In-Mast or In-Boom Furling Mainsail for a Catamaran?

I was wondering if you have ever written an article about in-boom and in-mast furling for catamarans? Any experience with those systems? What are your opinions about it? If a boat did not come with such a system, can you retrofit it even though the boat was not designed with that in mind in the first place?

Answer: The Mainsail on a catamaran is the main source of power.

– by Stephen Cockcroft

The mainsail on a cat, unlike a monohull which relies heavily on the fore triangle for power, is the primary power source. The jib or genoa are less important for powering, but are good to balance the sail plan. Remember most catamarans have a fractional rig which means that the foresail is smaller than a top rigged monohull for example. So, considering the importance of a powerful mainsail, the object is to have a large roach or flat head main with a high aspect rig so that you can take full advantage of the winds aloft. Full battens help to keep the sail shape and ensure an effective and efficient sail.

In-Mast Furling Mainsail

When you have to cut a sail to be able to roll into a mast, the leech has to be cut concave, so you loose a lot of sail area. You also loose the fully battened sail, so the sail shape is never as good and the performance of the mainsail is more like a jib or genoa than a main sail. While this might be a good option for a monohull where the power source is both in the fore triangle and the main, on a catamaran this would be my absolute last choice. Some manufacturers have in-mast furling mainsails with horizontal battens so they can roll into the mast, but if this was so great then why do we not see a lot more of this? Then there is always the risk of the sail jamming in the mast and then you have a whole new set of problems. To change to an in-mast furling system, you would basically need to replace the entire rig. There were some furling systems in the early days that were tacked on to the existing mast, but it was very industrial and I advise against this.

*Picture courtesy Harken

In-Boom Furling Mainsail

If you are going to go with a mainsail furling system, the in-boom furler is a better option. When you are rolling the main into the boom it means that you can keep the full battens and have a small roach, so the sail shape issue is addressed. Consider that if there is an issue with the furler then, unlike in-mast furling, you would still be able to drop the main onto the deck like a conventional system. To change from a standard rig to in-boom furling you would not need to replace the entire rig. The boom can be replaced with the furling boom and then a track would be attached to the aft of the mast to take the bolt rope luff of the mainsail. I would say that a new main built specifically for the system would be a must so the standard main would not work.

My Personal Preference for a Cruising Catamaran Sail-Plan

My personal preference would be a fully battened mainsail with a good batten car system and a large roach with a standard head. This system, together with a set of lazy jacks and a zip up bag, is the most reliable and functional in my opinion. While I really like the flat top mainsail, there is always the issue of getting the head and top batten back into the bag since it sits at an awkward angle. There are now systems that allow you to unclip the top batten so it lies flat but it is another step that is required when stowing or deploying the mainsail.

Estelle Cockcroft

Join our community.

Get the latest on catamaran news, sailing events, buying and selling tips, community happenings, webinars & seminars, and much more!

3 thoughts on “In-Mast or In-Boom Furling Mainsail for a Catamaran?”

What about a third option; a boom furling main with a hybrid sail. The lower half of the sail compatible with the boom furler, and the top side of the sail fully battened and full roach. This way you could easily reef without leaving the cockpit while shorthanded. When dropping the main you roll the lower half and drop the rest. This will leave you with less than 50% of your sail to handle and stow. Lot easier for short hand sailing a big cat. Would this work?

That seems like a great option to me, but I am not a rigger. The ability to reef a main and stay in the cockpit would be very important to me.

Hi Gary, yes we find that some of our clients prefer that option. You will not get the best sail shape but handling is a lot easier.

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Recent Posts

First-Annual Virgin Islands Boating Exhibition (VIBE)

VIBE – It’s a Destination Boat Show! Join us May 10 – 12 at

BALI Catamarans Unveils The New Bali 5.8 Flagship

CATANA GROUP launches its 14th BALI CATAMARAN model, the BALI 5.8, for the brand’s

Love Stories At Sea…because it’s valentine’s day

Because it’s Valentine’s day, we wanted to celebrate all the couples that we helped

Your Go-To Resource for all your Catamaran Needs!

Check out our brochure to learn about all we have to offer and why

For more than 30 years, we have been a part of the catamaran community and created Catamaran Guru™ to encourage and educate all the aspiring sailing out there. We understand the dream of traveling the world by catamaran and created a one-stop-shop to make that dream a reality for you.

- Stephen & Estelle

- Testimonials

Get Started

- Yacht Sales

- Used Yachts

- Charter Management

- Boat as Business Programs

- Seminars & Events

Which Boom Furler is the Best?

When it comes to mainsail management systems, in-mast furlers appear to be losing popularity with cruisers while boom furlers keep popping up on more boats. We are noticing a huge increase in customers upgrading their conventional or even their in-mast units (yes, you read that right, read more below) to in-boom furling. I may even go as far as to say that in-boom furling will soon become standard equipment for the production boat market.

Like many other things in sailing, boom furlers owe their origins to custom designed solutions for mega and super sailing yacht customers, where pricing is of little significance. While I wouldn’t call the current production systems down right affordable to the cost conscious cruiser, there are now plenty of choices for furling your mainsail horizontally. However, most of these furling boom manufacturers only have a carbon fiber option for their spar material, which makes for one very expensive boom. So what are some more cost effective alternatives?

Aluminum extrusions seem to be the answer here. So, for the sake of cost and to narrow down our discussion a bit, let us take a look at who’s building aluminum boom furlers:

- The Pro Furl MKR by Wichard-Sparcraft (No longer in production)

- Furlboom by Hood-Pompanette (No longer in production)

- Schaefer Marine’s Boom Furler

- The Leisure Furl by Forespar

As each of us here at TRC has had experience with all of these systems at one point or another, allow us to give you our thoughts on these seemingly similar, but yet ‘oh so’ different boom furlers. For more carbon fiber options please take a look at the links provided at the bottom of the article.

PRO FURL MKR

Coming in at a tie for 3rd place is the Pro Furl MKR. Pro Furl boasts of a very sturdy double gooseneck assembly, and it does appear quite sturdy. This is a good feature when considering the concerns of boom weight with these systems, especially while gybing.

TIP: TRC always recommends the addition of a good boom brake system to help control the effects of an unruly gybe.

Pro Furl’s overall spar design is sleek and attractive. They also have the furling drum mounted on the inboard end, which we like because it keeps the weight inboard. The Pro Furl in-boom furling system is only available in painted aluminum. The system uses a proprietary vang which is a must, as it is with most of the manufacturers. Pro Furl’s vang is essentially a hard vang (with no adjustment) that kicks the boom up to its ideal furling position. This is a very good concept, the user just eases the main sheet, the sail flogs, and the boom returns to its proper position for furling. There have been problems reported with the vang however, users have stated issues about vang leaks and parts failure.

If you look at Pro Furl’s behind the mast track, it is very far stood-off behind the mast. This is likely for a clean lead into the sail track as the drum occupies the front of the boom and requires the sail roll to start pretty far aft. This, if nothing else makes for a very unsightly track system. The only real plus I see to this track system is it makes climbing the mast very convenient, it offers almost a ladder of sorts to the top of the mast ;-0). How does this system do in off wind hoisting and dousing situations?? Pro Furl In-Boom customers are encouraged to leave us a few thoughts below .

This brings me to the other tie for 3rd (a close 2nd). Furlboom has changed hands recently to a new owner and hopefully they can take this seemingly promising design to the next level of refinement. Available in anodized or painted aluminum only, Furlboom’s spar is a square/rectangular style section that is tapered and can look at home on almost any modern day sailboat. Their biggest niche within the market, IMO, is pricing. Furlboom comes in as the least expensive of all of the options. This is a very appealing perk as these systems are known to cost a small fortune. Furlboom does not offer a manufacturer specific vang, instead recommends the use of Selden’s Rodkicker Vangs . Selden’s vangs are perhaps not the top of the heap when it comes to rigid vangs, but it is already a better option than what Pro Furl attempted. Leave the vangs to the guys that make…vangs. Furlboom has a lot going for it: low weight (relative to boom furlers), a manual override feature, a solidly mounted behind the mast track, a low profile tapered spar design, and it is very well priced (comparatively).

