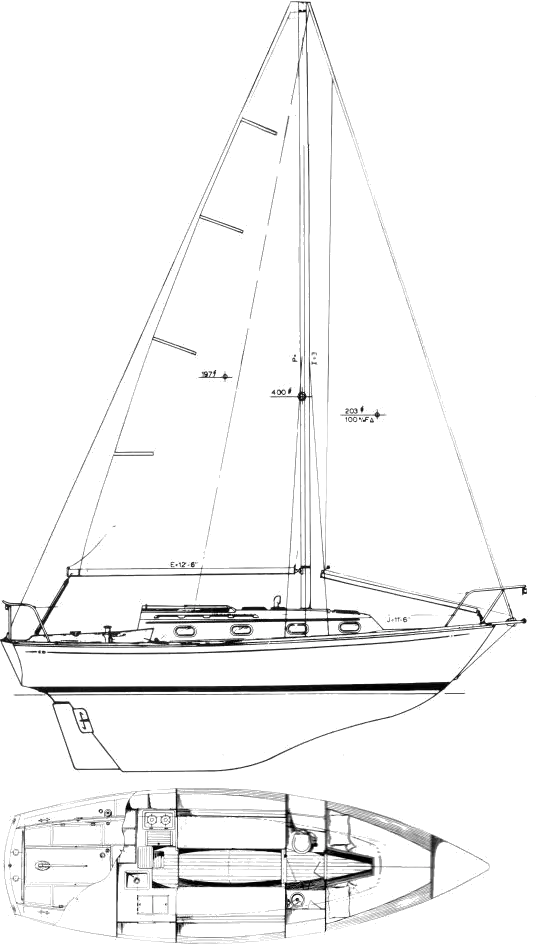

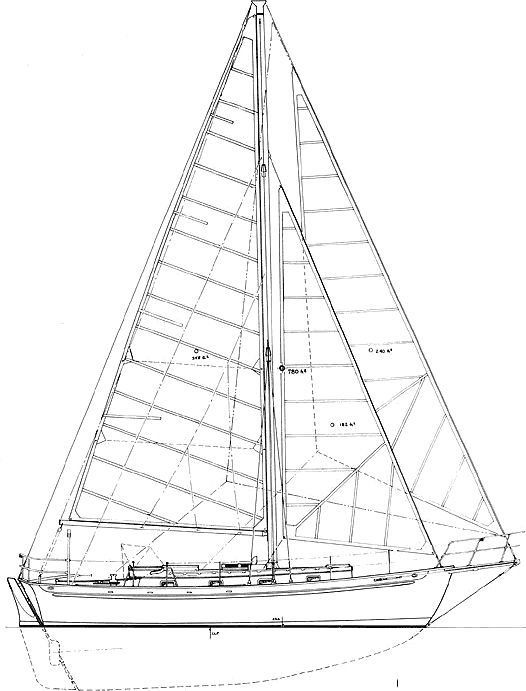

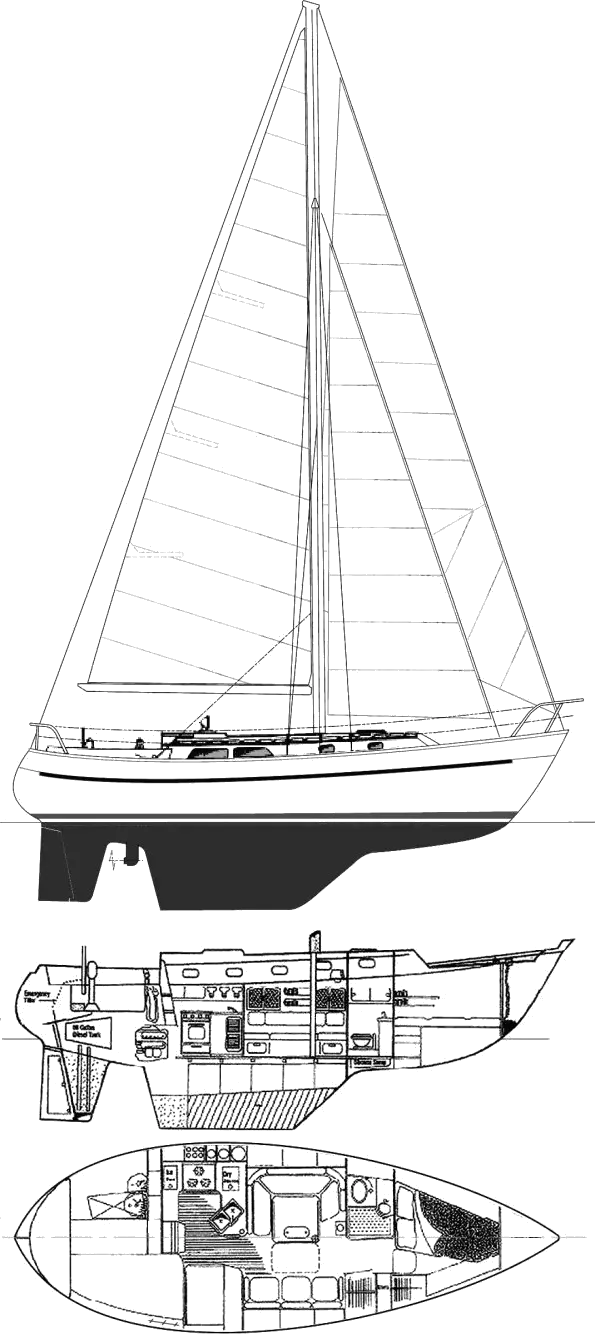

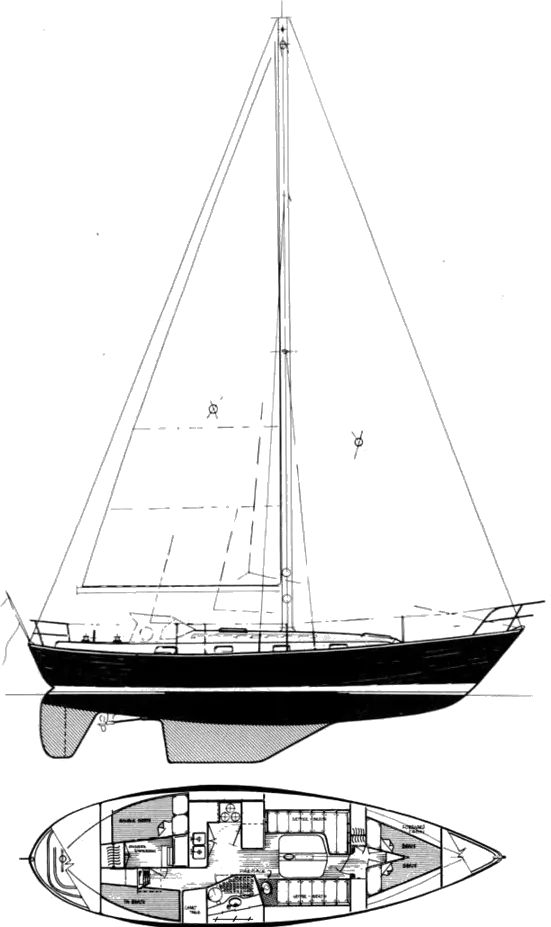

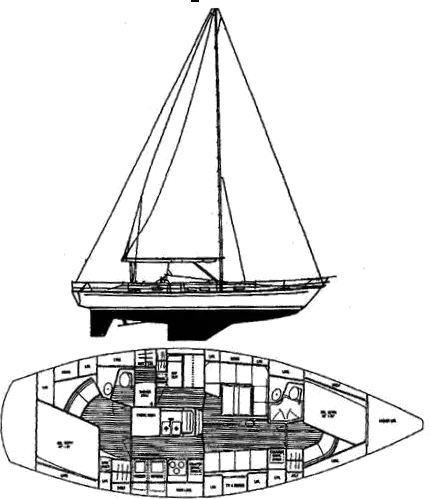

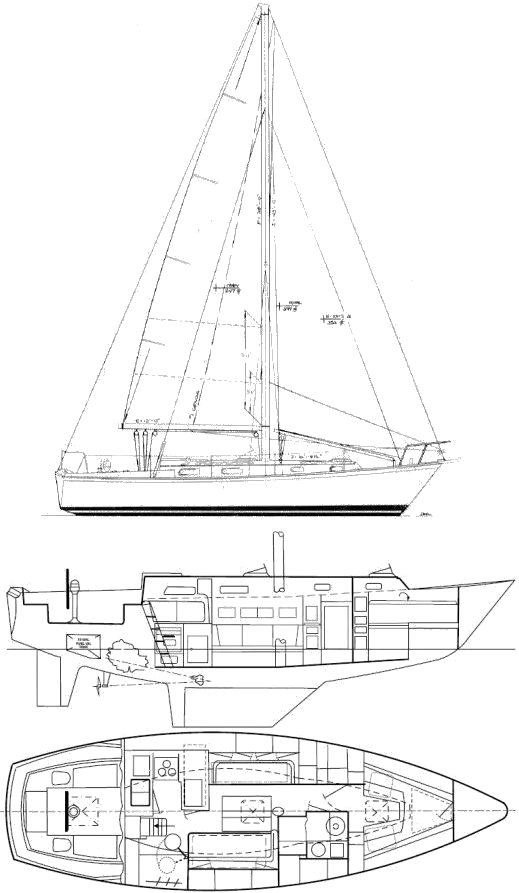

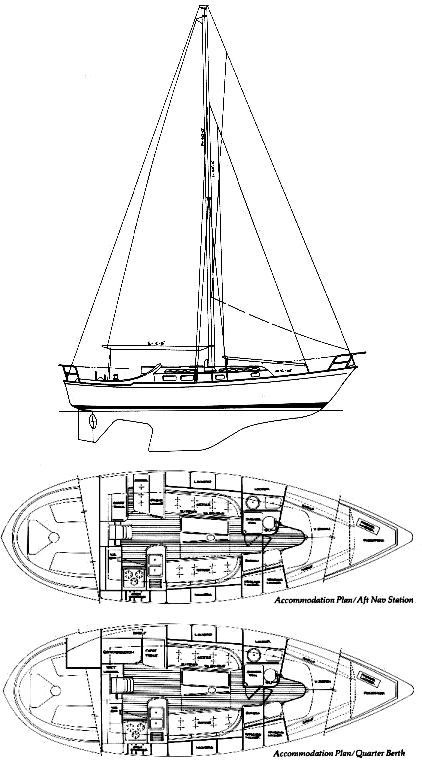

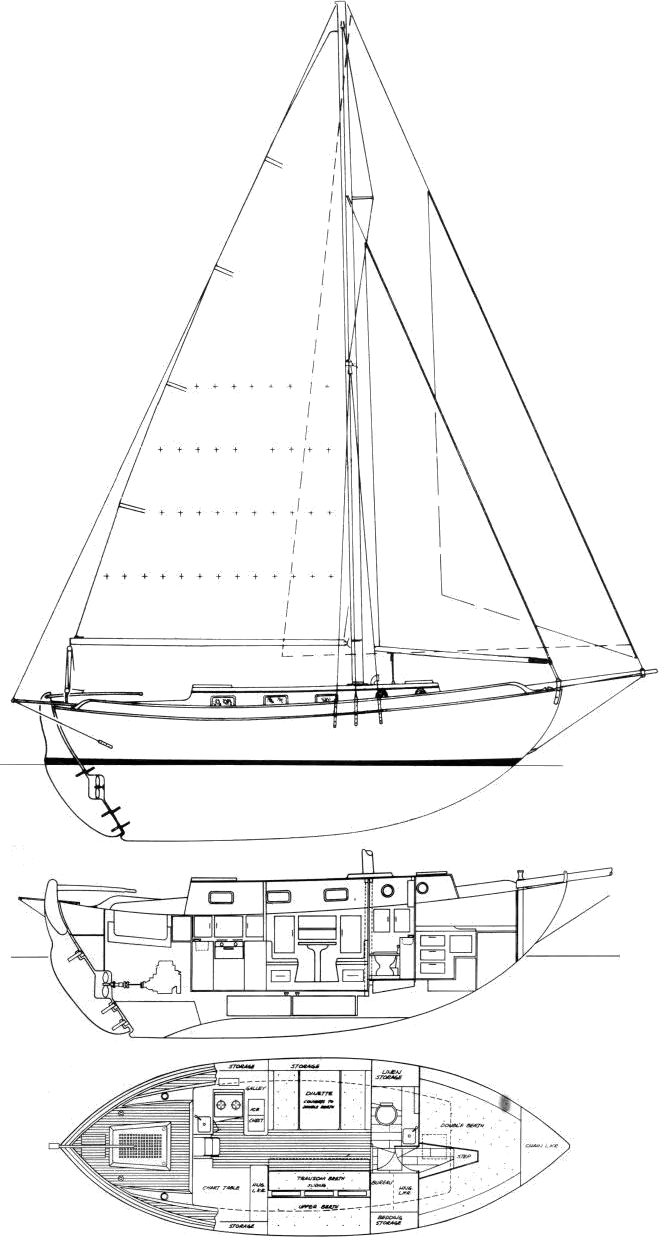

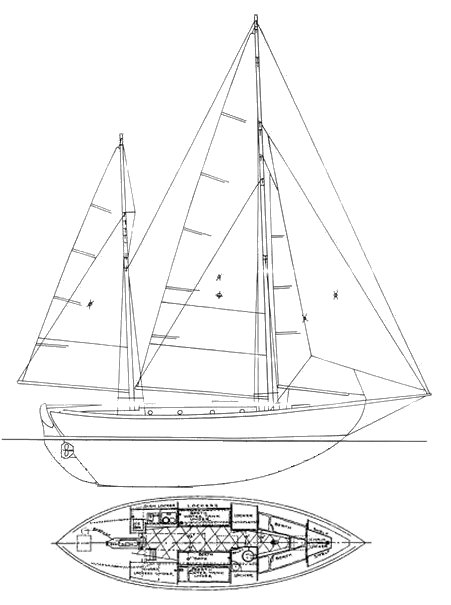

1. the westsail 32.

