- PRO Courses Guides New Tech Help Pro Expert Videos About wikiHow Pro Upgrade Sign In

- EDIT Edit this Article

- EXPLORE Tech Help Pro About Us Random Article Quizzes Request a New Article Community Dashboard This Or That Game Popular Categories Arts and Entertainment Artwork Books Movies Computers and Electronics Computers Phone Skills Technology Hacks Health Men's Health Mental Health Women's Health Relationships Dating Love Relationship Issues Hobbies and Crafts Crafts Drawing Games Education & Communication Communication Skills Personal Development Studying Personal Care and Style Fashion Hair Care Personal Hygiene Youth Personal Care School Stuff Dating All Categories Arts and Entertainment Finance and Business Home and Garden Relationship Quizzes Cars & Other Vehicles Food and Entertaining Personal Care and Style Sports and Fitness Computers and Electronics Health Pets and Animals Travel Education & Communication Hobbies and Crafts Philosophy and Religion Work World Family Life Holidays and Traditions Relationships Youth

- Browse Articles

- Learn Something New

- Quizzes Hot

- This Or That Game New

- Train Your Brain

- Explore More

- Support wikiHow

- About wikiHow

- Log in / Sign up

- Cars & Other Vehicles

- Boat Building

How to Make a Sail

Last Updated: November 8, 2023

This article was co-authored by Nitzan Levy . Captain Nitzan Levy is a Sailor, Social Entrepreneur, and the Founder of Sailors NYC, a recreational sailors’ club based in Jersey City, New Jersey that specializes in cruising boats and a variety of community programs. Capt. Levy has over 20 years of sailing experience and has sailed in many places around the world including: the Atlantic Ocean, the Mediterranean Sea, The Caribbean, and the Indian Ocean. Capt. Levy is a U.S. Coast Guard Licensed Master of vessels up to 50 Tons with Auxiliary Sail and Assistance Towing Endorsements. Capt. Levy is also a NauticEd Level V Captain Rank Chief Instructor, an American National Standards Assessor, an SLC instructor, an ASA (American Sailing Association) Certified Instructor Bareboat Chartering, and an Israeli licensed skipper on Boats for International Voyages. This article has been viewed 108,647 times.

Ships and boats of all sizes have harnessed the power of wind for centuries. Sailing boats have continued to use sails to this day for recreational sports and hobbies. Whether you’re looking for a calm day on the water or to compete in a race, making your own sail can be a beneficial skill.

Getting Started

- Research the dimensions of similar sails and have an idea of what kind of sailing you’d like to do. This gives basic reference points to research and execute.

- If you are planning to sew the sail yourself, you will also need a special sewing table to be able to support the industrial sewing machine. This table needs to be about twice the size of a table tennis table in order to support the size of the sail.

- Shorter booms give you more maneuverability.

Designing the Sail

- The luff curve won’t match the curve of the mast. The top third of the luff curve will be slight and the bottom of the curve, close to the boom, will be greater than the mast curve. There are different theories on what the perfect luff curve should be so research how to optimize the luff curve for your prefered type of sailing.

- If you want more stability, add more battens; however, use less battens to make your boat easier to manoeuvre and more lightweight.

- Use heavier materials near the bottom of the sail. Seams also help to optimize the amount of material you use.

- Tape fabric or newspaper together for more surface area when creating a large sail.

- The luff curve and shaping the seam will create a three dimensional sail so don’t worry if your sail lies flat as you construct your pattern.

- Ensure that the material you choose resist stretching and can withstand rips.

- Heavy monofilm and woven sailcloth are common choices.

Assembling the Sail

- Stick and sew two panels at a time until the sail is all in one piece. You can now trim it to your design on the table and draw on the batten pockets.

- Create an adjustable head for your sleeve if this is your first attempt at a sail.

- Use pulleys from old sails or get them from a sail maker.

Expert Q&A

- Know what shape you want and rig your sail until it takes that exact shape. Thanks Helpful 0 Not Helpful 0

- Learn what type of sails work best for your vessel relative to the sailing conditions. Thanks Helpful 0 Not Helpful 0

- Create a budget to ensure you optimize your resources. Thanks Helpful 1 Not Helpful 1

- Design with safety first, do not cut corners to favor aesthetics or cost. Thanks Helpful 0 Not Helpful 0

Things You'll Need

- Sailcloth, polytarp, nylon or Dacron sail material

- Industrial sewing machine

- Measuring tape

- Sail pattern

- Double sided adhesive tape

- Dacron tape or reinforced monofilm tape

You Might Also Like

- ↑ http://www.startedsailing.com/sail-battens.html

- ↑ http://jezebel.com/5916905/how-to-turn-your-dress-idea-into-reality-by-making-your-very-own-custom-pattern

- ↑ Nitzan Levy. Sailing Instructor. Expert Interview. 24 April 2020.

About This Article

To make a sail, first sketch the luff curve using your boom and mast measurements. Next, choose a scratch-resistant material that works best for your budget and sailing needs, such as Monofilm or Pentex taffeta scrim laminate. Then, place your pattern onto your material and outline the panel, battens, and seams. Once you have your sail’s shape, cut out the panels, and stitch them together, leaving extra cloth at the edges for seams. For more tips from our Nautical co-author, such as how to reinforce your sail against the elements, read on! Did this summary help you? Yes No

- Send fan mail to authors

Did this article help you?

Featured Articles

Trending Articles

Watch Articles

- Terms of Use

- Privacy Policy

- Do Not Sell or Share My Info

- Not Selling Info

wikiHow Tech Help Pro:

Develop the tech skills you need for work and life

The Perfect Gear for Any Sailing Adventure

How to Make a Sail for Beginners: Learning the Basics

How to make a sail is much harder than it may initially seem. You’ll need the right materials and plenty of space to lay out the material, tools, and supplies. We’ll guide you through the entire process, but keep in mind that if you want to make a sail for your specific boat, you’ll need to adjust measurements and may even want to choose different types of material based on climate and average weather conditions.

If you’re interested in how to get into yachting and want to learn how to create and repair your own sails, our guide will give you an in-depth look at the step by step process the pros use to make their own sails.

Key Takeaway: While complicated, learning how to make and care for your sail can help you save some serious cash in the future. Additionally, every sailor should know how to make their own sails and alter the sail’s design based on boat size and style. Following our maintenance tips will also help you to get the most out of each and every sailing experience, ensuring your sail is in peak form for your next sailing adventure.

If you’d like to learn more about sailing gear and accessories for this new and exciting sport, click here to check out our sailing shoes buyer’s guide.

Now, let’s get started.

Table of Contents

Tools and Materials

The steps we’ll discuss will give you a basic idea of the sail making process. Organization and space will be key to a well-made sail and a more streamlined process altogether.

First off, you’ll need a large flat table and a room with a level floor. The cloth from which you’ll make the sail is sold in strips or on a roll. The strips are usually around sixty centimeters wide. The strips should be laid out on the table or floor, cut to size, and marked. When marking the strips, you’ll want to use a pencil, T-square, and tape measure. To cut the sail cloth you’ll need a sharp knife.

A sailmaker’s bench is a handy tool for sail making. Of course, the bench is designed for sitting on when you’re making a sail, however, it’s also the perfect place for storing your tools and keeping them organized, so everything is easily accessible. The bench contains a wooden stick with twine, a sail maker’s palm, and a small pointed hook. The hook is used to apply tension to the work piece when sewing, which makes sewing much easier.

Other materials we recommend include the following:

- Sail needles

- Sail making thread

- Seam rubber

- Marlinspike

- Hollow punch

The First Step

The sail cloth strips are first cut to the correct length. This is accomplished with a drawing of the sail. The best way to draw up the sail is on the floor, then place the strips on top of the drawing to mark them off. Next, you’ll sew the strips together until you achieve a rough shape of the sail.

The next steps will involve a series of finishing that will heavily depend on the shape of the sail, in addition to the function and location of the sail.

The sail’s outside edge is folded into the hem, which is reinforced by adding and sewing rope onto it. This is called the leech. Loops are added to the leech using rope. For reefing the sail and securing it to the yard, reinforced holes called cringles are made.

Reinforcing the Seams

Once you’ve marked and measured the strips and cut them, you can sew them together with the help of a thick flat needle. For this step, you’ll need to lay a couple of strips overlapping for three centimeters. Before you sew up the complete seam, you’ll tack the seam first every fifty centimeters. Some sail makers also use double-sided tape for this step.