Some of the downsides of this system are found at the top of the track; they utilize a sheave to extend the halyard out to the aft face of the track. This in conjunction with a non-hinging track, can make for some pretty severe halyard chafe, especially when off the wind or when the halyard is just sitting static for long periods of time in the stowed position. Although the boom material and construction seem to be a very nice quality, it seems that some of the track parts were cheaply cast and painted, instead of extruded/machined and anodized. The last part that is questionable is the chain drive which links the furling drum (mounted below the gooseneck on the aft side of the mast) to the mandrel. Regular maintenance and inspection of this chain is highly recommended. If the chain drive fails, the manual override feature cannot be used. When considering a boom furler for a smaller boat, the Furlboom is and has been always our first choice due to weight, size, and price.

NOTE: Only Furlboom and Leisure Furl offer manual override features!!!

Schaefer boom.

Schaefer makes the podium at 2nd place, living up to their reputation for being robust and high quality. This boom is rock solid. It is made of high quality machined and extruded aluminum with a deep anodized finish. The Schaefer system lacks only in four departments: looks (no taper and just plain big), a loosely mounted behind-the-mast main sail track (must be noisy and is not attractive), the vang is a fixed length rod, and lastly Schaefer utilizes a furling drum that is mounted at the very outboard end of the boom; not an ideal place for added weight especially when considering the already big size of this boom. This can make gybing an already heavy boom even more interesting, especially if it is accidental. Although I am not in love the with their behind the mast track, it does seem to offer very good off the wind hoisting and furling due to the hinged design of the track. Schaefer’s proprietary vang is mandatory. The vang is really more of a strut as it is set at a fixed length. Although this guarantees an optimal boom height for furling and hoisting at all times, it restricts the users sail trim options.

LEISURE FURL

This leads us to the winner………the Forespar Leisure Furl {LF} System. This system has been around a long time. LF has had many years of R & D which usually means they have worked out most of the kinks. Leisure Furls are available in many sizes, configurations, and finishes: anodized, painted, as well as carbon fiber. There are also two smaller, entry level, models called the Leisure Furl Coastal and the ALL NEW LF Coastal Plus; which focus more on the small to medium size boat market. Here are some of the big pluses of the LF system:

- A sleek solidly mounted behind the mast track

- A fully functional (and required) Forespar Yacht Rod (one of the best rigid vangs on the market)

- A tapered attractive spar design

- An inboard mounted furling drum

- A manual override (excluding coastal and coastal plus)

Over the years Forespar has only simplified, instead of adding to, or over-complicating their original design. We like that concept as it is in line with our company motto. They have also eliminated most of the plastic pieces except for the bottom feeder track, they call this the ‘Flexy Feeder’. This piece, which has been duplicated by many in-boom furling manufacturers, is crucial for better off the wind furling and hoisting. Another great feature of the boom is that it keeps a majority of the weight inboard by mounting the furling drum on the forward face of the mast. Initially, I was a bit skeptical (as I am sure most of you are) not just of the drum hanging off of the front of the mast, but also of the 1″+ hole that needs to be drilled at the gooseneck for the furling mandrel to connect to the drum. It turns out that by putting a solid stainless steel rod through it, along with the massive gooseneck bracket that accompanies it, this typically weak and highly loaded area of the mast, is actually strengthened. Keep up the good work Leisure Furl.

Looking to Ditch Your In-Mast Furler for an In-Boom Furler???

Forespar, who have been building masts for many years, and is one of the most respected names in the industry, has developed and tested a custom made kit for converting in-mast furling masts, to conventional masts. The long and the short of it is, they have a specially designed tool which bends aluminum plates to the exact shape of your mast section. These plates are then installed so that the two mast walls, port and starboard, are tied together and the long slot that once served as the entrance for the sail housing is eliminated. Once this is installed the existing mast can be used to facilitate the Leisure Furl In-Boom Furling System. Want to know more? Please ask our experienced sales staff about details and pricing.

To wrap things up (pun intended)…

…. these booms are all priced very comparably and offer similar but different design features. I recommend checking each one out in detail for yourself by clicking on the images to link to the manufacturers website and find out for yourself. Keep in mind, all furling systems are convenience items and thus can become the opposite of convenient (a problem) if not properly installed, used, and maintained. The big plus with horizontal furling systems is the halyard can always be released and the sail just comes down….just like in the old days.

Additionally, before you pull the trigger, keep in mind that there are some other final cost considerations that are required but not included…all of these manufacturers will most likely require replacing the mainsail, a specific vang, an electric winch , and something to ‘snub’ with (i.e. snubber winch or polished stainless cleat).

Wondering who else makes in-boom furling systems?

The companies mentioned below only offer carbon fiber (even possibly only powered drive units). Here is a list of all of the ones that we know of, that we did not discuss, but are worth checking out:

- Offshore Spars

- Furler Boom

- Formula Spars

- Southern Spars

Be sure to ask us about any of these products or manufacturers. We’d be glad to help.

Thanks for the read and see you on the water.

Similar Posts

Single handed around the world 2011.

Just a quick look at one of the epic moments of Thomas Coville’s voyage around the globe! [youtube http://www.youtube.com/watch?v=85mIDnNRptg&w=560&h=315]

Stamm’s Handful

Stole this one again from sailinganarchy.com. This might be what happens when you try and go sailing around the world by yourself, in a race. Fast forward to 00:50 to begin the action. Enjoy…. [youtube http://www.youtube.com/watch?v=QgJhkkXK8ik&w=560&h=315] ….Good on him though for staying so patient and calm. Was that noise the hydraulic canting keel? Pretty smooth…

Views From Aloft

Just another day at the office. Here I had to go aloft to take a perfectly good internal halyard that went to a brand new rope clutch and make it external. Don’t ask me why, it is just what the customer wanted. As we always say “as long as it is safe and functional”, it is…

Riggers Spotted in Grand Cayman

The Rigging Company was back at it again, but this time enjoying a little slice of paradise. I have to say there are many great things about this line of work, but being able to travel to desirable locations to work on peoples yachts has to top the list. The Cayman Islands has no shortage…

The three big winch players are Harken, Lewmar, and Andersen. Selden is also trying to make a splash in the production winch market. Almost all of these manufacturers offer different drum finishes from anodized aluminum, stainless steel, and chrome plated bronze (even un-chromed bronze upon special request). So what are some of the other differences? One of the number one companies…

First AC 72

Well, Team New Zealand did it. Check out the footage of the new AC 72 revealed and christened in the city of sails Auckland, NZ. Man, those things are going to be fast. It’s okay to fast forward as I did to cut to the chase. Do they really expect us to sit through 15 minutes…

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

45 Comments

What is the easiest way to get a ballpark cost for a leisure furl for a 44-46 catamaran? Inclusive of installation, exclusive of the sail and the electric winch?

We live here in Annapolis and are in the market for said catamaran. These numbers will help us put together the ever growing post-purchase refit budget.

Just asking is the easiest….;0) We’ve recently completed two Lagoon installs in the same size range, so it is fresh in our mind. The boom system itself was around $22k and all in the two customers averaged around $30k for the final invoice. Hope that helps and let us know how we can help if you need us.

Cheers, ~T.R.C.

Thank you for the prompt response. Very helpful. I will circle back when the time comes.

I have two profurl boom furlers in my 50 ft ketch, both are now 15 years old. Many repairs to every part of them over the years, always due to user error, I have banned gybing. Putting a 3di main was an error as the system is now way over stressed. The extruded track is ugly, and no good for a ladder up the mast as the foot holds are too far apart, if you grab the track it bends. Boom is too heavy, even with the drum at the front. I love the convenience though and will be sorry to loose it

Hello Mark, I’ve designed a custom ‘boom furler’ to simply suspend a typical furler above my existing boom, using 2 pieces of metal bolted to the aft end of the boom and a band wrapped around the mast, to which a cable with the extrusion can be attached, with a ProFurl ‘flying sail spool’ https://www.profurl.com/fiche-A%7CPROFURL%7CNEX40V2-0202010000000000-theme-UK.html instead of a drum furler, nearest the mast, attached to the band around the mast. This will cost a fraction of a Schaefer Boom Furling system and should be simple enough to be bullet proof.