The Westsail 32 is one of the most iconic bluewater cruisers. Built by the Westsail Corporation in the 1970s, this plucky, small sailboat has developed a cult following over the decades. Since 2009, 19 have set out to cross the Pacific in the PPJ rallies.

The Westsail 32 is known for its sturdy construction, seaworthiness, and classic looks. In fact, it set the standard for what a real bluewater cruiser should look like. In 1973, the Westsail 32 was featured in Time magazine and inspired many Americans to go cruising.

Though popular, this boat has earned the unenviable nickname “ Wetsnail 32″, a reference to its poor ability to windward and sluggish performance. But Westsail 32 owners don’t care that they won’t be winning any races.

What the boat lacks in speed it makes up for in classic looks and excellent offshore cruising characteristics. Many owners have crossed oceans and circumnavigated the globe in their Westsail 32s.

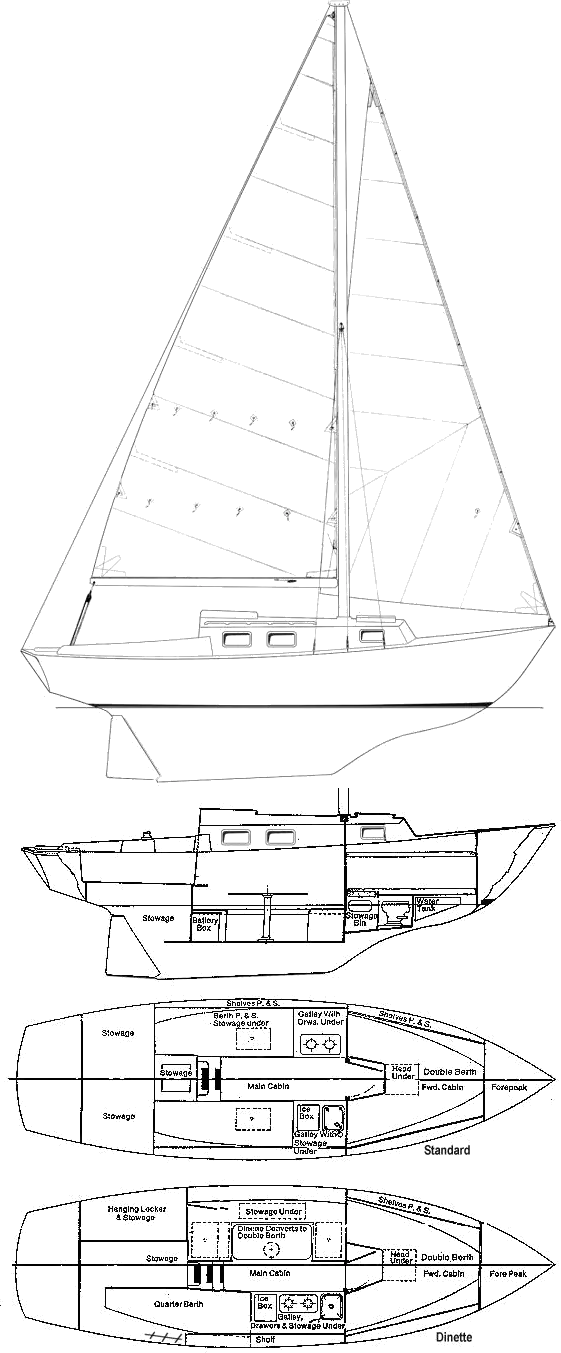

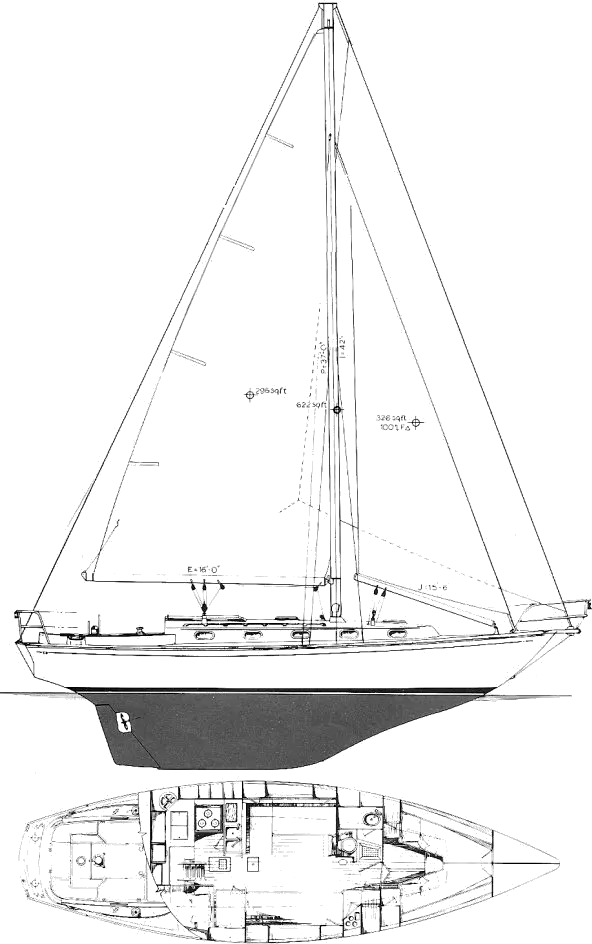

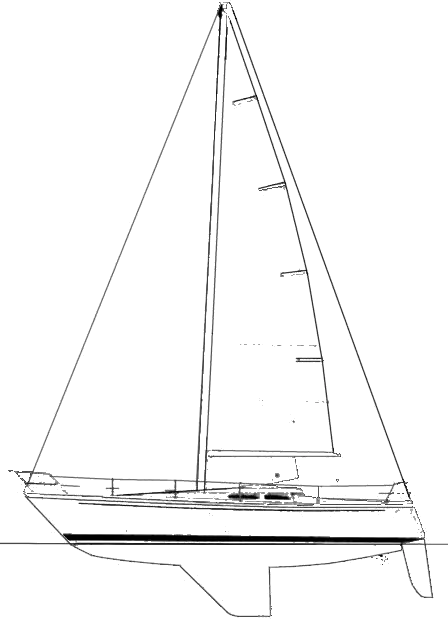

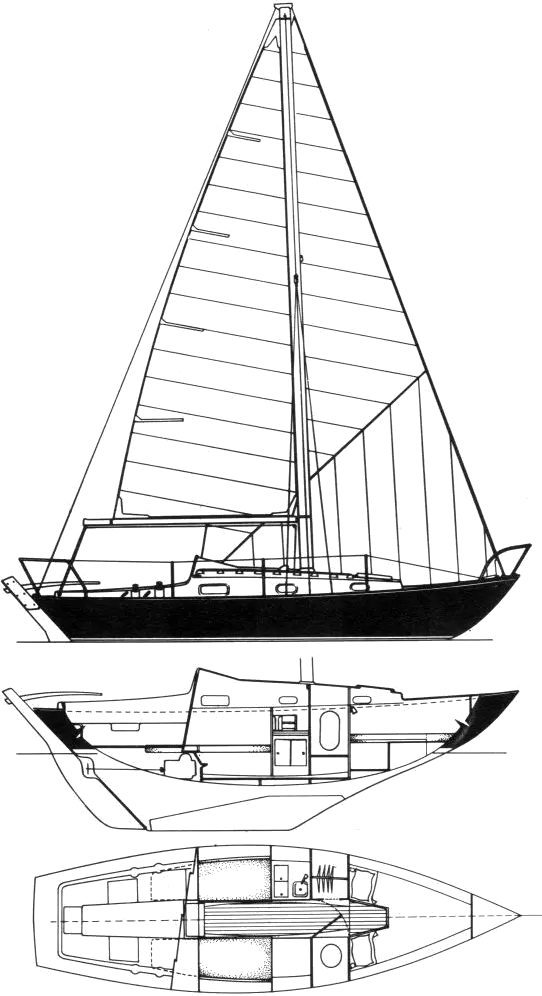