To sew the seams, you’ll use a straight stitch, stitching from point A to B. If you’re left-handed, you’ll work from left to right if you’re right-handed you’ll work from right to left. Use the sail maker’s bench with the strips laid out on the table to keep everything organized. Thread the needle and begin. You’ll want to keep the seam flat in front of you.

Once you’ve sewn up the seam on one side, you’ll use a flat stitch, turning over the sail to sew up the seam on the opposite side using the flat stitch.

The corners of the sail are reinforced using an extra sailcloth to create additional layers. Some sails have as many as six layers. These layers are sewn onto the sail using sail making thread.

Once the corners have been reinforced and the basic shape of the sail is ready, you can create a hem that measures a few centimeters all the way around the sail. This can be done by placing the sail flat on the floor. Next, fold the edges of the sail four centimeters, making a crease. You can force down the crease with the help of a wooden seam rubber.

Once the hem has been rubbed all the way around and creased you can sew up the hem using the flat stitch. In order to do this, use the bench and sailmaker’s palm in order to tension the work piece as you sew.

Sewing Through Multiple Layers

When sewing, use the needle and palm to push the needle through the cloth. You will also use the pliers to pull the needle through. For areas in which there are more than a couple of layers, use the awl to punch holes for the needle. Several layers of cloth on top of each other are pretty strong, which means you won’t be able to push the needle through the cloth by hand.

Next, you’ll use leech ropes to reinforce the stitches. For small sails, you’ll want to use thinner rope, while larger sails will require a thicker rope.

How to Make Cringles

You’ll need to make cringles before you sew up the leech ropes. These are rope grips and loops for the sheets, through which you’ll feed the ropes in order to allow you to easily handle the sail. You’ll use knot techniques to make the cringles. The cringles will be tied to the ropes before they’re sewn onto the sail.

At the top of the sail’s hem, you’ll make a series of holes called eyelets to run the ropes through. Each of the eyelets is then fitted with grommets. The grommets are tacked in place with the help of tack stitches.

Based on the type of sail you need additional strips may need to be sewn across the sail’s width in order to secure reefing lines. A knot should be tied at the end of the ropes on each side of the eyelet to keep the rope securely in place.

Sail Maintenance Tips

- Did you know that over time, leech flutter and flogging can actually degrade the sail’s performance? So the sails fill rather than flog, after hoisting the sails make sure you trim promptly and steer a course.

- Adjust the leech line correctly in order to avoid leech flutter. Make sure the line is tensioned correctly in order to prevent the flutter.

- Make sure you avoid any type of unnecessary contact between the standing rigging and the sails and never release the genoa sheet late in a tack.

- Always use sails in their designed wind ranges.

- Be sure to cover spreader ends in order to combat chafe. You should also make sure that there aren’t any exposed cotter pins, split pins, or sharp edges around the turnbuckles, lifelines, foredeck, and mast.

- The sail you make should have extra reinforcement in high chafe areas.

- Always limit sun exposure because UV rays can cause damage when the sails are exposed for an extended period of time.

- The sails should be rinsed with fresh water and thoroughly dried before storing in order to prevent color bleeding and mildew growth.

- Never fold the sails on the same fold lines. Doing so can create permanent creases.

- Never use bleach to clean your sails.

- Always patch up tears as soon as possible using a type of pressure sensitive adhesive

- Never use duct tape to repair your sail

- Before heading out, check hardware to ensure that they’re still attached securely to the sail.

- Seam stitching should also be check regularly to ensure no repairs are needed.

- Practice makes perfect. Don’t expect a pro quality sail your first time around. Sail making is a delicate process and a skill that you must hone over time.

As we mentioned, you’ll need to make some adjustments to the process depending on the size of sail in terms of the number of layers you need. How to make a sail can be challenging if you don’t have much sewing experience. We hope our tips and tricks will help to streamline the process and make your next sail making project a success.

Additionally, beginners may benefit more from buying a sail kit, which contains all of the supplies you’ll need and patterns you can easily follow.

- Sailing Pants

- Sailing Shoes

- Uncategorized

- Privacy Overview

- Strictly Necessary Cookies

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Become the Confident Skipper of Your Own Sailboat

How to make a small sailboat.

- Post author: Anns

- Post published: October 11, 2022

- Post category: Uncategorized

- Post comments: 0 Comments

Introduction

Are you looking for a fun and rewarding hobby? Making your own sailboat is a great way to spend your free time, and it can also be a very rewarding experience. A small sailboat takes about six months to complete, but if you have the right materials and tools on hand, it’s not too difficult.

Getting Started

In this series, we’ll be going through the entire process of making a small sailboat. This will cover everything from ideas and plans to building and launching.

By the end of the series, you should have all the knowledge required to build your own boat.

Buying the Materials You Need

When you are building a small sailboat, it’s best to buy the materials you need from an online store. That way, you can be sure that the parts will fit together correctly and that everything is of high quality. The following list includes all of the materials needed for this boat:

- Wood for framing (plywood)

- Planking (plywood)

- Balsa wood sheets or blocks for covering the hull with fiberglass resin and cloth tape

Constructing the Hull

When constructing your boat, it is important to consider all aspects of the hull. You want it to be strong enough for rough seas, able to withstand collisions with rocks and other boats, and watertight so that you don’t sink into the ocean. The hull will also have a significant effect on how long it takes you to build your boat—if it’s too heavy or difficult to transport, you’ll need more time than if you built one out of lightweight materials like carbon fiber or aluminum.

In addition to shaping its overall form, keep in mind that there are many different ways to construct a hull: some boats use wooden planks while others use composite materials such as carbon fiber or Kevlar; some have flat bottoms while others have rounded bottoms (rounded bottoms make fast sailing possible); some are made from metal sheets riveted together while others are molded together using plastic resin such as epoxy resin glue. The construction method that works best for you depends on what type of material(s) you’re using—and even then it may be necessary to experiment before finding optimal results!

Constructing the Sailboat’s Keel

Once you have the hull and deck formed, it’s time to attach the keel. The keel is one of the most important parts of your sailboat because it:

- Is heavy. The keel is usually made from fiberglass or wood, so it will be very heavy and add a lot of stability to your boat.

- Keeps the hull straight while sailing downwind at high speeds (called point-to-point sailing). It prevents wobbling around in circles when you’re using all that power!

The Deckhouse

The deckhouse is the cabin of your sailboat. It should be large enough for you to comfortably stand up in, and it needs to keep out water when it’s raining or when you’re going through waves. Also, if you want your sailboat to have a nice aesthetic, then you’ll want your deckhouse to look good!

The shape of your hull will determine the shape of your deckhouse. For example, if you have a round-hulled sailboat with no keel (a flat bottom), then there’s no reason why you shouldn’t make your deckhouse rectangular or square-shaped instead of attempting something more complex like an L-shaped design with rounded edges along each side because this would just waste materials without providing any functional benefit whatsoever compared against just using straight lines instead which are easier both financially as well as physically speaking since they don’t require any additional tools than what’s already available whereas curved lines do require special tools such those used by carpenters who work with wood frames such as saws designed specifically for cutting curves into wood pieces rather than straight lines which can be done easily without fancy equipment at all).

If however you were building this same boat using plywood sheeting rather than solid lumber boards though then different considerations might apply depending on whether or not there was sufficient space within those sheets’ thicknesses (they could only handle so much weight before breaking apart) versus their widths (how wide each sheet would need be before splitting along its lengthwise edge). In either case though I’d recommend sticking with simple geometric shapes unless absolutely necessary due to space limitations; otherwise stick with simple rectangles/squares since these tend

Fitting the Sailboat Together

Now that the hull, keel and mast are in place and secured, it’s time to make sure your boat is ready for water. First things first: check that your boat is watertight by testing it with a bucket of water. If any leaks appear, tighten the screws or add more glue before continuing on.

Next, turn your attention to the rigging and rudder. The rigging should be secure at all times; however if you feel like something is loose or if there are sharp edges poking out somewhere then feel free to trim them down as needed with scissors or sandpaper while they’re still attached to their respective parts (you can always cut off extra threads later).

If you haven’t already done so earlier this week, now would also be an ideal time for me for me test out my rudder on land before attaching it permanently into place on our sailboat!

Finishing and Painting Your Small Sailboat

Now that you have your boat, you can paint it. You’ll want to make sure that the paint is dry before using it. Make sure you are happy with the color before applying a second coat! If the paintbrush feels good on your hand and has a good point, then it will be easy to apply the paint evenly. If not, replace it with one that does so (be sure not to use an old one because then you might get some unwanted colors). Good luck!