It lloks that you would need a mast that either have a plate on top to place the back stay further back from the mast or does that piece comes with the system

Thanks for the comment. Usually the track will stop well short of interfering with the backstay so no backstay extension is required.

We have the Profurl version with the track that stands off behind the mast. The ‘pincer’ fitting which feeds the luff into the track was very poorly engineered and we have had another made. We have also increased the bolt rope diameter by 0.5mm so it doesn’t come out the track. The fixed vang means we can’t easily adjust leach tension so there is a lot of twist in the main only overcome by dropping the traveller down and sheeting hard. Not ideal. I love the concept but the engineering execution by Profurl is poor as too is their support for the system. I would like to upgrade to your No1 choice if I could!

Thanks for contacting us, and the comment. It appears ProFurl has discontinued their boom furling line, last I heard. Perhaps it is somewhat due to the reasons you have mentioned. Converting from the Pro Furl to the Leisure Furl is a pretty straight forward conversion. Please contact us at [email protected] for pricing and lead time information. Alternatively, you can use our Work Request Form found on this site. This will ensure a speedy reply and give us all of your pertinent info.

We are looking forward to hearing from you.

After reviewing all the boom furler designs and associated issues, I decided to keep my ‘standard’ hank up main sail configuration.

Thinking of changing rig on a Hylas70 from aluminum to carbon.mast and carbon furling boom. Any thoughts on which manufacturer(s) is/are best for that size boat. Many thanks

Thanks for commenting. We work with several Carbon spar manufacturers: Offshore Spars, Southern, GMT, Selden, just to name a few. All have good carbon options. The decision often times comes down cost and timing. My initial thoughts are GMT as they provide both quality carbon spars and carbon furling booms (powered) and if i’m not mistaken already have made several OEM Hylas spars.

I also seem to remember there being a similar conversion done here recently, A Hylas 70 aluminum spar to Selden Carbon Spar, but no boom furler…if I remember correctly.

Feel free to email us some more boat details for discussion. EMAIL [email protected]

Good morning I am owner of a Westerly Conway 36 (sloop), that has an additional (external) dysfunctional mainsail furlind system. Αs I think to change it to a boom furler, I’d like to know the cost (approximately) of the materials

There’s a bit to it, but for round numbers and the sake of conversation. You may need a budget of at least $15k. This is for the Leisure Furler System. The Boom Furler may be a bit less and also the Schaefer system may come around the same.

This won’t include a new mainsail, and is required. Also required is a powered winch.

Hope that helps, let us know if you need any further assistance. Feel free to use [email protected] .

Thank’s a lot

Hello, I am the proud owner of a Tai Chiao CT – 56, (Bob Perry / Taiwanese / heavy displacement cruiser ketch), which still has the classic lazy jack / flaking mainsail ‘system’. She is currently docked in Fort Lauderdale. Well, the mizzen is a furling (behind the mast) system and the jib and cutter are furling too. But, since I would be modifying the main, I want to do the ‘right thing’ and get a boom furling system. Which boom furling system would you suggest? Thank you, Doug Sabbag S/V Triumph http://www.TriumphCharters.com

Nice looking boat. Bob Perry is one of my fav’s. I’ll keep this answer short. This boat, without question, I would recommend the Forespar Leisure Furl system. Let us know if you need further information by emailing us at [email protected] .

I would welcome input and recommendations on installing in boom furling on our privilege 745 catamaran.

My initial thoughts are carbon fiber GMT, Offshore, Southern Spars, or Leisure Furl (maybe Romar version). Are the boat’s headsail furlers powered? Electric or Hydraulic? What brand are they? Please contact us via email fro further details at [email protected] .

Thanks, ~T.R.C.

Hi Team, I am in Australia .I have had a Leisurefurl since 1993 (yes 24 years ), 12yrs of which was sailing around the world in my 35′ catamaran. The system has been trouble free except for one irksome problem. I keep having to replace luff tapes because the plastic batten ends on the luff fatigue and wear the luff tape. I have tried webbing and cloth ends but that creates too much buIk. I notice that Schaffer address this problem with an articulating mast track. Could I have your thoughts please.

Hi Chris, Hi from USA! I can certainly say that is a great Leisure Furl product testament and an interesting issue. The question is, is the track system and feeder the latest iteration. They have since (last 10 years or so) made some improvements, hopefully they are addressing this batten issue. My first thought is Kevlar reinforcement at the In-board end of the batten, AND batten tension (so that it is not driving so hard against the mast in lighter air). That is just my initial thinking and please keep in mind, I am no sailmaker. Having said…if you have the track, feeder and top piece upgraded, then go to a sailmaker (preferably one that knows LF sails) and see what they prescribe.

Thank you for commenting and I hope that helps.

Dear Sirs, Now i am sailing a Corsair 28R trimaran with Carbon rotation mast and rotation boom. The boom rotate with a handle trough the mast. You must go to the front of the mast to turn the boom with the handle hoist the mainsail with the cord into the groove of the mast give some space ( resistance) and also steering into the wind. The way back give the same problems. With two persons it’s working well,but allone it’s nearly impossible.(nobody on the helm) Buying a Southern spars in boom furler is maybe to use on my trimaran. But is it a good solid and functional alternative? They are the only one with a offer for such a small boat. If you have a solution please contact me: Hans Weijer IJsseldijk Noord 272 2935 BR Ouderkerk aan de IJssel The Netherlands Mob 0031 6 38540132 E-mail [email protected]

This Southern Spars boom seems to be great solution. We are a dealer for them as well, so let us know if you have any product needs or questions as well. Beyond that option, I have just converted my other customer to stowing the sail conventionally (flaked) on top of the boom with a set of our Dyneema lazy jacks.

Hi RTC, Please tell me more abouth stowing the sail conventionally (flaked) on the top of the boom with a set of Your Dyneema lazy jacks. If possible drawings and descriptions.

Hi Hans, Have you seen this diagram? https://theriggingcompany.files.wordpress.com/2012/02/images5.jpg

…also this article may be of use https://theriggingco.com/2015/04/17/tides-track-and-lazy-jacks/

Beyond that please feel free to give us a call, 443-847-1004 or shoot us an email @ [email protected] for more information. We’d be glad to help.

Merhaba benim kılasik yelkenli leopard 45 catamaranım var furlin boom sistemi taktırmak istiyorum yardımcı olurmusunuz Türkiyeden yazıyorum

Hi Mustafa,

Hi, I have the older version of the Profurl boom furler on both my main and mizzen. The mizzen has worked well, yet the main boom, has had lots of issues as it is much larger and thus heavier. Agree 100% that it has an ugly extrusion behind the mast, yet I do see in your picture above that they now cover this up, so maybe I can retro fit one of these. I have had vang issues on both booms as you suggest, yet an upgrade of parts has fixed all of the problems, I only get 3 years out of the gas struts though. The main problem I have had is the nuts hold everything together coming loose, so I would recommend changing them regularly with new ones. As they come loose the components work themselves to death which has led to most of my issues. I use boom brakes on both booms, and I would use them even if I didn’t have a boom furler, they are much better than a preventer. Considering my furlers are now close to 20 years old and how easy they make sail handling, I thank the previous owner that forked out the $ and installed them. Rgds Mark Hunter. SV. Evening Star, Hinckley 49

Thanks for the thoughtful comment. Yes, I would have to do a little research but I am sure that these ProFurl systems can be upgraded…track or anything else for that matter.

Sounds like you are doing all of the right things to ensure that this system keeps working for you. Nice to see. Also ‘good on ya’ for using the boom brakes , they’re great!

Let us know if you need us to find about more ie ProFurl.

I am about to order a new Lagoon 52F cat which has a Leisure Furl in boom option. With a ‘senior’ crew of two, it seemed like a no-brainier. What would be your main positive and negative considerations? We will be sailing the lesser Antilles chain primarily. Will servicing or maintenance be problematic? (base in St. Maarten) Thanks so much!