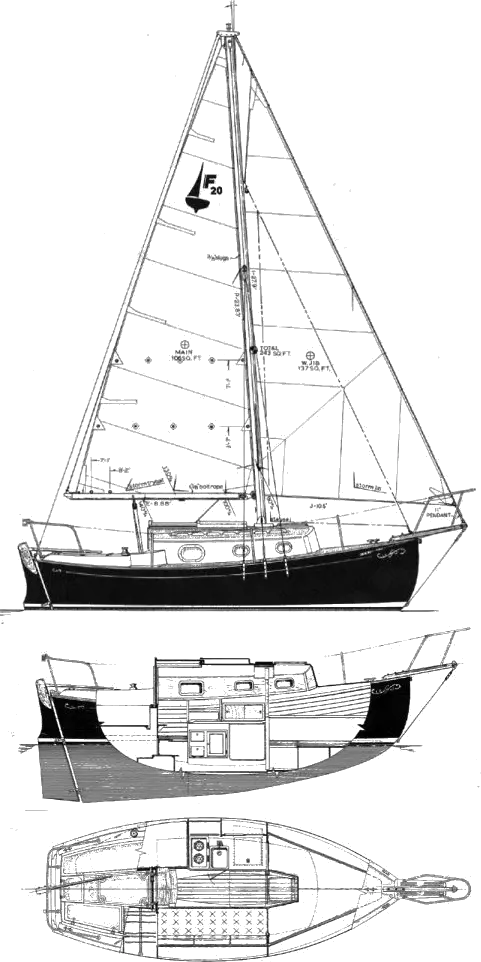

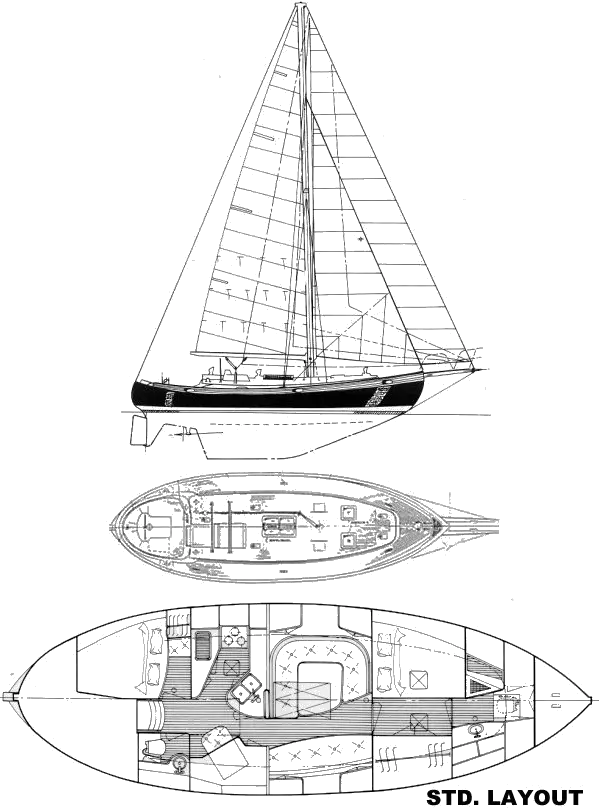

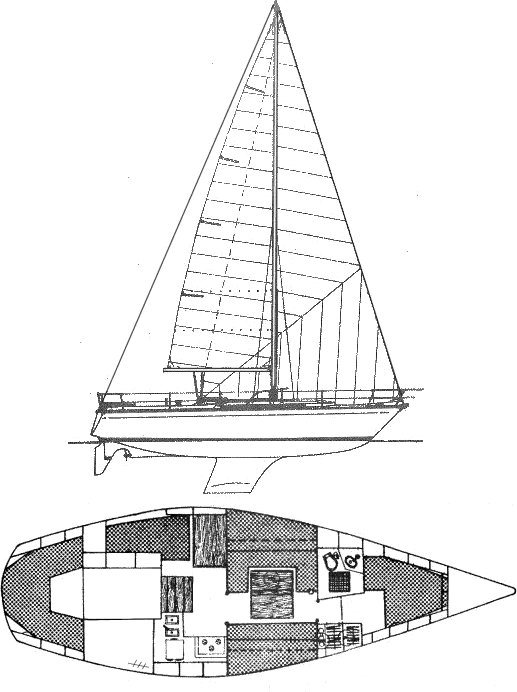

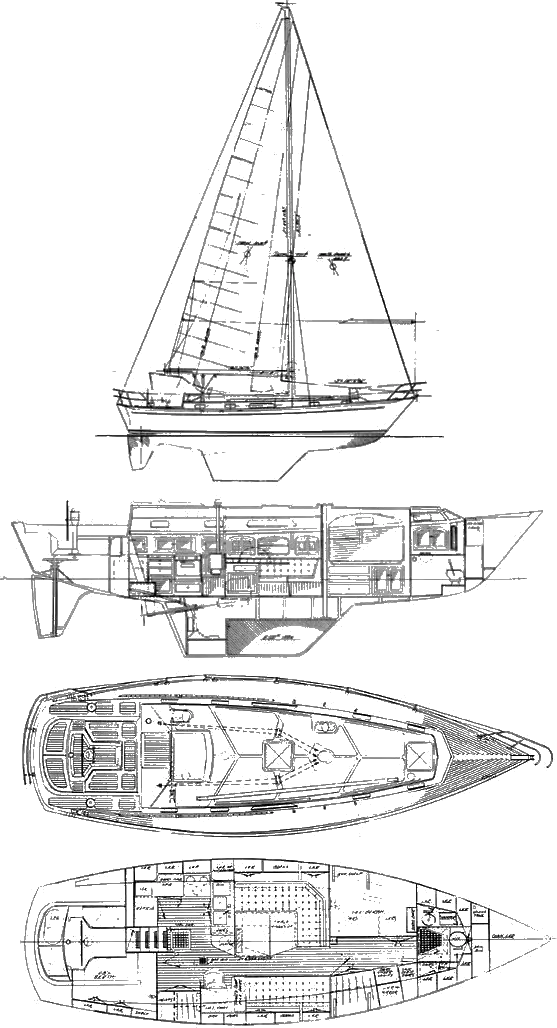

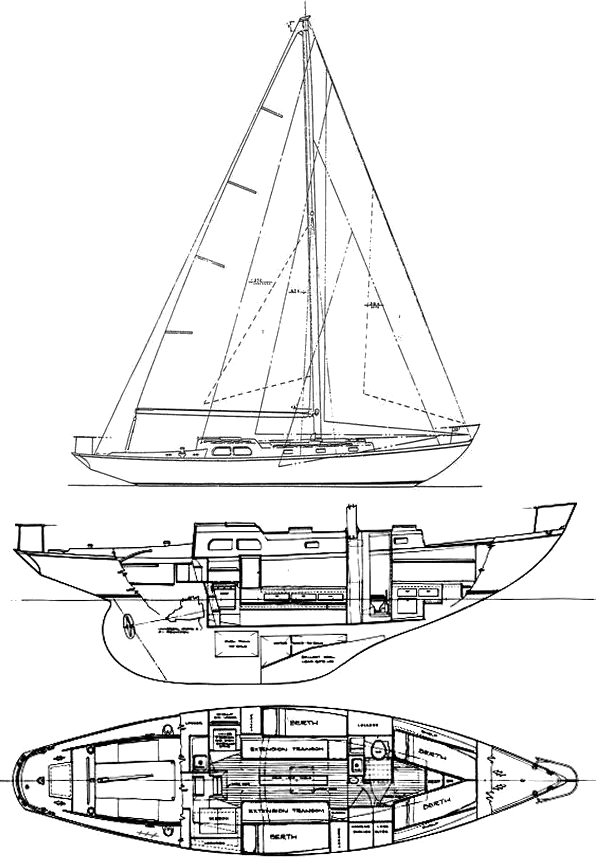

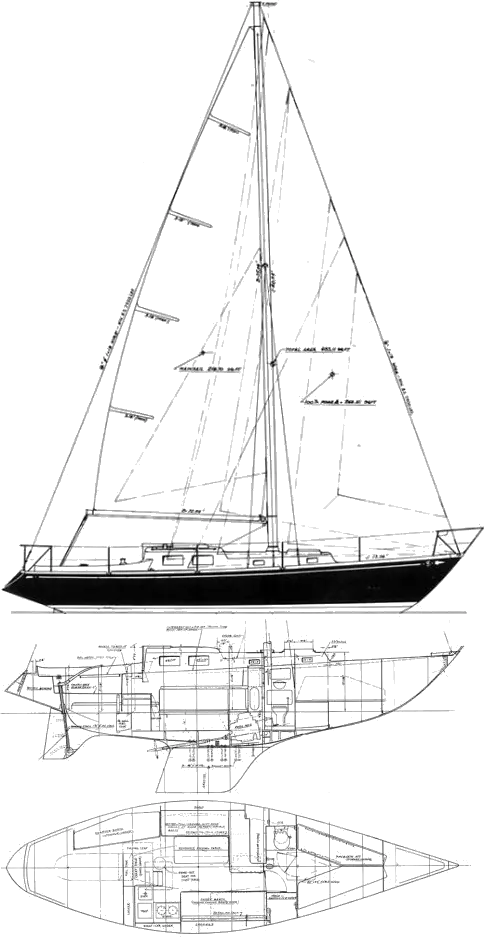

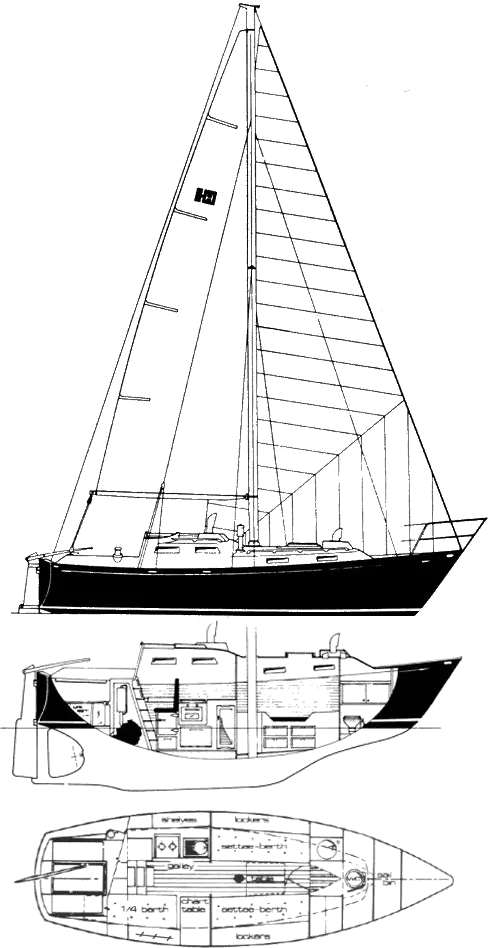

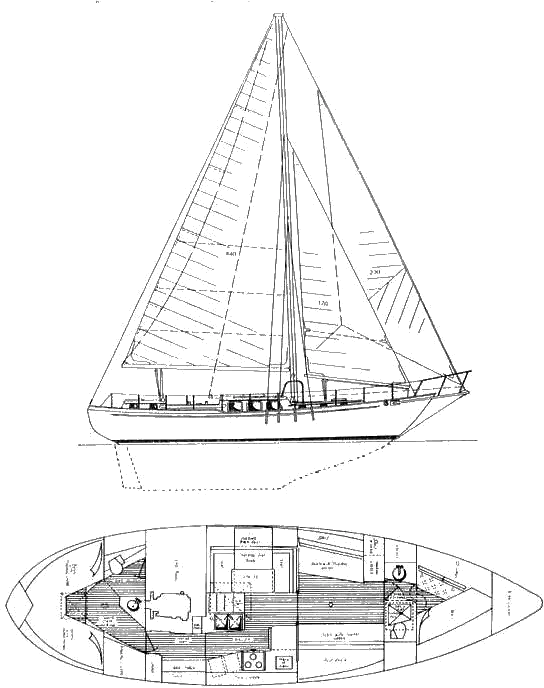

2. Tayana 37

The Tayana 37 is a wildly popular Bob Perry design. It first rolled off the production line in 1976 and there are now several hundred of them sailing the world’s oceans.

Above the waterline, the Tayana 37 boasts beautiful traditional lines. However, Perry wanted to avoid the unenviable (read: sluggish) performance characteristics, associated with double-enders.

So, he designed the Tayana 37 with a cut-away long keel and moderate displacement, maintaining the classic look, while achieving reasonable performance.

The Tayana 37 has a devoted following of offshore enthusiasts. Since 2009, 12 Tayana 37s have set out to cross the Pacific in the PPJ rallies.

Read more about the Tayana 37 in this Practical Sailor review .