Learn how to make your own sailboat

Learning how to make your own sailboat is one of those activities that can be a real eye-opener. It’s not for everyone, but for those who are interested in taking on such an endeavor, it can be a rewarding and enjoyable experience. There are many advantages to building your own sailboat; for example, you can choose the type of boat you want and customize it as much as possible based on your personal preferences.

The first step in learning how to make your own sailboat involves choosing a design that suits both your needs and abilities as well as finding the right materials needed for construction. You might find yourself working with wood or fiberglass if the project calls for either one of these materials (or both). If so, there are several ways this may be done including using traditional woodworking tools like saws while others prefer using power tools instead which speeds up production time greatly compared with hand tools but requires more investment upfront since these types require expensive equipment purchases before starting any projects needing them such as sanding machines used when finishing off surfaces after applying paint coats or varnishes coatings onto finished pieces made from different materials such as metal sections which may need buffing out after being painted over twice during initial stages before final touches were added later down line depending on type work being done which could range anywhere from weeks months depending size job being tackled at time being completed

In this article, we’ve covered everything you need to know about building your own small sailboat. We hope that by following these steps and examples, you will be able to design and construct your own boat!

You Might Also Like

The best dinghy sailboats for all your sailing activities., our sailing boat and our reason for living, leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

How to Build a Wood Sailboat

Introduction: How to Build a Wood Sailboat

I've been wanting to combine my two favorite hobbies - woodworking and sailing for a long time, so I thought I'd build a boat. It's got classic lines and looks so dazzling in the sunshine that people constantly stop me at the boat ramp to ask me about it. There's something unbelievably rewarding about building something like this from scratch. This is definitely a boat that is much better built than bought . Here's how I did it.

The boat takes about 100 hours to build. I did it over 3 months, working a little bit just about every day and full days when my schedule permitted.

It will take about $1,000 in total to build if you buy everything at full retail cost (not including tools you might need to buy), but you can spread that across the length of the project. For example, you only need to buy one $30 sheet of plywood at a time, take it home, draw out the parts (loft) that fit on just that sheet and cut them out. That will take a couple of hours right there. Some boating supply stores (chandleries) might let you setup an account which might give you a discount if you tell them you're building a boat.

All of the skills needed to build a sailboat can be learned slowly, one step at a time. For example, if you've never fiber-glassed plywood before, just practice on a small piece first to get your confidence up. This was my first boat build, so I did a lot of learn as you go . Not only am I going to show you the right way to successfully build your own sailboat, but I'm going to share with you the mistakes I made along the way to hopefully save you from repeating them.

The end result will be a very attractive little 8 foot long pram, that is easily made out of 4x8 sheets of plywood that is light enough to put in the back of a small pickup truck or roll down to the local lake on the optional dolly. Anything longer would require you to either make a scarf joint (which is a bit tricky) or buy longer sheets of plywood (which is considerably more expensive).

What you will need:

Boat building plans

8 panels of 1/4" oak plywood 4'x8'

Pencil, Sharpie, ruler, tape measure, yard stick, etc.

Long flexible straight edge

Box of 1" brad nails

2 gallons of epoxy resin

1 gallon of epoxy hardener - SLOW

1 quart silica thickener

5 quarts wood flour thickener

1" masking tape

Japanese pull-saw

Table saw (helps, but optional)

Round-over router bit

Flush trim router bit

Palm/random orbital sander

220 sanding discs

Combination square

Drill bit set

Drill bit extension

Basic hand tools

Small diameter wire or zip ties

Wire cutter

12 C-clamps - 3"

Mixing cups, mixing sticks, rubber/nitrile gloves

16' x 60" of 6oz fiberglass cloth

2" plastic spreader

Gallon of waterproof glue

Glue roller

Silicone bronze screws

Stainless steel fasteners

Small blocks

Gudgeon & pintle - dinghy size

Patience - large

Elbow grease - large

For more detailed explanations on each step and more specific info/reviews on the materials and parts used, check out my boat build blog: www.Midnight-Maker.com

Step 1: Cutting Out the Parts...

First, you'll need boat building plans. I purchased some very nice ones from a popular boat building website because I had a specific style in mind to build, a "pram". It's a Norwegian design with lots of buoyancy in the bow and building a pointy boat is a little more difficult. There are a bunch of free boat building plans (search "dinghy") online. Also, I wanted my boat parts to fit in a standard (read cheap) 4'x8' sheet of plywood. It also had to be light enough for me to load/unload/move myself. This boat weighs in at about 70 pounds. When on the custom dolly I built, it's very easy to move from the parking lot to the lake.

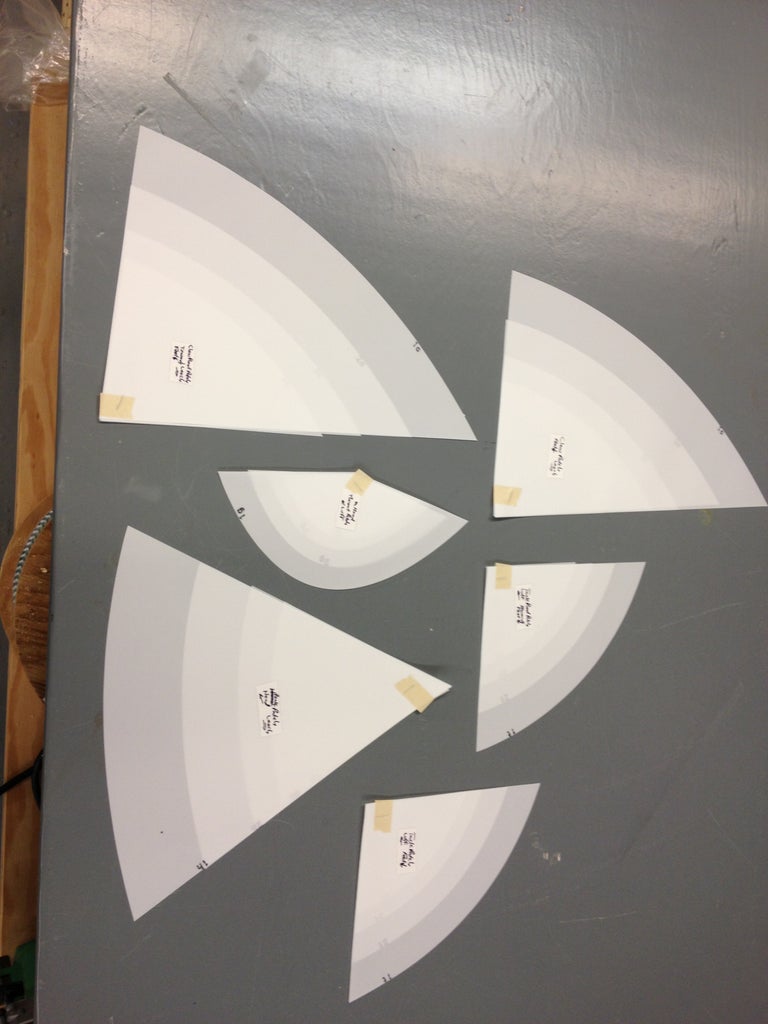

Next, you'll need to draw out the parts of the boat full-sized onto the plywood (lofting). I actually did this step on hardboard/masonite because I wanted to make templates of all the parts in case I ever wanted to build another one.

This step requires you to be very meticulous. Carefully transfer the measurements (offsets). They may or may not look correct because it's very non-intuitive to look at curved boat parts that are laying flat. Some parts actually bend the opposite way you think they should. To make the curves, I nailed a bunch of 1" brads into the panel and used a long, flexible straight edge (yard stick, etc.) bent to follow the curve, then I traced the curve with pencil/Sharpie. Once I removed the brads, I had perfectly smooth curves. Keep in mind that with the side panels that are symmetrical to both sides of the boat, only draw out one version and cut two stacked sheets at a time. This ensures the boat will not be lop-sided. Make sure to immobilize the two sheets together with screws outside of the boat parts or use double-sided tape/clamps, etc. to keep the parts registered properly.

Using a Japanese pull-saw allows you to control the cuts very carefully and it can follow the graceful curves. They cut on the pull stroke which means they're very easy to control. Make sure you leave a bit of your cut line, meaning cut just outside the line. This allows you a bit of a safety margin and you can always sand to the line to sweeten it up. This is where the elbow grease really kicks in. It takes hours to cut out the hull panels by hand, but it's worth it. I tried cutting the first part out with the jigsaw and it wandered all over the place and quickly cut inside the line before I knew it. Also, a jig saw blade can lean to one side which could mean two panels might not be the exact same shape. Using hand tools is a classic way to do woodworking and is a very gratifying process. With hand tools, things happen slow enough for you to be in total control, whereas power tools can quickly do unexpected damage. With the understanding that you're building a classic boat, using hand tools wherever possible is part of the philosophy.