Thanks for using us for your questions. These systems, as long as they are installed and operated correctly, will offer many years of trouble free and maintenance free service. Definitely, take the time to have someone show you the system…a customer sail so to speak, with someone who knows boom furlers. Also call Leisure Furl directly and speak with Alan Massey for specific tips and tricks. He will be a good contact should you ever have any questions or problems. Also take plenty of time to practice hoisting and reefing in light air conditions before setting off on any major trips.

This may have been a shorter answer than what you are looking for, but the negatives once set up correctly are relatively small. Clearly the closer you are to the wind the better the system will work for in terms of hoisting and dousing. Heavy air runs may require you to come up a few ticks to help unload things. The positives are quite a long list as stated in the article .

Thanks for the read and for commenting.

I have a Swan 47 with a carbon fiber mast and boom. Have you had any experience with a similar installation?

Hi Barry, we do. We do have experience in all aspects ….commissioning, repair, construction, stepping, assembly, refinishing? Even with Swan yachts in particular and/or carbon fiber spars in general.

Let us know how we can be of service further. Thanks.

Is there a boom fuler for a Victoria 18 ?

No…;)

What about in boom furling system for a 80 feet blue cruiser? Better fiber carbon boom or aluminium? Thanks for any suggestion and an idea of costs. Massimiliano

I would likely recommend a carbon boom for something that size. It is very likely that any aluminum boom manufacturer may not have a boom big enough to fit your boat…80 foot is kind of on the edge. The manufacturers I would recommend are Leisure Furl (especially alu.) or GMT. For price you can expect to spend almost double for carbon, but as I said that may be your only option. Pricing installed can range from $35k (if we can get alu.) to $60k, not including the sail (which will also need to be replaced). The boat will require a hydraulic vang and an electric main halyard winch as well. I can generate a quote for you if you like… I will need the boat’s P dimension (mainsail max hoist), E dimension (mainsail max outhaul), and the boats displacement. Also the more info the better; what kind of boat is it, who is the manufacturer, etc…?

Thanks and I hope that helps.

I have a Jon Meri 40 (1988). What would Leisure Furl cost. My main is 10%!linger than standard main. Is Leisurefurl the best choice?

Thanks for taking the time. I would need some specific info, but can give you rough pricing. The system for this boat can run anywhere between $15-$19k (in aluminum, carbon and faired options available at additional costs) depending on what size boom is required. This is the system only price and not installed. Complete with install the $15k version could end up running around $20k installed. This does not include the new mainsail that would be required. A unit specific vang or hydraulic vang will also be a requirement. The boat will need a low stretch main halyard and an electric main halyard winch, which would also be utilized for the main furling line (electric drive versions also available, eliminating the furling line). Lastly we always recommend the use of a boom brake to help ease the forces of jibes.

Yes, Leisure Furl is the way to go here. Pricing is roughly the same throughout the various manufacturers, but LF’s product is superior.

I hope this helps answer some of your questions. Please let us know how we can help further, when you are ready.

I have a Jon Meri 40 sloop., 1988. It has a larger than standard Jon Meri main, +10% along the foot.

I am interested in a boom furling mostly because I am now 81 and still actively cruise. I sail almost exclusively in New England. I want the ease of putting the main away at the end of the day and the safety of reefing more simply.

Thanks for commenting, and yes a properly set up boom furling system can make for years of easier mainsail handling.

Feel free to contact us via email or telephone with any questions and more product information on the various Systems.

We’d be glad to help.

I have a Sabre 452 looking for approximate price for new boom curling system liesure furl and Schaefer . I have an electric winch which I currently use to raise the mainsail. Also looking for quality instillation. Will be replacing main. Boat is in Greenport Long Island . Thanks Steve Scaring

Good morning, I’m trying to sell my Moody 46 1998, she’s sloop rigged and have had an enquiry asking if the in mast furling (Selden) can be changed to in boom furling. Please can you give me some advice and ball park numbers for the conversion. Many thanks Tony Donnelly

Thanks for asking Tony. Leisure Furl just started OFFERING IN-MAST conversion kits. Essentially 6′ plates that are painted (or anodized) and riveted across the span of the opening tying the two sides of the mast together. This is a fairly new product so there is very little owner feedback other than what LF has done with field testing on customer boats. That conversation is better had with Alan Massey of Forespar.

This conversion, with new boom furling system, all said and done could run approx. $30k. Overall we think it would be best to purchase a new conventional mast (custom TRC or Selden). This would make the total more in the $50k range. PLEASE NOTE! These are very loose numbers, (and can vary as much as $5-10k up or down) so please don’t hold us to it. A proper detailed estimate can be provided upon request .

However, this should give the new owner a feel for anticipated costs. Hope this helps…

Username or Email Address

Remember Me

Lost your password?

Review Cart

No products in the cart.

- Privacy Overview

- Strictly Necessary Cookies

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

- Yachting World

- Digital Edition

Is in-boom furling the next big thing in sail handling technology?

- August 24, 2020

The engineering of in-boom furling systems has been considerably refined over the years and today’s systems are much better than early iterations, writes Rupert Holmes

Easy reefing on the Kraken 66 White Dragon during our heavy airs test, with an in-boom system by Southern Spars. Photo: Kraken Yachts

What’s on the market? 9 options for in-boom furling

This newly launched system has a V-shape carbon boom and is available in five sizes for boats of 40-70ft. The Danish company, whose team has 50 years of experience with in-boom systems, says it paid attention to every detail to make the system “both elegant and practical.”

The prototype was tested on an Xc45 using the boat’s electric coachroof winches. When hoisting, one turn of the furling line can be held around a winch to give the necessary resistance and the same can be done with the halyard when lowering the sail.

Following the trial, sales and marketing director Peter Westfal told Yachting World : “We are very happy with the result [and] all features were working like we expected.”

Mainfurl system sits within a V-shaped carbon boom

An electric motor can be built into the mandrel to provide a more automated solution, with the endless manual furling line retained as a backup.

A Dyneema strop of exactly the right length is provided to hold the boom against the gas vang at the correct height. The gooseneck fittings and luff track are designed for easy retrofitting to existing carbon and aluminium masts.

Neat features include grooves for attaching both sail cover and cockpit awnings. The mandrel is raised at the outboard end of the boom, which gives a more appealing aesthetic, as the aft end of the boom doesn’t appear to be raised as high.

On the downside, Westfal tells me the system can’t be used to furl when sailing downwind, but that it is possible on a reach if mainsheet and vang are eased to take the pressure out of the sail. Price: £33,600 for a 45ft yacht.

A Grand Soleil 45 sailing in Rhode Island with a Schaefer in-boom furling system

Schaefer Marine

Massachusetts-based Schaefer Marine engineers its systems using machined aluminium components, which are sleeker and lighter than castings, but more expensive. A key benefit of this system, which was originally developed in 2001, is that reefing can take place on any point of sail, including with the wind aft. This is achieved with a ‘scoop’ that leads the luff tape into a patented articulating mast track that maintains alignment with the gooseneck.

The furling drum is mounted at the aft end of the boom to free up space for a neat arrangement at the gooseneck. The downside is this furler position adds a little friction, but that’s unlikely to be a problem on a boat with electric winches. To minimise friction elsewhere, oversized dual race Torlon bearings are used at each end of the mandrel.

A heavy duty fixed rigid vang ensures the boom is always at the correct angle for consistently reliable operation at the expense of losing control of mainsail twist.

The system is available in two versions, Beta and Gamma, to suit maximum luff lengths of 13.4m (44ft) and 16.4m (54ft). The UK distributor is Warsash-based Sea Sure. Prices ex VAT: Beta US$13,800 (approx £11,000); Gamma US$19,900 (approx £16,000).

Leisure Furl

This well established brand is part of California-based Forespar and has produced thousands of systems for boats from 9-24m (24-79ft), plus custom units for yachts up to 100ft.

The company says furling can be carried out when sailing downwind, with the boom sheeted in to 45° to move the sail away from shrouds and spreaders. The furling drum is on the front of the mast and incorporates a manual override option.

Leisure Furl produces eight models for boats from 27-70ft in aluminium or carbon. Average price ex VAT for a 45-footer: US$16,000 (approx £13,000).