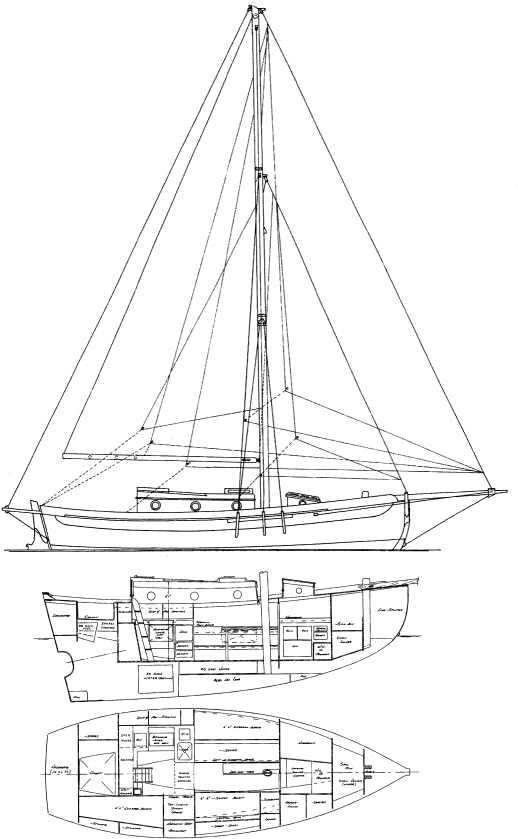

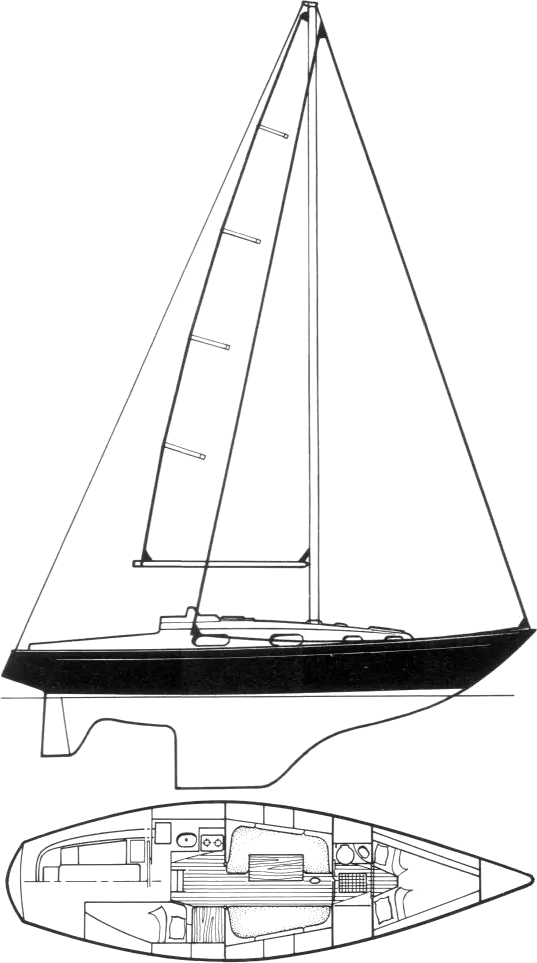

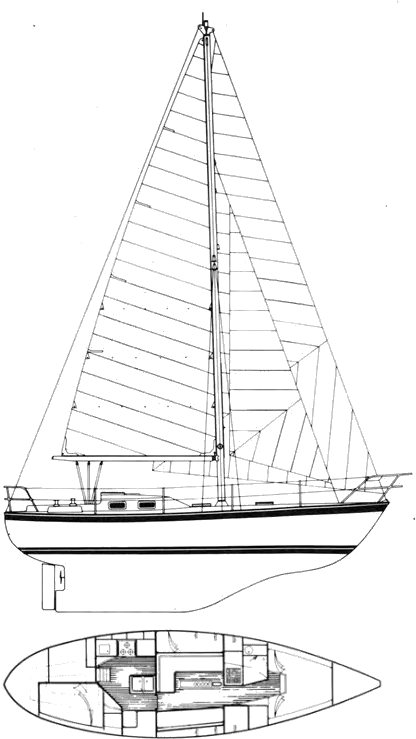

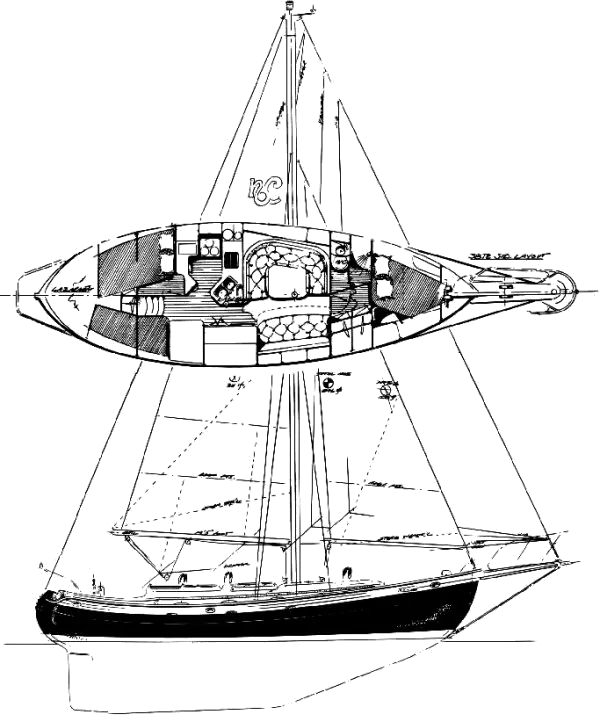

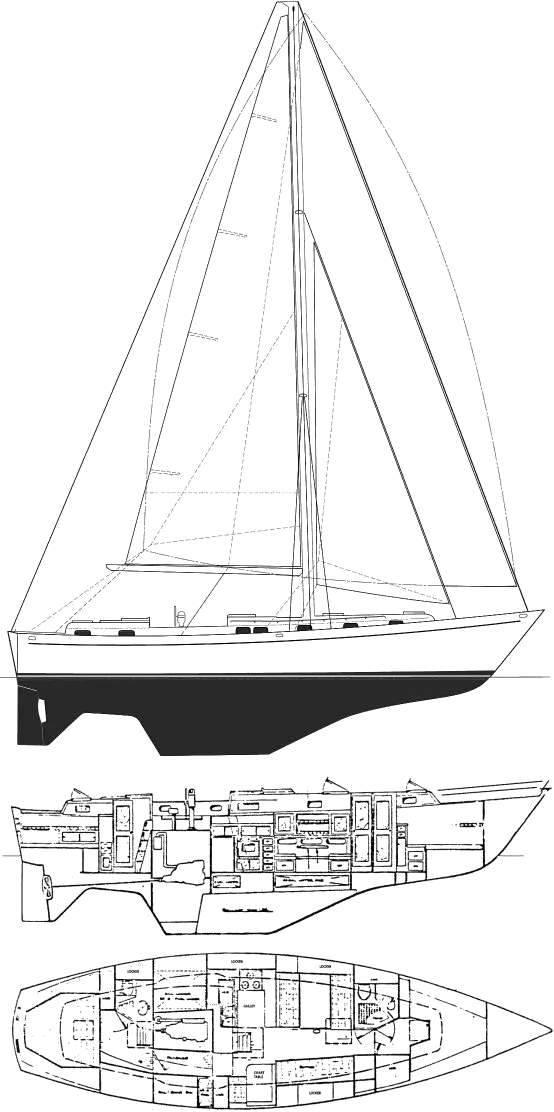

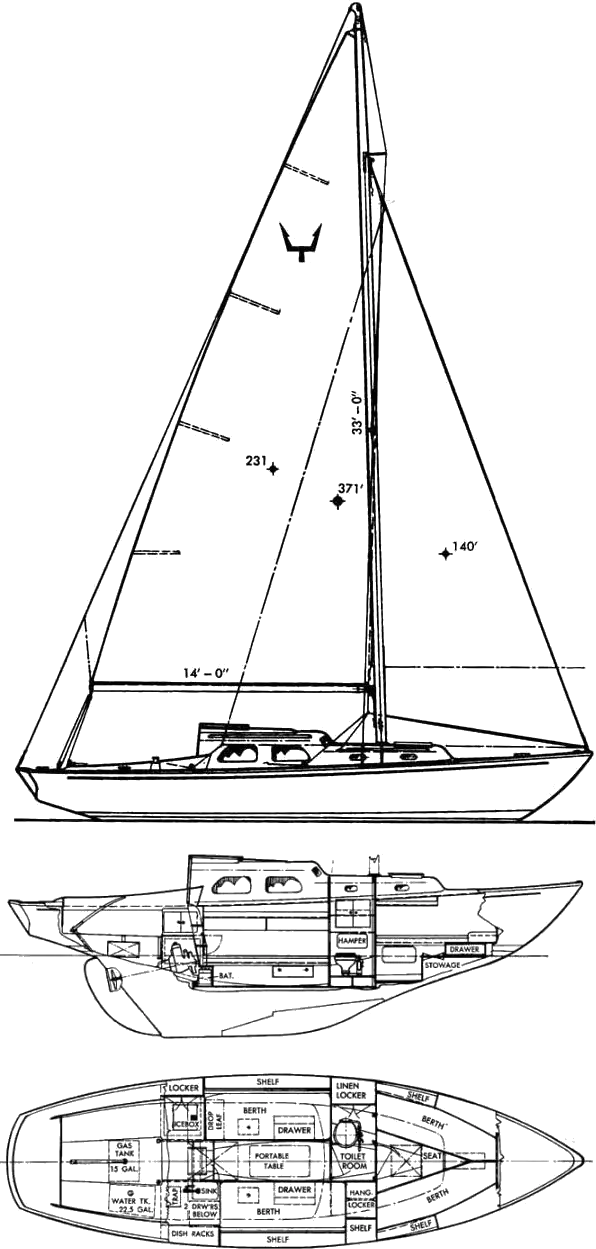

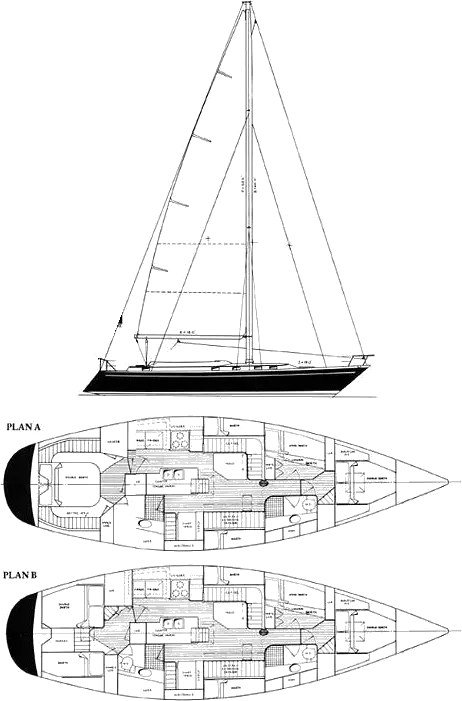

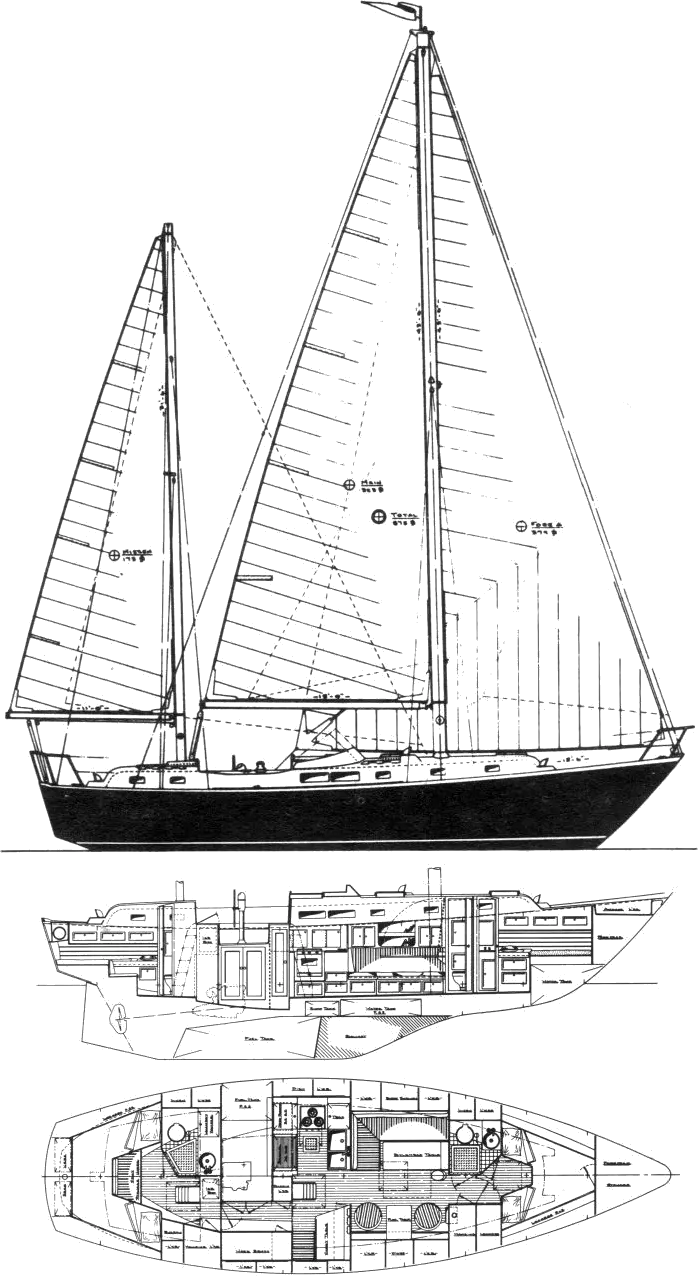

3. Hans Christian 38T

The Hans Christian 38T is a full-keeled, heavy displacement bluewater boat with a long bowsprit and a clipper bow, giving it a distinctive appearance. It was first introduced in 1976 and was produced until the early 1990s.

If you hadn’t already guessed, the “T” in the name stands for “Traditional”. Like many boats on this list, it takes a cue from Crealock’s famous Westsail 32 which sparked a craze in the 1970s and 80s for Scandinavian-style doubled-enders.

It’s gained a reputation as a capable and seaworthy cruising yacht. Many owners have crossed oceans and completed circumnavigations in Hans Christian 38Ts.

By our count, eight Hans Christian 38Ts have participated in Pacific Puddle Jump rallies over the last 12 years.