The plans I bought were in metric and called for 6mm (1/4") and 9mm (3/8") plywood, but I wanted to make everything out of 1/4" plywood so the thicker parts in the plans were glued together with two layers of 1/4" (so at 1/2" they were a bit thicker than designed). I actually liked this because it made the boat feel sturdier and of course it was cheaper that way. The trade-off was that the boat would be a bit heavier.

For any of the parts that need to be doubled-up/laminated (e.g. the transoms), now is a good time to do that. Make sure you use "waterproof" glue instead of "weatherproof" glue like I did...

Spread a thin layer of glue over one of the "bad" sides (plywood usually has a good side and a bad side, glue bad sides together so good sides show on both outside faces), making sure it's completely covered (I used a special glue roller), then carefully place the other half on top. Align all of the edges together, then clamp them in place. Now put heavy things carefully on top to press the parts together. The glue should be dry in about 6 hours.

NOTE: It's considerably easier and safer to do any woodworking processes to the parts before you assemble the boat. This way, you can safely clamp pieces to the work bench and cut out handle holes, etc. Since my boat is a "lapstrake" design, I had to route a rabbet (groove located on the edge) carefully on the bottom edge of each side panel. This creates a shoulder for the parts to sit on, positively locating them while you're stitching the panels together. Likewise, the grab handles in the transoms are much easier to cut out before putting the boat together.

Also keep in mind that any mistake will be considerably more painful the further you are along in the build. For example, if I biff cutting out the grab handle holes while they're just loose pieces rather than when they're a permanent part of the boat, it's much easier to recover - just make another transom. If you had to patch a hole in the boat, it would be difficult and possibly never look perfect. No pressure...

Step 2: Assembling the Hull...

Once you have the bottom and sides cut out, you can start to "stitch and glue" the hull together. This is a technique used usually for smaller boats to be able to pull the hull form together without the need to build a frame or mold (which can take almost as long and as much wood as the boat itself).

I built a gauge stick to make sure my holes were perfectly spaced at 4" at 1/2" in from the plywood edge. It was 1" wide so either edge was the required 1/2" from the centerline. I worked my way down one side of each of each mated seam and drilled all those holes at once while the panels could lay flat on the bench. Make sure to use a backer block to prevent tear out on the back side, even with such a small drill bit.

With one mating panel drilled with a 1/16" drill bit, hold the mating panel in it's relative position. I used some spare twine to wrangle my panels into the proper orientation as I was marking them. Make a pencil mark where the mating hole should be, remove the pre-drilled panel and drill the second set of holes 1/2" in from the edge. This makes sure there's enough strength to hold the boat together.

The first pass on the stitches is just to get the hull together structurally. You can always go back and make the stitches fancier/tighter and tweak the position of the panels.

The stitches go from the inside out. Cut 6" lengths of wire and bend them into long, narrow U's that are the width of the distance between the holes. Stick the ends through the holes and carefully twist the tails together on the outside of the hull, making sure not to damage the plywood. If you're using zip ties, then the holes you drill will need to be bigger and you'll have to start on the outside, go in, turn around, then back out, then "zip".

Make sure your panels' rabbet shoulders are resting securely on the mating panel and carefully tighten all the stitches. For my boat, once I had two panels stitched to the bottom panel on each side, it was time to attach the transoms (ends). Once all of the exterior parts are stitched together, you should have something that looks like a boat. It will be a little rickety at this stage, but that's okay.

NOTE: In the photos I took of my build, you'll notice that the transom doublers (reinforcers) aren't in place. That was because I was following the instruction manual, but I think that was a mistake, so I highly recommend laminating (gluing) the doublers to the transoms before you stitch the boat together.

Step 3: Reinforcing the Hull Joints...

Now that the hull is stitched together, flip it over upside down. You'll be surprised at how stiff it is, considering how difficult it was to wrangle all those panels into position. Be careful, there's lots of poky wire ends sticking out all over the place.

I used a technique called "tabbing", meaning I made small, structural tabs from thickened epoxy that fit between the stitches, then I removed the stitches and made one long, larger fillet to connect the hull panels together.

Make sure your panels are perfectly aligned and tightened. I used a nipper to lop off most of the tails so they wouldn't get in the way, but that left very sharp spikes.

Make sure your boat is square. Take diagonal measurements from corner to corner, make sure the boat parts are parallel to each other, etc. because if there's a twist in your boat, the next step will make it permanent, which will affect the boat's performance.

Now mix up a batch of epoxy and silica thickener according to the manufacturer's directions (meaning each type of epoxy has a different resin to hardener ratio) until it's between the consistency of thick ketchup, but runnier than peanut butter (make sure to mix the 2 parts of epoxy together first very well before adding a thickener). Too thick and it won't fill the void, too thin and it'll run down inside the boat. Both are bad. I used a small syringe to inject the mix into the V intersection between the panels and checked underneath/inside to see if there were any runs.

Once the epoxy has partially set, use a glove wet with denatured alcohol to smooth out the "tabs" so they fit inside the V groove and don't extend above the intersection between the panels. This will give you good practice for the seams that will show on the finished boat. Be careful of the wire spikes.

Repeat this process for every seam on the hull. Let it cure overnight.

Once the tabs have cured, carefully remove the stitches. If the wire seems to be epoxied permanently to the hull, heat the wire with a lighter. That will soften the epoxy enough to pull the wire out. Be careful not to scorch the boat (you don't want a Viking funeral). Now repeat the thickened epoxy process for each overlap, except this time each seam will need to be one long, smooth joint. Let it cure overnight. This goes a long way in making the boat hull structural.

Step 4: Fiberglassing the Hull...

Now that you've got a permanent hull shape, it's time to make it waterproof and rugged. Fiberglass and resin over plywood is a tried and true Do It Yourself boat building technique which makes it strong and light.

Mask off the bottom panel and roll out your fiberglass cloth. Smooth the cloth out very carefully so as not to snag or tweak the fibers' orientation. Mix up an unthickened batch of epoxy (it will be the consistency of syrup). Starting at the stern, pour a small puddle of epoxy and spread it out nice and thin. You should be able to squeeze most of the epoxy out of the cloth, leaving only saturated cloth with no dry spots (which will appear white) but the weave should still be showing (meaning no extra epoxy is pooling). You should easily be able to see the wood grain through the cloth now.

Let the epoxy partially cure and using a razor, slice the dry fiberglass cloth away on the taped seam. Then remove the masking tape. Let the epoxy cure overnight.

Flip the hull over and mix up a batch of epoxy that is the consistency of peanut butter. I masked off the joint, but this step is optional, but keep in mind that it will be visible if you plan on finishing the interior bright (varnished wood). It's not as critical if you're painting the interior. With a plastic spreader, carefully make a large radius transition (fillet) between the bottom panel and the first side panel (garboard). Remove the masking tape when the epoxy mixture is partially cured and carefully scrape/wipe any unwanted mixture. It's much easier to remove now than having to sand it all off later. At this point, it's also a good time to fillet the transoms to the sides using 3/4" radius tabs between stitches and 1" finished fillets after you've removed the stitches. Let the fillets cure overnight.

Now, repeat the entire fiberglassing process on the inside. Except instead of just doing the bottom panel, make sure both the bottom and the garboard are fiberglassed. This is basically the waterline of the boat. The fillet should allow the fiberglass cloth to smoothly make the bend between boards. Remove the excess cloth when partially cured and let sit overnight. Some people fiberglass up onto the transom at this stage which will make the boat stronger, but that means you have to have already filleted the transoms to the bottom.

Step 5: Installing Interior Parts...

The bulkheads get stitched in place just like the panels. They will make the already stiff (and much heavier boat) completely structurally sound and push/pull the sides into their final shape. Then make 3/4" "tab" fillets between the stitches to lock them in place, remove the stitches and make long, smooth 1" fillets. The smaller fillets will get covered by the larger fillets. I used two different modified plastic spreaders to do this step. Each spreader was cut with a box knife and filed/sanded into its final shape.

While you're doing the previous steps, if you're in a time crunch, go ahead and build the daggerboard trunk. It's made of numerous parts that are pre-coated with a couple layers of unthickened epoxy, then glued together with silica-thickened epoxy. This makes it strong and waterproof as it will be below the waterline so must be completely waterproof.