Romar Leisure Furl

This Dutch company was a Leisure Furl distributor, but now offers its own product in carbon or aluminium construction, with most being aluminium for yachts in the 45-80ft bracket. These are fabricated from shaped aluminium plates, bonded with epoxy resins using techniques developed in the automotive and aerospace sectors.

“This switch was done to get rid of any corrosion and to create a stiffer boom,” says CEO Johan Mulder. It also reduces costs by around 50% compared to a carbon boom, although a carbon fibre mandrel is used for extra stiffness. Manual, electric or hydraulic operation is available. Prices start from €18,000 for a 45ft yacht.

This is a 20-year-old Danish company whose products have been fitted to a wide range of yachts, from production cruisers to top quality designs.

Booms are produced in fibreglass, carbon and composite with a carbon appearance, for yachts from 36-70ft. They incorporate cockpit lights – white for use in port and red for night sailing – on the underside of the boom. Guide prices ex VAT for a 45ft yacht: fibreglass €27,432; carbon €41,208.

Danish spar manufacturer John Mast which produces the Hi-Low reefer system in three models to suit boats from approximately 6-12m (20-40ft). This costs €8,292 for a 40ft yacht.

Part of the French Wichard Group, Profurl has a wide range of in-boom systems for boats from 5-18m (17-59ft) with aluminium spars.

Sailtainer is a long-standing brand, with more than 1,000 units produced, and is sold in the UK by Jeckells. The furling drum is at the aft end of the boom and the system is available in sizes to suit luff lengths from 5-24m (16-79ft).

Hall Spars, part of the North Technology Group, produces five all-carbon models, catering for yachts from 40-100ft. The system’s geometry allows the mainsail to be furled or reefed while sailing downwind. Manual, hydraulic and electric drives are available.

First published in the July 2020 edition of Yachting World.

- 1. Introduction

- 2. What’s on the market? 9 options for in-boom furling

Yachting Monthly

- Digital edition

Mainsail furling systems: an expert guide

- Graham Snook

- December 21, 2020

Some sailors swear by mainsail furling systems, others swear at them. Graham Snook looks at way to keep your furling mainsail in check

In-mast furling mainsails (left) have evolved significantly, and vertical battens allow more roach and better sail shape. Credit: Graham Snook

Mainsail furling systems have come on a long way.

Sails no longer need to be wrapped around a boom, nor does an in-mast mainsail need to be the hollow-leached, baggy triangle we first saw decades ago.

Furling mainsail systems can now offer more sail area than a traditional slab-reefed mainsail.

Be that as it may, every slab-reefed sailor knows a horror story about in-mast or in-boom furling that is enough to make them steer well clear, while those that have furling mains wouldn’t put to sea without one.

There is little doubt that furling mainsails are gaining in popularity, even for serious offshore cruising boats.

Get mainsail furling wrong and it can lead to costly and potentially dangerous problems. Credit: Graham Snook

In 2018, 38% of boats sailing round the world in the World ARC had furling mainsail.

Hallberg Rassy reports that almost all new owners buying boats over 40ft opt for furling mainsail systems, with Discovery reporting a similar trend.

So has the reputation of furling mainsails been unfairly tainted, and are they more prone to user error, or have the systems ironed out the glitches?

Whether you’ve got a furling main on your own boat, or if you’ll be using one when you charter, it’s worth knowing how to avoid the pitfalls of furling mainsails.

How do furling mainsail systems work?

In an age where we expect everything just to be simple and to work, letting off one line, and pulling another to make the mainsail appear or disappear sounds appealing, but what is the best way to furl the mainsail?

Is there a correct way to do it?

‘Carefully,’ replies Jeremy White,of Elvstrøm Sails UK. ‘They’re mechanical systems and they need to be operated correctly.’

Whether you have in-boom or in-mast, they both work on a similar principle which anyone with a furling genoa will be familiar with.

Inside the mast is an aluminium foil that takes the luff of the mainsail, and in a boom a mandrel takes the foot of the mainsail; both the foil and the mandrel revolve to roll up the sail.

A lot of issues with in-mast furling are caused by the sail not furling properly inside the mast and the furl being too bulky or the sail rubbing on the inside of the mast.

Many in-boom problems are caused by an uneven furl with the sail bunching at one end or the other.

There are a number of issues to look out for with each system to ensure stress-free furling.

Different options

If you’ve bought a new boat that was ‘good value’ and it came with sails, question how good those sails really are.

Many original Dacron sails are built to a price that will get you on the water and get you sailing, but they may not be built for longevity or performance unless you’ve specified them and know what you’re getting.

There has been much advancement in furling mainsail design, improved materials, vertical battens, and increased sail area.

Many new furling mainsail systems present a larger sail area than that of a conventional slab reefing sail.

But what should you be looking for when buying a new sail?

‘Whichever sailmaker you choose, get the highest quality material you can afford,’ advises Jeremy.

It’s a false economy to buy cheaper sailcloth as it will stretch and you’ll be left with a baggy sail after a few seasons.

For example, the luff of laminate sail (on a 45ft yacht) might only stretch 15mm over its lifetime, but on a polyester sail that might be as much as 15 cm.

That excess sail has to roll up in the same space as did when it was new.

For those wanting maximum sail area, and sail support, full-length vertical battens are the way forward.

These support the leech giving a good full roach, and importantly, they support the sail over its full height which gives it rigidity while it’s being furled, whereas shorter, vertical roach battens can leave the sail unsupported at their base causing furling problems.

For those without the budget or desire for a battened sail using modern materials, a sail with a hollow leech still offers many advantages over a slab reefing system, namely ease of reefing, the ability to set exactly the right amount of sail, and the simplicity of stowing, even if you do lose some power from a smaller sail area and a less perfect aerofoil sail shape.

If you’re having new sails made consider getting them silicone-coated.

This helps the sail slide over itself making the furl inside the mast tighter.

In-mast furling

It may be a simple system, but how you unfurl and furl the main will help avoid problems.

If you were to look down from the top of the mast, the foil usually rolls onto the foil in anti-clockwise direction, that is, the unfurled sail comes off the starboard side of the foil, though it’s worth checking on yours.

This is the key to getting in-mast furling to work correctly; trying to furl on a port tack drags the full height of the sail over the side of the mast slot, adding friction where there shouldn’t be any.

Furling on starboard tack obviates most of this friction while you furl.

Full-height battens support a larger roach, but make the furled sail more bulky. Credit: Graham Snook

Whether letting the sail in or out, the first thing is to release the backstay (to straighten the mast so the foil doesn’t rub) and put the boat on a starboard tack – with the wind slightly forward of the beam – this is so the sail feeds cleanly into the mast and around the furler inside.

Unfurling the sail is usually pain-free if the sail was furled correctly.

With the yacht on a starboard tack and the wind forward of the beam, release the mainsheet and vang.

Ensure the furling line is released then pull out the sail using the outhaul.

Ease the outhaul as your furl so the sail doesn’t flog but isn’t loaded up either. Credit: Theo Stocker

You shouldn’t need to control the furling line as there should be no pressure on the sail, even on a windy day.

If you intend to be reefed, however, don’t let it run unchecked. When the right amount of sail is out, make off the furling line. If you’re reefed, tension the outhaul to give the sail the correct shape (flatter in stronger winds and when close-hauled) then set the mainsheet and vang and away you sail.

- Release the backstay (if you have one)

- Put the boat on a starboard tack – with the wind slightly forward of the beam

- Release the mainsheet and vang

- When the right amount of sail is out, make off the furling line

- Tension the outhaul to give the sail a correct shape, then sheet in

To furl the sail, after letting off the backstay and putting her on a starboard tack with the wind slightly forward of the beam, let off the mainsheet and then ease the outhaul a little and start to furl.

Always look at the sail as you’re furling – you’ll be able to notice issues as they happen and not after you’ve wound an inch-thick clump of sail through a half-inch gap.

Having different coloured lines can make things simpler for your crew. Credit: Theo Stocker

If your sail has full-length vertical battens ensure the first batten is parallel with the mast when it enters, and if reefing, leave a batten just outside the mast groove.