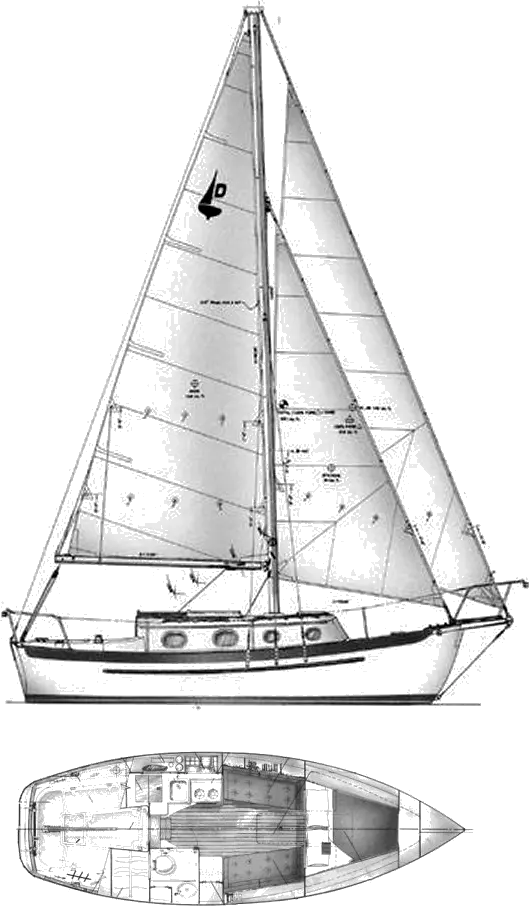

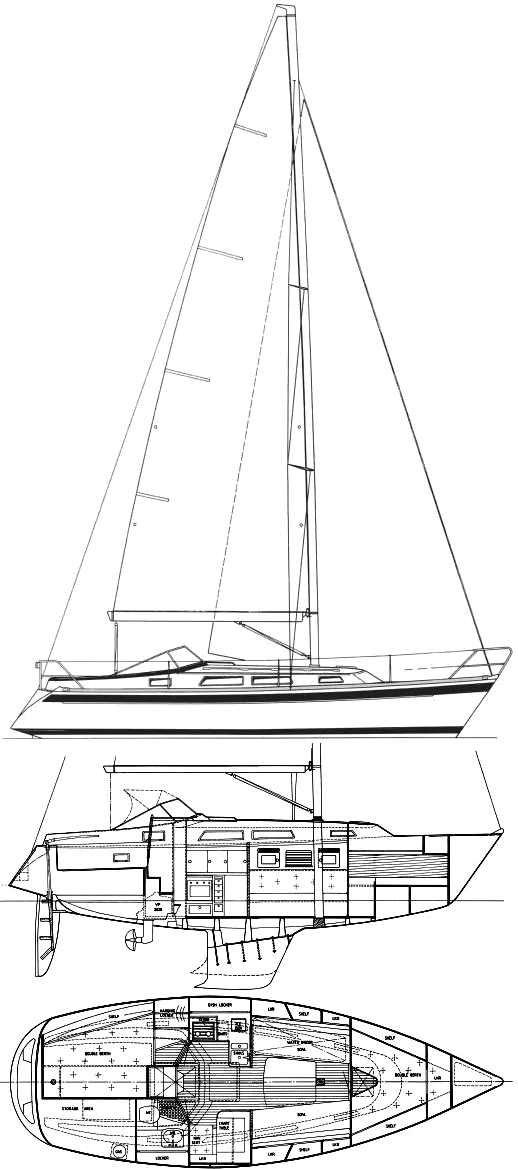

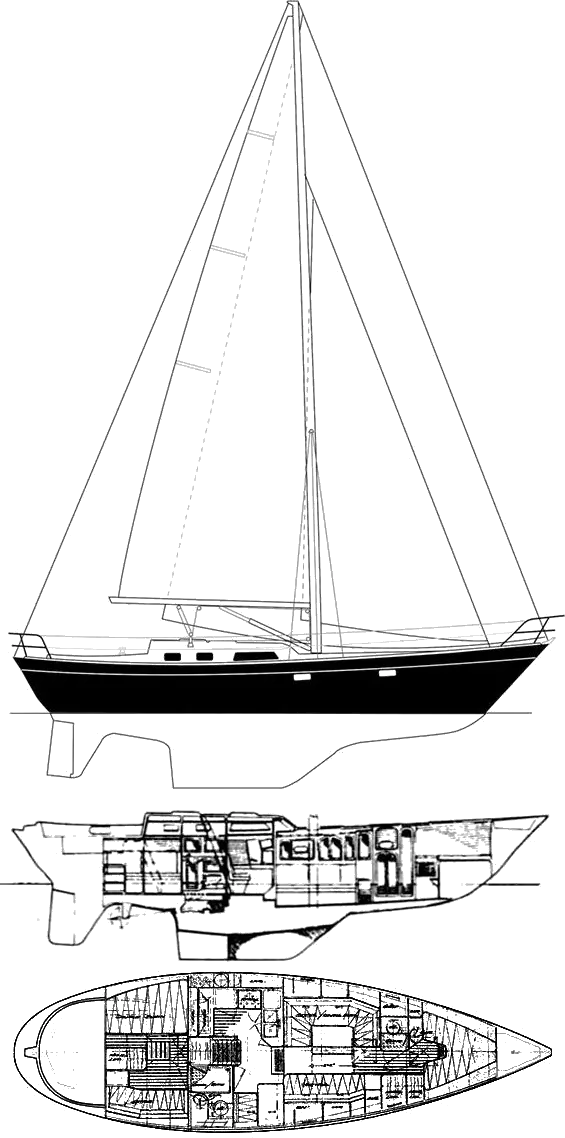

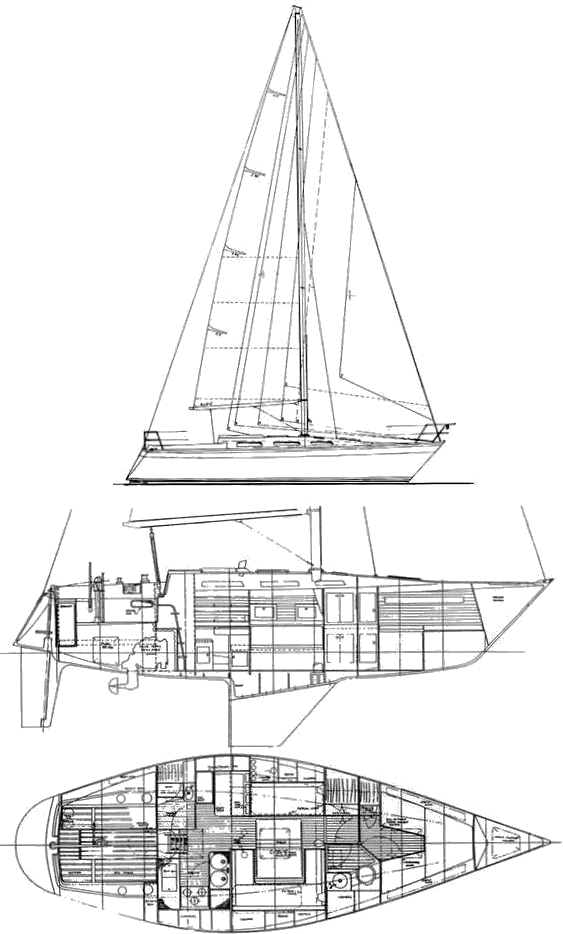

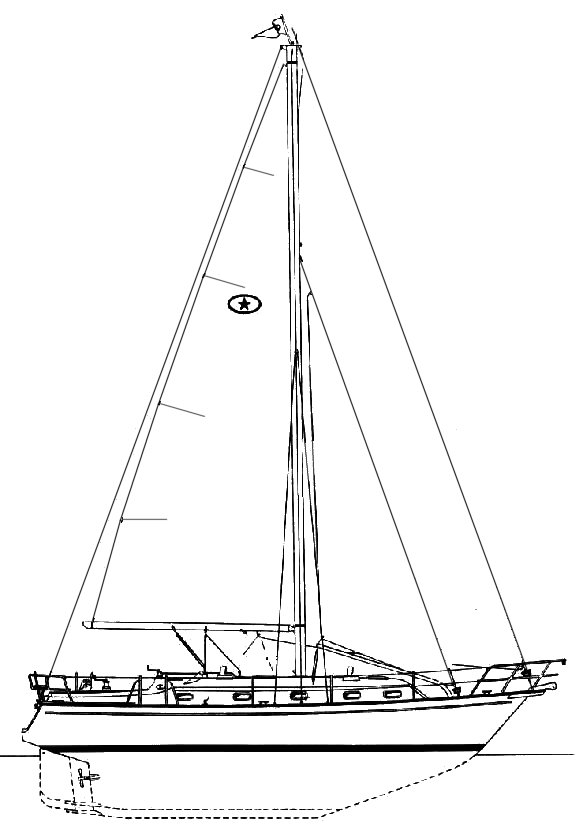

4. Island Packet 380

I’ve always considered Island Packets the Rolls-Royce of the bluewater boat world. Their distinctive cream-colored topsides make them easy to spot and their robust bluewater construction makes them the envy of many far-flung anchorages.

Designed by Bob Johnson and built by Island Packet Yachts in Florida, the Island Packet 380 was first introduced in 1998. 169 were built before 2004, over which time it gained a reputation as a capable and comfortable offshore cruiser.

Having been built in the ’90s and early 2000s, this is a relatively newer boat. In many ways, it offers the best of both worlds, a classic-looking boat with all the modern cruising conveniences.

The Island Packet 380 design prioritizes safety and stability. It also has several offshore features including standard twin bow rollers, a divided anchor locker, and ample storage for cruising gear.

Life below deck is comfortable too. With a 13-foot (4 meter) beam there’s plenty of room for liveaboard amenities.

The Island Packet 380 is a popular choice for long-distance cruising and offshore passages. Since 2009, six Island Packet 380s have set out to cross the Pacific in PPJ rallies.

Read more about the Island Packet 380 in this review by Yachting Monthly .

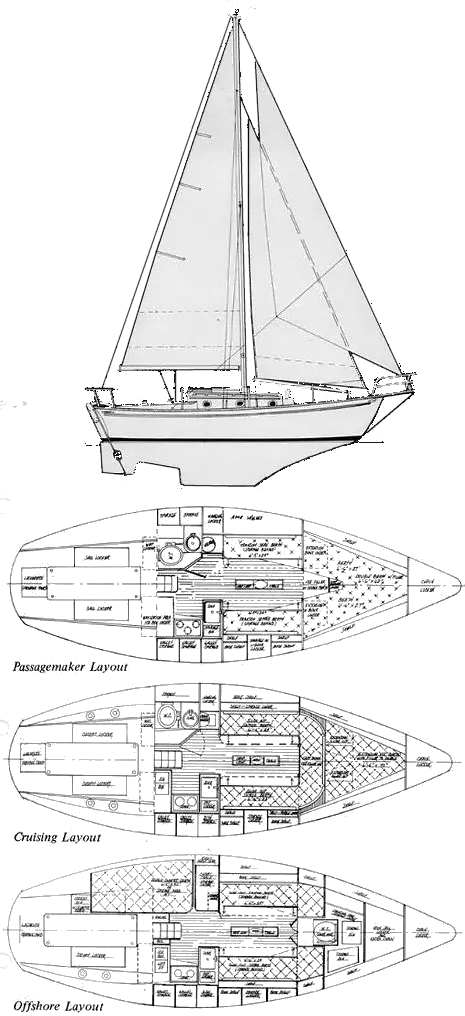

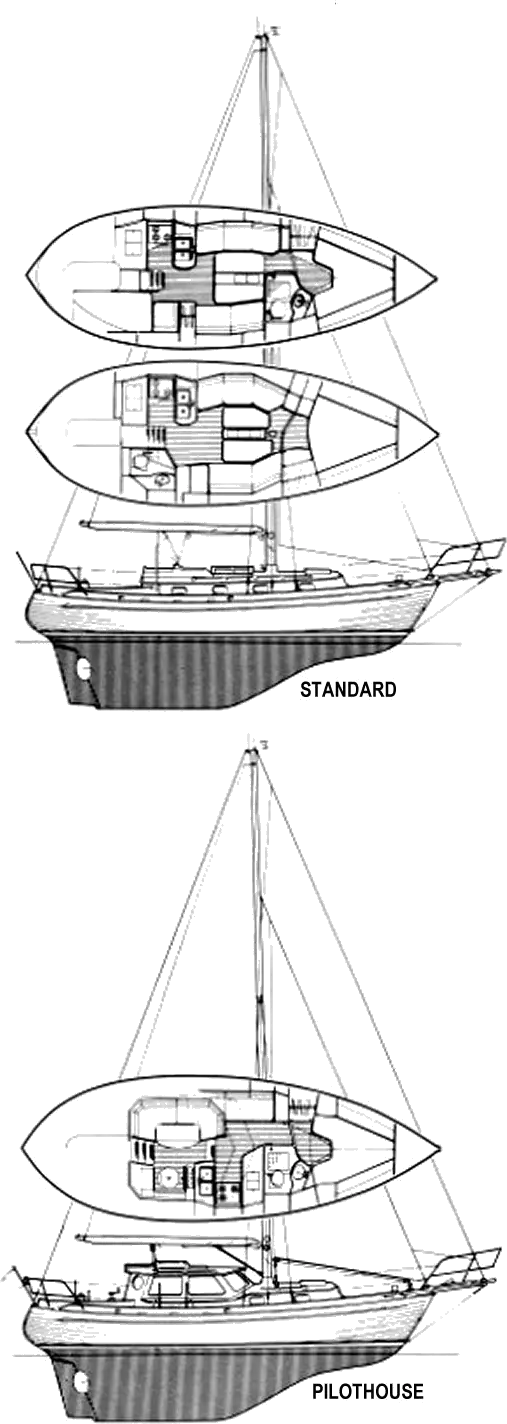

5. Ingrid 38

The Ingrid 38 is a double-ended sailboat that was originally designed for wood construction in 1938.

In 1971, Bluewater Boat Co. began building a fiberglass version. The design proved hugely popular and more than 140 were built.

With a full keep and heavy displacement, the Ingrid 38 epitomizes the traditional bluewater cruiser. Yet, it remains a well-loved design today. Since 2009, six Ingrid 38s have set out to cross the Pacific in PPJ rallies.

Description

Fiona McGlynn is an award-winning boating writer who created Waterborne as a place to learn about living aboard and traveling the world by sailboat. She has written for boating magazines including BoatUS, SAIL, Cruising World, and Good Old Boat. She’s also a contributing editor at Good Old Boat and BoatUS Magazine. In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat.

Terms and Conditions - Privacy Policy

FREE ON-DEMAND WORKSHOP FOR ASPIRING BLUEWATER CRUISERS

WATCH THIS TO GET ACCESS NOW

Discover the 3 secrets to start sailing the world & living a life of adventure (sooner than you thought possible), here's what you will learn, what you will learn, during the workshop.