The daggerboard trunk is the most important part of the boat, especially if you're making a sailboat version (this boat can easily just be used as a rowboat). Not only does it support the center seat (thwart), but it has to transfer all of the force from the sail to the water and if you run the boat aground, it takes all the shock loading from the daggerboard.

The daggerboard gets filleted into place like everything else. Make sure it's perfectly on the centerline of the boat as that will affect its sailing characteristics.

Next, let's make the daggerboard slot in the center thwart. I set up a straight edge with a spiral upcutting router bit. Make sure to enlarge the slots at the end of the center thwart so that it can fit around the fillets of the center bulkhead. Now is the time to ease the edges of the center thwart because you'll be sitting on it a lot, so it needs to be comfortable. Because it's so thin, I only routed the top edge of the center thwart that shows and just hand sanded the edge underneath (it's very problematic to use a round-over bit on the second side of a thin board). Paint all of the thwarts with three coats of unthickened epoxy, especially the undersides. Once the woodworking is done, the thwart can be epoxied into place with peanut butter (or you can jump to cutting the daggerboard slot in the bottom of the hull). Make sure the thwart fits snugly in place. Drop dollops of peanut butter on the top edges of the center bulkhead and daggerboard case and spread it out evenly (make sure none gets inside the slot to interfere with the daggerboard). Firmly seat the thwart (pun intended) into the goop and weight it down. Let it cure overnight.

While you've making sawdust, cut out the mast hole (partner) in the forward thwart by drilling holes in the four corners (for the square mast we're going to make), then cut out the sides, file it smooth, then round over the top edge with the router.

Any time after the bulkhead thwart fillets have cured, you can seal the airtank chambers. Paint the bottom, sides, inside of the bulkhead and transom up to the level where the thwart will be.

Step 6: Rail & Sailboat Parts...

There are several processes in this boat building instructable that can be done concurrently. While you're waiting for the epoxy on one part to cure, you can be doing woodworking or epoxying another part. This step illustrates that point. While you're waiting for the epoxy on the rub rail (outwale) to cure, you can be fabricating the sailboat accessories (e.g. daggerboard, rudder, tiller, spars, etc.).

In order for the outwale to be thick/strong enough to be effective, you'll need to laminate it in two strips on each side. You can't bend a single piece that thick around the curvature of the hull without either breaking the wood or softening it by steaming it which is a complicated process.

Take a strip that's half the final thickness and a little longer than the boat edge (I made mine a bit beefier), mix up some peanut butter with the colloidal silica and carefully spread it on the inside of the strip. Starting at the stern, clamp it in place, perfectly align it with the top edge of the plywood. Now you have a long, springy lever to bend the wood strip along the compound curve. It dips both vertically (shear), and bows out at the widest part of the boat (beam), then back in toward the bow. At least every foot, clamp it as you go, moving forward. More is better. Toward the bow, the strip will get stiffer as it gets shorter. Once clamped in place, scrape/wipe off all the squeeze-out. It's much easier to remove now than after it hardens. Let it sit overnight. You'll have to repeat this three more times, meaning this step takes four days (if you're using "slow" epoxy hardener).

During those four days that you're dealing with the outwale, you can make major progress on the sailboat parts. They're completely separate from the hull. If you're just making a rowboat, then you can skip making these parts.

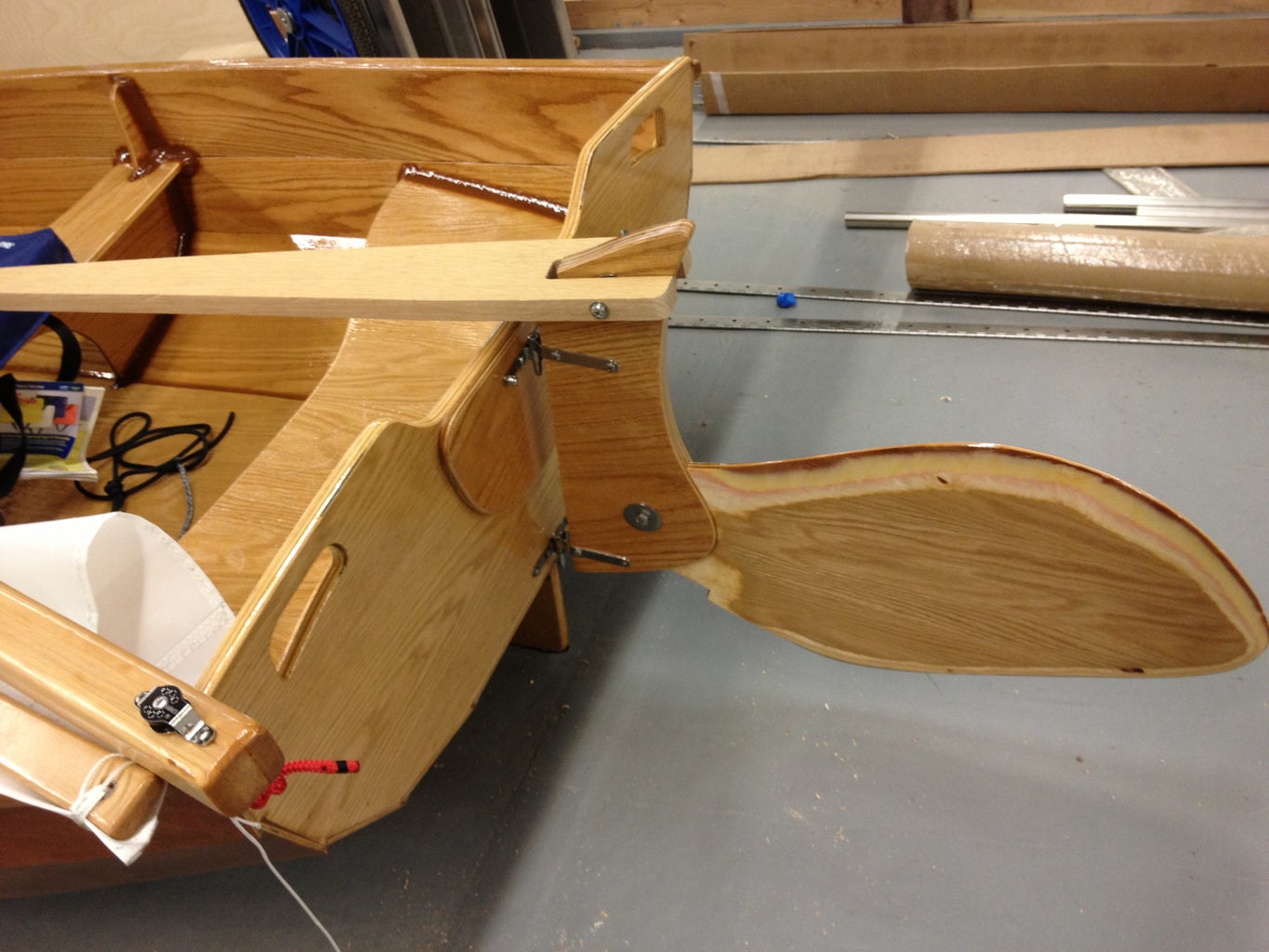

The daggerboard and rudder are cut out and laminated. Then a bevel is ground onto the leading and trailing edges to make it slice through the water more efficiently. Then they're covered in layers of epoxy. The mast step is assembled. This has to be very strong because all of the force of the sail is transmitted to the boat through the mast step and the mast is a very long lever arm. The rudder cheek plates and tiller also have to be assembled similarly to the daggerboard case.

NOTE: Whenever there's a hole to be drilled into any part of the boat, you must take additional steps to make sure the water doesn't penetrate and damage the wood. The correct procedure is to drill an over-sized hole, completely fill that hole with epoxy (I usually put a piece of masking tape on the back side to act as a dam), then once the epoxy cures, re-drill in the center of the epoxy plug the correct hole size. That makes each hole in the boat possibly a 2 day process, so plan accordingly. You can also use 5 minute epoxy to knock out a bunch of holes quickly, but be careful, they're not kidding. This stuff gets rock hard very quickly and will permanently glue anything touching. This is exactly how you drill the hole for the pivot point for the rudder/cheek plate assembly. If the pin is 1/4", then drill 1/2" hole and fill that with epoxy. Now the 1/4" hole will fit nicely in the center and be completely waterproof.

Since all the parts need several coats of unthickened epoxy and they just about all have holes in them, I hung them up with some twine and painted them on all sides, one layer at a time, for several days. Make sure the rudder doesn't get too thick to fit inside the cheek plates.

Step 7: Making the Spars...