Keeping too much tension on the outhaul will drag the foil aft in the mast, bending it and causing the sail to rub against the inside of the mast, creating friction.

Once you’ve taken the slack out of the sail, ease the outhaul and take in on the furling line again.

Try not to let the sail flog as this also bends the foil and causes more friction.

Repeat the ease-furl process until only the UV protection strip is showing.

Sail on starboard with wind forward of the beam for easy furling. Credit: Theo Stocker

If you have laminate sails, and they have been furled away wet, try to dry them at the first opportunity.

If you’re having problems furling using the lines, don’t be afraid to go to the mast with a winch handle and furl the sail at the mast.

Try it one day, it is remarkably easy.

If you’re having to do anything different, such as raising the boom or chanting a prayer to the god of furling fails, it’s worth looking at your system in detail for problems.

- Release the backstay

- Ease the outhaul a little

- Take in on the furling line

- Keep easing the outhaul and taking in on the furling line

- Furl the sail until the UV strip is showing at the mast

Problem solving

If furling the right way still isn’t working for you, there are a number of things to consider…, 1. understand your system.

First to check is to have a look inside your mast at which way your system should furl.

If your furling system has the option, put a winch handle in the furling mechanism at the mast and turn it the direction indicated to make sure the sail is going into the mast in the correct direction.

Clicking over the ratchet at the mast before it’s time to furl will ensure it always rolls in the right direction.

2. Assess your sails

The biggest cause of problems is the sail itself – how old it is and the material it is made from.

Stretch in the cloth makes baggy sails, which furling systems will happily munch on.

Furling mainsails are cut flatter than conventional slab-reefing sails as accommodating the belly of the sail is problematic.

An old or baggy sail may cause jams, as will creases from not enough halyard tension. Credit: Theo Stocker

Some older furling mains may have be made with an inappropriate, fully-bellied shape.

If your polyester sails have a deep belly, think about getting new ones as you’ll be fighting a losing battle.

As the belly folds, it doubles the thickness of the furl, causing unsightly and inefficient creases at best, and hideous sail jams or rips at worst.

3. Adjust halyard tension

Excess halyard tension can also cause the fabric to bunch up; vertical creases at the luff cause the sail to fold over itself.

Vertical creases at the luff reveal too much halyard tension, and potential for more snags. Credit: Theo Stocker

To resolve this, release the halyard until you have horizontal creases at the luff, then add just enough tension to remove them, though you may need to adjust this when underway.

4. Check the backstay

While the mast is bending, the foil inside it remains straight; the furled sail will bind at the apex of the mast’s bend.

If all of this fails, it’s worth calling a rigger to check the foil tension.

If this has gone slack, as you furl the foil will bend and rub against the mast.

5. Smooth it out

The next thing to look at is reducing friction.

As is often the case, the lines to your furling gear and outhaul are led through various fairleads and blocks across the deck and up the mast.

Move deck organisers to give slacker turning angles. Credit: Theo Stocker

Make sure all the angles they have to go through are a wide as possible – consider moving them if not – and all blocks and sheaves are running smoothly.

A good wash with fresh water and a squirt of dry lubricant can work wonders.

In-boom furling

Not a new concept, in-boom furling is an elegant solution, but brings its own challenges.

Unlike in-mast furling, in-boom systems can be retrofitted in place of conventional slab reefing.

For an in-boom furling system to work efficiently, however, it has to overcome a number of problems.

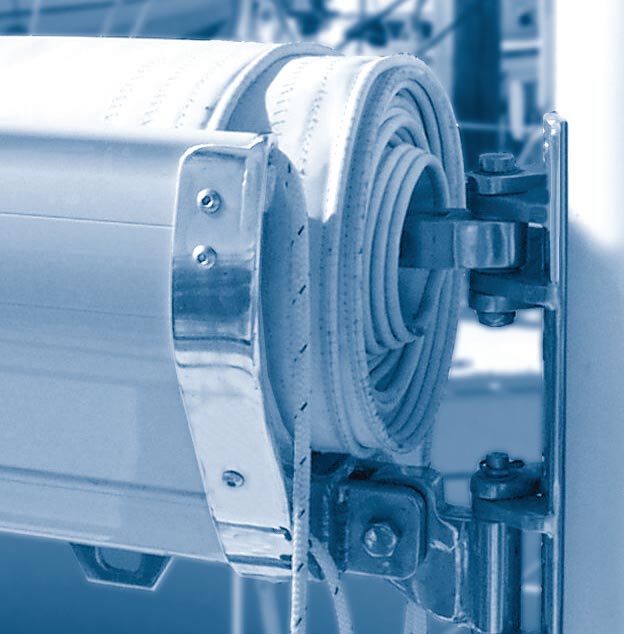

To start with, have a crew on deck to watch the sail as it furls to spot any issues. Credit: Advanced Rigging and Hydraulics

First of all, the sail has to be led from the boom to the mast, but there needs to be space for the bearings for the central mandrel and the boom’s gooseneck fitting, so the whole sail has to move aft along the boom.

To combat this, many in-boom systems have a protruding track on the trailing edge of the mast, while other units have the reefing mechanism at the aft end of the boom, or sometimes you’ll find a combination of both.

Whatever the system, there is usually a flexible feeder to guide the sail from the boom and feed it into the mast track.

The furling drum at the outboard end of the boom brings the main closer to the mast. Credit: Advanced Rigging and Hydraulics

Another issue with in-boom furling is the bolt rope, as Andy Cross from Crusader sails explains.

‘The sail has to use a bolt rope, and with it comes friction. Unlike a furling genoa that may only be raised and lowered once a season, the mainsail is nearly always used so the luff tape has to be reinforced.’

Any wear or damage to the bolt rope also requires a new bolt rope along the full luff of the sail, as any repairs would soon wear through and increase the friction.

The necessary extra reinforcement at the luff brings with it another problem: extra cloth thickness at the front end of the sail.

When reefing, stop when a batten is just above the mandrel, then take in on the furling line. Credit: Graham Snook/Yachting Monthly

As the sail rolls around the mandrel there is more sail material at the luff than across the rest of the sail.

The solution?

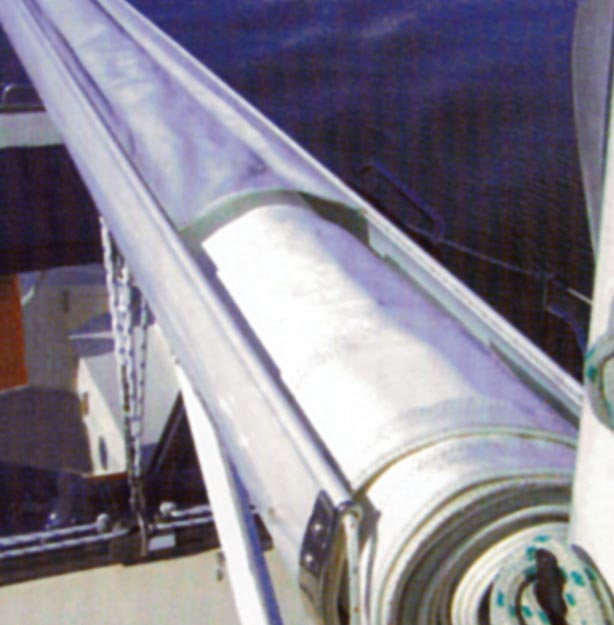

To slightly raise the aft end of the boom, allowing the extra sailcloth at the luff to roll at a rate that matches the leech.

The angle from the mast to the top of the boom has to be 87° to the mast, 3° above perpendicular.

The full-length battens in the mainsail help stabilise the sail as it furls and the batten pockets have been attached to the sail to match the mandrel angle.

It’s the thickness of cloth at the luff and the battens that make the correct boom angle the most important part of the system.

The necessary bulk of the boltrope makes the boom angle critical.

Get that right and your life suddenly becomes a whole lot easier.

It’s essential to mark the vang when the boom angle is correct.

Some owners choose to make a strop, running next to the vang, out of a low-stretch material like Dyneema, so the topping lift can be pulled taught and the strop prevents the boom raising higher than it should.

When marking or limiting the boom angle, it must be easy for any crew to see, by day or night.