THE BOAT SELECTION FORMULA We'll show you How To Find the perfect Boat that fits your needs. (Even If You've Never Sailed Before)

How to prepare your family it's a big change for everyone we'll help you understand how to prepare your family for the adventure ahead., making it work financially we'll explore the strategies and steps to setting up your finances and income even if you think you can't afford it, face the waves we'll teach you how to overcome your fears, avoid expensive mistakes and stay safe while your exploring the open waters (regardless of your experience level), how to prepare, your family, it's a big change for everyone we'll help you understand how to prepare your family for the adventure ahead., the boat selection formula, we'll show you how to find the perfect boat that fits your needs. (even if you've never sailed before), making it work financially, we'll explore the strategies and steps to setting up your finances and income even if you think you can't afford it, face the waves, we'll teach you how to overcome your fears, avoid expensive mistakes and stay safe while your exploring the open waters (regardless of your experience level), what our clients are saying...

learn from the experts

Meet your hosts, keith whitaker, from sailing zatara.

In summer of 2016, we sold our home in our quiet suburban Texas neighborhood, said goodbye to friends and family, liquidated most of our assets...

...And bought a sailboat to circumnavigate the globe.

The kids were really excited about that in the beginning.

Then 90 days later we were thinking what on earth have we done?

Without any prior sailing knowledge we've since sailed over 50,000 miles through three different oceans in both a monohull and a Catamaran.

And now, we're showing you how!

chris biasutti

Head captain of bluewater cruising.

7 years ago and one month before my youngest daughter was born we bought a boat to sail the world.

Sounds crazy right? Why'd we do it?

We wanted to experience more life.

I'd spent nearly 8 years of my life running an international investment sales business. I reached a point where I realized I was not happy and I needed to do something different.

Today, I've sailed over 20,000 miles with my family through 2 different oceans and loved (almost) every minute of it.

The experience has forever changed our life for the BETTER.

It's time you experience that too.

Chris Biasutti

Back in 2016, one month before my youngest daughter was born we bought a boat to sail the world., it's your turn, are you ready to create your bluewater cruising plan, learn how you can turn your dream of setting sail and living a life of freedom and adventure intro a reality. it's time to stop waiting and start taking the steps towards your dream life..

© 2024 Bluewater Cruising All Rights Reserved

Privacy Notice | Disclaimer | Terms and Conditions

© 2022 Bluewater Cruising All Rights Reserved

Messing about in boats since 1975. Online Since 1997.

Home | Intro | Our Design Process | Stock Design Info | Motor Yacht Designs | Sailing Yacht Designs | Prototype Designs Plans List | Articles | Our CAD Design Stream | Maxsurf | News..! | SITE MAP..! | Site Search | Design Team | Contact Us Please see the AVAILABLE BOAT PLANS web page

METAL BOATS For Blue Water Introduction | Which Metal...? | Aesthetics & Hull Form | Design Features Scantling Calcs & Framing | Advantages of NC Cutting | Corrosion Protection | Conclusion Introduction This essay is intended to bring to light a few of the issues surrounding the use of metal for boats. You can access any of the specific topics via the links above. While the pros and cons of various metals expressed here are quite relevant to one's choice of hull material, they are also central to the actual process of designing and building in metal, whether one chooses in favor of steel, aluminum, copper nickel, monel, stainless, or what have you... The following is therefore not solely aimed at potential metal boat owners, but also at boat builders and designers who may wish to make better use of metal as a structural material for boats. Which Metal...? One of the primary choices one will face when considering metal is just which metal to use, where to use it, and what metals are best suited to each vessel type . To begin the discussion, here are a few brief thoughts with regard to steel versus aluminum. If an existing boat design is being considered, in other words a vessel that already has a fixed hull shape, then we can very generally observe the following: In terms of sea kindliness, some boats may be better if built in steel, due mainly to the extreme lightness of aluminum, which in some hulls may result in a more active / harsh motion. This is the case to a greater degree with larger boats or very beamy boats. Provided that the design has adequate displacement and stability to carry the added structural weight, boats in general will have a more gentle motion at sea if built in steel. This is not only due to the additional weight, but also to the distribution of that weight towards the perimeter, resulting in a greater roll moment of inertia. On the other hand, somewhat narrower or lighter displacement boats will often be best if constructed of aluminum. They'll generally have a narrower waterplane, and so less inherent shape stability. Therefore, due to having a relatively narrower waterline, they will react less avidly to the water's surface contours (waves), and will have a relatively easier motion at sea. In order to have sufficient stability, weight must be kept down, favoring an aluminum structure. It is usually a simple matter to adapt a steel vessel design to being built in aluminum, since the resulting vessel will have a lower center of gravity and enhanced stability (less structural weight, more ballast). But a design that has been optimized for aluminum construction will not ordinarily be able to be built in steel, due to the substantially greater weight of structure. The exception is an aluminum vessel that has been designed with relatively heavier displacement than needed. If we were to start from scratch and create a new design, we have the chance to optimize the hull form to take best advantage of the preferred material. With steel , we must design a hull with sufficient displacement to carry the structure. At 490 pounds per cubic foot, the weight of a steel structure adds up very quickly indeed. For smaller vessels, say below around 35 feet, this makes for a fairly heavy displacement. In larger sizes, say above 40 feet, one can make excellent use of steel. Above 45 feet and steel structure begins to come into its own. Above around 50 feet, a steel hull can actually be quite light for her length (by traditional cruising vessel standards). I have somewhat arbitrarily given the lower limit of a good steel vessel as being around 35 feet of length. This is of course not a fixed limit. The boundary of what can be built in steel is less a matter of boat length than it is a matter of shape and displacement. With proper design, one can successfully create a steel boat for coastwise or blue water sailing down to around 28 to 30 feet LOD. Smaller is actually possible but compromises must be made...! Adequate displacement must be maintained to carry the structure, and thus draft and beam may not be decreased below a certain point. Therefore, roughly below around 30 feet the boat will require rather heavy displacement, likely resulting in a less graceful shape in order to carry the structure. There will be that much less carrying capacity remaining for fuel, water, and the desired number of sandwiches and beer...! For small vessels of say less than around 40 feet, one can make a very convincing argument in favor of aluminum . At 168 pounds per cubic foot, we can easily make use of greater plate thickness without much of a weight penalty, and still have a light weight structure. When built to the same strength standard as a steel vessel, a bare aluminum hull "as fabricated" will weigh some 30% less than an equivalent steel hull. As an added bonus, the lighter weight of aluminum will permit a given hull form to be built with much greater strength than the same hull in steel. In other words, given the same weight budget an aluminum structure will be able to increase scantlings in order to have a considerably higher strength than the same design in steel. What other materials can be considered...? Any design optimized for steel construction can be readily adapted to being built in Copper Nickel or Monel without having to make changes to the hull shape. The overall weights will turn out to be within a similar range and the placement of internal framing will usually be identical or extremely similar. We can also say that any design that has been optimized for aluminum construction could be adapted to the use of Titanium for the hull structure without requiring any hull shape changes. A titanium structure having an equivalent strength to a steel structure will be approximately 40% lighter than the steel structure, and roughly 10% lighter than an aluminum structure. Since we know from experience that "form follows budget" the choice of materials for a boat's structure ultimately comes down to a question of cost, which we will consider below. Steel Mild Steel: Due to fabrication issues, one cannot readily make use of less than 10 gauge mild steel plating (0.134 inch, or 3.5 mm). Even 10 gauge mild steel plating can be very problematic to keep fair. It will have much greater distortion levels while welding than plate of a greater thickness. Even so, with a few essential metal boat building tricks learned, it is not much trouble to avoid distortion altogether in a 10 gauge steel hull. With a few innovative approaches to the arrangement of structure, even less thickness is possible, down to say 12 gauge mild steel. For an amateur builder however, working in 10 gauge mild steel without knowledge of a few essential tricks, the result will often be excess distortion. The natural temptation then is to use greater plating thickness, but there must be adequate displacement to carry the greater weight. A design intended for 10 gauge steel will be grossly over-weight if the plating is arbitrarily increased to, say, 3/16 inch, and it will neither float at the intended waterline, nor be able to carry the required amount of ballast, and as a result it will not have the intended stability. It turns out that in the battle against distortion, it is better to use a few more strategically placed longitudinals. Other tricks will also ordinarily be employed to preserve fairness, such as temporary external long's, etc. In general it is possible to design and build very fine steel boats down to around 35 feet (give or take a few feet), these smaller vessels will necessarily make use of 10 gauge mild steel plate and they will therefore necessarily require much greater skill in building. If the vessel can be large enough, say over 45 feet, or of sufficiently heavy displacement, then 3/16 inch mild steel plating can be used to advantage (just under 5 mm) and will be far easier to keep fair. For boats above 60 feet, 1/4 inch plate can be used and the boat will still be lighter than one could achieve with traditional plank on frame wood construction. Corten Steel: For smaller steel vessels that must use 10 gauge steel for plating, one can make a very good case for using Corten steel. Corten has about 40% greater yield strength than mild steel. This means that 10 gauge Corten plate will resist welding distortion and denting more or less the same as 3/16" mild steel plate. The higher yield strength is the primary justification for the use of Corten steel for metal boats, rather than imagining there to be any possible corrosion benefits. Although Corten tends to rust much more slowly than mild steel, whether a boat is built of mild steel or of Corten steel it still must be sandblasted and painted everywhere both inside and out. Corten is just as easy to weld and cut as mild steel, so aside from the slightly greater cost of Corten, it is to be recommended for all steel vessels having a steel plate thickness of less than 3/16 inch. "Cor-Ten A" is also known as ASTM A-242, which is an older specification for the current ASTM A-606 (usually for sheet under 3/16") and ASTM A-588 (usually for plate over 3/16" thickness). ASTM A-588 is also known as "Cor-Ten B" and is the more commonly encountered current spec for Cor-Ten, with a minimum yield strength of 50k psi in plates of greater thickness. An alloy sometimes specified for low temperature applications is "Tri-Ten" also known as ASTM A-441. An alternate (newer) spec for this alloy is A-607 when referring to sheet, or A-572 and A-572-M when referring to plate. "Tri-Ten" alloys contain a small amount of vanadium (A-572), or they may contain both vanadium and manganese (A-572-M). The addition of these alloying elements allows these steels to achieve greater strength by producing a more refined microstructure as compared with plain carbon steel (mild steel). The alloying elements provide a smaller crystalline grain size and a fine dispersion of alloyed carbides, thus providing higher yield strength without sacrificing ductility. High Strength Low Alloy (HSLA) Steel Common Names & Properties HSLA STRUCTURAL STEELS ASTM A572-50 EX-TEN 50 Offers 50k PSI minimum yield. ASTM A441 TRI-TEN Offers 50k PSI minimum yield. Resistance to atmospheric corrosion twice that of carbon steel. ASTM A242 COR-TEN A Resistance to atmospheric corrosion four times that of carbon steel. Excellent paint adhesion. ASTM A588-A COR-TEN B Similar to A242. Modified chemistry offers 50k PSI minimum yield. Resistance to atmospheric corrosion four times that of carbon steel.

In General: The advantages of steel can be summarized as follows...

- Steel is more rugged than aluminum, being tougher and much more abrasion resistant.

- The various HSLA steels are even more so.

- Welds in steel are 100% the strength of the surrounding plates, whether mild steel or Corten.

- Steel is more "noble" than aluminum, making steel less prone to electrolysis and allowing a steel hull to use regular copper bottom paint.

Aluminum is light, strong, corrosion resistant, non sparking, conducts electricity and heat well, and is readily weldable by MIG or TIG processes. In terms of ease of construction, aluminum is excellent. It can be cut with carbide tipped power tools, dressed with a router, filed and shaped easily, and so forth. Aluminum is light, clean, and easy to work with.

Aluminum is therefore faster to fabricate than steel and welding aluminum is a very quick process, both resulting in a labor savings. In terms of thickness, 3/16 inch (around 5 mm) is generally considered the minimum plate thickness for MIG welding. However, if pulsed MIG welding is available then 5/32 inch plating (4 mm) can be used, particularly for deck and house structures.

Pound for pound, the cost of aluminum is much greater than steel. In 2012, aluminum in the 5000 and 6000 series costs between USD $3.00 and $3.50 per pound and pre-primed steel plate costs round USD $0.80 per pound.

Since the weight of an aluminum structure will be some 30% lighter than an equivalent steel structure, considering only the cost of materials an aluminum structure will still be roughly 2.5 times that of the equivalent steel structure. That aluminum is faster to fabricate and weld does help to reduce that ratio after labor costs are factored in.

Since aluminum is much lighter than steel, there is the option to use much greater plate thickness within a given weight budget, which means that not only can the overall strength be greater than with steel, but the distortion levels can be much more easily managed. In so doing, of course the cost will be proportionally greater.

Aluminum alloys for use on boats are generally limited to the 5000 and the 6000 series. These two alloy groups are very corrosion resistant in the marine environment due to the formation of a tough aluminum oxide. These alloys are subject to pitting, but the pitting action slows as the oxide film thickens with age.