More sailboat parts you can make while waiting for other parts to cure are the spars, the structural parts that support the sail. The mast is another glue up. I used 3 - 1x3's of hemlock. A relatively soft wood, but with a nice tight grain with no knots. A mast would break at a knot, regardless of how strong the wood is. Using the waterproof glue, align the pieces as perfectly as you can then clamp up the assembly and let dry overnight. Then run it through a table saw to get the final dimensions. Use a router and a round-over bit to ease the edges. Cut to length and sand the sharp corners. It should fit easily, but snugly into the forward thwart.

The boom (bottom of sail) is a little more complicated. Cut out the gooseneck (boom pivot point) by using a hole saw first, making sure to clamp it securely to the workbench, then cut out the profile. This gets attached to another piece of 1x3 hemlock, after it's been cut to length and the edges have been rounded over.

The yard (top of sail) is easy. Just cut to length and round over the edges. Drill and fill any holes in the spars at this time. You'll need at least one hole on each end to lash the sail grommets to.

This time, everything gets covered with several coats of varnish, epoxy is not necessary. The varnish protects the wood from water and UV damage.

The reason we had to make at least the mast at this point is because we'll need it in the next step to establish the location of the mast step.

Step 8: Finishing Up the Interior & Exterior...

Once the outwales are successfully attached, trim them flush with the face of the transom(s). While you're at it, use a flush cut saw (with no sawtooth offset to mar the wood) to trim the sides flush with the transom. This will show you how well your injected silica mix worked earlier. Now you're ready to install the mast step.

The mast step must be precisely located on the floor (sole) of the boat to give the mast the proper angle (rake). This is very important because it directly affects the boat's ability to sail upwind. Using your mast, insert it into the forward thwart (partner) and into the mast step. With the mast at a 3° angle (mostly vertical but with a small, yet noticeable and graceful tilt toward the stern of the boat), trace the location of the mast step. Use a combination square to make sure it's perfectly aligned side to side (athwartship). You can now set the mast aside. Drill and fill holes in the bottom of the boat so that you can securely screw the mast step from the outside of the hull. The mast base must also be epoxied to the sole with peanut butter. After it's screwed into place but before the epoxy cures, make sure to test fit the mast again and verify the rake angle is correct. It would be a little messy at this point if you had to tweak it, but at least you wouldn't have to cut it off.

Now comes the most unpleasant part of the whole build. On your hands and knees, make a 1" radius fillet on the underside of every part in the boat. I didn't worry about making these pretty, just structural and water tight (these create the flotation tanks that keep the boat from sinking if you capsize). Let that cure overnight.

Next is the scariest part of the build, making the slot in the hull for the daggerboard. Using a drill bit extension, from the inside of the boat, reach down through the daggerboard case and drill a hole at each end of the slot through the bottom of the boat (make sure to use a backer board). Drill a couple holes in between, then take a jigsaw and connect the dots. This weakens the hull enough so that the router won't tear out any extra wood. Note, this step can easily be done prior to affixing the center thwart. Using a flush trim/laminate router bit, let the bearing run around the inside of the daggerboard case. This will make the hole in the hull perfectly match the slot. This is important because you don't want a shoulder on the inside for the daggerboard to hit and you don't want to damage the waterproof lining of the case. Last, ease the sharp edge of the daggerboard slot with the router and a small radius round-over bit.

The skeg must be cut to fit the curve of the hull (rocker), then using silicone bronze screws, attach it to the hull using the same drill and fill/peanut butter techniques. Make sure to snap a chalk line on the centerline of the boat for reference. Then make a 1" fillet where it meets the hull which will support the skeg and make it strong. The skeg keeps the boat tracking straight in the water. I optionally used some fiberglass cloth to cover the skeg and overlap onto the bottom to make the entire assembly stronger and more waterproof. The skeg will take the brunt of the abuse when launching, beaching, loading and unloading, etc. I also installed a stainless steel rubstrake on the aft end of the skeg with this in mind. In wooden boat building, silicone bronze screws are often used because they won't corrode when encapsulated like stainless steel screws can.

Install the skids parallel to the skeg. These are solid pieces of hardwood because they will also take a lot of abuse when the boat is sitting on shore, protecting the thin hull from rocks, etc. They get installed the same way as the skeg, although it's a little tough to bend the wood along the rocker. Scrape off the excess peanut butter once they're screwed in place.

I also installed the optional outboard motor pad at this point because I plan to use an electric trolling motor on the back to quietly putter around the lake in the evenings to relax with the family after work.

That should be the last parts that go into making the boat!

Step 9: Finishing the Hull...

Now comes the last dash to the finish line. One of the more tedious steps is that you now have to sand the entire boat. I actually built the entire boat inside, but for the sanding stage, I took her outside. Several hours of sanding all of the fillets nice and smooth. Everything will show in the finished product whether you paint the boat or leave it "bright" (unpainted). If you've been careful about cleaning up the peanut butter as you go, you should be able to sand the boat with mostly 220 grit. Be careful not to sand through the thin veneer of the plywood. After the sanding is done (make sure to use a dust mask), vacuum the entire boat and then wipe it down with a tack cloth to remove any dust. I also reversed the hose on the shop vac and used it to blow the sawdust off since I was outside.

Next, you must coat the entire interior and exterior with 3-4 coats of unthickened epoxy. This makes the entire boat waterproof. It will also give you an idea of how beautiful the wood will look when varnished. This is why a lot of boat builders decide to leave their boats bright so the beauty of the wood shows through.

Mix up 1 cup batches of unthickened epoxy and pour out large puddles onto the surface. Taking a foam roller, distribute the epoxy in a smooth coat. Now take a wide foam brush and gently smooth (tip) the rolled out surface. This should remove any lap marks or bubbles. Move along to the next area, making sure to not touch the wet parts. Also, make sure no dust or bugs get on your finish or it'll mean even more sanding later.

Start with the exterior first. It'll be much easier to get good by practicing on the convex surfaces. The interior is more tricky because you want to prevent sags and pooling by only applying very thin coats.

Make sure to check with the manufacturer's directions during this step in case you have to deal with "blushing", a thin layer that can sometimes form on the surface of epoxy when it cures. This could cause your layers to not stick to each other. If your epoxy does blush, it's easy to just wipe the entire boat down with a rag soaked in acetone after each coat has cured. Some people sand between coats of epoxy. This is how you would make an extremely smooth/shiny finish, so if you want your boat to be museum quality, invest the effort. I'm planning on banging my boat around so opted out of an extreme, fancy, mirror finish.

I was originally going to paint the exterior of the hull, which would require priming and painting, but I'm leaving it bright for the time being. The good news is that you can always paint later if you change your mind, but if you paint it and change your mind, it's tough to go back. There aren't a lot of pics of this step, which took a couple of days because there wasn't much visible progress after that first coat went on. At this point, any surface that's not painted should be varnished using the same "roll and tip" method as the epoxy, with the optional sanding between coats. Note that epoxy has no UV resistance, so to keep your boat from getting sunburned, you must either paint or varnish every surface. Giving a boat a "museum quality" paint and/or varnish finish can literally take as long as building the boat.

Step 10: Making the Sail...

Another step you can do while other parts are curing is make the sail. This particular design uses a "lug" sail, a classic looking sail for small boats with wood masts. It increases the sail area (therefore the force generated by the wind) without it having to be as tall as a modern sailboat mast made of aluminum. There is a kit from an online sailmaking company that you can get for a reasonable price. The Dacron cloth panels are all cut out by a CNC machine, so they fit perfectly together. I used a regular, domestic sewing machine, not an industrial one. The only time I had trouble was when sewing through all 7 layers at the reinforcement patches. When I got to those parts, I had to manually push down on the foot of the sewing machine with a flat-bladed screwdriver (minus) to help push the needle through the Dacron. We jokingly call Philips head screwdrivers "plus".

The panels/parts all come labeled. The directions were a bit confusing because they suggest you make sub-assemblies after the fact to make wrangling the large sail easier but they mention it after you've already sewn the large panels together. It's important to understand what parts go together while the panels are still small and more manageable. For example, the batten pockets are tricky enough to build on a single panel, much less the finished sail. Building the sail was about as difficult for me as building the boat, but it was worth it.

The lug sail gets reinforcement patches on all four corners where you attach it to the spars (bend), and there's also a reefing point for when the wind starts to pick up (freshen). Modern sails have three corners (Marconi rig).

I opted for the less expensive white Dacron sail kit, but there's also a classic red (tanbark) colored kit that's $100 more expensive. Before I sewed a single stitch, I carefully traced every part of the sail kit onto painter's tarp poly film so I can always use the templates to build another sail, all I need to do is buy the tanbark cloth.