How to get it right

1. prepare to set sail.

‘Before raising, lowering, or reefing the mainsail,’ explains Kim Petersen, Elvstrøm Denmark’s in-boom sail specialist, ‘get into the habit of always releasing the backstay tension – this will successfully straighten the mast and takes any flattening tension out of the sail – and then making sure the boom is at the correct angle – this is extremely important.’

Be careful with electric winches not to over-tighten halyards. Credit: Graham Snook

To raise the sail, after slackening the back stay and adjusting the boom level, point the boat into the wind, release the mainsheet and take up on the mainsail halyard, making sure that the furling line can run free as you hoist the mainsail.

Once set, increase the halyard tension until the horizontal creases at the luff have just gone.

2. Reducing sail power

If you don’t need full sail, only raise the sail until the nearest batten is at the mandrel.

Rather than being able to reef at any point, where the lower battens are fitted, the sailmaker will have reinforced the sail to take the clew loads.

Not reefing at these points means an area of unreinforced leech could be required to take a load it was not designed for.

Each batten represents a reefing point. Credit: Graham Snook

You’ll end up with fullness at the foot of the sail and a stretched leech, or a damaged sail.

If you need to flatten the sail, for better pointing or in stronger winds, take in on the furling line without adjusting the halyard tension.

This will give the same result as using a cunningham to tighten the luff.

Furling the main

When lowering the sail, release the backstay and set the boom at the correct angle.

It’s then best to take all the pressure off the sail by heading into the wind.

It doesn’t matter if the sail is flogging; the battens keep the sail rigid and support it as it furls.

If there is any pressure on the sail, this will cause it to furl unevenly.

With in-boom reefing you should still have a good sail shape even when deeply reefed. Credit: Graham Snook/Yachting Monthly

Unlike an in-mast furling system, where the sail is visible, on an in-boom system everything is happening on top of the boom, overhead and out of sight.

If you have a crew member spare and it’s safe, sending them to the mast to keep an eye on the sail as it furls can prevent damage, at least for the first few times using the system.

Pull in on the furling line, slowly and smoothly releasing the mainsail halyard, but keep a bit of tension on it.

Continues below…

The tools and spares you shouldn’t sail without

Give a thought to your inventory this winter to keep you cruising next season, says Rachael Sprot

Why you should regularly check your deck fittings

What’s really going on under your deck fittings? Ben Sutcliffe-Davies investigates the hidden weaknesses

Essential reefing tips for cruisers

Reefing: how, when and why do we do it? The answers may not be as straightforward as you think, says…

How to: replace a halyard

Whether you’re replacing an old halyard for new, or mousing the mast over winter, Rubicon 3’s Rachael Sprot explains how…

If you have too much tension the sail will want to roll away from the mast; if you’re seeing creases running from the bottom of the track to the boom at 45°, release the halyard a little more.

If the sail is rolling up toward the mast, you’ll need to increase the tension a little.

As the sail furls, the luff tape will naturally first roll aft, then move forward and repeat this – it’s all perfectly normal.

Once the sail is fully down, tuck the head into the boom if your system allows it, and add the sail cover.

Reefing underway

To reef when sailing, release the backstay and set the boom angle.

In rough weather, or when there are big seas, it’s best to take up on the boom’s topping lift to secure the boom and stop it rising and falling as the yacht goes over the wave crest.

Cover the sail once stowed to protect from UV. Credit: Advanced Rigging and Hydraulics

You’ll find it easier if you can bring the boat onto the wind and release the mainsheet to remove all drive from the mainsail; if the sail is flogging it’s depowered and can still be furled.

Next, take in on the furling line while slowly and smoothly easing the halyard as the sail furls.

Graham Snook is a marine photographer and journalist who has been involved in testing yachts and equipment for over 20 years. Credit: Graham Snook

Once you’ve reached a point where the batten is at the mandrel on top of the boom, make off the halyard and then furl the sail until the batten is under the mandrel.

Without reefing pennants to hold and support the clew of the sail, the loads are transferred to the batten and the cloth around it.

Because of this, it’s recommended that for in-boom reefing mainsails, a stronger stretch-resistant cloth like Dacron reinforced with Vectran or Dyneema or a tough cruising laminate cloth be used.

Whichever mainsail furling system you have or choose, spending a bit of time practising what works and what doesn’t on your system, at a time when it’s convenient to you, will pay dividends when you find you do need to reef.

Mainsail furling has had a bad reputation in the past, but used properly and with a little care, there’s no reason why it shouldn’t give you trouble-free sailing for years to come.

To raise the sail

- Release the backstay tension

- Make sure the boom is at the correct angle – use a strop or mark the vang if necessary

- Head up into the wind – it doesn’t matter if the main flogs as it goes up

- Release the mainsheet

- Take up on the mainsail halyard, but do not overtighten

To lower the sail

- Make sure the boom is at the correct angle

- Point the yacht into the wind

- Take in on the furling line as you ease the halyard at a steady rate

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

Check Your Shorepower System for Hidden Dangers

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

Gonytia Hot Knife Proves its Mettle

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

In-Boom Furling: Five Systems

Our last good look at in-boom furling systems was in the August 1, 1998 issue, when we liked both ProFurl and Leisure Furl, giving the edge to the latter despite its greater cost. The recent introduction of Schaefer’s new in-boom system gives us an excuse to revisit the subject and the systems in the field.

From the outset we’d acknowledge that with each passing year, sailhandling systems get more and more refined and efficient—never mind the days of footropes and gaskets, of one hand for the headsail and one for yourself during routine jib changes.

Even so, the mainsail remains a challenge. Stacking systems, lazy jacks, the Dutchman, in-mast furlers… all contribute their share of convenience and control, but none has proven to be the answer. Stowing, furling, and reefing the main is still a sizable chore, especially as the size of your boat increases. And, as always when we attempt to conquer the considerable forces of wind and wave by mechanical means, we tread a fine line between convenience and chaos.

Background In the late ’80s, Hood Systems introduced the Stoboom, and rolling the sail inside the boom became an option. More affordable and less risky than furling the main inside the mast, these boom furlers were a big hit. However, the newly-engineered hardware proved to be more complicated and ultimately less convenient than it looked. It was, according to one owner who sailed a Hunter 42, “the costliest consumer mistake I ever made.”

The sail entered and exited the Hood boom through a narrow slot in the top of the tube. For that and several other reasons Stobooms proved jammable. They were also fickle in terms of boom angle, and costly in terms of luff chafe. Hood tried education (a special aftermarket owner’s manual) and hand-holding (extensive customer service) before eventually pulling the Stoboom off the market. “However,” says Paul Boyce of Hood Yacht Systems, “we’re still involved in in-boom furling with hydraulic systems fitted to larger boats, most of which are in Europe.”

The advantages of in-boom furling that prompted Hood’s “noble experiment” have not disappeared with Stoboom. Compared with in-mast furling, the boom-based systems weigh less and keep weight lower. Probably the most significant selling point of a sail that lives in the boom, however, is its shape. In-mast furlers require roachless, high-aspect triangles, thus reducing mainsail area, distorting ideal shape, and lessening draft control. We’ve talked with sailmakers, and most peg the overall performance loss that you’ll pay for the convenience of in-mast furling at 20% or worse. With a boom-furling system you can assure yourself of a powerful modern sailplan with plenty of roach, with the additional bonus of being able to use full-length battens to help control sail shape and reduce flogging.

There are other plusses—freedom from reefing-line clutter, variable sizing potential, automatic sail-covering, and the ability to retain your original spar, to name a few—but to us the most telling difference is safety: If an in-mast furler jams it’s probable that someone will need to go aloft to free it. Until then, you’ll be stuck with a hoisted mainsail in what may be exactly the wrong conditions. A jam in the boom can be addressed from on deck. If all else fails, just drop the sail as you would a normal main and furl it on the boom instead of inside.

But boom furling has plenty of detractors. Butch Ulmer, veteran sailmaker from City Island, NY, feels cautious about it: “The geometry still needs to be worked out. Big roaches drive battens forward. Overcoming that friction isn’t easy and it’s certainly not automatic.”