Aluminum alloys are subject to crevice corrosion, since they depend on the presence of Oxygen to repair themselves. What this means is that wherever aluminum is in contact with anything, even another piece of aluminum or zinc, it must be cleaned, properly prepared, and painted with an adhesive waterproof paint like epoxy, then ideally also protected with a waterproof adhesive bedding such as Sikaflex or 3M-5200 to prevent water from entering the interface.

Paint preparation is critical. Thorough cleaning, and abrasive grit blasting will provide the best surface for adhesion of paint or bedding. Alternately, a thorough cleaning and then grinding with a coarse 16 grit disk will provide enough tooth for the paint to stay put.

Aluminum is anodic to all other commonly used metals except zinc and magnesium, and must be electrically isolated from other metals. A plastic wafer alone as an isolator is not sufficient. Salt water must be prevented from entering the crevice, which means that properly applied epoxy paint, adhesive bedding, and a non-conductive isolator should all be used together.

In aluminum, welds done in the shop are at best around 70% of the strength of the plate (in the 5000 series). Usually, one will compensate for the reduced strength in the heat affected zone either by providing a backup strip at any plate joint, and welding the plate joint thoroughly on both sides, or by providing additional longitudinal members to span any butt welds in the plating.

Ideally, plating butts will be located in the position of least stress. For most general plating, this is ordinarily at one quarter of the span between frames. In other words, with proper engineering and design, the reduced strength of aluminum in the heat affected zone is a non issue.

Aluminum hulls require special bottom paint. Organo-tin based anti-fouling paints can no longer be used as bottom paint except in such diluted formulations as to be nearly useless. Currently, the best antifouling paint for aluminum hulls is called "No-Foul EP-21" made by the E-Paint Company (800-258-5998).

No-Foul EP-21 is an update of the original "No-Foul ZDF" both of which make use of a controlled release of hydrogen peroxide to prevent fouling. Practical Sailor Magazine did a controlled study of a large variety of anti-fouling paints over several years, during which they discovered that No-Foul ZDF outperformed ALL other antifouling paints during the first year of immersion in all waters. They also discovered that No-Foul ZDF performs significantly less well than the other AF paints during the second year... The conclusion? Refreshing the No-Foul coatings annually will result in a top performing system, as well as frequent inspection intervals for the hull.

The new formulation for No-Foul EP-21 is considered to be an improvement due to the addition of an environmentally preferred booster biocide that helps control slime and grass. Another improvement is the change from a vinyl binder to an epoxy. This makes the paint harder, and allows it to be applied over a wider variety of existing paints.

Other non-copper based anti-fouling technologies continue to appear, and they all should be considered provided that there are no metals present that are more noble than aluminum.

A big savings with aluminum is that it is ordinarily not necessary to sand blast or paint the inside of the hull. Generally, due to its very good conductivity one must insulate an aluminum hull extremely well. The most common insulation is blown-in polyurethane foam, although our present recommendations have drifted away from those materials. In combination with a light primer or mastic, one can make an excellent case for the use of cut-sheet foams, such as Ensolite and Neoprene, where it is desirable to lightly blast the aluminum, and provide an epoxy primer or other barrier coating prior to insulating.

Various coatings for the interior of an aluminum boat are available which provide sound deadening and insulation. Two products in particular are Mascoat DTM for insulation, and Mascoat MSC for sound attenuation. Our preference is to use Mascoat MSC at 20 mils thickness throughout, with an additional 60 mils thickness in the engine room for sound attenuation. Then to apply Mascoat DTM at 120 mils thickness throughout over that as insulation. With this system it is not necessary to pre-paint the surfaces, nor to use additional insulation, although for colder waters a cut sheet foam can be added.

On the exterior , except on the bottom or locally where things are mounted onto the hull surface, it is completely unnecessary to paint an aluminum hull. This represents such a large cost savings that if the exterior is left unpainted, building in aluminum will often cost LESS than building the same vessel in steel. More or less, the cost difference amounts to the cost of painting the exterior of the aluminum hull...

We have already seen that a point in favor of aluminum is that a much lighter weight boat can be built than would be possible in steel. This is a performance advantage as well as a cost advantage. Not only will the lighter displacement boat be relatively less costly to build, it will also be much less costly to push through the water. Lighter weight means less horsepower is needed for the same speed, which means less fuel will be used to achieve the same range, both of which augment the overall savings in weight.

One might argue that with a lighter boat there will possibly be less room below, the lighter boat being narrower on the waterline, and possibly less deep. With proper planning, this need not be an issue.

On the plus side, even if an aluminum boat costs slightly more than a steel vessel to build (if painted), an aluminum boat will have a much higher re-sale value than a steel boat.

Stainless Steel

I am occasionally asked, "What about building a boat in Stainless?"

A structure built in stainless will weigh approximately the same as one built in mild steel, although on occasion one may be able to make use of somewhat lighter scantlings due to the somewhat higher strength of stainless. There are several major drawbacks to the use of stainless, not the least of which is cost. Stainless of the proper alloy will cost nearly six times the price of mild steel!

Even if it were not so costly, stainless has numerous other problems:

- Stainless is quite difficult to cut, except by plasma arc.

- Stainless work hardens when being formed and can become locally tempered such as when being drilled.

- Stainless deforms rather extremely when heated either for cutting or for welding, meaning distortion will be very difficult to control.

- Stainless, even in the low carbon types, is subject to carbide precipitation in the heat affected zone adjacent to the weld, creating an area that is much more susceptible to corrosion as well as to cracking.

- Stainless is subject to crevice corrosion when starved of oxygen. This can be prevented only by sandblasting and painting the surfaces wherever an object is to be mounted onto the stainless surface. The same applies to the back side of any stainless fittings which are applied to hull surfaces.

If the above issues with stainless can be properly accounted for in the design and building of the vessel, then stainless can be a viable hull construction media.

Type 316-L stainless is generally the preferred alloy. Type 316-L is a low carbon alloy, and is used in welded structures to help prevent carbide precipitation in the heat affected zone. When available, the use of type 321 or 347 stainless will be of considerable benefit in preventing carbide precipitation, since there are other alloying elements (tantalum, columbium, or titanium) which help keep the carbides in solution during welding.

In my view, as a builder the main battle one will face is the rather extreme distortion levels when fabricating with stainless. Stainless conducts heat very slowly and has a high expansion rate. Both of these characteristics conspire against maintaining fairness during weld-up. Short arc MIG welding will be an imperative. In fact Pulsed MIG will probably be desired in order to sustain the right arc characteristics while lowering the overall heat input.

Copper Nickel

Another material which should be considered along with steel, stainless, and aluminum is Copper Nickel. One can ignore paint altogether with CuNi, inside, outside, top and bottom. Copper Nickel acts as its own natural antifouling. In fact, bare Copper Nickel plate performs better than antifouling paint..! Being a mirror-smooth surface, any minor fouling is very easily removed.

Besides not having to paint CuNi and its natural resistance to fouling, CuNi is also easy to cut and weld, it has relatively high heat conductivity, it is extremely ductile, and it is therefore very favorable with regard to distortion while welding.

There are two alloys of Copper Nickel which are the most common: 70/30 CuNi, and 90/10 CuNi. The numbers represent the relative amounts of Copper and Nickel in the alloy. Having a greater amount of Nickel, 70/30 CuNi is the stronger of the two and also the more expensive of the two.

In the US as of February 2007, 90/10 CuNi was priced around USD $8.50 per pound, and 70/30 CuNi around USD $13.00 per pound, both based on a minimum order of greater than 15,000 pounds. In other words, roughly ten to fifteen times the cost of the same structure in steel. I have not investigated current (2015) prices for CuNi, but we can be certain they are higher (i.e. the value of the dollar less) thus the ratio of costs vs. steel much higher.

The issues with CuNi are not only those of cost, but also of strength. For example, the ultimate strength of 90/10 Cu Ni is about one third less than that of mild steel, and the yield strength about half that of mild steel. In practice, this means that a hull built of Cu Ni will have to use heavier scantlings. CuNi, being slightly heavier than steel per cubic foot, the CuNi hull structure will end up being slightly heavier than an equivalent steel hull structure.

In most materials, we usually "design to yield." This means that the ultimate failure strength of a material is more or less ignored, and the yield strength is instead used as the guide for determining scantlings. For example, if we were to desire a 90/10 CuNi structure having the same yield strength as there would be with a similar steel structure, we would be tempted to actually double the scantlings. Naturally this would result in quite a huge weight penalty, BUT....

In practice, a CuNi structure need not be taken to this extreme. Using the ABS rules to calculate the scantlings, an all 90/10 Cu Ni structure will have around 25% more weight than a similar structure in steel. It is best to use the same plate thickness as with steel, and compensate for the lower yield strength by spacing the longitudinals more closely.

It is unlikely that one would choose CuNi for the internal framing, primarily because of its cost, its relatively low strength, and the relatively much larger scantlings and weight that would result. In other words, there is no reason not to make use of CuNi for the hull skin in order to take full advantage of its benefits, but it is possible to use a stronger and less expensive material for all the internal framing.

What is the best choice for the internal framing...? Probably type 316-L Stainless . As long as the various attributes of stainless are kept in mind, this is a combination having considerable merit. Here is why...

- Stainless can be readily welded.

- One can easily make a weld between stainless and Cu Ni.

- Scantlings of stainless internal framing would not need to be increased, in fact they would be less than those required for mild steel.

- The weight of stainless internal framing would therefore be roughly 10% less than with mild steel, or approximately equal to the weight of a Corten steel internal structure.

- 316-L Stainless costs (February 2007) around USD $4.50 per pound based on a minimum order of 10,000 pounds. Therefore the cost of stainless is roughly half that of 90/10 Cu Ni, and about one third the cost of 70/30 Cu Ni... Combined with there being much lighter scantlings, the overall cost factor would be reduced considerably.

With this strategy the weight can be kept to roughly the same as an equivalent mild steel structure.

And to further reduce costs, NC plasma cutting or water jet cutting can be used for all plates and internal structure.

Are there still more options to reduce costs...?

Fiberglass...! Compared to the weight and cost of an all CuNi / Stainless structure, both cost and weight can be reduced by using fiberglass for the deck and house structures, or possibly just for the house structures. A cold moulded wooden deck and / or superstructure is also a possibility.

Even with GRP or composite wood for the house structures, it probably would be most advantageous to plate the deck with Cu Ni. In so doing, one could then use CuNi for all the various deck fittings: stanchions, cleats, bitts, etc. Pipe fittings are readily available in either alloy of CuNi, so this would be a natural. The resulting integral strength and lack of maintenance would be an outstanding plus.

While the expense of Copper Nickel may seem completely crazy to some, given a bit of extra room in the budget and the will to be completely free from ALL requirements for painting, this is the bee's knees....! The savings realized by not having to paint the entire vessel inside and out - EVER - will go quite a long way toward easing the cost differential.

Per existing research on a number of commercial vessels, their operators have shown a very favorable economic benefit over the life of a Copper Nickel vessel. This is due to there being a much longer vessel life; far less cost for dry docking; zero painting costs; no maintenance; no corrosion; few if any repairs; etc.

Per the Copper Alliance, and organization that has studied the economic benefits of CuNi for boat hulls, the cost saved on a commercial vessel's maintenance routine pays for the added cost of the CuNi structure within 5 to 7 years. And... if the resale value of a CuNi boat is considered, the ROI is further enhanced.

Monel 400 is an alloy of around 65% Nickel, around 30% Copper, plus small percentages of Manganese, Iron and Silicon. Monel is extremely ductile, and therefore will take considerable punishment without failure. Monel is easily welded, and Monel has extraordinary resistance to corrosion, even at elevated temperatures.

Monel is much stronger than mild steel, stronger than Corten, and stronger than the usual varieties of stainless. As a result of this greater strength, Monel could be used for the entire structure. As compared to a similar steel structure, Monel will therefore permit lighter scantlings and would allow one to create a lighter overall structure than with steel. Alternately one could use the same scantlings in order to achieve a vessel having greater strength .

To reduce costs even more, one could use the same strategy as with CuNi, i.e. use Monel just for the plating, and then use 316-L Stainless for the internal framing. This is probably the sweet spot, offering light scantlings and extraordinary freedom from on-going maintenance costs.

If cost is not an important factor, an all Monel structure may well be the ultimate boatbuilding material of all time.

Titanium has been used in the aircraft and aerospace industries for quite a long time. As well, several Russian submarines have been built using Titanium. With very high strength alloys available, extreme nobility on the galvanic scale, virtual immunity to corrosion in sea water and in the atmosphere, and about half the weight of steel, there are only a few considerations that stand in the way of Titanium being the "perfect" hull material, not least of which is cost .