Step 11: Rigging Your Sailboat...

This seems to be the trickiest part for most people, probably because there are numerous ways it can be successfully rigged, depending on your experience, preferences or criteria. It's confusing because you have to know what the finished setup will look like in your mind while you're staring at a pile of ropes. I chose a setup that allows the most room in the cockpit for a full-sized adult, so the mainsheet is led forward of the skipper's position. This keeps the skipper's attention forward so they're looking where they're going. I have another boat where the mainsheet is behind the skipper and it takes some practice getting used to.

The lines I made up (rope becomes a line when you give it a job description) were the halyard (hauls the sail up), the mainsheet (adjusts the angle of the sail to the wind = trim) and a traveler bridle (where the mainsheet attaches to the boat). I got fancy and spliced all my ends, but you can just as well use a bowline knot.

I installed a cheek block at the top of the mast instead of the large diameter hole in the directions. I wanted the halyard to run as smoothly as possible when setting the sail. Then I installed a pair of cleats at the base of the mast, one for the halyard and one for the downhaul (cunningham). With both of these lines pulling in opposite directions, it locks the sail in place, flat, so it effectivley acts like a wing. The main halyard attaches to the gaff with a snap onto a padeye. This allows easy on/easy off when rigging at the boat ramp. I also used a small loop (parrel) around the mast and through the eye to keep the gaff located close to the mast. I looped the downhaul over the boom and down to the cleat to try to keep the gooseneck from twisting. Note, except for the blocks, just about all of the hardware used on rigging a boat this size can come in stainless steel or brass/bronze, depending on the look you're going for. If you plan on installing oarlocks to row the boat, this decision becomes even more important to the final look of the boat.

For the mainsheet, I made a short bridle between the handles on the transom with a small eye tied in the center. This allows a place for the snap on the end of the mainsheet to attach to. I could've just as easily allowed the snap to slide, which would give the bridle the function of a traveler, but would affect its pointing ability (sail upwind). The mainsheet is then run to a block on the end of the boom, then to another block in the middle of the boom. This leaves the main cockpit area unobstructed with running rigging. Make sure your mainsheet is long enough for your boom to swing forward of 90° to the boat, with enough to still come back to the cockpit for the skipper to control. A stop knot at the end of the mainsheet will keep the mainsheet from getting away from you and give you something to grip.

The rudder pivot hardware (gudgeons and pintles) must be installed perfectly vertical and on the exact centerline of the boat so that she will sail well. Drill and fill the necessary holes for this hardware. Be careful with the spacing. It's designed to be easily installed and uninstalled while underway.

With this particular rigging layout, when under sail, the skipper must constantly keep the mainsheet in hand, which is a good idea anyway for safety reasons (if you get hit by a gust of wind = puff, you won't get blown over = capsize). The tension on the mainsheet is easily manageable for any size skipper. On larger boats, the mainsheet is held by a fiddle block with a cam cleat, which is not necessary for a boat this size. With that being said, a possible future upgrade would be to install a block and a camcleat somewhere on the centerline of the boat so that more advanced sailors wouldn't need to constantly have to oppose the tension on the mainsheet. Of course the trade-off would be the hardware would probably be somewhere you might want to sit.

Another upgrade I figured out after actually taking her sailing would be to rig up a bungee/shock cord system that will hold the daggerboard both in an up and down position. With the current setup, the centerboard is held down by gravity and must be pulled out of the slot when beaching.

Step 12: Go SAILING!

Because I wanted to be able to go sailing by myself if needed, I made a dolly out of 2x4's and large pneumatic tires (which makes the dolly float). The dolly fits securely between the center and aft thwarts when driving out to the lake. The sides on the dolly lock against the skids on the bottom of the boat so it can't twist. Roll the sail up with the spars and wrap it with the main halyard. At the designed length, the mast doesn't fit inside the boat, but it seems a bit long, so some people have cut the mast down enough so that it fits inside the boat.

Out at the lake, unload the boat, slide the dolly underneath and you're ready to roll down to the ramp. At the launch, roll the boat out into the water until it floats off the dolly, toss the dolly off to the side out of everybody else's way. Drop the daggerboard into the slot and install the rudder assembly. Facing into the wind (important), stick the mast into the receiver hole (partner), tie off the downhaul (cunningham) and hoist the sail until the downhaul is tight, then cleat off the main halyard. Reave the mainsheet (run the line through the blocks) and you're ready to go sailing.

I've found that this boat sails very well. The lug sail makes it very easy to sail upwind (weather helm), it's a little more tender for a large adult, more so than a boat with a hard chine, like an El Toro/Optimist but it's a lot more graceful looking. The payload is very reasonable for a boat this size. My wife and son can easily (and safely) go sailing with me and I don't even need anyone's help to get it rigged and launched. All in all, this is one of the best projects I've every built. I hope you too can discover the joy of building your own boat and then take her sailing. Remember, in sailing, the wind is free, but nothing else is...

This is my very first Instructable after many years of referencing this excellent site to build numerous cool projects (you should see my next post). Anyway, I hope you enjoy it and please feel free to ask any questions you may have and I'll do my best to answer them. I'm planning on building a larger boat in the near future so stay tuned...

Participated in the Wood Contest

Participated in the On a Budget Contest

Recommendations

Remake It - Autodesk Design & Make - Student Contest

Make it Resilient

Making Time Contest

WOODEN BOW TIES

How to build a wooden sailboat: a beginner's guide.

Are you interested in building your own sailboat? If so, building a wooden sailboat can be a rewarding and fulfilling experience. Not only will you have a unique vessel to call your own, but you’ll also learn valuable woodworking skills along the way.

To get started, you’ll need to gather the necessary materials and tools. This may include oak plywood, epoxy resin and hardener, thickener, brad nails, masking tape, a pull-saw, and a table saw. Once you have everything you need, you can begin the process of building your sailboat. From creating a jig and frame assembly to making the mast, there are many steps involved in building a wooden sailboat. But with patience and attention to detail, you can create a beautiful and functional vessel that will bring you joy for years to come.

Understanding the Basics of a Wooden Sailboat

If you are interested in building a wooden sailboat, it’s important to understand the basics of how a sailboat is constructed. In this section, we’ll cover the parts of a wooden sailboat and the different types of wooden sailboats.

Parts of a Wooden Sailboat

A wooden sailboat is made up of several parts, each with its own unique function. Here are some of the most important parts:

- Hull : The hull is the main body of the boat. It is the part of the boat that sits in the water and provides buoyancy.

- Keel : The keel is a long, narrow fin that extends down from the bottom of the hull. It helps to keep the boat from capsizing by providing stability.

- Rudder : The rudder is a flat piece of wood or metal that is attached to the back of the boat. It helps to steer the boat.

- Mast : The mast is a tall, vertical pole that supports the sails.

- Sails : The sails are large pieces of fabric that are attached to the mast and other parts of the boat. They catch the wind and propel the boat forward.

- Boom : The boom is a horizontal pole that is attached to the bottom of the mast. It helps to control the shape of the sail.

Types of Wooden Sailboats

There are many different types of wooden sailboats, each with its own unique characteristics. Here are some of the most common types:

- Dinghy : A dinghy is a small sailboat that is typically used for recreational sailing or racing.

- Sloop : A sloop is a sailboat with a single mast and a fore-and-aft rig.

- Ketch : A ketch is a sailboat with two masts, with the main mast taller than the mizzen mast.

- Yawl : A yawl is a sailboat with two masts, with the mizzen mast located aft of the rudder post.

When choosing a type of wooden sailboat to build, it’s important to consider your needs and experience level. A dinghy is a good choice for beginners, while a ketch or yawl may be more suitable for experienced sailors.

By understanding the basics of a wooden sailboat and the different types available, you can make an informed decision about which type of boat to build.

Choosing the Right Materials

When building a wooden sailboat, choosing the right materials is crucial to ensure the boat’s durability and performance. In this section, we will discuss the two most important materials you’ll need to choose: wood and sails/rigging materials.

Selecting the Right Wood

Choosing the right type of wood for your sailboat is critical. You want a wood that is strong, lightweight, and resistant to rot and decay. Some of the most popular types of wood used in sailboat building include:

- Cedar: Lightweight and easy to work with, cedar is an excellent choice for planking and decking.

- Mahogany: Strong and durable, mahogany is often used for building frames and keels.

- Oak: A dense and hard wood, oak is commonly used for building frames and planking.

When selecting your wood, make sure it is free of knots, cracks, and other defects that could weaken the boat’s structure. You should also consider the wood’s grain pattern, as this can affect the boat’s strength and appearance.