We asked the owner of a 73-footer who undertook a complete and costly refit why he hadn’t put a boom furler aboard. “I don’t need a $20,000 sailcover,” he replied.

Peter Harken, whose company makes headsail furling systems, said “We haven’t gotten into in-boom furlers because we think there’s a better way. We may be a bit prejudiced, but we feel that the batt-car system we’ve devised is the safest, surest, easiest way for getting a sail up and down easily and when you really need it. I can just about guarantee those cars won’t jam, and you can’t say that about anybody’s boom-furler. Most of these systems work most of the time, but when you really need it, give me something that’s simple and foolproof.”

The In-Boom Furling Field Today there are five in-boom systems on the market. We’ve sailed them all, noting design, construction, and performance. Given the conditions, we did our best to see how each delivers on the promise of boom furling. And at what price?

One overall conclusion is that, while Stoboom may have spoiled the boom-furling parade for lots of sailors, today’s systems really work. We put the gear through paces that occasionally created problems, but those snags never kept us from executing our set/reef/reset/douse evolution.

Schaefer and John Mast have relatively narrow openings in the top of their booms, but among the others there’s a trend toward open-topped extrusions.

You can still hold the boom up with a topping lift while rolling the main in, but all the systems we saw used a fixed, solid vang to do the job.

While you can get by without power winches, the whole process of setting and reefing, especially singlehanded, is easier if your winches have power. This is not to say that there isn’t a certain swashbuckling appeal in rolling the sail with one hand cranking the self-tailer and the other easing the halyard (keeping good tension for a nice tight roll).

Though they share the same basic idea, the five systems are significantly different. So are the companies that produce them. Leisure Furl has been around since the early ’90s, and its track record and testimonials are impressive. Schaefer Marine, a well-established hardware company, on the other hand offers a new system born of three years of design and development, but without much time in service. ProFurl engaged in extensive aerodynamic testing and material analysis before introducing a boom-furler just over three years ago. The big French company with dealers in 52 countries has since been energetic in promoting boom-furling to both the general public and among sailmakers.

Furlboom (“designed and built in Australia by Aussie yachtsmen to suit our rugged sailing conditions”) has had a varied career and is now built and sold by the recently-formed Yachting Systems of America in Costa Mesa, CA. Like Leisure Furl, the company has concentrated efforts on centralizing manufacture and now offers a system that is entirely American-made.

The John Mast (JM) Hi-Low Reefer is imported from Denmark by Lars Pedersen of Bente Trading Company, Mercer Island, WA. Pedersen has long been a boom-furling zealot; he worked with the Danish mastmaker to develop the system. Over 1,500 boom-furlers have been sold in Europe since 1990.

Leisure Furl Over a decade ago New Zealand sparmaker Don Baverstock first came out with his roll-up system. Today KZ Marine, for whom Baverstock is a consultant, claims that “over 85 % of the new boats launched in New Zealand have our booms.” Says Bill Hanna at Forespar, US manufacturer of Leisure Furl, “Our system began with bigger boats and has evolved into boats closer to the everyday as it has gone along. The point is, we’ve been dealing with loads that are very significant right from the outset.”

Click here to view Leisure Furl images .

The first thing you notice about the Leisure Furl system is that the boom is virtually topless, with a wide “gutter” covered by a clever sliding sail cover. It has an attractively tapered silhouette and affords the convenience of letting you see and service the innards. The two key elements in the furler, however, are its “through-the-mast” drive shaft and the universal joint that joins it to the mandrel at the gooseneck. The “free-floating” universal means maximum power can be applied to rolling the sail. (Leisure Furl is the only manufacturer to use a universal; the other four systems rely on drum drives).

“We found it incredible that we could furl downwind in 50 knots in Bass Strait in the Sydney-Hobart Race,” reports one user.

Chuck Poindexter (Sound Rigging, Essex, CT) has installed 14 Leisure Furl units. “I was surprised to learn when we had a naval architect do the calculations that the drive shaft actually strengthens the mast…by 11% to be exact. When I first got involved it was because a customer wanted me to survey the gear on a boat that had made one and a half circumnavigations. It had a Leisure Furl. I ‘dissected’ the universal and it was perfect.”

Other components include a foot groove halfway from tack to clew. It captures a short bolt rope on the middle third of the sail, holding it to the mandrel. With a loose-floating tack and two-part clew pendant you can roll the sail (similar to the first rolls of a custom-luff headsail) so that the middle rolls in while tack and clew stay loose. What this gives you, we soon realized, was a flattening reef that offers an elegant range of draft control by adjusting the furling line while keeping the halyard tight.

A significant difference between systems is how they attach to the mast. Leisure Furl uses a conventional luff tape, captive in a “self-aligning” feeder that leads to a fixed luff groove. Dr. Robert Leaf, one of the first Americans to put Leisure Furl on his boat, had a big problem “chewing up luff tapes to the tune of three or four a season.” Cutting sails to minimize “pullback” and new, tougher luff tapes seem to have solved the problem.

“It’s how the sail drops at the tack,” Poindexter says. “If it drops right onto the mandrel you’re fine. I’ve been impressed that Leisure Furl has continued to evolve and improve.”

With halyard tension and boom angle you can control how your sail rolls onto the mandrel to a large degree.

Leisure Furl’s chafe problems at the tack seem to be its biggest Achilles Heel, and one to which sailors can address themselves as they learn their systems.

Leisure Furl is moderately encouraging about retrofitting your old mainsail to suit the system, but we wonder if it isn’t something of a false economy to marry top-of-the-line furling gear with a recycled sail, given the critical nature of how the sail fits and is reinforced. Because of the number of components, relationships, and variables, we think Leisure Furl’s “riggers only” installation scheme makes sense, too.

John Mast Hi-Low Reefer This reefer is the departure point from which the others have developed. The main idea at its inception was to make boom furling easy and accessible. Judging by the more than 1,000 boom furlers now afloat in Europe, it worked. The Hi-Lo gooseneck bracket is adjustable, and job one is mounting it to your mast. The boom is open at its forward end for sail access and transfer. The sail’s bolt rope is inserted in a flexible PVC luff track, which can be fitted to the mast in different ways. The system is simple and works well, but it does not appear as solid as its rivals. (Even the furling drum looked somewhat undersized to us.) When we rolled in a reef (using a handheld electric winch grinder) a pleat formed along the boom. Rolling the sail out to re-reef did the trick, but the full-length battens pushed forward of the mast track and created more friction than we thought reasonable.

Click here to view John Mast Hi-Low images .

With the John Mast and the other in-boom reefers it’s best to reef down to a full-length batten, which can then help support the foot of the sail. Being incompressible, it acts like an outhaul to keep the cloth stretched well aft. “Infinite” reefing between battens is discouraged.

Schaefer Marine Fred Cook at Schaefer says, “We’ve studied some of the problems associated with boom furlers for quite some time and tried to come up with answers.”

To reduce friction the company’s new design incorporates four bearing races, two at either end of the boom. Made of Torlon, the bearings require no lubrication and are meant only to be flushed occasionally with fresh water. Hoisting the sail by hand felt significantly easier than with any of the other systems.

Click here to view Schaefer Marine images .

To handle the transition between the mandrel and the mast groove Schaefer developed a unique and practical “sugar scoop” guidepiece. While we tested only in medium (12-15 knot) air, it seemed superb at sliding the sail back and forth from mandrel to luff groove.

The drum is mounted on the after end of the boom and worked via a single control line. The gooseneck pivot pin is hefty and made from 316-stainless bar stock. We wondered if the luff groove, a UV-resistant polymer, was as sturdy as the rest of the unit, but from the flogging that we put it through on our test sail it seems ready to withstand realistic abuse.

The track articulates with the boom, and this makes power-reefing (without completely depowering the sail) possible.

It’s good seamanship to take the strain off sail and gear by luffing the sail and/or bringing the boat into the wind when it’s time to reef or douse your mainsail. In a race, or due to navigational needs, however, this isn’t always possible. With the Schaefer system (and all others except ProFurl) you can reef without totally depowering the sail if you must. We think that adds to a system’s versatility and tolerance for error.