Cost : Due to the higher cost of titanium as compared to, say stainless or aluminum, the choice in favor of using titanium for a fabricated structure such as a boat must be made on the basis of the resulting structure having lower operating costs, longer life, or reduced maintenance in order to justify its use. In other words, titanium will only be chosen if it is perceived to have a lower total life cycle cost.

Plastic Range: Among the Commercially Pure (CP) grades of Titanium, and with most Titanium Alloys there is little spread between the yield point (the point at which a material is deformed so far that it will not return to its original shape when released) and the ultimate failure point. Thus most grades and alloys of titanium have a very limited plastic range.

Elongation : The percentage of elongation before failure is on par with mild steel, and is roughly twice that of aluminum. Thus most grades of CP Titanium and most alloys are readily formable, and have a fatigue resistance on par with steel.

Stiffness: Another characteristic is "stiffness" which is expressed by the modulus of elasticity. For steel, it is 29 million psi. For aluminum, it is 10 million psi. For Titanium, it is 15 million psi. This indicates behavior that is somewhat closer to aluminum in terms of material rigidity. In other words, Titanium will flex about twice as much as steel, but about 50% less than aluminum. Interestingly, Ti has about the same modulus of elasticity (stiffness) as Silicon Bronze, but Ti has less stiffness than copper nickel, which has an elastic modulus of 22 million psi.

Welding: Yet another consideration is the welding of Titanium, which is somewhat of a mixed bag due to several of the material's properties.

The melting point of Titanium (3,042 deg F) is well above that of steel (2,500 deg F) and about three times that of aluminum (1,135 deg F). Titanium forms a very tough oxide immediately on exposure to the air, and is highly reactive with nitrogen, therefore welding must be done only after thorough cleaning of the weld zone, and the welding process must assure a complete inert gas shroud of the weld zone both on the side being welded and on the opposite side. The weld zone must then continue to be shielded until the metal cools below 800 degrees.

These factors may provide considerable difficulty, but they are surmountable by thorough attention to detail, good technique, and aggressive measures to assure post-weld shielding. These factors however dramatically increase fabrication costs over that of other metals.

Among the other material properties that contribute to ease of fabrication of any metal are its heat conductivity, and its thermal expansion rate. Aluminum expands twice as much as steel per degree of temperature change, and is three times as conductive thermally. The thermal conductivity of aluminum is a big help, but the expansion makes trouble in terms of distortion. As a benefit though, an equivalent aluminum structure will have greater thickness and thus locally greater yield strength, so the score is more or less even between steel and aluminum, with aluminum having a slightly greater tendency toward distortion while welding.

With Titanium, this latter consideration will be the overriding factor in determining the minimum practical thickness for plating. Thermal conductivity is given as 4.5 BTU / Sq Ft / Hr/ Deg F / Ft for Titanium. For steel, it is 31, for aluminum it is 90. Thermal expansion is given as .0000039 in / in / deg F for Titanium, about 50% the expansion of steel and about 30% that of aluminum. These figures seem to indicate that the material would be fairly stable while welding, but that welds would take a much longer time to cool as compared to steel and vastly longer compared to aluminum. In other words, the heat would not dissipate - it would remain concentrated in the weld zone.

Industry consensus is that Titanium is slightly more prone to distortion due to welding as compared to steel. Considering these factors along with its much higher strength, as a very rough guess a thickness of around 3/32" may possibly be the minimum practical thickness for a welded structure in Titanium, with 1/8 inch thickness being a more likely lower practical hull thickness limit. As a comparison, the minimum thickness for other materials (mainly due to welding ease and distortion issues) is 10 gauge for mild steel (.1345"), and 5/32" for aluminum, although 3/16 inch thickness is a more practical lower limit for aluminum boat structures.

Corrosion: Titanium is extremely corrosion resistant due to the immediate formation of a tenacious Titanium Dioxide on exposure to air or oxygenated water. This means it is practically immune to corrosion in sea water, but there is one catch... Like aluminum, Ti depends on free access to oxygen, therefore it can be susceptible to crevice corrosion wherever it is deprived of free access to oxygen and cannot form a protective oxide. Crevice corrosion can be prevented in the same way as is done with aluminum, and some grades of Ti are more resistant to crevice corrosion than others.

Titanium Grades: Titanium Grade 2 is the most commonly available Commercially Pure (CP) grade, having 40k psi yield, 50k psi ultimate strength and a 20% elongation before failure. It is highly formable and weldable, and is available in most shapes, i.e. plate, bar, pipe, etc. These are highly favorable properties for hull construction.

Titanium Grade 12 includes Mo and Ni for a higher strength alloy having superior resistance to crevice corrosion, with 50k psi yield, 70k psi ultimate strength and an 18% elongation before failure. The 20k psi spread between yield and failure is a highly favorable property. It is a highly formable grade, readily weldable and is available in a variety of plate sizes, pipes and bar shapes. All of these are highly favorable properties for hull construction, making Grade 12 one of the best choices to be favored for boat structure.

Titanium Alloys : An interesting Titanium alloy is the experimental Alloy 5111 (5% Al; 1% SN; 1% Zr; 1% V; 0.8% MO) with 110k psi yield, 125k psi ultimate strength and a 15% elongation before failure. Described as "a near alpha alloy having excellent weldability, seawater stress corrosion cracking resistance and high dynamic toughness." It has a high elongation before failure, a "medium" overall strength of about twice that of mild steel, and has a slightly greater spread between its yield point and failure point than the "high" strength Titanium alloys. It is favored for submarines, but its high strength is not especially necessary for boats or large yachts.

Another Titanium alloy is the proprietary ATI Alloy 425 being made by Allegheny Technologies Inc. (ATI) who are targeting this alloy at ship structures. With 132k psi yield, 152k psi ultimate strength and a 13% elongation before failure, its use is likely to be relegated to applications requiring very high strength. Its low elongation before failure is an indication that it could be prone to cracking, and it is unlikely to be a candidate for typical boat structures (i.e. non-military usages).

Light weight, high strength, immunity from corrosion in sea water... sounds ideal. Although it is obvious that Titanium would be an outstanding hull material, it requires extreme care during construction, thus labor costs would be high. If those factors can be mitigated or if cost is not an issue, then Titanium may possibly be the "ultimate" boat hull material...!

Despite its immunity from corrosion in sea water, a titanium hull will still require paint below the WL in order to prevent fouling.

Relative Cost

If we ignore the cost of the hull materials themselves for a moment and consider what may impact costs in other ways, we can observe the following... Vessel construction costs will vary more or less directly with displacement, assuming a given material, and a given level of finish and complexity in the design. Since displacement varies as the cube of the dimensions, we can see that the costs for a vessel will increase exponentially with size.

With regard to the complexity of a vessel the same can be said. Complexity in whatever form affects cost perhaps to the fourth power...! Assuming a given budget, a simpler boat can just plain afford to be made larger!

Estimating actual construction costs is relatively straightforward but it does require a detailed look at every aspect of the process. A reliable construction cost estimate must consider the hull material, degree of finish, complexity of structure, building method, whether the structure is computer cut, the complexity of systems specified and the degree of high finish for the joinery. This is only possible with a well articulated vessel specification, a complete equipment list, and a detailed set of drawings that show the layout and the structure.

Assuming we are considering vessels of equal size and complexity, when all is said and done, and if painted to the same standard on the exterior, an aluminum vessel may possibly be around 10% more expensive to build than the same vessel in steel. If the aluminum vessel is left unpainted on the exterior except where necessary, many yards can build for less in aluminum than in steel, or might quote the two materials at parity. This has been verified by several yards via actual construction estimates for boats of my design.

As compared to a steel boat, maintenance will be less costly on an aluminum boat and resale value will be higher. Taken as a whole, any increased hull construction costs for an aluminum hull will shrink into insignificance in the context of the entire life of the boat.

Of course a Copper Nickel, Monel, or Titanium vessel will be considerably more costly than one built in steel or aluminum, however in terms of longevity a boat built with any of those metals will provide the ultimate as a family heirloom...

For more information, please review our comprehensive web article on Boat Building Costs .

The materials of construction need not dictate the aesthetics of a vessel. Much can be done to make a metal boat friendly to the eye. On the interior for example with the use of a full ceiling and well done interior woodwork, there will generally be no hint that you're even aboard a metal boat.

On the exterior, if metal decks are preferred for their incredible strength and complete water tightness, one can make the various areas more inviting by devious means. An example would be the use of removable wood gratings in way of the cockpit. Fitted boat cushions made of a closed cell foam work equally well to cover the metal deck in the cockpit area, and some will prefer to laminate a cork or teak deck over a painted and protected metal deck.

Many metal boats we encounter seem "industrial" in their appearance. In my view, classic and traditional lines, if attended to faithfully, will completely eliminate that industrial look. With a bit of classic gracefulness introduced by the designer, a metal boat will be every bit as beautiful as a boat of any other material.

My design work often tends to be drawn toward fairly traditional aesthetics, which some may regard as being somewhat old fashioned. What I have done in these designs however, is to take maximum advantage of up to date materials and current knowledge of hydrodynamics, while retaining the look and feel of a classic boat. In so doing, my overall preference is to provide a boat that is very simple, functional, and rugged, while carrying forth a bit of traditional elegance.

Everyone's needs are different of course. When considering a new design, nearly anything is possible. The eventual form given to any vessel will always be the result of the wishes of the owner, the accommodations the boat must contain, the purpose for which it is intended, and the budget that is available for its creation.

Regarding Hull Form

Efficiency and performance are high on the list amongst the myriad considerations that go into shaping a hull. With metal hulls, there is always a question of whether a vessel should be rounded or "chine" shaped.

Assuming two vessels are of equally good design, whether the hull is rounded or single chine will not have much impact on their performance, i.e. they will be more or less equivalent. Here are a few considerations that may be of some benefit when considering the choice between rounded or single chine hull shapes...

- If one were to take a single chine hull form and simply introduce a fairly large radius instead of the chine, the newly rounded vessel's wetted surface would be less; displacement would be less; and initial stability would be less, and the comparison somewhat skewed.

In terms of interior hull space, a chine hull form will often be slightly less wide at sole level and slightly wider at the waterline level, so possibly a bit less room to walk around but larger seats and berths. The single chine hull form will have slightly greater initial stability (greater shape stability), and will therefore have slightly greater sail carrying ability at typical heel angles under sail. The single chine hull form will have greater roll dampening (faster roll decay). The rounded hull form will have a slightly more gentle rolling motion. The chine hull form will have slightly greater wetted surface. This implies that the rounded hull form will have slightly less resistance at slow speeds where wetted surface dominates the total resistance. The chine hull can be designed to equalize or reverse that resistance equation at higher speeds due to wake differences resulting from the chine hull being able to have a slightly flatter run.

Aside from these generalities, relative performance would be difficult to pre-judge. We can however observe the following:

- Given the same sail area, when sailing at slow speeds in light airs, one might see the rounded hull form show a slight advantage due to having slightly less wetted surface.

- When sailing fast , a chine hull form will be more likely to exhibit greater dynamic lift, especially when surfing.

- Especially in heavier air, one might even see a slight advantage to windward with the chine hull.

Given that those observations do not reveal any special deficiency with regard to a single chine hull we can additionally observe the following:

- When creating a new design, wetted surface is one of the determining factors of sail area.

- Having slightly greater wetted surface, a single chine hull should therefore be given slightly more sail area, so its slightly greater wetted surface will become a non-issue .

- If the chine hull is given slightly more sail area, it will therefore be subject to a slightly greater heeling force.

- However the single chine hull form will have inherently greater "shape stability" in order to resist that heeling force.

- One can therefore expect the sail carrying ability to be essentially equalized .

- Therefore with good design, there is no performance hit at low speeds, and there is ordinarily a performance gain at high sailing speeds.

Among the above considerations, the one factor that seems to favor the rounded hull form most definitively is that of having a slightly more gentle rolling motion. In other words, a slower "deceleration" at the end of each roll. On the other hand, rolling motions will decay more quickly with a single chine hull form. Even these factors can be more or less equivocated via correct hull design.

Rounded Metal Hulls

As we have seen, one cannot claim that a rounded hull form is inherently better in terms of performance without heavily qualifying that claim. The primary trade-offs between a rounded hull and a chine type of hull form for metal boats therefore turn out to be purely a matter of cost and personal preference.

I have designed several rounded hulls for construction in metal. These are true round bottom boats designed with the greatest ease of plating in mind. Some are double ended, some have a transom stern, others have a fantail stern, and still others have a canoe stern where stem nicely balances the shape of the stern.

Having an easily plated shape, any of these rounded hull forms can be economically built. These rounded shapes require plate rolling only in a few places and are elsewhere designed to receive flat sheets without fuss. These are not "radius chine" boats. They are simply easily plated rounded hulls.

With any of these types, the keel is attached as an appendage, there being no need when using metal to create a large rounded garboard area for the sake of strength, as would be the case with a glass or a wooden hull. This achieves both a more economically built structure, as well as a better defined keel for windward performance under sail and better tracking under sail or power.