Choosing Sails and Rigging Materials

The type of sails and rigging materials you choose will depend on the type of sailboat you’re building and your sailing needs. Some of the most common materials used in sail and rigging construction include:

- Dacron: A strong and durable synthetic material, dacron is commonly used for sailcloth.

- Nylon: Lightweight and flexible, nylon is often used for spinnaker sails.

- Stainless Steel: Strong and corrosion-resistant, stainless steel is commonly used for rigging hardware.

When selecting your sails and rigging materials, consider the conditions you’ll be sailing in and the type of sailing you’ll be doing. For example, if you’ll be racing, you may want to choose lightweight sails and rigging materials that will help you achieve maximum speed. On the other hand, if you’ll be cruising, you may want to choose more durable materials that can withstand rougher conditions.

By choosing the right materials for your wooden sailboat, you can ensure that your boat is strong, durable, and performs well on the water.

Designing Your Sailboat

Before you start building your wooden sailboat, you need to design it. This will involve creating a blueprint and determining the size and shape of your boat.

Creating a Blueprint

Creating a blueprint is an essential step in designing your sailboat. It will help you visualize your boat and ensure that you have all the necessary components in place. You can create a blueprint using software such as AutoCAD or SketchUp, or you can draw it by hand.

When creating your blueprint, consider the following:

- The length, width, and height of your boat

- The position of the mast and sails

- The location of the rudder and keel

- The number of cabins and their layout

- The placement of any storage compartments or equipment

Determining the Size and Shape

The size and shape of your sailboat will depend on several factors, including your budget, the type of sailing you plan to do, and the number of people who will be on board.

Consider the following when determining the size and shape of your sailboat:

- The type of sailing you plan to do (coastal cruising, racing, etc.)

- The number of people who will be on board

- The amount of storage space you will need

- The amount of deck space you will need

- Your budget

Once you have determined the size and shape of your sailboat, you can start gathering materials and building your boat.

Building the Hull

When building a wooden sailboat, the hull is the most important part of the boat. It is the main structure that holds everything together and keeps the boat afloat. Building the hull requires cutting and assembling the wooden frame.

Cutting the Wood

To begin building the hull, you will need to cut the wood into the appropriate sizes and shapes. The wood should be cut according to the plans or blueprints that you have created. You can use a saw or a jigsaw to make the cuts.

It is important to use high-quality wood that is free of knots or other defects. The wood should be strong enough to withstand the pressure and weight of the water. Common types of wood used for building a wooden sailboat include cedar, oak, and mahogany.

Assembling the Frame

Once you have cut the wood, you can begin assembling the frame of the hull. The frame is made up of vertical pieces of wood called frames, which hold the shape of the boat. The frames are attached to the keel, which is the main structure that runs down the center of the boat.

To assemble the frame, you will need to use a sawhorse or other support to hold the lumber in place. You can then use screws or bolts to attach the frames to the keel. It is important to ensure that the frames are level and straight.

After the frames are attached to the keel, you can add the planks to the hull. The planks are attached to the frames and keel using screws or nails. It is important to ensure that the planks are properly aligned and spaced.

Once the planks are attached, you can sand and finish the hull to give it a smooth and polished look. This will also help to protect the wood from the elements.

Building the hull of a wooden sailboat requires patience and attention to detail. With the right tools and materials, you can create a strong and beautiful hull that will last for years to come.

Installing the Deck and Cabin

Installing the deck and cabin of your wooden sailboat is a crucial step in the construction process. It not only adds to the aesthetics of your boat but also provides structural support. Here are some tips to help you through the process.

Deck Installation

The deck of your wooden sailboat should be installed after the hull has been completed and before the cabin is built. It is important to ensure that the deck is watertight to prevent any leaks. Here are the steps to follow when installing the deck:

- Cut the deck to fit the hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the hull and deck joint to seal it.

- Secure the deck to the hull using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the deck to make it watertight.

- Sand the surface of the deck to prepare it for painting or varnishing.

Cabin Installation

The cabin of your wooden sailboat provides shelter and storage space. It is important to ensure that it is properly installed to prevent any leaks. Here are the steps to follow when installing the cabin:

- Build the cabin on a flat surface using marine-grade plywood.

- Cut the cabin to fit the deck and hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the cabin and deck joint to seal it.

- Secure the cabin to the deck using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the cabin to make it watertight.

- Install any windows, hatches, or doors in the cabin.

- Sand the surface of the cabin to prepare it for painting or varnishing.

By following these steps, you can ensure that your wooden sailboat’s deck and cabin are properly installed and watertight. This will not only make your boat look great but also ensure that you have a safe and enjoyable sailing experience.

Setting Up the Mast and Sails

Now that you have built your wooden sailboat, it is time to set up the mast and sails. This process may seem daunting, but with a little patience and attention to detail, you can have your boat ready to sail in no time.

Step 1: Install the Mast

The first step is to install the mast. Depending on the design of your boat, the mast may be a single piece or assembled from multiple sections. Make sure the mast is secured properly and is straight. Use a level to ensure the mast is vertical in both directions.

Step 2: Prepare the Sails

Next, prepare the sails. Make sure the sails are clean and free of any debris or damage. Attach the sail to the mast using the halyard, which is a rope used to raise and lower the sail. Make sure the sail is hoisted all the way to the top of the mast.

Step 3: Attach the Boom

Attach the boom to the mast and secure it with a boom vang, which is a rope used to control the angle of the boom. The boom is the horizontal spar that holds the bottom edge of the sail.

Step 4: Set the Sail

Once the boom is attached, set the sail. Adjust the angle of the boom and the sail to catch the wind and start moving. You can use the main sheet to control the angle of the sail and the boat’s speed.

Step 5: Trim the Sail

Finally, trim the sail to optimize its performance. This involves adjusting the sail’s shape and position to maximize its power and minimize drag. Use the sail controls, such as the cunningham and outhaul, to adjust the sail’s shape. Use the main sheet to control the sail’s position relative to the wind.

Congratulations! You have successfully set up the mast and sails of your wooden sailboat. Now it’s time to hit the water and enjoy the thrill of sailing.

Applying Finishing Touches

When it comes to building a wooden sailboat, applying the finishing touches is a crucial step that can make all the difference in the final product. Here are some tips and tricks to help you get the perfect finish.

Sanding and Finishing

Before you can apply any finish, you need to make sure the surface is smooth and free of imperfections. This means sanding the wood with progressively finer grits of sandpaper until you achieve the desired smoothness. Once you’ve finished sanding, you can apply a wood conditioner to help the wood absorb the finish more evenly.

When it comes to choosing a finish, you have several options. Some popular choices include varnish, paint, and oil. Varnish is a popular choice for wooden boats because it provides a durable, glossy finish that can withstand the harsh marine environment. Paint is another option, but it requires more maintenance than varnish and may not provide as much protection against the elements. Oil is a good choice if you want a more natural look, but it may not provide as much protection as varnish or paint.

Painting and Varnishing

If you decide to go with paint or varnish, there are a few things to keep in mind. First, make sure you apply the finish in a well-ventilated area to avoid inhaling fumes. Second, make sure you apply thin, even coats and allow each coat to dry completely before applying the next. This will help prevent drips and ensure a smooth finish.

When it comes to varnishing, it’s important to use a high-quality brush and work quickly to avoid brush marks. You may also want to consider using a foam brush for hard-to-reach areas. Once you’ve applied the final coat of varnish, you can buff the surface with a soft cloth to achieve a high-gloss finish.

Painting requires a different approach. You’ll need to choose the right type of paint for your boat and make sure you apply it evenly. If you’re painting a large area, you may want to consider using a paint sprayer to achieve a smooth, even finish. Once the paint has dried, you can apply a clear coat to protect the paint and give it a glossy finish.

In conclusion, applying the finishing touches to your wooden sailboat is an important step that requires careful attention to detail. By following these tips and using the right tools and materials, you can achieve a beautiful, long-lasting finish that will protect your boat and make it stand out on the water.

Safety Measures

When building a wooden sailboat, safety should always be your top priority. Here are some safety measures you should take to ensure a safe and successful build.

Installing Safety Equipment

Before you start building, make sure you have all the necessary safety equipment installed in your workshop. This includes fire extinguishers, smoke detectors, and first aid kits. You should also have a clear and unobstructed path to the exit in case of an emergency.

When working with power tools, always wear eye and ear protection, as well as a dust mask to protect your lungs. If you are using chemicals, make sure you are working in a well-ventilated area and wear gloves and a respirator if necessary.

Conducting a Safety Check